SEED PRODUCTION OF ONION (Allium cepa L.) - Efresh India

SEED PRODUCTION OF ONION (Allium cepa L.) - Efresh India

SEED PRODUCTION OF ONION (Allium cepa L.) - Efresh India

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Seed Production of Onion(Alliun <strong>cepa</strong> L.)<br />

<strong>SEED</strong> <strong>PRODUCTION</strong> <strong>OF</strong> <strong>ONION</strong> (<strong>Allium</strong> <strong>cepa</strong> L.)<br />

Agricultural production and productivity are influence by several factors. Of them, seed is<br />

the vital input which significantly helps in enhancing the productivity of crops. The seed<br />

production of onion is very difficult phenomena as it is produced in two phases. In first phase, the<br />

bulb production is required, while under second phase the seed production takes place from the<br />

bulbs.<br />

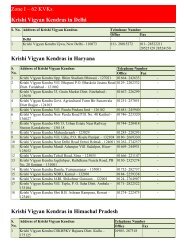

Method of Seed Production<br />

Seed- to- seed method<br />

Seed sowing in rows Healthy onion nursery Seedling Transplanting<br />

Bulb storage<br />

Transplanted Field<br />

www.efreshindia.com Page 1 of 19

Seed Production of Onion(Alliun <strong>cepa</strong> L.)<br />

Bulb harvesting<br />

Onion bulb production<br />

The bulb is as such left and allows bolting and flowering in the same field where the transplanting<br />

was earlier done. The seeds are sown in the nursery from June to August and transplanting is done<br />

from August to October. Bolting starts in January-February and seeds are ready for harvesting by<br />

mid May. Seeds of onion varieties like Agrifound Dark Red, Baswant-780, Arka Kalyan and other<br />

kharif varieties are produced this method.<br />

Merits<br />

• Low-cost method of seed production<br />

• Early maturity<br />

• No need to store the bulbs.<br />

Demerits<br />

• It is not possible to select the true type<br />

bulbs and thus high quality seed<br />

production is not possible.<br />

• Seed yield is low.<br />

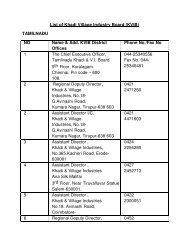

Bulb- to -seed method<br />

Bulb Transplanting<br />

Growing<br />

www.efreshindia.com Page 2 of 19

Seed Production of Onion(Alliun <strong>cepa</strong> L.)<br />

Distribution<br />

Flowering stage<br />

Packaging<br />

Pollination<br />

Final seed cleaning<br />

Harvest ready<br />

Pre-cleaning<br />

Drying of umbels<br />

www.efreshindia.com Page 3 of 19

Seed Production of Onion(Alliun <strong>cepa</strong> L.)<br />

In this method the bulbs are lifted from field and after proper selection they are replanted in<br />

the field. There are two methods used for seed production.<br />

Annual method: The seeds are sown in June – July, transplanting in August – September. Bulbs<br />

are ready by November–December. The bulbs are lifted and cured. Selected bulbs are replanted<br />

in another field after 10-15 days that is from mid-November to mid-December. The bolting in this<br />

case starts in January-February and seeds are ready by May. Seeds of onion Agrifound Dark<br />

Red, N-53, Baswant-780, Arka Kalyan and Phule Safed are produced by this method.<br />

.<br />

Biennial method: The seed of onion is sown in October-November and seedlings are<br />

transplanted in December-January. The bulbs are ready by April end to mid May. The selected<br />

bulbs are stored up to mid-October and planted in well-prepared fields. Since this takes about one<br />

and half year, it is called as biennial method. The seeds of Agrifound Light Red, NHRDF Red,<br />

Pusa Red, N-2-4-1, and other rabi onion varieties are produced by this method.<br />

Merits<br />

• Selection of true-to-type bulbs is possible<br />

and quality seeds are produced by this<br />

method.<br />

• Higher yield is obtained.<br />

Demerits<br />

• It takes more time<br />

• Losses of onion bulbs during storage<br />

• Cost of seed production is more<br />

The bulbs to seed methods is better method and gives pure and high quality seed.<br />

Storage of mother bulbs<br />

In annual method, selected bulbs are planted in well-prepared beds after curing for 10-15<br />

days, but under biennial methods bulbs are stored from June to October in well-ventilated godown<br />

for further use for planting during October-November.<br />

Manglore tiled storage<br />

Improved ventilated<br />

storage strucrure<br />

www.efreshindia.com Page 4 of 19

Seed Production of Onion(Alliun <strong>cepa</strong> L.)<br />

Cultivation Practices in brief<br />

Climate<br />

Temperatures of 4.5-14 o C is favourable for seed stalk formation. Longer these prevails more<br />

flower stems will each plant produce and more flower will be there in each umbel. The best seed<br />

producing areas are those where there is low humidity. Long rainy periods or heavy dew and fog,<br />

favour the development of Stemphylium blight and Purple blotch. During flowering of onions, clear<br />

and bright days are necessary to ensure activity insects for pollination. It is equally important to<br />

have hot and dry weather during the harvesting, curing and threshing of seeds.<br />

Soil<br />

Onion seed crop can be grown on a wide range of soils but very light sandy soils are avoided.<br />

Light heavier soils should be preferred because they are cooler, have a high water retaining<br />

capacity and are more productive.<br />

Selection of Bulbs<br />

Medium sized bulbs (4.5-6.5 cm) especially single centered should be selected for planting to get<br />

maximum yield. Though the big sized bulbs give more number of sprouts and thus give higher<br />

seed yield but it is not economical as the cost increases. Medium sized bulbs are better and<br />

economical for seed production.<br />

Land Preparation<br />

The field is ploughed by tractor-drawn implements or deshi plough to a fine tilth by giving four<br />

ploughings with a sufficient interval between two ploughings. The planking should be done for<br />

proper levelling. The field is then divided into beds and channels. The water logging affects<br />

production and quality of seeds. The beds for planting of bulbs under drip irrigation system should<br />

be raised as per system the fitted in the field.<br />

Planting Time of bulbs<br />

www.efreshindia.com Page 5 of 19

Seed Production of Onion(Alliun <strong>cepa</strong> L.)<br />

Last week of October to first fortnight of November is best time for planting of bulbs in rabi onion<br />

varieties. Kharif onion bulbs since are available during November end or early December, they<br />

should be planted by 15th December from the same crop and this way seed production can be<br />

taken within a year. The cutting of one third top of bulb and dipping for 5 minutes with 1%<br />

carbendazim + 1% potassium nitrate or 1% potassium orthophosphate increases seed yield in<br />

kharif onion bulbs.<br />

Spacing<br />

Selected bulbs of 4.5 cm-6.5 cm size are planted in well-prepared field at the distance of 45 cm x<br />

30 cm in normal loam to clay loam soil. If the spacing is kept closer because of less ventilation,<br />

drying of field is slow after irrigation, thus heavy dew and rains favour the disease. In sandy soils,<br />

spacing may, however, be reduced to even 30 cm x 30 cm. The depth is kept 7.5 cm. Irrigation is<br />

given immediately after transplanting. The spacing can be reduced if seed production is being<br />

taken under drip system of irrigation. About 25-30 quintals bulbs are enough to plant one hectare<br />

area.<br />

Manures and fertilizers:<br />

About 20-25 tonnes of FYM/ha is required to use at the time of field preparation. The requirement<br />

of nutrients depends on soil type, region of growing, varieties and removal of major nutrients.<br />

About 80-100 kg of nitrogen, 60 kg of P 2 0 5 and 50 kg of K 2 0/ha is recommended in general. If soil<br />

is low in nitrogen 120 kg N/ha should be applied. Whole quantity of phosphorus, potash and half<br />

of nitrogen should be mixed in soil before planting. The rest half doses of nitrogen should be<br />

given as topdressing in two equal split doses, first dose should be applied 30 days after planting<br />

whereas second 45 days after planting.<br />

Irrigation and aftercare:<br />

Irrigation is given at 7-10 days interval depending upon the types of soils and seasons. Earthing is<br />

done after two months of transplanting to avoid lodging. Weeding and hoeing are done as per the<br />

requirement. Specific precautions are taken in irrigating the crop more frequently during flowering<br />

and seed setting. The use of drip irrigation and mulching with wheat or paddy straw recommended<br />

for effective management and getting higher seed yield. Use of paddy straws as mulch in seed<br />

crop with drip irrigation increases seed yield by 42% in onion variety Agrifound Dark Red with a<br />

higher net return.<br />

Drip Irrigation<br />

Sprinkler Irrigation<br />

www.efreshindia.com Page 6 of 19

Seed Production of Onion(Alliun <strong>cepa</strong> L.)<br />

Weed management:<br />

Weeds are to be kept down to get good yield. Use of stomp @ 3.5 litre / ha before bulb planting<br />

and one hand weeding at 45 days is required.<br />

Isolation<br />

Onion is highly cross pollinated crop. During seed production, onion varieties require isolation.<br />

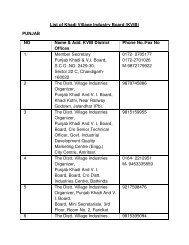

The required isolation distances are given below:<br />

Contaminant<br />

Minimum isolation distance (m)<br />

Field of other variety<br />

Field of the same variety not conforming to<br />

varietal purity requirement for certification<br />

For mother bulb production<br />

Foundation seed<br />

1,000<br />

1,000<br />

Certified seed<br />

500<br />

500<br />

5<br />

5<br />

For breeder seed production isolation distance should be 1,500 m.<br />

Important Diseases and Insect Pests:<br />

Diseases:<br />

Purple blotch<br />

The disease is caused by Alternaria porri (Ellis) Cif. The typical eye-shaped symptoms<br />

appear on leaves and flower stalks as small, sunken, whitish flecks with purple colored centre.<br />

Further large purple area develops forming dead patches. The disease appears at the<br />

temperature of 28-30° C and RH 90-100%. The fungicides such as Mancozeb (Dithane M-45) @<br />

0.25% or Chlorothalonil (Kavach) @ 0.2% or Iprodion (Rovral) @ 0.25% should be sprayed at<br />

fortnightly interval just after appearance of disease. The sticker, triton/indtron/sandovit should be<br />

mixed in spray solution @ 0.06%.<br />

www.efreshindia.com Page 7 of 19

Seed Production of Onion(Alliun <strong>cepa</strong> L.)<br />

Stemphylium blight:<br />

The disease is caused by Stemphylium vesicarium (Wallr.) Simmons. The symptoms occur on<br />

leaves and seed stalk from late-March to early-April. Infection appears as small yellow to pale<br />

orange spots or streaks in middle of leaves on inner side and flower stalks. The disease is more<br />

severe, after infestation of onion thrips. Thus both fungicides and insecticides sprays are required.<br />

Spraying of fungicide such as Mancozeb @ 0.25% or chlorothalonil (Kavach) @ 0.2 % along with<br />

insecticides deltamethrin (Decis) @ 0.10% and sticker triton at fortnightly interval should be<br />

followed just after appearance of the disease.<br />

Iris yellow spot virus:<br />

The disease is caused by Tomato spotted wilt virus (tospo virus group). The typical symptoms are<br />

yellowish, straw coloured, eyelike or diamond-shaped lesions on flower stalks. Some lesions on<br />

flower stalk have concentric rings altering with green and yellow colour pigment. The number of<br />

spots varies from one to several in a seed stalk at a time as well as spots appears on upper,<br />

middle and lower portion of stalk. The curling and banding of seed stalk are observed from the<br />

point of infection where necrotic spots develop. In severe condition, spots may griddle the scape,<br />

drying the umbel and reducing the seed yield and quality.<br />

www.efreshindia.com Page 8 of 19

Seed Production of Onion(Alliun <strong>cepa</strong> L.)<br />

Disease Transmission: Thrips (Thrips tabaci) is the only known vector for transmission of this<br />

disease.<br />

Control of the vector (thrips) is done by,<br />

spraying with Deltamethrin 2.8 % EC (Decis) @ 0.1 % or spinosad 2.5 % SC (Success) @ 0.1 %<br />

or Fipronil 5 % SC (Reagent) @ 0.15 % at 15 days intervals.<br />

Insect Pests:<br />

Onion Thrips<br />

Onion thrips, Thrips tabaci Lindeman (Thysanoptera: Thripidae) is a regular and potential pest of<br />

onion in tropical areas.<br />

Thrips attack onion at all the stages of crop growth. Both nymphs and adults cause direct damage<br />

by puncturing the epidermis of the leaves and seed stalk and suck out sap with modified piercing<br />

and sucking mouthparts. Sometimes plants show twisting and curling. And the flowers become<br />

discoloured, deformed and dry. Good cultural practices can help reduce onion thrips infestation.<br />

Volunteer onion plants are an important source of infestation for thrips. So removal of<br />

unharvested plant parts from owns the field can reduced the thrips population. Weed are the<br />

alternate host for thrips, weed free plots/sanitation can also reduced the thrips population.<br />

Predators, parasitoids and insect pathogens comprise the biological agents for suppressing pest<br />

population. Many such natural enemies are successfully employed in pest management<br />

programme in various vegetable ecosystems. In <strong>India</strong> and abroad, many biological agents like<br />

onion Orius albidipennis, Aeolothrips collaris, Laius externotatus, Scymnus nubilus are reported<br />

attacking T. tabaci in onion fields. Spray formulations of Beauveria bassiana are recommended to<br />

control thrips. Insecticides likes Deltamethrin 2.8 % EC @ 0.095%, Lambda cyhatothrin 5<br />

EC @ 0.05%, Fipronil oscs @ 0.1%, spinosad 45% EC @ 0.1% EC and profenophos 50EC @<br />

0.1% are found effective to suppress thrips population. The insecticides should reach the base of<br />

the leaves where the majority of thrips are located. Addition of sticker @ 0.06% is useful for<br />

retention and spread of spray fluid on erect leaves.<br />

www.efreshindia.com Page 9 of 19

Seed Production of Onion(Alliun <strong>cepa</strong> L.)<br />

Gram Caterpillar:<br />

Gram caterpillar (Helicoverpa armigera Hubner) is a polyphagous pest, occurring sporadically on<br />

onion grown for seed crop. Larvae feed inside the stem and move upwards to reach the base of<br />

the umbel at early stages of flowering. Subsequently, it invades the umbel and feeds on seeds. As<br />

a result, complete drying of flowers and complete loss of seed occurs. Spraying of Heliothis NPV<br />

@ 250 LE/ha, and Endosulphan @ 0.3% is effective in control of Helicoverpa armigera.<br />

Roguing<br />

Diseased and off-type plants are rogued out before flowering for quality seed production.<br />

Mode of Pollination<br />

Onion is highly cross pollinated crop and bees are main pollinating agents. So, it is necessary to<br />

have good number of bees for proper pollination and seed setting.<br />

Following points should be taken care for improving the pollination.<br />

• Bee colonies are kept in field<br />

• Irrigation should be given more frequently at the time of flowering and seed setting<br />

• Only safer insecticides for control of insects should be sprayed during flowering. The spray<br />

should be done in evening or early morning, when there are no bees.<br />

www.efreshindia.com Page 10 of 19

Seed Production of Onion(Alliun <strong>cepa</strong> L.)<br />

• In case of more wind, sometimes bees do not sit on flowers. The plant windbreaks all around<br />

the field should be grown.<br />

Harvesting and Curing<br />

Optimum stage of harvest<br />

All seed heads do not mature simultaneously, therefore, harvesting is done in instalments. When<br />

seed inside capsules become black and 20-25% black seeds are exposed the umbels should be<br />

cut with 10-15 cm stem attached. The umbels are spread on ground or canvas to avoid attack of<br />

mould for drying.<br />

Threshing, Cleaning and Seed Extraction<br />

After proper drying, the umbels are threshed either by rubbing with hands manually or by<br />

movement of bullocks or tractor on seed umbels.<br />

• Seeds are threshed when capsules are brittle and break readily. Threshing is done by flairing<br />

method. Cleaning is done by air screen machine by using 1 / l4 x 1 / 2 as grading screen.<br />

• Seed is cleaned by using hand winnowers and fans.<br />

• Use of seed cleaners, graders and gravity separator with appropriate sequence is useful for<br />

getting cleaning and graded seeds.<br />

• Dipping of seeds in water for cleaning, in no case is done for more than 2-3 minutes as<br />

otherwise the germination is affected adversely. Upgrading is further done on gravity<br />

separator.<br />

Drying, Packing and Storage<br />

For safe storage, seeds are dried to a level of about 6% moisture and then packed in aluminium<br />

foil or tins which are moisture proof. Seeds are then stored in air-conditioned and dehumidified<br />

stores having temperature of 16-20° C and relative humidity of 30-40%. In hot and humid climate<br />

the viability of onion seed is lost within a year. The onion seed if dried to 6.0% moisture level and<br />

stored in sealed containers, the life of seeds may be prolonged to 3-4 years without loss in<br />

germination.<br />

www.efreshindia.com Page 11 of 19

Seed Production of Onion(Alliun <strong>cepa</strong> L.)<br />

Seed Yield<br />

The normal seed yield is 6-8 q/ha. Sometimes when weather conditions are favourable 12-15<br />

quintals seed yield can be obtained from one hectare.<br />

Seed Certification<br />

The different steps/ requirements of certification for onion seed production are mentioned<br />

as under:<br />

Minimum seed certification standard<br />

Application and amplification of general seed certification standards<br />

The general seed certification standards are basic and together with following specific standards<br />

constitute for certification of onion seed.<br />

Land requirement<br />

The land to be used for seed production of onion shall be free from volunteer plants.<br />

Field inspection<br />

A. Mother bulb production stage<br />

• First inspection shall be made after transplanting of seedlings in order to determine isolation,<br />

volunteer plants, off-types including bolters and other relevant factors.<br />

• The second inspection shall be made after the bulbs have been lifted to verify the true<br />

characteristics of bulbs.<br />

B. Seed production stage<br />

• The first inspection should be made before flowering in order to determine isolation, off types<br />

including bolters and relevant factors.<br />

• The second and third inspection shall be made during flowering to check isolation, off types<br />

and other relevant factors.<br />

• The forth inspection shall be made at maturity to verify the true nature of the plant and other<br />

relevant factors.<br />

Field standards<br />

(A) General requirements<br />

Isolation<br />

Contaminant<br />

Isolation distance (m)<br />

Mother bulbs production<br />

Seed production<br />

Foundation<br />

Seed<br />

Certified<br />

Seed<br />

Foundation<br />

Seed<br />

Certified<br />

Seed<br />

Field of other variety<br />

Field of the same variety not<br />

conforming to varietal purity<br />

requirement for certification<br />

5<br />

5<br />

5<br />

5<br />

1,000<br />

1,000<br />

500<br />

500<br />

www.efreshindia.com Page 12 of 19

Seed Production of Onion(Alliun <strong>cepa</strong> L.)<br />

(B) Specific requirements<br />

Factor<br />

Maximum permitted limit<br />

* Bulbs not confirming to the<br />

varietal characteristics<br />

**Off-types<br />

Foundation<br />

0.10% (by number)<br />

0.10%<br />

Certified<br />

0.20% ( by number)<br />

0.20%<br />

* Maximum permitted at second inspection at mother bulb production stage<br />

** Maximum permitted at and after flowering at seed production stage<br />

v. Seed standard<br />

Factor<br />

Maximum permitted limit<br />

Pure seed (minimum)<br />

Genetic purity (minimum)<br />

Insert matter (maximum)<br />

Other crop seed (maximum)<br />

Weed seeds (maximum)<br />

Germination (minimum)<br />

Moisture (maximum)<br />

For vapour-proof containers (maximum)<br />

Foundation Seed<br />

98.0%<br />

98.0%<br />

2.0%<br />

5.0/kg<br />

5.0/kg<br />

70.0%<br />

8.0%<br />

6.0%<br />

Certified Seed<br />

98.0%<br />

98.0%<br />

2.0%<br />

10.0/kg<br />

10.0/kg<br />

70.0%<br />

8.0%<br />

6.0%<br />

Do’s and Dont’s:<br />

www.efreshindia.com Page 13 of 19

Seed Production of Onion(Alliun <strong>cepa</strong> L.)<br />

Do’s<br />

Dont’s<br />

1. Mother bulb production should be done<br />

by adopting improved methods of<br />

cultivation.<br />

2. The variety and bulbs selected for seed<br />

production should be of notified variety<br />

and bulbs should bear the specified<br />

characteristics like shape, colour, size<br />

etc.<br />

3. Avoid cultivating seed crop in highly<br />

alkaline and saline soils.<br />

4. Always adopt bulb to seed method of<br />

seed production technology.<br />

5. Avoid, planting seed crop in high humid,<br />

and rainfall conditions.<br />

6. Always select medium sized bulbs for<br />

seed production.<br />

7. Field should be ploughed to a fine filth for<br />

better crop growth.<br />

8. Bulbs for seed production should be<br />

planted in between last week of October<br />

to first fortnight of November for rabi<br />

onion varieties.<br />

9. For Kharif onion varieties, ideal time of<br />

planting is last week of November to 15 th<br />

December.<br />

10. Dip the 1/3 rd top cutted bulbs for 5<br />

minutes in the solution of 0.1%<br />

carbendazim + 1% potassium nitrate or<br />

1% potassium orthophosphate before<br />

planting for fast sprouting.<br />

11. Spacing of 45 cm x 30 cm is ideal for<br />

better crop growth and seed yield.<br />

12. Maintain recommended isolation<br />

distance for avoiding admixture in the<br />

variety.<br />

13. Roughing of off-type plants should be<br />

done regularly.<br />

14. Keep honey bee colonies in field for<br />

better pollination and more seed yield.<br />

15. Harvest umbels, only when 20-25%<br />

seeds become black in the capsules and<br />

are exposed.<br />

1. Don’t adopt seed-to-seed method.<br />

2. Don’t take seed production in the area<br />

where rainy periods are long or heavy<br />

dew and fog prevails.<br />

3. Avoid very light or sandy soil.<br />

4. Don’t select the bulbs below 4.5 cm<br />

diameter and above 5.5 cm, for planting.<br />

5. Never plant bulbs for seed production<br />

before November and after December.<br />

6. Don’t plant the bulbs in close spacing, as<br />

due to dense plants, the soil moisture will<br />

not evaporate, and leads to infection of<br />

disease.<br />

7. Don’t forget to maintain required isolation<br />

distance.<br />

8. After flowering, never spray insecticides<br />

for thrips control except endosulphon, as<br />

other insecticides may repell honey bees,<br />

and pollination will be affected.<br />

9. Never harvest immature seed umbells.<br />

Such umbells leads to low germination.<br />

10. Never store seed having moisture more<br />

than 6%.<br />

11. Don’t use diseased and insect affected<br />

bulbs for planting.<br />

12. Don’t select discolour, double, bruised<br />

bulbs for planting.<br />

13. Don’t purchase the seed from market<br />

unless, source of seed is known, and<br />

germination, moisture and purity is given<br />

on the seed packet.<br />

www.efreshindia.com Page 14 of 19

Seed Production of Onion(Alliun <strong>cepa</strong> L.)<br />

16. Thresh the seed only when the capsules<br />

are brittle and break readily.<br />

17. Seeds should be dried to a level of about<br />

6% moisture.<br />

18. Seeds should be stored at dry and less<br />

humid place, so as to avoid loss of vigour<br />

and vitality.<br />

19. Treat seed with thiram or captan 2 gm /<br />

kg seed before storage or before sowing<br />

in the field.<br />

20. For marketing and transportation pack<br />

the treated seed in cloth bags, and put<br />

polythene lining before packing in gunny<br />

bags.<br />

21. Before sowing the seed in the field,<br />

check germination.<br />

22. Before purchasing seed from market,<br />

see the year of production and<br />

germination report.<br />

Onion Seed Certification Proceduresd<br />

Phases of Seed Certification<br />

Certification shall be completed in six broad phases listed under<br />

• Receipt and scrutiny of application.<br />

• Verification of seed / bulb source, class and other requirements of the seed / bulb used for<br />

raising the seed crop.<br />

• Field inspections to verify conformity of the standing crop to the prescribed field standards.<br />

• Supervision of post-harvest stages including processing and packaging;<br />

• Seed sampling and analysis, including genetic purity test and / or seed health test, if any, in<br />

order to verify conformity to the prescribed standards and<br />

• Grant of certificate and certification tags, bagging and sealing.<br />

Seed Certification Procedures<br />

www.efreshindia.com Page 15 of 19

Seed Production of Onion(Alliun <strong>cepa</strong> L.)<br />

All the seed / bulb material to be used for seed production programme is subject to verification by<br />

the Agency. The seed producer should submit to the Agency relevant evidence such as<br />

certification tags, seals, labels, seed containers, purchase records, sales records etc, as may be<br />

demanded by the Agency during scrutiny of the application and/or during the first inspection of the<br />

seed crop in order to confirm that the seed / bulb used for raising the crop has been obtained from<br />

a source approved by the Agency and conforms to the class of seed / bulb required for seed<br />

production. A source-verification register containing relevant information as prescribed should be<br />

maintained by the seed producer for verification by Agency staff. After source verification<br />

application for certification should be submitted in the prescribed FORM-1 in triplicate to the<br />

concerned Seed Certification Office. FORM-1 is available with the divisional and zonal offices of<br />

the Agency. FORM-1 should be submitted within 30 days from the date of sowing or 15 days from<br />

the date of planting as the case may be. The relevant seed certification charges such as<br />

Registration fee, inspection fee grow out test charges (wherever necessary), seed testing<br />

charges, etc. should be remitted along with FORM-1. Separate FORM-1 should be submitted for<br />

certification of each variety. The FORM-1 should contain complete details of the name and<br />

address of the seed producer; season of production; name and address of the grower; location of<br />

the seed plot; crop/ variety and class of seed to be produced; area under seed production; details<br />

of parental seed materials used with lot number; date of sowing and the particulars of seed<br />

certification charges remitted.<br />

• In a single application, the maximum area that can be offered for certification is 25 acres.<br />

Additional area will require separate application.<br />

• No refund of inspection and registration fee will be made once the seed plot has been visited /<br />

inspected by the Seed Certification Officer.<br />

• The seed producer should assist the Agency staff in locating the seed plots during the first<br />

inspection.<br />

• Seed producers should guide their growers in agronomic practices, pest/disease control etc., for<br />

seed production.<br />

• Only seed from plots meeting all the prescribed field standards for certification is accepted for<br />

processing at the recognised seed processing plants.<br />

• All the necessary care should be taken to avoid admixture during harvesting, threshing and<br />

transportation.<br />

• Harvested seed produced from the approved fields should be brought to the seed processing<br />

unit and seeds are certified within 2 ½ months from the date of harvest.<br />

• Certification of a seed lot will be taken up only if the seed lots have met the prescribed field and<br />

seed standards.<br />

Field inspection<br />

Inspection of the standing crop is an essential step in verifying conformity of seed crop to<br />

prescribed minimum seed-certification standards. All the registered seed production fields will be<br />

inspected by qualified, trained and experienced officers of the Agency.<br />

www.efreshindia.com Page 16 of 19

Seed Production of Onion(Alliun <strong>cepa</strong> L.)<br />

Verification of all factors affecting seed quality in the field may not normally be possible in a single<br />

inspection as all the factors in the field may not be apparent or may not occur at the same time or<br />

all of them may not affect seed quality at the same stage of crop growth. Hence two or more<br />

inspections phased to cover all the important stages of crop growth are required for most crops.<br />

The number of inspections and the stages of crop growth at which they should be conducted vary<br />

from crop to crop depending on the crop duration, pollination behavior, susceptibility to<br />

contamination, disease-susceptible stages, nature of the contaminating factors, etc.<br />

Accordingly field inspection of seed certification plots is conducted at vegetative or pre-flowering<br />

stage; flowering stage, post-flowering and pre-harvest stage.<br />

Field Inspections at vegetative or pre flowering stages are done to confirm the actual acreage<br />

planted and compare it with the acreage allotted or for which the application was submitted and to<br />

record the excess area if any and to confirm actual date of sowing/planting.<br />

* advise the removal of all off types on the basis of vegetative characters.<br />

* detect occurrence of any contamination within the isolation distance and to determine the area to<br />

be rejected due to inadequate isolation.<br />

* verify morphological characters of the crop.<br />

* Confirm that the grower had done thorough roguing after the inspection at flowering.<br />

verify the removal of contaminating factors, objectionable weed plants and diseased plants/heads.<br />

* educate the grower about harvesting technology, give guidance regarding the care to be<br />

taken during harvesting, threshing and transportation, and assess the expected yield<br />

(approximate) from the seed crop.<br />

Prescribed field standards for onion under certification:<br />

Maximum permissible level of off types in Foundation seed 0.10 % Certified seed 0.20 %<br />

Field counts<br />

For all crops five counts are taken for an area up to 2 acres, and an additional count taken for<br />

each additional five acres as given below.<br />

Area of the field crop,<br />

Hectares<br />

No. of counts to be taken<br />

Upto 2 5<br />

2-4 6<br />

4-6 7<br />

www.efreshindia.com Page 17 of 19

Seed Production of Onion(Alliun <strong>cepa</strong> L.)<br />

6-8 8<br />

8-10 9<br />

Above 10 10<br />

In any inspection, if the first set of counts shows that the seed crop does not conform to<br />

the prescribed standards for any factor, 'a second set of counts should be taken for that factor.<br />

However, when the first set of counts shows a factor is more than twice the maximum permitted, it<br />

is not necessary to take a second set of counts. Two sets of counts are called double counts.<br />

Some crops tiller others do not, some are planted narrow. Others wide, thus the number of<br />

plants/heads comprising a single count differs from crop to crop. No. of plants/head per count in<br />

onion is 100.<br />

Seed crops meeting the prescribed field standards for certification will be harvested, threshed and<br />

transported to seed processing plants authorised by STATE <strong>SEED</strong> CERTIFICATION AGENCY<br />

alongwith Final Filed Inspection Report issued by the concerned Seed Certification Officer.<br />

Rejection of seed plots<br />

The agency has the authority to reject seed plots offered for certification on the following grounds.<br />

• The isolation distance is inadequate.<br />

• The seed crop does not conform to the prescribed field standards for any factor or<br />

contaminant<br />

• One-third or more is lodged just prior to or during flowering so that inspection during flowering<br />

is difficult / not possible.<br />

• The application in Form-1 has been submitted late viz., when the crop has crossed the<br />

flowering stage by the time of the first inspection.<br />

Re-inspection<br />

In case of seed fields rejected due to nonconformity to the prescribed field standards at a certain<br />

inspection, the Agency shall, at the producer's request and after removal of source of<br />

contamination or contaminant plants in the seed field by the grower, undertake one re-inspection<br />

over and above the number of inspections prescribed for the crop provided the removal of the<br />

source of contamination can ensure conformity of the seed crop to the standards prescribed and<br />

www.efreshindia.com Page 18 of 19

Seed Production of Onion(Alliun <strong>cepa</strong> L.)<br />

provided further that no irreversible damage has been caused to the quality of the seed by the<br />

contaminant(s)<br />

Harvesting, threshing and transportation<br />

A seed crop meeting the field standards for certification shall be properly, harvested, threshed,<br />

dried and transported to the registered seed processing unit and certified within 2+ months from<br />

the date of harvest. During these operations seed producers/growers should take all necessary<br />

precautions to safeguard seed quality by preventing seed admixture and other causes of<br />

contamination at any stage, not supervised by the Agency.<br />

************<br />

www.efreshindia.com Page 19 of 19