Flex Form - Continental Research Corporation

Flex Form - Continental Research Corporation

Flex Form - Continental Research Corporation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

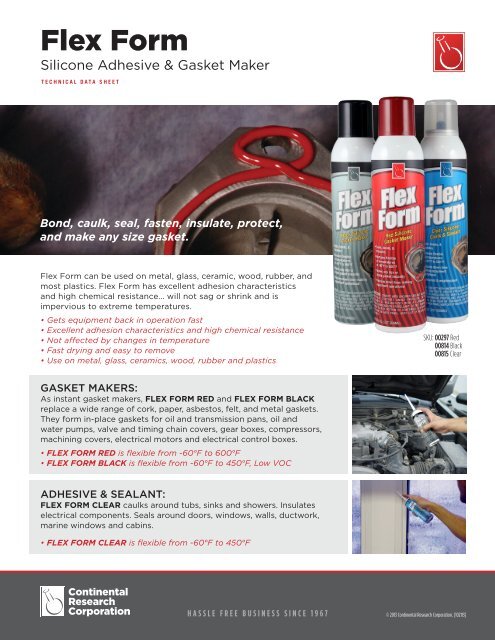

<strong>Flex</strong> <strong>Form</strong><br />

Silicone Adhesive & Gasket Maker<br />

TECHNICAL DATA SHEET<br />

Bond, caulk, seal, fasten, insulate, protect,<br />

and make any size gasket.<br />

<strong>Flex</strong> <strong>Form</strong> can be used on metal, glass, ceramic, wood, rubber, and<br />

most plastics. <strong>Flex</strong> <strong>Form</strong> has excellent adhesion characteristics<br />

and high chemical resistance... will not sag or shrink and is<br />

impervious to extreme temperatures.<br />

• Gets equipment back in operation fast<br />

• Excellent adhesion characteristics and high chemical resistance<br />

• Not affected by changes in temperature<br />

• Fast drying and easy to remove<br />

• Use on metal, glass, ceramics, wood, rubber and plastics<br />

SKU: 00297 Red<br />

00814 Black<br />

00815 Clear<br />

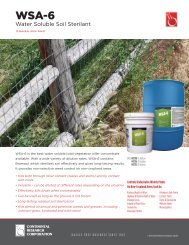

GASKET MAKERS:<br />

As instant gasket makers, FLEX FORM RED and FLEX FORM BLACK<br />

replace a wide range of cork, paper, asbestos, felt, and metal gaskets.<br />

They form in-place gaskets for oil and transmission pans, oil and<br />

water pumps, valve and timing chain covers, gear boxes, compressors,<br />

machining covers, electrical motors and electrical control boxes.<br />

• FLEX FORM RED is flexible from -60°F to 600°F<br />

• FLEX FORM BLACK is flexible from -60°F to 450°F, Low VOC<br />

ADHESIVE & SEALANT:<br />

FLEX FORM CLEAR caulks around tubs, sinks and showers. Insulates<br />

electrical components. Seals around doors, windows, walls, ductwork,<br />

marine windows and cabins.<br />

• FLEX FORM CLEAR is flexible from -60°F to 450°F<br />

HASSLE FREE BUSINESS SINCE 1967<br />

© 2013 <strong>Continental</strong> <strong>Research</strong> <strong>Corporation</strong>. [102113]

PRODUCT LABEL<br />

<strong>Flex</strong> <strong>Form</strong> Black Silicone Gasket Maker can be used on metal, glass, porcelain,<br />

ceramics, wood, rubber, and most paint and plastics. As an instant gasket<br />

maker, this product replaces a wide range of cork, paper, asbestos, felt and<br />

metal gaskets. This product has excellent adhesion characteristics, high<br />

chemical resistance and will not sag or shrink. Withstands intermittent<br />

temperatures up to 600°F and pressures up to 330 psi. Offers unmatched<br />

performance under the most severe operating conditions. Virtually unaffected<br />

by chemical deterioration, extreme weather, temperature or aging.<br />

FORMS IN-PLACE GASKETS & SEALS FOR: Pumps, High Pressure Pipe<br />

Joints, Oil and Transmission Pans, Oil and Water Pumps, Valve and Timing<br />

Chain Covers, Electric Motors and Electrical Control Boxes, Gear Boxes,<br />

Compressors, Machine Covers, Rigid Flange Assemblies, Equipment Housings.<br />

Specifically designed for all oxygen sensor equipped vehicles.<br />

This product meets the requirement of FDA Regulation 21 CFR 177.2600, when<br />

fully cured and washed.<br />

DIRECTIONS: Read Material Safety Data Sheet before using.<br />

1. Surface must be clean, dry and free of oil, tar, dirt and dust for best adhesion.<br />

2. Hold can at 45° angle and apply a continuous bead of 1/16” to 1/8” to the<br />

mating surface, encircling all bolt holes.<br />

3. For adhesion to both parts, assemble immediately. One part adhesion, allow<br />

10-15 minutes for bead to skin.<br />

4. Assemble parts, but do not squeeze gasket out by over tightening bolts.<br />

5. Starts to cure immediately, fully cures in 24 hours and reaches optimum<br />

strength in 7 days.<br />

6. After sealant is completely cured, for food applications, wash part before use.<br />

Excess cured material can be removed by trimming with a sharp blade. Avoid<br />

undercutting the seal.<br />

NOTE: After each use, leave a small bead of material, which will form a sealing<br />

“plug” for reuse. To use, gently pull “plug” and begin to use material. If plug<br />

breaks, leaving the dispensing tip sealed, use a paper clip or other wire object<br />

to remove and loosen the remainder of the cured material.<br />

NOT RECOMMENDED FOR USE ON: Cylinder heads, exhaust manifolds, intake<br />

manifolds, carburetors, or parts requiring continuous immersion in gasoline.<br />

CAUTION: CONTACT WITH UNCURED SEALANT CAUSES IRRITATION. OUTER<br />

CONTAINER IS PRESSURIZED WITH A FLAMMABLE HYDROFLUOROCARBON<br />

PROPELLANT. DO NOT REMOVE RUBBER PLUG IN BOTTOM OF CONTAINER.<br />

Use with adequate ventilation. Product releases acetic acid (vinegar-like odor)<br />

during curing. Contact lens wearers take appropriate precautions. Contents<br />

under pressure. Do not puncture or incinerate. Do not store at temperatures<br />

above 120°F (50°C). Do not store in automobiles, in direct sunlight or any area<br />

with temperatures above 120°F.<br />

CONTAINS: Amorphous Silica (7631-86-9), Methyltriacetoxysilane (4253-34-<br />

3), Ethyltriacetoxysilane (17689-77-9) and Difluoroethane (75-37-6).<br />

FIRST AID: IF EYE CONTACT: Flush with large amounts of cool running water<br />

for at least 15 minutes while holding upper and lower lids open. Seek medical<br />

attention immediately. IF SKIN CONTACT: Wipe off excess sealant with dry<br />

paper towel or cloth, and wash with soap and water. If irritation persists seek<br />

medical attention. EXCESSIVE INHALATION: Remove to fresh air. Seek medical<br />

attention immediately. If breathing stops give artificial respiration. IF INGESTED:<br />

Do not induce vomiting. No additional first aid should be needed.<br />

SOLD BY:<br />

6000003061-000_1003403-11607 MFD-CS 6/13<br />

<strong>Flex</strong><br />

<strong>Form</strong><br />

Black Silicone<br />

Gasket Maker<br />

• Seals, bonds, &<br />

insulates<br />

• Remains flexible<br />

at temperatures<br />

of -60°F to 500°F<br />

• Makes any size or<br />

shape gasket instantly<br />

• Reduces down time making<br />

equipment operational<br />

CAUTION: CONTACT WITH UNCURED SEALANT CAUSES<br />

IRRITATION. CONTENTS UNDER PRESSURE. OUTER<br />

CONTAINER IS PRESSURIZED WITH A FLAMMABLE<br />

HYDROFLUOROCARBON PROPELLANT. DO NOT REMOVE<br />

RUBBER PLUG IN BOTTOM OF CONTAINER. SEE OTHER<br />

CAUTIONS ON BACK PANEL. KEEP OUT OF REACH OF<br />

CHILDREN.<br />

NET WT. 8 OZ. (227 GRAMS)<br />

HASSLE FREE BUSINESS SINCE 1967<br />

© 2013 <strong>Continental</strong> <strong>Research</strong> <strong>Corporation</strong>. [102113]

PRODUCT LABEL<br />

<strong>Flex</strong> <strong>Form</strong> Red Silicone Gasket Maker can be used on metal, glass, porcelain, ceramics,<br />

wood, rubber, and most paint and plastics. As an instant gasket maker, this product<br />

replaces a wide range of cork, paper, asbestos, felt and metal gaskets. This product<br />

has excellent adhesion characteristics, high chemical resistance and will not sag or<br />

shrink. Withstands intermittent temperatures up to 650°F and pressures up to 330 psi.<br />

Offers unmatched performance under the most severe operating conditions. Virtually<br />

unaffected by chemical deterioration, extreme weather, temperature or aging.<br />

FORMS IN-PLACE GASKETS & SEALS FOR: Pumps, High Pressure Pipe<br />

Joints, Oil and Transmission Pans, Oil and Water Pumps, Valve and Timing<br />

Chain Covers, Electric Motors and Electrical Control Boxes, Gear Boxes,<br />

Compressors, Machine Covers, Rigid Flange Assemblies, Equipment Housings.<br />

Specifically designed for all oxygen sensor equipped vehicles.<br />

This product meets the requirement of FDA Regulation 21 CFR 177.2600, when fully<br />

cured and washed.<br />

DIRECTIONS: Read Material Safety Data Sheet before using.<br />

1. Surface must be clean, dry and free of oil, tar, dirt and dust for best adhesion.<br />

2. Hold can at 45° angle and apply a continuous bead of 1/16” to 1/8” to the mating<br />

surface, encircling all bolt holes.<br />

3. For adhesion to both parts, assemble immediately. One part adhesion, allow 10-15<br />

minutes for bead to skin.<br />

4. Assemble parts, but do not squeeze gasket out by over tightening bolts.<br />

5. Starts to cure immediately, fully cures in 24 hours and reaches optimum strength<br />

in 7 days.<br />

6. After sealant is completely cured, for food applications, wash part before use.<br />

Excess cured material can be removed by trimming with a sharp blade. Avoid<br />

undercutting the seal.<br />

NOTE: After each use, leave a small bead of material, which will form a sealing “plug”<br />

for reuse. To use, gently pull “plug” and begin to use material. If plug breaks, leaving<br />

the dispensing tip sealed, use a paper clip or other wire object to remove and loosen<br />

the remainder of the cured material.<br />

NOT RECOMMENDED FOR USE ON: Cylinder heads, exhaust manifolds, intake<br />

manifolds, carburetors, or parts requiring continuous immersion in gasoline.<br />

CAUTION: CONTACT WITH UNCURED SEALANT CAUSES IRRITATION. OUTER<br />

CONTAINER IS PRESSURIZED WITH A FLAMMABLE HYDROFLUOROCARBON<br />

PROPELLANT. DO NOT REMOVE RUBBER PLUG IN BOTTOM OF CONTAINER. Use with<br />

adequate ventilation. Product releases acetic acid (vinegar-like odor) during curing.<br />

Contact lens wearers take appropriate precautions. Contents under pressure. Do not<br />

puncture or incinerate. Do not store at temperatures above 120°F (50°C). Do not<br />

store in automobiles, in direct sunlight or any area with temperatures above 120°F.<br />

CONTAINS: Amorphous Silica (7631-86-9), Methyltriacetoxysilane (4253-34-3),<br />

Ethyltriacetoxysilane (17689-77-9) and Difluoroethane (75-37-6).<br />

FIRST AID: IF EYE CONTACT: Flush with large amounts of cool running water for at<br />

least 15 minutes while holding upper and lower lids open. Seek medical attention<br />

immediately. IF SKIN CONTACT: Wipe off excess sealant with dry paper towel or<br />

cloth, and wash with soap and water. If irritation persists seek medical attention.<br />

EXCESSIVE INHALATION: Remove to fresh air. Seek medical attention immediately.<br />

If breathing stops give artificial respiration. IF INGESTED: Do not induce vomiting. No<br />

additional first aid should be needed.<br />

See Material Safety Data Sheet for complete safety information.<br />

CONTAINS NO OZONE DEPLETING CHEMICALS!<br />

MADE IN THE U.S.A.<br />

SOLD BY:<br />

6000015313_1003403-11507 MFD-CS 8/13<br />

<strong>Flex</strong><br />

<strong>Form</strong><br />

Red Silicone<br />

Gasket Maker<br />

• Seals, bonds, &<br />

insulates<br />

• Remains flexible<br />

at temperatures<br />

of -60°F to 600°F<br />

• Makes any size or<br />

shape gasket instantly<br />

• Reduces down time making<br />

equipment operational<br />

CAUTION: CONTACT WITH UNCURED SEALANT CAUSES<br />

IRRITATION. CONTENTS UNDER PRESSURE. OUTER<br />

CONTAINER IS PRESSURIZED WITH A FLAMMABLE<br />

HYDROFLUOROCARBON PROPELLANT. DO NOT REMOVE<br />

RUBBER PLUG IN BOTTOM OF CONTAINER. SEE OTHER<br />

CAUTIONS ON BACK PANEL. KEEP OUT OF REACH OF<br />

CHILDREN.<br />

NET WT. 8 OZ. (227 GRAMS)<br />

HASSLE FREE BUSINESS SINCE 1967<br />

© 2013 <strong>Continental</strong> <strong>Research</strong> <strong>Corporation</strong>. [102113]

PRODUCT LABEL<br />

<strong>Flex</strong> <strong>Form</strong> Clear Silicone Caulk & Sealant is ideal for use wherever a strong<br />

permanently elastic weatherproof caulk, sealant, or adhesive is needed.<br />

Designed to seal non-porous surfaces around ceramic tile, cultured marble,<br />

showers, tubs, sinks and plumbing fixtures. Ideal for caulking windows,<br />

doors, sills and ceiling cracks and crevices. Features excellent adhesion and<br />

high chemical resistance.<br />

<strong>Flex</strong> <strong>Form</strong> Clear will not sag or shrink during severe temperature changes.<br />

Useful for sealing cracks in machinery, heating and ventilation duct work,<br />

plumbing fixtures, electrical connections and low pressure water and drain<br />

lines. Bonds nameplates, machinery flanges, glass, signs, electrical insulation,<br />

etc. Offers unmatched performance under the most severe conditions.<br />

Remains flexible and will not shrink, crack, crumble or dry out. NOTE:<br />

Paint will not adhere to cured material. Not recommended for continuous<br />

immersion in water or application to porous surfaces such as masonry. This<br />

product meets the requirement of FDA Regulation 21 CFR 177.2600, when<br />

fully cured and washed.<br />

DIRECTIONS: Read Material Safety Data Sheet before using.<br />

1. Surface must be clean, dry and free of oil, tar, dirt and dust for best adhesion.<br />

2. Hold can at 45° angle and apply a continuous bead of 1/16” to 1/8” to<br />

the mating surfaces.<br />

3. Starts to cure immediately, fully cures in 24 hours and reaches optimum<br />

strength in 7 days.<br />

NOTE: After each use, leave a small bead of material, which will form a<br />

sealing “plug” for reuse. To use, gently pull “plug” and begin to use material.<br />

If plug breaks, leaving the dispensing tip sealed, use a paper clip or other<br />

wire object to remove and loosen the remainder of the cured material.<br />

CAUTION: CONTACT WITH UNCURED SEALANT CAUSES IRRITATION. OUTER<br />

CONTAINER IS PRESSURIZED WITH A FLAMMABLE HYDROFLUOROCARBON<br />

PROPELLANT. DO NOT REMOVE RUBBER PLUG IN BOTTOM OF CONTAINER.<br />

Use with adequate ventilation. Product releases acetic acid (vinegar-like<br />

odor) during curing. Contact lens wearers take appropriate precautions.<br />

Contents under pressure. Do not puncture or incinerate. Do not store at<br />

temperatures above 120°F (50°C). Do not store in automobiles, in direct<br />

sunlight or any area with temperatures above 120°F.<br />

CONTAINS: Amorphous Silica (7631-86-9), Methyltriacetoxysilane (4253-<br />

34-3), Ethyltriacetoxysilane (17689-77-9) and Difluoroethane (75-37-6).<br />

FIRST AID: IF EYE CONTACT: Flush with large amounts of cool running<br />

water for at least 15 minutes while holding upper and lower lids open. Seek<br />

medical attention immediately. IF SKIN CONTACT: Wipe off excess sealant<br />

with dry paper towel or cloth, and wash with soap and water. If irritation<br />

persists seek medical attention. EXCESSIVE INHALATION: Remove to fresh<br />

air. Seek medical attention immediately. If breathing stops give artificial<br />

respiration. IF INGESTED: Do not induce vomiting. No additional first aid<br />

should be needed.<br />

See Material Safety Data Sheet for complete safety information.<br />

CONTAINS NO OZONE DEPLETING CHEMICALS!<br />

MADE IN THE U.S.A.<br />

SOLD BY:<br />

6000003062-000_1003403-11707 MFD-CS 10/13<br />

<strong>Flex</strong><br />

<strong>Form</strong><br />

Clear Silicone<br />

Caulk & Sealant<br />

• Seals, bonds, &<br />

insulates<br />

• Remains flexible<br />

at temperatures<br />

of -60°F to 500°F<br />

• Reduces down time<br />

making equipment<br />

operational<br />

• Waterproof & weatherproof<br />

CAUTION: CONTACT WITH UNCURED SEALANT CAUSES<br />

IRRITATION. CONTENTS UNDER PRESSURE. OUTER<br />

CONTAINER IS PRESSURIZED WITH A FLAMMABLE<br />

HYDROFLUOROCARBON PROPELLANT. DO NOT REMOVE<br />

RUBBER PLUG IN BOTTOM OF CONTAINER. SEE OTHER<br />

CAUTIONS ON BACK PANEL. KEEP OUT OF REACH OF CHILDREN.<br />

NET WT. 8 OZ. (227 GRAMS)<br />

HASSLE FREE BUSINESS SINCE 1967<br />

© 2013 <strong>Continental</strong> <strong>Research</strong> <strong>Corporation</strong>. [102113]