We are transfluid®. - transfluid® tube processing machines

We are transfluid®. - transfluid® tube processing machines

We are transfluid®. - transfluid® tube processing machines

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Chipless orbital cutting <strong>machines</strong><br />

Our chipless orbital cutting machine allows you to achieve precise<br />

cutting results – so that your <strong>tube</strong>s <strong>are</strong> immediately ready for further<br />

<strong>processing</strong>. Because the cut is so clean, it is possible for you to<br />

carry out forming directly at the cut surface – there is no need for<br />

any further treatment. There is no chance of any deforming at the<br />

cutting position because there is a pulling process during the cutting<br />

operation with varying torques that depend on the <strong>tube</strong> sizes.<br />

Equipment options:<br />

Cutting rates up to 1,800 pieces per hour, cut length optimization<br />

to minimize residual lengths, from coil with straightening unit<br />

or with loading magazine for straight <strong>tube</strong>s, controlled multiple<br />

ejection of cut lengths.<br />

»<br />

RT 622<br />

Blade cutting unit from 6 - 22 mm, ideal for accurate trimming<br />

Scarfing knife cutting process<br />

RTO 628 6 - 28 mm orbital cutting process<br />

RTO 2076 20 -76 mm orbital cutting process<br />

Our cutting process is ideal for accurate trimming and allows you<br />

to shear the pipes precisely. It produces right-angled, sharp-edged<br />

cuts even where awkward pipe geometries <strong>are</strong> involved. The two<br />

metal chips that arise can be reliably detected during the process.<br />

Absolute circularity at the cut section is a given for all materials.<br />

You can also employ this cutting process on our bending <strong>machines</strong><br />

for cutting curved geometries.<br />

The use of up to three blades is possible in order to meet extreme<br />

requirements. An internal mandrel may also be used to optimize the<br />

process. In addition, it is possible to modify the process in order to<br />

produce cuts in different degrees of the pipe end.<br />

»<br />

Orbital<br />

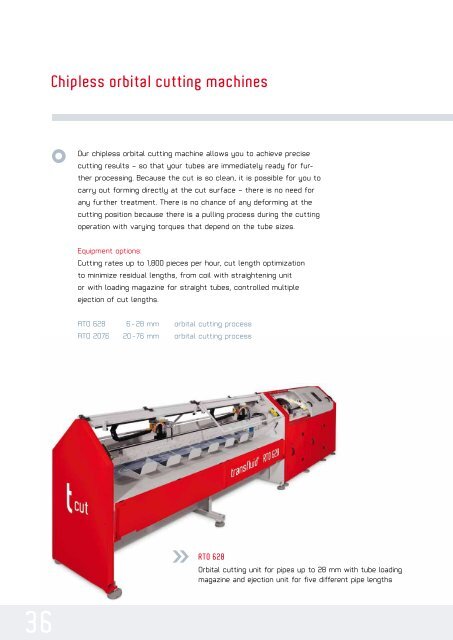

RTO 628<br />

cutting unit for pipes up to 28 mm with <strong>tube</strong> loading<br />

magazine and ejection unit for five different pipe lengths<br />

RT 622<br />

RT 1040<br />

6 - 22 mm<br />

10 - 40 mm<br />

knife cutting<br />

knife cutting<br />

The latest information can be found at: www.transfluid.de<br />

36<br />

° ° ° ° ° ° ° 37