You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>TTP</strong>-<strong>245</strong>/<strong>343</strong><br />

THERMAL TRANSFER / DIRECT THERMAL<br />

BAR CODE PRINTER<br />

SERVICE<br />

MANUAL

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

1. FUNDAMENTAL OF THE SYSTEM ........................................................................ 1<br />

1.1. Overview .................................................................................................................. 1<br />

1.1.1. Front View ..................................................................................................... 1<br />

1.1.2. Rear View ...................................................................................................... 2<br />

1.2. Specification ............................................................................................................. 2<br />

1.2.1. Printer ............................................................................................................ 2<br />

1.2.2. LED ............................................................................................................... 4<br />

1.2.3. Button ............................................................................................................ 4<br />

1.3. Supply Specification ................................................................................................. 7<br />

1.3.1. Paper .............................................................................................................. 7<br />

1.3.2. Ribbon ........................................................................................................... 7<br />

2. ELECTRONICS ........................................................................................................ 8<br />

2.1. Circuit Description .................................................................................................... 8<br />

2.2. MCU Circuit and MCU PIN Description..................................................................10<br />

2.2.1. MCU PIN Description: .................................................................................. 11<br />

2.3. Reset Circuit ............................................................................................................16<br />

2.4. Memory Circuit .......................................................................................................17<br />

2.5. Decoder Circuit ........................................................................................................18<br />

2.6. Memory Map ...........................................................................................................19<br />

2.7. Print Head Circuit ....................................................................................................21<br />

2.8. Stepping Motor Drive / Protection Circuit ................................................................22<br />

2.9. Power Circuit ...........................................................................................................24<br />

2.10. Parallel Interface Circuit ........................................................................................25<br />

2.11. Serial Interface Circuit ...........................................................................................27<br />

2.12. USB Circuit ...........................................................................................................28<br />

2.12.1. USB PIN Function ......................................................................................29<br />

2.13. Sensor Circuit ........................................................................................................31<br />

2.13.1. Gap and Black Mark Sensor ........................................................................31<br />

2.13.2. Head Open Micro Switch ............................................................................32<br />

2.13.3. Peel-off Sensor ............................................................................................33<br />

2.13.4. Ribbon Sensor .............................................................................................34<br />

2.14. Cutter Drive / Protection Circuit .............................................................................35<br />

2.15. DC Motor Driver / Encoder Circuit ........................................................................36<br />

2.16. Summary of PCB connectors .................................................................................37<br />

3. REPLACE IMPORTANT PARTS ........................................................................... 40<br />

3.1. Replacing Top Cover................................................................................................40<br />

3.2. Replacing Top Inner Cover ......................................................................................42<br />

3.3. Replacing Lower Cover ...........................................................................................44<br />

3.4. Replacing Main Board .............................................................................................45<br />

i

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

3.5. Replacing Platen Assembly ......................................................................................46<br />

3.6. Replacing the Stepping Motor Bracket / Metal Assembly and Stepping Motor .........47<br />

3.7. Replacing Label Guide & Gap Sensor Assembly ......................................................49<br />

3.8. Replacing Black Mark Sensor Assembly ..................................................................51<br />

3.9. Replacing Print Head Assembly ...............................................................................52<br />

3.10. Replacing Head Open Micro Switch ......................................................................53<br />

3.11. Replacing Ribbon Motor and Ribbon Sensor ..........................................................55<br />

3.12. Replacing Feed Button and Feed Button PCB ........................................................57<br />

3.13. Install Memory Card (Option) ................................................................................58<br />

3.14. Install Peel Off Module (Option) ............................................................................59<br />

3.15. Loading the Label in Peel-off Mode .......................................................................61<br />

3.16. Install Cutter Module (Option) ...............................................................................63<br />

3.17. Loading Label in Cutter Mode ...............................................................................67<br />

3.18. Install Internal Ethernet Module (Option) ...............................................................68<br />

4. Power on Utilities ................................................................................................. 72<br />

4.1 Ribbon and Gap/Black Mark Sensor Calibration .......................................................72<br />

4.2 Gap/Black Mark Calibration;Self-test;Dump mode..............................................73<br />

4.3 Printer Initialization ..................................................................................................76<br />

4.4 Black Mark Sensor Calibration .................................................................................77<br />

4.5 Gap Sensor Calibration .............................................................................................77<br />

4.6 Skip AUTO.BAS ......................................................................................................77<br />

5. GAP AND BLACK MARK SENSOR SELECTION ................................................ 79<br />

6. BIOS Update.......................................................................................................... 79<br />

7. TROUBLESHOOTING ........................................................................................... 80<br />

8. MAINTENANCE ..................................................................................................... 84<br />

9. PARTS LIST ........................................................................................................... 85<br />

9.1 Cover ........................................................................................................................85<br />

9.1 Cover drawing ..........................................................................................................86<br />

9.2 Main Board ...............................................................................................................87<br />

9.2 Main Board drawing .................................................................................................88<br />

9.3 Top Inner Cover ........................................................................................................89<br />

9.3 Top Inner Cover drawing ..........................................................................................91<br />

9.4 Ribbon Mechanism Assembly ...................................................................................92<br />

9.4 Ribbon Mechanism Assembly drawing .....................................................................93<br />

9.5.1 Lower Inner Cover .................................................................................................94<br />

9.5.1 Lower Inner Cover drawing ...................................................................................95<br />

9.5.2 Lower Inner Cover .................................................................................................96<br />

9.5.2 Lower Inner Cover drawing ...................................................................................97<br />

9.6 Stepping Motor Assembly .........................................................................................98<br />

ii

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

9.6 Stepping Motor Assembly drawing ...........................................................................99<br />

9.7 Option and accessories ............................................................................................ 100<br />

9.7 Option and accessories drawing .............................................................................. 102<br />

Update History ........................................................................................................ 103<br />

iii

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

1. FUNDAMENTAL OF THE SYSTEM<br />

1.1. Overview<br />

1.1.1. Front View<br />

Label Roll Capacity<br />

View Window<br />

Ribbon Access Window<br />

LED Indicator<br />

Feed Button<br />

Top Cover Open Lever<br />

Fig. 1.1.1 Front View<br />

1

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

1.1.2. Rear View<br />

1. USB Interface<br />

2. Centronics Interface<br />

3. RS-232 Interface<br />

4. Power Jack<br />

5. Power Switch<br />

6. Rear Paper Guide<br />

6<br />

1 2 3 4 5<br />

Fig. 1.1.2 Rear View<br />

1.2. Specification<br />

1.2.1. Printer<br />

Item <strong>TTP</strong>-<strong>245</strong> <strong>TTP</strong>-<strong>343</strong><br />

Mechanism<br />

Resolution 203 dpi. 300 dpi<br />

Max. Print Width 108 mm. 104 mm<br />

Max. Print Length 1000 mm ( 39” ). 420 mm<br />

Ribbon Capacity 300 meter with 1” core. (Max. OD 67 mm)<br />

Printing Speed 2, 3, 4 and 5 ips selectable.<br />

peeler function 2, 3 ips selectable 3 ips selectable<br />

Printing Method Direct thermal and thermal transfer printing.<br />

2

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

Enclosure<br />

Structure<br />

Double-walled plastic.<br />

Dimension<br />

Standard Model: 314mm(L) x 213mm(W) x 188mm(H)<br />

Operation Panel One push switch, and one indicator LED (Green,<br />

Orange, Red colors).<br />

Hardware<br />

Sensor<br />

Transmissive sensor (offset 6 mm from liner<br />

edge).<br />

Reflective sensor (position adjustable).<br />

Head open micro switch.<br />

Ribbon end sensor<br />

Memory<br />

2M byte Flash memory<br />

2M bytes DRAM<br />

Interface<br />

RS-232C (max baud rate, 19,200 bps).<br />

USB: V1.1.<br />

Centronics.<br />

Power<br />

AC input: 100-240V universal auto switching power<br />

supply.<br />

DC output: 24V 3.75A.<br />

Firmware<br />

Font Type<br />

8 alpha-numeric bitmap fonts, and 1 true type font.<br />

Rotation<br />

0, 90,180 and 270 degrees.<br />

Barcode Format 1D Bar code<br />

Code 39, Code 93, Code 128UCC, Code128 subsets<br />

A.B.C, Codabar, Interleave 2 of 5, EAN-8, EAN-13,<br />

EAN-128, UPC-A, UPC-E, EAN and UPC2(5) digits<br />

add-on, MSI, PLESSEY, POSTNET, ChinaPOST,<br />

ITF-14, EAN-14.<br />

2D Bar code<br />

PDF-417, Maxicode, and DataMatrix, QR CODE.<br />

Command Set TSPL2<br />

Environment<br />

Operation Temperature: 5℃ ~ 40℃.<br />

Relative Humidity: 25% ~ 85% (Non Condensing).<br />

Storage Temperature: -40℃ ~ 60℃.<br />

Relative Humidity: 10% ~ 90% (Non Condensing).<br />

3

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

1.2.2. LED<br />

LED Color<br />

Green/ Solid<br />

Green/ Flash<br />

Amber<br />

Red / Solid<br />

Red / Flash<br />

Description<br />

This illuminates that the power is on and the device is<br />

ready to use.<br />

This illuminates that the system is downloading data<br />

from PC to memory and the printer is paused.<br />

This illuminates that the system is clearing data from<br />

printer.<br />

This illuminates printer head open, cutter error.<br />

This illuminates a printing error, such as paper empty,<br />

paper jam, ribbon empty, or memory error etc.<br />

1.2.3. Button<br />

Feed • Press the button when the LED is green.<br />

• It feeds the label to the beginning of the next label.<br />

Pause • Press the feed button during printing<br />

Ribbon Sensor and<br />

Gap/Black Mark<br />

Sensor Calibration<br />

• The printing job is suspended.<br />

1. Turn off the power switch.<br />

2. Hold on the button then turn on the power switch.<br />

3 Release the button when LED becomes red and blinking.<br />

(Any red will do during the 5 blinks).<br />

Note:<br />

• It will calibrate the ribbon sensor and gap/black<br />

mark sensor sensitivity.<br />

• The LED color will be changed as following order:<br />

Amber red (5 blinks) amber (5 blinks) <br />

green (5 blinks) green/amber (5 blinks) <br />

red/amber (5 blinks) solid green<br />

Please select gap or black mark sensor by GAP or<br />

BLINE command prior to calibrate the sensor.<br />

For more information about GAP and BLINE command,<br />

please refer to TSPL2 programming manual.<br />

4

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

Gap/Black Mark<br />

Sensor Calibratio,<br />

Label Length<br />

Measurement, Self<br />

1.Turn off the power switch.<br />

2. Hold on the button then turn on the power switch.<br />

3. Release the button when LED becomes amber and<br />

blinking. (Any amber will do during the 5 blinks).<br />

Test and enter Dump<br />

Mode<br />

• The LED color will be changed as following order.<br />

Amber red (5 blinks) amber (5 blinks) <br />

green (5 blinks) green/amber (5 blinks) <br />

red/amber (5 blinks) solid green<br />

• It calibrates the sensor and measures the label<br />

length and prints internal settings then enter the<br />

dump mode.<br />

Note:<br />

Please select gap or black mark sensor by GAP or<br />

BLINE command prior to calibrate the sensor.<br />

For more information about GAP and BLINE command,<br />

please refer to TSPL2 programming manual.<br />

Printer Initialization 1. Turn off the power switch.<br />

2. Hold on the button then turn on the power switch.<br />

3. Release the button when LED turns green after 5 amber<br />

blinks. (Any green will do during the 5 blinks).<br />

• The LED color will be changed as following:<br />

Amber red (5 blinks) amber (5 blinks) <br />

green (5 blinks) green/amber (5 blinks) <br />

red/amber (5 blinks) solid green<br />

Note:<br />

Always do gap/black mark sensor calibration after<br />

printer initialization.<br />

Force Black Mark<br />

Sensor Calibration<br />

1. Turn off the power switch.<br />

2. Hold on the button then turn on the power switch.<br />

3. Release the button when LED turns green/amber after 5<br />

green blinks. (Any green/amber will do during the 5<br />

blinks).<br />

• The LED color will be changed as following:<br />

Amber red (5 blinks) amber (5 blinks) <br />

green (5 blinks) green/amber (5 blinks) <br />

red/amber (5 blinks) solid green<br />

5

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

Force Gap Sensor 1. Turn off the power switch.<br />

Calibration 2. Hold on the button then turn on the power switch.<br />

3. Release the button when LED turns red/amber after 5<br />

green/amber blinks. (Any red/amber will do during the 5<br />

blinks).<br />

• The LED color will be changed as following:<br />

Amber red (5 blinks) amber (5 blinks) <br />

green (5 blinks) green/amber (5 blinks) <br />

red/amber (5 blinks) solid green<br />

Skip AUTO.BAS<br />

1. Turn off printer power.<br />

2. Press the FEED button and then turn on power.<br />

3. Release the FEED button when LED becomes solid<br />

green.<br />

• The LED color will be changed as following:<br />

Amber red (5 blinks) amber (5 blinks) <br />

green (5 blinks) green/amber (5 blinks) <br />

red/amber (5 blinks) solid green<br />

4. Printer will be interrupted to run the AUTO.BAS program.<br />

6

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

1.3. Supply Specification<br />

1.3.1. Paper<br />

Item<br />

Specification<br />

Type<br />

Label (Continuous , Die-cut , Fan-fold).<br />

Wound Type Outside wound.<br />

Width 20~112mm (0.78" ~ 4.4")<br />

Length<br />

( for peel and cutter )<br />

10mm ~ 1000mm (0.4” ~ 39”).<br />

25.4mm ~ 1000mm (1” ~ 39”).<br />

Thickness<br />

0.06mm ~ 0.19mm.<br />

Roll Diameter 5”.<br />

Roll Core Diameter 25.4mm ~ 76.2mm (1” ~ 3”).<br />

Gap Height<br />

2mm min.<br />

Black Mark Height 2mm min.<br />

Black Mark Width 8mm min.<br />

1.3.2. Ribbon<br />

Item<br />

Specification<br />

Type<br />

Wax, Wax / Resin, Resin.<br />

Core Diameter 1".<br />

Width<br />

Max 110mm.<br />

Capacity<br />

300m with 1" core.<br />

Wound Type Outside wound.<br />

Ribbon End<br />

Clear or silver end tape.<br />

7

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

2. ELECTRONICS<br />

2.1. Circuit Description<br />

Fig.2.1 Circuit Diagram<br />

The main board of printer includes 10 system blocks:<br />

1. MCU.<br />

2. Memory System.<br />

3. Decoder System.<br />

4. Print Head System.<br />

5. Motor System.<br />

6. Power System.<br />

7. Communication Interface System.<br />

8. USB System.<br />

9. Sensor System.<br />

10. Cutter System.<br />

8

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

The following figure shows the PCB system areas:<br />

Sensor System<br />

Memory System<br />

Cutter System<br />

Motor System<br />

Print<br />

Head<br />

System<br />

MCU<br />

USB System<br />

Communication<br />

Interface System<br />

Decoder System<br />

Power System<br />

9

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

2.2. MCU Circuit and MCU PIN Description<br />

Fig. 2.2 MCU PIN Description Diagram<br />

10

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

2.2.1. MCU PIN Description:<br />

11

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

12

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

13

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

14

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

15

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

2.3. Reset Circuit<br />

Fig. 2.3 Reset Circuit Diagram<br />

80945 reset IC is used to detect the voltage. When the driving voltage is lower than<br />

4.5VDC, reset will be enabled.<br />

16

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

2.4. Memory Circuit<br />

Fig. 2.4 Memory Circuit Diagram<br />

This is the memory circuit. The U6 & U7 are 2M Byte FLASH ROM and U8 is 2M<br />

Byte DRAM.<br />

17

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

2.5. Decoder Circuit<br />

Fig. 2.5 Decode Circuit Diagram<br />

18

FFFF FFFF<br />

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

2.6. Memory Map<br />

ON-CHIP RAM<br />

FFFF F000<br />

RESERVED<br />

FFFF 8800<br />

FFFF 87FF<br />

REGISTER<br />

FFFF 81A0<br />

FFFF 8000<br />

RESERVED<br />

00FF FFFF<br />

.<br />

.<br />

0200 0000 .<br />

.<br />

DRAM SPACE<br />

0100 0000 00E0 0000 TPH STB<br />

00D8 0003 Motor Phase2<br />

I/O<br />

00D8 0002 Motor Phase1<br />

00D8 0001 RTC register data<br />

00C0 0000 00D8 0000 RTC register address<br />

ECP<br />

00D0 0003<br />

Memory Card<br />

00D0 0002 Ribbon Sensor value<br />

00D0 0001 Black mark sensor value<br />

0080 0000 00D0 0000 Gap sensor Value<br />

Memory Card<br />

00C8 0003<br />

00C8 0002<br />

Buzzer<br />

Reserved<br />

19

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

00C8 0001 Mem_load signal<br />

0040 0000 00C8 0000 Cutter Control<br />

00C0 0003 Motor Current<br />

00C0 0002 USB Data<br />

0010 0000 ROM2 00C0 0001 Centronic Control<br />

0000 0000 ROM1 00C0 0000 Centronic Data<br />

20

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

2.7. Print Head Circuit<br />

VDD<br />

Fig. 2.7 Print Head Circuit Diagram<br />

CLK and LAT connect to thermal head control clock and data latch respectively.<br />

TPH_EN signal controls the DC24V voltage of the thermal head. When TPH_EN is<br />

high, the thermal head will be separated from 24V (V DD ). U21 controls protecting print<br />

head. It is used to make sure the power of print head is off when switch off the printer.<br />

Q1 and Q2 are used to limit current of print head.<br />

Both /STB1 and /STB2 determine whether to heat the thermal head or not. The RC<br />

charging time of U15 and 74HC123 limit the heating time of print head to avoid burning<br />

the print head.<br />

DI signal sends printer data to the print head.<br />

TM signal is the temperature/voltage sensor for thermal head.<br />

The Vdet feeds back the voltage and compensates the heat time for voltage accuracy<br />

when printing.<br />

21

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

2.8. Stepping Motor Drive / Protection Circuit<br />

Fig. 2.8 Stepping Motor Drive/ Protection Circuit Diagram<br />

Connector, JP8, sends the pattern as shown in table1. The status of I0 & I1<br />

determines the stepping motor power level. The power level pattern is shown in<br />

table2. The motor port is a protection pin. When it is at low level, the power of the<br />

motor system will be closed. Power will be on again until motor pin is the pulse of<br />

high level. Phase1 and phase2 determine the pattern of stepping motor drive<br />

circuit. For example, the sequence of phase 1/ phase 2 in full step mode is 0/0 →<br />

0/1 → 1/1 → 1/0.<br />

22

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

Table 1 Stepping Motor Pattern<br />

Pin on<br />

Step<br />

JP12<br />

1 2 3 4 Phase<br />

1 on on A<br />

2 on on /A<br />

3 on on /B<br />

4 on on B<br />

Table 2 Stepping motor power pattern<br />

Motor Current Current percentage I0 I1<br />

High Level 100% L L<br />

Medium Level 60% H L<br />

Low Level 20% L H<br />

Zero Current 0% H H<br />

23

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

2.9. Power Circuit<br />

Fig. 2.9 Power Circuit Diagram<br />

The U3 SI-8050JD converts 24Vdc to 5Vdc. the limit current protest is 1.6A.<br />

24

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

2.10. Parallel Interface Circuit<br />

Fig. 2.10 Parallel Interface Circuit Diagram<br />

The Centronic interface supports one-way transmission, SPP mode or ECP mode.<br />

The parallel interface circuit is used with the externally connected personal<br />

computer parallel interface through the printer cable. When PC’s strobe signal<br />

comes in, the printer responds busy status until it reads the data from parallel<br />

interface. Printer will respond error signal to PC when it is in error status.<br />

25

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

The pin assignments for nibble mode parallel interface connector is as following:<br />

Table 3. Pin Assignments For nibble mode Parallel Interface Connector<br />

Pin SPP Mode Nibble Mode In/Out Function<br />

1 Strobe HostClk In<br />

A low on this line indicates that there are valid<br />

data at the host. When this pin is de-asserted, the<br />

+ve clock edge should be used to shift the data<br />

into the device.<br />

2-9 Data 0-7 Data 0-7 In Data Bus. Single-directional.<br />

10 Ack PtrClk Out<br />

11 Busy PtrBusy Out<br />

A low on this line indicates that there are valid<br />

data at the Device. When this pin is de-asserted,<br />

the +ve clock edge should be used to shift the<br />

data into the host.<br />

When in reverse direction, a high indicates data,<br />

while a low indicates a command cycle. In forward<br />

direction, it functions as PtrBusy.<br />

12<br />

Paper Out /<br />

End<br />

AckDataReq Out When low, device acknowledges reverse request.<br />

13 Select X-Flag Out Extensibility flag<br />

14 Auto Linefeed HostBusy In<br />

When in forward direction, a high indicates data,<br />

while a low indicates a command cycle. In reverse<br />

direction, it functions as HostBusy.<br />

15 No Defined NC N/A<br />

16-17 Ground Ground GND Ground<br />

18 Logic High High / Vcc Out<br />

19-30 Ground Ground GND Ground<br />

31 Initialize nInit In A low indicates data in reverse direction<br />

32 Error / Fault nDataAvail Out<br />

A low set by the device indicates that the reverse<br />

data is available<br />

33-35 Ground Ground GND Ground<br />

36 Select Printer 1284 Active In<br />

A high indicates that host is in 1284 transfer<br />

mode. Taken low to terminate.<br />

26

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

2.11. Serial Interface Circuit<br />

Fig. 2.11 Serial Interface Circuit Diagram<br />

RS-232 is an asynchronous transfer interface, which used with externally connected<br />

personal computer and keyboard unit. JP15 connects to PC serial interface through the<br />

RS-232 cable. RxD is a data receive pin of MCU. CTS is clear to send of MCU, which<br />

sends a signal from the external device. TxD is a data output pin of MCU. RTS is the<br />

request to send signal, which sends signal to the external device.<br />

27

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

2.12. USB Circuit<br />

Fig. 2.12 USB Circuit Diagram<br />

28

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

2.12.1. USB PIN Function<br />

The standard USB 1.1. PIN function is as following:<br />

29

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

30

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

2.13. Sensor Circuit<br />

2.13.1. Gap and Black Mark Sensor<br />

Fig. 2.13.1 Gap / Black Mark Sensor Circuit Diagram<br />

1. The gap sensor is a penetrable sensor with 64 levels.<br />

2. Black mark sensor is a reflecting sensor with 64 levels.<br />

3. The gap sensor activates when gap and black mark SW signal is high. The<br />

black mark sensor activates when GAP& BM_SW signal is low.<br />

31

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

2.13.2. Head Open Micro Switch<br />

Fig. 2.13.2 Head Open Micro Switch Circuit Diagram<br />

The head open micro switch is a micro-switch. The voltage is low when the print<br />

head opens; otherwise, it is high.<br />

32

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

2.13.3. Peel-off Sensor<br />

Fig. 2.13.3 Peel-off Sensor Circuit Diagram<br />

This is a reflecting sensor. The peel-off sensor signal voltage is high when the<br />

paper is detected; otherwise, it is low.<br />

33

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

2.13.4. Ribbon Sensor<br />

Fig. 2.13.4 Ribbon Sensor Circuit Diagram<br />

This ribbon sensor is a reflecting sensor. The RIBB1~3 can be changed by command<br />

or auto-calibration. The REND signal voltage is high when the ribbon is detected;<br />

otherwise, it is low.<br />

34

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

2.14. Cutter Drive / Protection Circuit<br />

Fig. 2.14 Cutter Drive / Protection Circuit Diagram<br />

RESET signal is high when the printer is turned on. The cutter is activated when<br />

CTEN signal is low. CTPhase signal controls the rotated direction. U15B<br />

74HC123 controls the breaking of the DC motor of the cutter. The sensor of the<br />

cutter sends high - low signal to MCU through the CTSENS pin that detects action<br />

of a cutter.<br />

35

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

2.15. DC Motor Driver / Encoder Circuit<br />

Fig. 2.15 DC Motor Drive/ Encoder Circuit Diagram<br />

DCM signal is used to switch on/off the motor driver, The DC PHASE signal is to<br />

control the direction of the rotate the encoder circuit, which is used to detect the rotary<br />

rate. DC SENS signal voltage is high when the hole of the gear is detected; otherwise,<br />

it is low.<br />

36

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

2.16. Summary of PCB connectors<br />

Connector Description Remark<br />

JP1 Reserved<br />

J1A Internal Ethernet connector Pin 1 with red wire<br />

J1B Internal Ethernet connector<br />

JP2 DC power jack<br />

JP3 JTAG connector For CPLD program update<br />

JP4 For firmware update card At the back side of PCB<br />

JP5 Button & LED<br />

JP6 Memory card connector At the back side of PCB<br />

JP7 Canceled<br />

JP8 Stepping motor<br />

JP9 Ribbon DC motor For thermal transfer printer only<br />

JP10 Cutter<br />

JP11 TPH connector<br />

JP12 Centronics port connector<br />

JP13 USB connector<br />

JP14 RS-232 pin 9 +5V jumper JP14 Shorted can provide 5V<br />

on RS-232 pin9<br />

JP15 RS-232 connector<br />

JP16 Head open sensor<br />

JP17 Peel off sensor<br />

JP18 Gap/black mark sensor (emitter &<br />

receiver)<br />

JP19 Ribbon end sensor<br />

JP20 Reserved<br />

JP21 Gap/black mark sensor (emitter &<br />

receiver)<br />

JP22 Reserved<br />

JP23 Reserved<br />

JP24 Reserved<br />

JP25 Provide 5V DC for Centronics pin 18 Shorted JP25 can provide 5V<br />

DC 0.3A for Centronics port<br />

pin18<br />

JP26 5V DC connector Provide 5V DC, 0.3A<br />

JP27 Hardware ID<br />

37

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

Top side of Main PCB<br />

Power switch JP14<br />

J1A J1B<br />

JP25<br />

JP5<br />

JP11<br />

JP20<br />

JP16<br />

CPU<br />

JP19<br />

JP21<br />

JP27<br />

JP18<br />

JP9 JP8 JP10<br />

JP17<br />

JP26<br />

38

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

Bottom side of PCB<br />

JP4<br />

JP6 Memory<br />

card connector<br />

U14 Cutter driver chip<br />

39

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

3. REPLACE IMPORTANT PARTS<br />

Please turn off the power switch and unplug the power adapter before replacing parts.<br />

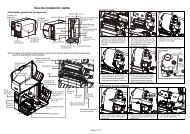

3.1. Replacing Top Cover<br />

1. Open the printer top cover by pushing the top cover open levers to the<br />

paper outlet direction. The top cover support will hold the printer top cover.<br />

Top cover support<br />

Top cover open<br />

lever<br />

2. Open the top cover to the ultimate open angle. Push the top cover support to<br />

the communication port direction to disconnect the separate the lower inner<br />

cover and top cover support.<br />

40

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

3. Remove the 6 screws in the top inner cover.<br />

Screws<br />

Screws<br />

4. Disconnect the harness from the Feed button PCB. Replace the top cover.<br />

5. Reassemble parts in reverse procedures.<br />

41

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

3.2. Replacing Top Inner Cover<br />

1. Refer 3.1 to remove the top cover.<br />

2. Remove the 6 screws of lower inner cover. Turn the printer upside down,<br />

remove the 2 screws of hinge holder, 1 screw of memory card cover.<br />

screws<br />

screws<br />

screw of memory<br />

card cover<br />

2 screws of hinge holder<br />

3. Disconnect all the harnesses from Main Board. Lift up the lower inner cover.<br />

Turn the lower inner cover upside down, and remove the 6 screws of lower<br />

inner cover and hinge holders.<br />

42

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

4. Replace the top inner cover.<br />

5. Reassemble in reverse procedures.<br />

43

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

3.3. Replacing Lower Cover<br />

1. Refer to 3.1 to open the top cover.<br />

2. Remove the 6 screws of lower inner cover. Turn the printer upside down,<br />

remove the 2 screws of hinge holder, 1 screw of memory card cover.<br />

screws<br />

screws<br />

screw of memory<br />

card cover<br />

2 screws of hinge holder<br />

3. Disconnect all the harnesses from Main Board. Lift up the lower inner cover.<br />

4. Replace lower cover.<br />

5. Reassemble in reverse procedures.<br />

44

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

3.4. Replacing Main Board<br />

1. Please refer to 3.3 for disassembling the LOWER COVER and LOWER inner<br />

cover.<br />

2. Disconnect all harnesses.<br />

3. Remove 4 screws on the main board.<br />

Screw<br />

Screw<br />

Main Board<br />

Lower Cover<br />

Screw<br />

Screw<br />

4. Replace the main board/lower inner cover.<br />

5. Reassemble parts in reverse procedures.<br />

45

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

3.5. Replacing Platen Assembly<br />

1. Squeeze two sides of platen assembly and take it out.<br />

Squeeze Here<br />

Squeeze Here<br />

Platen<br />

2. Replace a platen.<br />

3. Reassemble it in reverse procedures.<br />

46

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

3.6. Replacing the Stepping Motor Bracket / Metal Assembly<br />

and Stepping Motor<br />

1. Please refer to 3.1 for disassembling the lower cover and lower inner cover.<br />

2. Disconnect all hardness.<br />

3. Turn the lower inner cover upside down.<br />

4. Remove 2 screws that fixed the stepping motor on the bracket<br />

5. Remove the stepping motor.<br />

Motor<br />

Screws<br />

Lower inner cover<br />

6. Use a screwdriver to screw off 8 screws of the stepping motor bracket /<br />

metal ass’y.<br />

47

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

Screws<br />

Screws<br />

7. Remove the stepping motor bracket / metal ass’y.<br />

8. Reassemble parts in reverse procedures.<br />

48

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

3.7. Replacing Label Guide & Gap Sensor Assembly<br />

1. Please refer to 3.1 for disassembling the lower cover and lower inner cover.<br />

2. Disconnect all the hardness.<br />

3. Turn the lower inner cover upside down.<br />

4. Screws off 4 screws and remove the plastic laminate.<br />

Plastic Laminate<br />

Screws<br />

Screws<br />

Lower inner cover<br />

5. Screws off 2 screws to remove the white label guide rack fixing plate<br />

6. Remove 2 screws from a gap sensor PCB then remove the gap sensor PCB.<br />

Screws<br />

Label Guide<br />

Rack Fixing<br />

Plate<br />

Gap Sensor<br />

PCB<br />

Screw<br />

49

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

7. Turn over the lower inner cover.<br />

8. Move right side and left side label guides to the end of each side. Rotates 90<br />

degrees and pull them out.<br />

Lower inner cover<br />

Label Guide<br />

9. Reassemble parts in reverse procedures.<br />

50

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

3.8. Replacing Black Mark Sensor Assembly<br />

1. Please refer to 3.1 for disassembling the lower cover and lower inner cover.<br />

2. Disconnect all hardness.<br />

3. Upside down the lower inner cover. Remove 4 screws and remove the plastic<br />

laminate.<br />

4. Remove 1 screw from the black mark sensor.<br />

Screw<br />

Black Mark<br />

Sensor<br />

Black Mark Sensor<br />

Lower inner<br />

cover<br />

Fixing Plate<br />

5. Upside down the lower inner cover.<br />

6. Replace the black mark sensor assembly.<br />

Lower inner cover<br />

Black Mark Sensor<br />

7. Reassemble parts in reverse procedures.<br />

51

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

3.9. Replacing Print Head Assembly<br />

1. Press right concave of the print head bracket and use a flat screwdriver to<br />

stick left side of the printer head bracket then pick up the print head assembly.<br />

2. Disconnect print head harnesses.<br />

3. Reassemble parts in reverse procedures.<br />

Print Head<br />

Bracket Concave<br />

Stick Flat<br />

Screwdriver Here<br />

52

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

3.10. Replacing Head Open Micro Switch<br />

1. Please refer to 3.1 for disassembling the top cover and top inner cover.<br />

2. Disconnect ribbon mechanism by removing 4 screws at top inner cover.<br />

Screws<br />

Screws<br />

Top inner cover<br />

Mechanism<br />

3. Remove 2 screws and remove the head open micro switch.<br />

53

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

Screws<br />

Head Open<br />

Micro Switch<br />

4. Reassemble parts in reverse procedures.<br />

54

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

3.11. Replacing Ribbon Motor and Ribbon Sensor<br />

1. Please refer to 3.1 for disassembling the top cover and top inner cover.<br />

2. Disconnect ribbon mechanism by removing 4 screws from the top inner<br />

cover.<br />

3. Remove 2 screws on the ribbon motor PCB.<br />

4. Replace the ribbon motor sensor.<br />

Screw<br />

s<br />

Ribbon<br />

Mechanism<br />

Screw<br />

s<br />

Screws<br />

Ribbon<br />

Motor<br />

Sensor<br />

5. Screw off 2 screws from the top inner cover.<br />

6. Replace the ribbon sensor.<br />

7. Reassemble parts in reverse procedures.<br />

55

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

Top inner cover<br />

Ribbon Sensor<br />

Screws<br />

56

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

3.12. Replacing Feed Button and Feed Button PCB<br />

1. Please refer to 3.1 for disassembling the top cover and top inner cover.<br />

2. Turn the top cover upside down.<br />

3. Screw off 2 screws on feed button PCB and remove feed button PCB.<br />

4. Use a flat head driver to poke up the feed button.<br />

Top Cover<br />

Screws<br />

Feed Button PCB<br />

5. Reassemble parts in reverse procedures.<br />

57

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

3.13. Install Memory Card (Option)<br />

1. Turn the printer upside down.<br />

2. Remove the screw that fixes the memory card cover.<br />

Screw<br />

Memory Card Cover<br />

3. Plug in a memory card, pin to pin, on main board.<br />

Memory Card<br />

4. Revert the memory card cover.<br />

Memory Card Cover<br />

5. Reassemble parts in reverse procedures.<br />

58

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

3.14. Install Peel Off Module (Option)<br />

1. Open the top cover.<br />

2. Remove two screws for hinge support and one screw for memory card cover in<br />

lower cover.<br />

3. Remove 6 screws on the lower inner cover.<br />

4. Hold the lower cover and lift up the top cover open levers to separate the lower<br />

inner cover and the lower cover. (Please refer to section 3.1 )<br />

5. Connect the harness of peel-off module through the slot of lower inner cover.<br />

slot<br />

6. Lift up the lower inner cover to gently push peel off panel into the two concaves of<br />

lower cover front side.<br />

Note : Must lift up the lower inner cover first, then, the peel-off module<br />

could be installed into the concave of lower inner cover.<br />

concave<br />

59

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

7. Connect the harness of peel-off module at JP17 on the main board.<br />

8. Put down the lower inner cover onto lower cover.<br />

9. Push peel off module to lock to the lower inner cover.<br />

10. Reassemble parts in reverse procedures.<br />

60

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

3.15. Loading the Label in Peel-off Mode<br />

Note: Both thermal paper and plain paper apply for peel-off function but<br />

neither PVC nor vynle work at peel-off function.<br />

1. Insert a 1” label spindle into a paper roll.<br />

2. Open the printer top cover by pushing forward the top cover open levers. The top<br />

cover support will hold the printer top cover.<br />

Peel-off panel<br />

Top Cover Open Lever<br />

Backing paper<br />

Opening<br />

3. Install the paper roll on the paper roll mount.<br />

4. Open the peel-off panel by pulling it out.<br />

Peel-off<br />

panel<br />

61

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

5. Feed the paper, printing side facing up, through the paper guide and pass over the<br />

platen.<br />

6. Lead the paper through the backing paper opening, beneath the roller, and tear off<br />

one piece of the label.<br />

7. Adjust the paper guide by removing left or right to fit the paper width.<br />

Top Cover<br />

Top Cover Support<br />

Roller<br />

Peel-off panel<br />

Lead the paper through the backing paper opening, beneath the roller<br />

8. Push the peel-off panel back to the printer.<br />

9. Close the top cover by lifting up the top cover support and close the top cover<br />

slowly.<br />

Note: Pull the label outward tightly after closing the top cover.<br />

Complete label installation for peel-off mode<br />

62

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

3.16. Install Cutter Module (Option)<br />

1. Upside down the printer to remove two screws of hinge holder in the lower<br />

cover.<br />

Screw<br />

hinge<br />

holder<br />

of<br />

Screw of<br />

hinge<br />

holder<br />

2. Remove the screw that fixes the memory card cover.<br />

Memory card<br />

cover<br />

3. Plug in the Cutter Driver IC at U14 socket on the main board.<br />

63

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

Cutter Driver IC<br />

4. Open the printer top cover by pushing the top cover open levers to the paper<br />

outlet direction. The top cover support will hold the printer top cover.<br />

Top cover<br />

support<br />

5. Open the top cover to the ultimate open angle. Push the top cover support to the<br />

communication port direction to disconnect the lower inner cover and top cover<br />

support.<br />

64

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

6. Pull up the front panel from the lower cover.<br />

7. Remove the 6 screws in lower inner cover.<br />

Screws<br />

Screws<br />

8. Lift up the lower inner cover from the Lower Cover.<br />

9. Install the 4 pin connector of the cutter onto JP10 on the main board. Pull the wire<br />

of the 4-pin connector through the slot of lower inner cover front side. Then, put<br />

back the lower inner cover.<br />

wire of the<br />

4-pin connector<br />

Location<br />

JP10<br />

65

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

Slot<br />

Cutter wire<br />

10. Gently push cutter module into the two slots of lower inner cover front side, then<br />

push cutter to lock into the lower inner cover.<br />

11. Assemble the memory card cover.<br />

12. Reassemble parts in reverse procedures.<br />

Lower inner<br />

cover<br />

66

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

3.17. Loading Label in Cutter Mode<br />

1. Insert a 1” label spindle into a paper roll.<br />

2. Open the printer top.<br />

3. Install a paper roll on the paper roll mount.<br />

4. Feed the paper, printing side face up, through the paper guide and pass over the<br />

platen.<br />

5. Lead the paper through the cutter paper opening.<br />

6. Adjust the paper guide by removing left or right to fit the paper width.<br />

Top Cover<br />

Paper Guide<br />

Platen<br />

Cutter<br />

Top Cover Support<br />

Label installation in cutter mode<br />

7. Close the top cover by lifting up the top cover support and close the top cover<br />

slowly.<br />

Complete label installation in cutter mode<br />

67

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

3.18. Install Internal Ethernet Module (Option)<br />

Checklist<br />

• Internal Ethernet print server module installation guide<br />

• Screw TP3*6 x 6 pcs<br />

• RJ45 / 8 PIN connector interface cable<br />

• Print server module / 36 PIN connector interface cable<br />

• Internal print server module (Including software CD / Driver / User’s manual)<br />

• Copper pillar<br />

• RJ45 interface daughter board<br />

RJ45 interface<br />

daughter board<br />

網 路 連 接 模 組<br />

轉 接 板<br />

Print Server Module ( With bracket )<br />

Copper pillar<br />

機 械 螺 絲<br />

M3*6+ 華 司<br />

1pcs Screw x 6<br />

機 械 螺 絲<br />

M3*6+ 華 司<br />

1pcs<br />

Print server module / 36 PIN<br />

connector interface cable 網 路 連<br />

接 模 組 轉 接 線 36PIN / 18PIN<br />

300mm<br />

RJ45 轉 接 線 / 8 PIN connector interface<br />

cable<br />

68

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

1. Break through the plastic partial tab at the rear side of lower cover to get the RJ45 interface<br />

opening.<br />

白 色 插 座 RJ45 interface<br />

opening 1.25mm 8PIN<br />

白 色 插 座 Remove<br />

the screw1.25mm<br />

8PIN<br />

2. Remove the screw from the main board. Fasten the copper pillar.<br />

Copper pillar<br />

3. Plug the RJ45 white connector to the RJ45 daughter board connector. Fasten the RJ45<br />

connector daughter board upon the lower cover and copper pillar. The ground wire from the<br />

mechanism must be screwed on the daughter board at copper pillar.<br />

Screws<br />

TP3*6 螺<br />

絲 Screw 4pcs<br />

TP3*6<br />

螺 絲<br />

4pcs<br />

RJ45 / 8 PIN connector<br />

interface cable interface<br />

cable 網 路 連 接 模 組<br />

轉 接 板<br />

4. Install the print server module in printer lower cover with the above 4 screws.<br />

Ground wire<br />

TP3*6 螺 絲<br />

4pcs<br />

RJ45 connect daughter<br />

board 網 路 連 接 模 組<br />

轉 接 板<br />

69

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

Screw<br />

Screw<br />

內 建 式<br />

內 建 式<br />

乙 太 網<br />

乙 太 網<br />

路 模 組<br />

Screw<br />

路 Screw 模 組<br />

內 建 式<br />

內 建 式<br />

Internal 內 建<br />

乙 太 網<br />

乙 太 網<br />

Print Server<br />

路 模 組<br />

路 模 組<br />

Module 式 乙 太<br />

網 路 模 組<br />

5. Connect the print server module interface cable (36PIN) and RJ45 interface cable to print<br />

server module.<br />

RJ45 interface cable<br />

網 路 連 接 模 組 轉 接 線<br />

36PIN / 18PIN<br />

300mm<br />

Print server module<br />

interface cable 網 路<br />

連 接 模 組 轉 接 線<br />

36PIN / 18PIN<br />

300mm<br />

6. Plug the print server module interface cable to connector J1A and J1B on the PCB, the left<br />

side harness (with red wire at the left side) is for J1A, the right side harness location is for J1B.<br />

J1A<br />

網<br />

J1B<br />

路<br />

網 路<br />

連<br />

連 接<br />

接<br />

模 組<br />

模<br />

轉 接<br />

7. Plug the 2PIN connector from the internal print server to the connector JP26 on the PCB for<br />

組<br />

線<br />

5V DC power.<br />

轉<br />

36PI<br />

接<br />

N /<br />

線<br />

18PI<br />

36P<br />

70<br />

N<br />

IN /<br />

300<br />

18P<br />

mm

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

2 PIN<br />

JP26<br />

網 路<br />

連 接<br />

模 組<br />

connector 網 路<br />

連 接 模 組 轉 接<br />

線 36PIN /<br />

18PIN 300mm<br />

轉 接<br />

線<br />

※ For print 36PIN server setup. Please refer to the print server software CD and manual.<br />

/<br />

18PIN<br />

300m<br />

m<br />

71

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

4. Power on Utilities<br />

There are six power-on utilities to set up and test printer hardware. These utilities are<br />

activated by pressing FEED button and by turning on the printer power simultaneously.<br />

The utilities are listed as below:<br />

1. Ribbon sensor calibration;Gap/black mark sensor calibration<br />

2. Gap/black mark sensor calibration;Self-test and dump mode<br />

3. Printer initialization<br />

4. Black mark sensor calibration<br />

5. Gap sensor calibration<br />

6. Skip AUTO.BAS<br />

4.1 Ribbon and Gap/Black Mark Sensor Calibration<br />

Gap/black mark sensor sensitivity should be calibrated at the following conditions:<br />

1. A brand new printer<br />

2. Change label stock.<br />

3. Printer initialization.<br />

Please follow the steps below to calibrate the ribbon and gap/black sensor.<br />

1. Turn off the power switch.<br />

2. Hold on the button then turn on the power switch.<br />

3 Release the button when LED becomes red and blinking. (Any red will do during the<br />

5 blinks).<br />

• It will calibrate the ribbon sensor and gap/black mark sensor sensitivity.<br />

• The LED color will be changed as following order:<br />

Amber red (5 blinks) amber (5 blinks) green (5 blinks) <br />

green/amber (5 blinks) red/amber (5 blinks) solid green<br />

Note:<br />

Please select gap or black mark sensor by GAP or BLINE command prior to<br />

calibrate the sensor.<br />

For more information about GAP and BLINE command, please refer to TSPL2<br />

programming manual.<br />

72

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

4.2 Gap/Black Mark Calibration;Self-test;Dump mode<br />

While calibrate the gap/black mark sensor, printer will measure the label length, print<br />

the internal configuration (self-test) and then enter the dump mode. To calibrate gap or<br />

black mark sensor, depends on the sensor setting in the last print job.<br />

Please follow the steps below to calibrate the sensor.<br />

1.Turn off the power switch.<br />

2. Hold on the button then turn on the power switch.<br />

3. Release the button when LED becomes amber and blinking. (Any amber will do<br />

during the 5 blinks).<br />

• The LED color will be changed as following order.<br />

Amber red (5 blinks) amber (5 blinks) green (5 blinks) <br />

green/amber (5 blinks) red/amber (5 blinks) solid green<br />

4. It calibrates the sensor and measures the label length and prints internal settings<br />

then enter the dump mode.<br />

Note:<br />

Please select gap or black mark sensor by GAP or BLINE command prior to<br />

calibrate the sensor.<br />

For more information about GAP and BLINE command, please refer to TSPL2<br />

programming manual.<br />

73

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

Self-test<br />

Printer will print the printer configuration after gap/black mark sensor calibration.<br />

Self-test printout can be used to check if there is any dot damage on the heater<br />

element, printer configurations and available memory space.<br />

Print head check pattern<br />

Firmware version<br />

Firmware checksum<br />

Printed mileage (meter)<br />

Serial port configuration<br />

Country code<br />

Print speed (inch/sec)<br />

Print darkness<br />

Label size (inch)<br />

Gap distance (inch)<br />

Gap/black mark sensor sensitivity<br />

Numbers of download files<br />

Total & available memory space<br />

Fig. 3 Self-test printout<br />

Note:<br />

1. The physical flash memory for RoHS compliant version is 2MB Flash and 2MB<br />

DRAM.<br />

2. System occupies 960 KB in Flash memory so total flash memory space for<br />

user downloading is 1088 KB<br />

3. System occupies 1792 KB in DRAM so total DRAM memory space for user<br />

downloading is 256 KB<br />

74

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

Dump mode<br />

Printer will enter dump mode after printing printer configuration. In the dump mode,<br />

all characters will be printed in 2 columns as following. The left side characters are<br />

received from your system and right side data are the corresponding hexadecimal<br />

value of the characters. It allows users or engineers to verify and debug the program.<br />

ASCII Data<br />

Hex decimal data<br />

related to left<br />

column of ASCII<br />

data<br />

Fig. 4 Dump mode printout<br />

Note:<br />

Turn off / on the power to resume printer for normal printing.<br />

75

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

4.3 Printer Initialization<br />

Printer initialization is used to clear DRAM and restore printer settings to defaults. The<br />

only one exception is ribbon sensitivity, which will note be restored to default.<br />

Printer initialization is activated by the following procedures.<br />

1. Turn off the power switch.<br />

2. Hold on the button then turn on the power switch.<br />

3. Release the button when LED turns green after 5 amber blinks. (Any green will do<br />

during the 5 blinks).<br />

• The LED color will be changed as following:<br />

Amber red (5 blinks) amber (5 blinks) green (5 blinks) <br />

green/amber (5 blinks) red/amber (5 blinks) solid green<br />

Printer configuration will be restore to defaults as below after initialization.<br />

Parameter<br />

Default setting<br />

Speed<br />

<strong>TTP</strong>-<strong>245</strong>, 127 mm/sec (5 ips)<br />

<strong>TTP</strong>-<strong>343</strong>, 76 mm/sec (3 ips)<br />

Density 7<br />

Label Width 4.25” (108.0 mm)<br />

Label Height 2.5” (63.4 mm)<br />

Sensor Type Gap sensor<br />

Gap Setting 0.12” (3.0 mm)<br />

Print Direction 0<br />

Reference Point 0,0 (upper left corner)<br />

Offset 0<br />

Tear Mode<br />

On<br />

Peel off Mode Off<br />

Cutter Mode Off<br />

Serial Port Settings<br />

9600 bps, none parity,<br />

8 data bits, 1 stop bit<br />

Code Page 850<br />

Country Code 001<br />

Clear Flash Memory No<br />

Note:<br />

Always do gap/black mark sensor calibration after printer initialization.<br />

76

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

4.4 Black Mark Sensor Calibration<br />

Set black mark sensor as media sensor and calibrate the black mark sensor.<br />

Please follow the steps as below.<br />

1. Turn off the power switch.<br />

2. Hold on the button then turn on the power switch.<br />

3. Release the button when LED turns green/amber after 5 green blinks. (Any<br />

green/amber will do during the 5 blinks).<br />

• The LED color will be changed as following:<br />

Amber red (5 blinks) amber (5 blinks) green (5 blinks) <br />

green/amber (5 blinks) red/amber (5 blinks) solid green<br />

4.5 Gap Sensor Calibration<br />

Set gap sensor as media sensor and calibrate the gap sensor.<br />

Please follow the steps as below.<br />

1. Turn off the power switch.<br />

2. Hold on the button then turn on the power switch.<br />

3. Release the button when LED turns red/amber after 5 green/amber blinks. (Any<br />

red/amber will do during the 5 blinks).<br />

• The LED color will be changed as following:<br />

Amber red (5 blinks) amber (5 blinks) green (5 blinks) green/amber<br />

(5 blinks) red/amber (5 blinks) solid green<br />

4.6 Skip AUTO.BAS<br />

TSPL2 programming language allows user to download an auto execution file to flash<br />

memory. Printer will run the AUTO.BAS program immediately when turning on printer<br />

power. The AUTO.BAS program can be interrupted without running the program by the<br />

power-on utility.<br />

Please follow the procedures below to skip an AUTO.BAS program.<br />

1. Turn off printer power.<br />

2. Press the FEED button and then turn on power.<br />

3. Release the FEED button when LED becomes solid green.<br />

• The LED color will be changed as following:<br />

77

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

Amber red (5 blinks) amber (5 blinks) green (5 blinks) green/amber<br />

(5 blinks) red/amber (5 blinks) solid green<br />

4. Printer will be interrupted to run the AUTO.BAS program.<br />

78

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

5. GAP AND BLACK MARK SENSOR SELECTION<br />

Gap Sensor selection<br />

<br />

<br />

Default setting. No extra action necessary.<br />

If you want to change sensor type from black mark sensor to gap sensor,<br />

please do printer initialization (refer to Initialization section).<br />

Black Mark Sensor<br />

<br />

<br />

<br />

<br />

Start Label View XLT+ or Nice Label LE software.<br />

Set label side in the software and select black mark sensor as sensor type.<br />

Install label media with black mark or hole for registration.<br />

Print one label to switch sensor from gap to black mark sensor.<br />

Remember, always do sensor calibration after sensor selection (refer to Gap and<br />

Black Mark Sensor Calibration section).<br />

6. BIOS Update<br />

If printer BIOS update is required, please do the following steps.<br />

Update the BIOS file and reset the printer.<br />

Update File<br />

1. Make sure the printer is at ready status and the LED is solid green.<br />

2. Copy the BIOS file to printer parallel port by the following command at<br />

MS-DOS prompt mode.<br />

C:\>COPY <strong>TTP</strong><strong>245</strong>.NEW /B LPT1 <br />

3. During BIOS updating process, the LED will blink red and orange alternately.<br />

When BIOS update is completed, printer will reset automatically and LED will<br />

become solid green.<br />

79

7. TROUBLESHOOTING<br />

This section lists the common problems that you may encounter when operating the<br />

printer. Also, it provides solutions.<br />

1. The printer is not receiving power.<br />

• Turn the power switch on.<br />

• Check power connection from both the socket to the power supply and<br />

the power supply to the printer.<br />

2. The printer is on and ready to use.<br />

• No action necessary.<br />

3. The printer is paused.<br />

• Press the feed button to resume printing.<br />

4. The LED is on red blinking.<br />

If the LED is on red blinking, which means that either label or ribbon runs out.<br />

Label runs out:<br />

• Load a roll of label and follow the instructions as following and then press the<br />

feed button to resume printing.<br />

.<br />

1. Insert a 1” label spindle into a paper roll<br />

2. Open the printer’s top cover by releasing the green top cover open levers<br />

located on each side of the printer and lifting the top cover. A top cover<br />

support at the rear of the printer will hold the printer top cover open.<br />

3. Place a roll of paper onto the center of the paper roll mount.<br />

4. Feed the paper, printing side face up, through the Teflon bar and the label<br />

guide and pass over the platen.<br />

5. Adjust the green center-biased label guides in or out so they are slightly<br />

touch the edges of the label backing.<br />

6. To close the printer top cover, lift the cover slightly and pull the top cover<br />

support forward toward the front of the printer. Close the printer top cover<br />

slowly and make sure the cover locks latch securely.<br />

Ribbon runs out:<br />

• Load a roll of ribbon and follow the instructions as following and then press

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

the feed button to resume printing.<br />

1. Push down on the ribbon access window to unlock and open the cover<br />

2. Place a paper core on a ribbon rewind spindle.<br />

3. Mount the ribbon rewind paper core on the front hubs.<br />

4. Install a ribbon on the ribbon supply spindle.<br />

5. Mount the ribbon supply spindle on the rear hubs.<br />

6. Attach the ribbon leader to the ribbon rewind paper core.<br />

7. Rotate the ribbon rewind paper core until the ribbon leader is thoroughly,<br />

firmly encompassed by the black section of the ribbon.<br />

8. Close the ribbon access window.<br />

Ribbon sensor or ribbon rewind encoder error<br />

• Remove the ribbon, close the ribbon mechanism then turn off/on the printer<br />

power. The printer will be switched to thermal direct mode automatically.<br />

If the printer LED is still on red blink, please check the following:<br />

A. Is a paper core installed on the ribbon rewind spindle?<br />

B. Is ribbon installed correct along the ribbon path?<br />

C. Is the ribbon too transparent?<br />

D. Is the rib of the ribbon spindle is broken?<br />

E. Is the ribbon gear broken or worn?<br />

F. Turn off printer power. Rewind the ribbon spindle by hand. Does the<br />

spindle rewind smoothly by hand? If the ribbon spindle doesn’t rewind<br />

smoothly, please replace the ribbon mechanism.<br />

G. Is the DC motor broken?<br />

H. Is the ribbon end sensor broken?<br />

Measure the current of pin2 of JP19. If the ribbon detects the ribbon, it<br />

should be 5V DC; otherwise, it should be 0V DC.<br />

I. Is the DC motor encoder sensor broken?<br />

Measure the current of pin2 of JP9. When sensor detects the gap of<br />

encoder, it is 5V DC; otherwise it should be 0V DC.<br />

Check if there is any black lubricant oil filled between gaps, which may<br />

cause error.<br />

J. Check the DC motor driver IC (U13) on the main board. If it can function<br />

all right, please replace the main board.<br />

Paper sensor error<br />

Please check the following items:<br />

A. Is label installed correctly? Please refer to previous 4. The LED is on red<br />

blinking – Label runs out to load a roll of label and then press the feed button<br />

81

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

to resume printing.<br />

B. Is there any label stuck on the label sensor? Is there any pre-printed logo on<br />

the label? Please refer to 5.2 Initialization to reset the system.<br />

If the pre-printed logo or text influences the auto gap calibration function, please<br />

calibrate the gap sensor with proper setting by try and error. Example:<br />

C:\>MODE COM1 96,N,8,1 <br />

C:\>COPY CON COM1 <br />

SET GAP 1 < Z><br />

Main board, gap sensor or black sensor failure.<br />

• Measure the current of pin3 of Q8. It is 5V DC when the label is detected and<br />

0V DC for gap. If the voltage is not correct as above mentioned, the U23 ,CPU<br />

(U1) or gap sensor may be broken. Please change the gap sensor receiver<br />

first because the receiver sensor failure rate is higher then the transmitter<br />

sensor.<br />

5. The printer setting runs error.<br />

Printer setting runs error:<br />

Refer to 5.2 Initialization to reset the system.<br />

6. Continuous feeding labels<br />

• The printer setting may go wrong. Please do the “Initialization” and “Gap and<br />

Black Mark Sensor Calibration”. (Refer to 5.2 and 5.3).<br />

7. No print on the label<br />

• Is the label or ribbon loaded correctly? Refer to No, 4 Label runs out and<br />

Ribbon runs out to load the paper or to load the ribbon.<br />

• Does the ribbon run out?<br />

• Is the thermal head connector connected?<br />

• Is the thermal head broken? Check it by printer self-test printout.<br />

• Is main PCB U21, U15, Q1 broken?<br />

8. Printer does not print.<br />

Printed by enclosed Label View XLT+ software<br />

• This may be driver conflict problem. Please remove all the drivers in the<br />

printer folder and then re-install the driver for your printer.<br />

Printed by printer command.<br />

• This problem is caused by incorrect syntax commands. <strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

82

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

series printer will ignore incorrect syntax commands. Please set the printer to<br />

the dump mode and make sure the printed command is identical to the<br />

commands sent from the application software.<br />

• The printer serial port setting is not correspondent to the PC’s setting<br />

Please do the configuration by the following commands.<br />

C:\>COPY CON LPT1 <br />

SET COM1 96,N,8,1<br />

SET COM1 19,N,8,1<br />

Z<br />

C:\><br />

9. Poor print quality<br />

• The head maybe dirty. Clean the thermal print head.<br />

• Adjust the print density setting.<br />

• Ribbon and paper media are not compatible.<br />

10. Stepping motor does not feed label<br />

• Does stepping motor function normally.<br />

• Are U11, and U12 (3717 driver IC) of main board broken?<br />

11. No 5V DC on main board.<br />

• Is switching power broken?<br />

• Is main board U3 broken? Please replace a new main board.<br />

12. Cutter functions abnormally.<br />

Cutter is not activated<br />

Cutter is broken or the main PCB is broken. If it still has problem after a new cutter<br />

replaced, the U14 (driver IC) or U5 IC on the main board may be broken.<br />

13. Black mark can’t be detected properly<br />

• Please check the position of the black mark, If it can be detected by the<br />

sensor. Is the width of black mark too thin to be detected? The suggested<br />

black mark width is 12 mm.<br />

• Does the sensor function properly?<br />

Measure the current of pin3 of Q9. It is 5VDC when the black mark is detected;<br />

otherwise it should be 0V DC. If the voltage is correct as above mentioned<br />

and the black mark still can’t be detected, CPU may have some problem.<br />

83

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

8. MAINTENANCE<br />

This session presents the clean tools and methods to maintain your printer.<br />

Use one or more of the following supplies that meets your needs:<br />

• Cleaning pens<br />

• Cleaning swabs<br />

• Lint-free cloth.<br />

The cleaning process is described as following<br />

Printer Part<br />

Method<br />

*Printer Head • Let the print head to cool for one minute<br />

• Use a cleaning pen to swab the print elements<br />

Platen Roller • Rotate the platen roller and wipe it thoroughly<br />

with 100% **ethanol and a cleaning swab, or<br />

lint-free cloth.<br />

Exterior • Wipe it with water-dampened cloth<br />

Interior • Brush or air blow<br />

* Do not touch printer head by hand. If you touch it careless, please use ethanol to<br />

clean it.<br />

**It’s industry alcohol. Please do not use regular alcohol, which may damage the printer<br />

head.<br />

84

<strong>TTP</strong>-<strong>245</strong> / <strong>TTP</strong>-<strong>343</strong><br />

9. PARTS LIST<br />

9.1 Cover<br />

Item Part No. Description Remark<br />

1 98-0250029-10LF TOP COVER ASS’Y includes:<br />

98-0250166-00LF 30-0250002-30LF*1 TOP COVER<br />

30-0250005-20LF*1 CLEAR TOP COVER<br />

36-0250009-00LF*2 PROTECTIVE FILM (FOR CLEAR TOP COVER)<br />

30-0250007-10LF*1 CLEAR WINDOW<br />

36-0250005-00LF*1 PROTECTIVE FILM (FOR CLEAR WINDOW)<br />

30-0250006-30LF*1 FEED BUTTON<br />

1set<br />

(for<br />

RMA)<br />

Spare<br />

parts<br />

36-0250003-00LF*2 LATCH FOR RIBBON ACCESS WINDOW<br />

2 30-0250001-30LF LOWER COVER<br />

3 30-0250008-30LF MEMORY CARD COVER<br />

4 37-1403020-31LF SCREW / TP 3 * 20 (For memory card cover)<br />

37-1403020-34LF<br />

1 pc.<br />

5 37-1402608-31LF SCREW / TP2.6*8 (For lower cover & hinge holders)<br />

37-1402608-34LF<br />

2 pcs.<br />

6 37-1403010-34LF SCREW TP3*10 (For lower cover to fix lower inner<br />

cover front side)<br />

4 pcs<br />

7 37-1403024-34LF SCREW TP3*24 (For lower cover to fix lower inner<br />

cover rear side)<br />

2 pcs<br />

8 98-0250013-00 FEED BUTTON ASS’Y<br />

98-0250013-10LF<br />

9 37-1403006-34LF SCREW TP3*6 (For feed button) 2 pcs<br />

10 36-0250003-00LF LATCH FOR RIBBON ACCESS WINDOW 2 pcs 2%<br />

11 37-1403020-31LF SCREW / TP3*20 (For top cover & top inner cover)<br />

37-1403020-34LF<br />

6 pcs<br />

12 30-0250026-30LF FRONT PANEL (standard)<br />