CONTENT

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

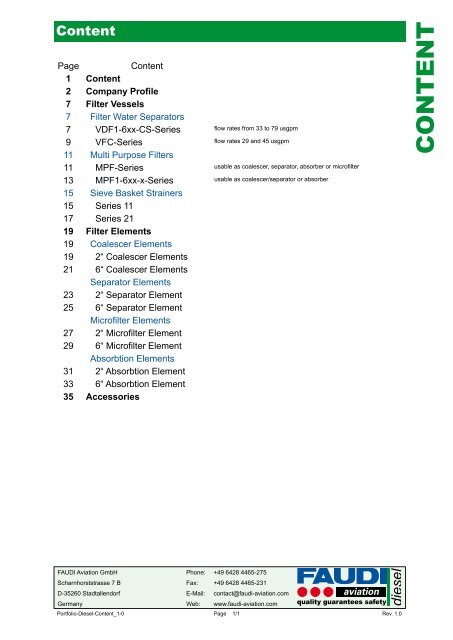

Content<br />

Page<br />

Content<br />

1 Content<br />

2 Company Profile<br />

7 Filter Vessels<br />

7 Filter Water Separators<br />

7 VDF1-6xx-CS-Series flow rates from 33 to 79 usgpm<br />

9 VFC-Series flow rates 29 and 45 usgpm<br />

11 Multi Purpose Filters<br />

11 MPF-Series usable as coalescer, separator, absorber or microfilter<br />

13 MPF1-6xx-x-Series usable as coalescer/separator or absorber<br />

15 Sieve Basket Strainers<br />

15 Series 11<br />

17 Series 21<br />

19 Filter Elements<br />

19 Coalescer Elements<br />

19 2“ Coalescer Elements<br />

21 6“ Coalescer Elements<br />

Separator Elements<br />

23 2“ Separator Element<br />

25 6“ Separator Element<br />

Microfilter Elements<br />

27 2“ Microfilter Element<br />

29 6“ Microfilter Element<br />

Absorbtion Elements<br />

31 2“ Absorbtion Element<br />

33 6“ Absorbtion Element<br />

35 Accessories<br />

<strong>CONTENT</strong><br />

FAUDI Aviation GmbH Phone: +49 6428 4465-275<br />

Scharnhorststrasse 7 B Fax: +49 6428 4465-231<br />

D-35260 Stadtallendorf E-Mail: contact@faudi-aviation.com<br />

Germany Web: www.faudi-aviation.com<br />

diesel<br />

Portfolio-Diesel-Content_1-0 Page 1/1 Rev. 1.0

diesel<br />

Ensuring<br />

Clean<br />

Diesel

Mining<br />

Business motor diesel<br />

Known for their flexible and diverse<br />

uses, diesel fuel systems bring more<br />

and more industries to corporate success.<br />

The global consumption of diesel fuels<br />

has been increasing across industries<br />

for years.<br />

Increasing operating costs that arise<br />

from long downtimes of machines can<br />

only be avoided by dry and clean diesel<br />

fuel. Technical development in the motor<br />

area, new market requirements and<br />

environmental requirements demand<br />

best and efficient use of diesel fuels free<br />

of contamination.<br />

Use of purest diesel fuels reduces the<br />

emission values of your machines and<br />

plants and thus keeps the environmental<br />

strain low.<br />

Agriculture<br />

FAUDI Aviation vessels<br />

Faudi Aviation GmbH delivers filtration<br />

solutions for highest diesel purity. Filters/<br />

water separators and absorption filters for<br />

particle filtration and water separation or<br />

micro filters for finest filtration of particles<br />

for many different flow rates, adjusted to<br />

customer demands.<br />

Ensuring Clean Diesel

Marine/Shipping<br />

From the refinery to fuelling<br />

Refinery<br />

Tank terminal<br />

Tank depot<br />

Power plants Shipping Mining Agriculture Transport Retail<br />

Fuel flow<br />

Filtration/Separation<br />

Quality from preventive measures<br />

To ensure high quality of the fuel, the diesel must be treated by filtration/separation processes<br />

at every placement in and removal from storage.<br />

Only compliance with this processing chain will make it possible to keep the diesel fuel free<br />

of dirt particles and undissolved water.<br />

It also protects the entire fuel logistics from contamination, corrosion and the formation of<br />

microorganisms.<br />

www.faudi-aviation.com

Power Generation<br />

Railroad<br />

application areas to customers.<br />

Effects from contaminated<br />

diesel fuel:<br />

• Mechanical failure<br />

• Machine wear<br />

• Power loss<br />

Product diversity in use<br />

Decades of experience in the area<br />

of fuel filtration have given the FAUDI<br />

Aviation GmbH range state-of-the-art<br />

filtration systems and monitoring tools.<br />

For the user, this means that the quality<br />

of his fuel can be optimised by diverse<br />

options for all volume flows. Of course,<br />

there are also the corresponding filter<br />

elements for exchange of the present<br />

installations. Continuous further<br />

developments and modernisations of<br />

filter elements and containers guarantee<br />

economic and effective solutions in all<br />

FAUDI Aviation Filter Elements<br />

Decades of experience in development<br />

and construction of many different filter<br />

units and elements are in every product<br />

by Faudi Aviation GmbH. Filter elements<br />

of different lengths and diameters reduce<br />

machine outages and maintenance times<br />

to a minimum and increase availability.<br />

Renowned companies from the areas<br />

of aviation and aerospace, automotive,<br />

energy supply trust in our products. Use our<br />

experience and know-how from consulting<br />

to on-site service - everything from a single<br />

source.<br />

diesel

Retail<br />

Efficient in use<br />

During transport and storage at the site of<br />

use, there often is the risk of contamination<br />

of the diesel fuel, which may cause severe<br />

motor and plant errors in use later.<br />

Roadworks<br />

Only clean and dry diesel makes it<br />

possible to avoid the risk of unnecessary<br />

downtimes and costs and to nurse the<br />

most efficient work process possible.<br />

The use of modern and professional<br />

filtration and separation technology<br />

ensures continued reliable machine use in<br />

the work processes of your company.<br />

FAUDI Aviation Quality Control<br />

State-of-the-art sensor technologies recognise<br />

water in the fuel, water levels in<br />

filter sumps or deviations in differential<br />

pressure curves, and thus considerably<br />

contribute to availability of operations.<br />

Detection and monitoring of the systems<br />

runs in real-time operation. The users are<br />

always informed about the quality of the<br />

fuel and can take action in time if there<br />

are any deviations.<br />

www.faudi-aviation.com

Daily use for your operational safety<br />

Qualität Made in Germany<br />

Founded in 1938, FAUDI Aviation GmbH<br />

specialised in filtration and drying of fuels.<br />

As an internationally acting company, it<br />

offers its customers around the world<br />

modern and professional filtration<br />

technology made in Germany.<br />

With the highest demands to high quality<br />

and resilience of the products, the<br />

customer-oriented sales department of<br />

FAUDI Aviation GmbH closely cooperates<br />

with the global network of distributors to<br />

help you in the best and uncomplicated<br />

manner.<br />

Our long experience in development<br />

of and work with filtration systems<br />

provides FAUDI Aviation GmbH with the<br />

best solutions to comply with today‘s<br />

requirements in the area of fuels.<br />

We represent:<br />

• Highest quality<br />

• Customer & service<br />

orientation<br />

• Technical know-how<br />

diesel<br />

Contact me.<br />

For direct and complete product and<br />

company information, contact me personally<br />

or visit us online.<br />

Konrad Bisser, Managing Director<br />

Business area diesel<br />

FAUDI Aviation GmbH<br />

Scharnhorststrasse 7b<br />

D-35260 Stadtallendorf<br />

Germany<br />

Phone: +49 6428 4465-275<br />

Fax: +49 6428 4465-231<br />

Email: contact@faudi-aviation.com<br />

Web: www.faudi-aviation.com<br />

Ensuring Clean Diesel

VDF1-6xx-CS Series<br />

Applications<br />

For stationary and mobile installations at refineries, fuel<br />

storages, marine depots, as well as tank farms.<br />

FAUDI Aviation Filter Water Separator Vessels are<br />

designed and built in accordance with the strict<br />

engineering guidelines DGRL 97/23/EG and pressure<br />

vessel regulation of AD-2000. The design according to<br />

other pressure vessel regulations like ASME code with<br />

or without U-Stamp, BS, GOST-R, etc., is possible on<br />

customers request.<br />

Technical Details<br />

■ For stationary and mobile applications<br />

■ For diesel, other fuels on request<br />

■ Max. flow rate up to 79 USGPM (300 l/min)<br />

Sample Identification<br />

Article Description:<br />

VDF1-629-CS<br />

1. Stage<br />

(Coalescer Element)<br />

2. Stage<br />

(Separator Element)<br />

Vessel-Series<br />

Installed Element Type<br />

Vertical Diesel Filter CS Coalescer/Separator<br />

Qty. of coalescer elements<br />

1 ea<br />

Element Outer Diameter<br />

6 inch 14 29 33<br />

Nominal Length L N<br />

in inch (element)<br />

FILTER WATER SEPARATOR<br />

Coalescer<br />

Element<br />

Separator<br />

Element<br />

Diesel Volume Weight<br />

Max. Flow Rate *1<br />

Type Model Qty. Model Qty. l/min USGPM ≈ l ≈ kg *2<br />

VDF1-614-CS FDC-614-x 1 FDS-814 1 125 33 40 95<br />

VDF1-629-CS FDC-629-x 1 FDS-829 1 258 68 60 100<br />

VDF1-633-CS FDC-633-x 1 FDS-833 1 300 79 65 110<br />

*1<br />

Depending from interfacial surface tension of the fuel<br />

*2<br />

Design in Stainless Steel acc. to AD-2000 or ASME code<br />

FAUDI Aviation GmbH<br />

Scharnhorststrasse 7 B<br />

D-35260 Stadtallendorf<br />

Germany<br />

Phone: +49 6428 4465-275<br />

Fax: +49 6428 4465-231<br />

E-Mail: contact@faudi-aviation.com<br />

Web: www.faudi-aviation.com<br />

diesel<br />

DS-VDF1-6xx-CS_EN_1-0 Page 1/1 Rev. 1.0

FILTER WATER SEPARATOR<br />

VDF1-6xx-CS Series<br />

Standard Design<br />

■ Made in stainless steel<br />

■ AD-2000 module H / ASME code without U-Stamp<br />

■ Design pressure: 12 bar<br />

■ Connections for:<br />

Dimensions in mm for stainless steel vessel standard<br />

b<br />

• Automatic air eliminator<br />

• Pressure relief valve<br />

• Water Level Indicator<br />

339<br />

273<br />

550<br />

a<br />

• Differential pressure measuring device (2-point)<br />

• Sample probe connections on inlet and outlet<br />

310 (ASME=320)<br />

310 (ASME=320)<br />

80<br />

80<br />

A<br />

A<br />

160<br />

160<br />

4x 14<br />

Sectional View A-A<br />

In-/Outlet Dimensions in mm*<br />

Type DIN ANSI Ø a b<br />

VDF1-614-CS DN 50 2” 273 1,120 900<br />

VDF1-629-CS DN 50 2” 273 1,485 1,200<br />

VDF1-633-CS DN 50 2” 273 1,600 1,300<br />

*<br />

Design in Stainless Steel acc. to AD-2000 or ASME code<br />

FAUDI Aviation GmbH<br />

Scharnhorststrasse 7 B<br />

D-35260 Stadtallendorf<br />

Germany<br />

Phone: +49 6428 4465-275<br />

Fax: +49 6428 4465-231<br />

E-Mail: contact@faudi-aviation.com<br />

Web: www.faudi-aviation.com<br />

diesel<br />

DS-VDF1-6xx-CS_EN_1-0 Page 2/2 Rev. 2.0

VFC Series<br />

Description<br />

Approved and tested according<br />

to EI 1581 5 th edition, Category<br />

C , Type S & S-LW and Category<br />

M, Type S.<br />

The verticale filter water separator<br />

Type VFC-1 fascinates<br />

by high economic efficiency as<br />

well as an easy installation and<br />

servicing.<br />

Applications<br />

■ Airfield refuelling cars<br />

■ Helicopter refuelling<br />

■ stationary and mobile fuelling units<br />

on small airfields/airports<br />

■ Refuelling of small aircrafts<br />

■ Filtration of diesel on low flow rates<br />

■ Filtration of heating oil<br />

■ Refuelling of small ships and barks<br />

Technical Details<br />

VFC-1/254-10<br />

Differential Pressure Gauge<br />

Outlet<br />

Inlet<br />

1. Stage Coalescer Element<br />

2. Stage Separator Element<br />

Sight glass<br />

Manual Drain<br />

max. Flow Rate (l/min)<br />

Micron<br />

Kerosine<br />

JP4, JP5, JP8<br />

rating<br />

Coalescer-/Separator Type (µm) Cat. C, Type S Cat. C, Type S-LW Cat. M, Type S<br />

Fuels<br />

■ Kerosine (Jet Fuel)<br />

■ Military Jet Fuels<br />

■ AVGAS<br />

■ Diesel (other type of element)<br />

Diesel<br />

max. Differential<br />

Pressure<br />

(bar)<br />

CS6-254-1 1 71 89 - 29 1.1<br />

MCS6-254-1 1 - - 52 1.1<br />

FILTER WATER SEPARATOR<br />

VFC-1/355-10<br />

max. Flow Rate (l/min)<br />

Micron<br />

Kerosine<br />

JP4, JP5, JP8<br />

rating<br />

Coalescer-/Separator Type (µm) Cat. C, Type S Cat. C, Type S-LW Cat. M, Type S<br />

Diesel<br />

max. Differential<br />

Pressure<br />

(bar)<br />

CS6-355-1 1 110 136 - 45 1.1<br />

MCS6-355-1 1 - - 74 1.1<br />

■ Design Pressure:<br />

■ Design Temperature:<br />

10 bar<br />

-10°C to +50°C<br />

Maintenance & Inspection<br />

■ Vessel cover with Quick Opening for easiest Maintenance<br />

FAUDI Aviation GmbH<br />

Scharnhorststrasse 7 B<br />

D-35260 Stadtallendorf<br />

Germany<br />

Phone: +49 6428 4465-275<br />

Fax: +49 6428 4465-231<br />

E-Mail: contact@faudi-aviation.com<br />

Web: www.faudi-aviation.com<br />

DS-VFC-EN_2-4 Page 1/2 Rev. 2.4

FILTER WATER SEPARATOR<br />

VFC Series<br />

Standard Design<br />

■ Head of vessel made from die-cast aluminium<br />

■ Vessel made from carbon steel (painted)<br />

■ Design pressure 10 bar on +50°C<br />

■ Vessel cover with quick opening<br />

■ In-/Outlet 1 ½“ NPT<br />

■ Manual water drain<br />

■ Sight glass<br />

■ Manual venting<br />

■ Differential Pressure Gauge<br />

■ Inclusive 1 ea CS6-254-1 or CS6-355-1<br />

Dimensions<br />

218 mm (8,6“)<br />

Differential pressure<br />

gauge<br />

VFC-1/254-10 = 421 mm (16,56“)<br />

VFC-1/355-10 = 522 mm (20,56“)<br />

VFC-1/355-10 = 440 mm (17,31“)<br />

VFC-1/254-10 = 338 mm (13,31“)<br />

152 mm (6“)<br />

Coalescer/Separator-Element<br />

1½“ NPT<br />

(In-/Outlet)<br />

VFC-1/355-10 = 580 mm (22,82“)<br />

VFC-1/254-10 = 478 mm (18,82“)<br />

Venting<br />

(manual)<br />

Sight glass<br />

165 mm (6,48“)<br />

Spare Parts Quantity Article No.<br />

VFC-1/254-10 1 3 002 528<br />

VFC-1/355-10 1 3 002 530<br />

Differential pressure gauge 1 3 002 531<br />

O-Ring for differential pressure gauge 20,5 x 3 (Viton ® ) 2 3 003 830<br />

O-Ring for differential pressure gauge 9,52 x 1,78 (Viton ® ) 2 3 003 831<br />

Seal 158x5,3 (BUNA-N) or 1 3 005 251<br />

Seal 158x5,3 (VITON ® ) 1 3 005 252<br />

Coalescer-/Separator Type CS6-254-1 3 003 983<br />

Coalescer-/Separator Type CS6-355-1 3 003 984<br />

Coalescer-/Separator Type MCS6-254-1 3 004 519<br />

Coalescer-/Separator Type MCS6-355-1 3 004 507<br />

FAUDI Aviation GmbH<br />

Scharnhorststrasse 7 B<br />

D-35260 Stadtallendorf<br />

Germany<br />

Phone: +49 6428 4465-275<br />

Fax: +49 6428 4465-231<br />

E-Mail: contact@faudi-aviation.com<br />

Web: www.faudi-aviation.com<br />

DS-VFC-EN_2-4 Page 2/2 Rev. 2.4

MPF Series<br />

Description<br />

Cascadable Multi-Purpose-Filter-Housing to use with a coalescer-, separator-, microfilteror<br />

absorbtion element. Realising a filter water separator for small flow rates with two<br />

MPF1-2xx. One fitted with a coalescer element, the second with a separator elements.<br />

With three MPF1-2xx it is possible to realize a filter water separator with a prefilter or<br />

with a downstream absorbtion filter. There are three different housing heights available<br />

to meet different flow rate requirements. For increasing the maximal flow rate over all the<br />

MPFs could be use in parallel condition. The connecting to the pipe system is possible by<br />

flanged connections or by optional available hose clamps. The MPF1-2xx-series offers<br />

various possibilities to create an economic filtration unit in lower flow rate ranges.<br />

Applications<br />

■<br />

■<br />

Filtration of diesel on low flow rates<br />

Refuelling of small ships and barks<br />

Fuels<br />

■ Diesel ■ Heating Oil<br />

Technical Details<br />

■ Design Temperature: -10°C to +50°C<br />

■ Connections: R 1 1/2 ‟ or flanged<br />

Flow Rates<br />

Vessel Type<br />

Element Lenght<br />

(Inch)<br />

Available Accessories<br />

FAUDI Aviation GmbH<br />

Scharnhorststrasse 7 B<br />

D-35260 Stadtallendorf<br />

Germany<br />

Flow Rate<br />

Coalescerelement<br />

*<br />

Air Vent<br />

3 010 777<br />

O-Ring NBR<br />

8 869 216<br />

Bracket for drum<br />

3 010 736<br />

Adaptor<br />

3 010 733<br />

Phone: +49 6428 4465-275<br />

Fax: +49 6428 4465-231<br />

E-Mail: contact@faudi-aviation.com<br />

Web: www.faudi-aviation.com<br />

diesel<br />

DS-MPF1-2xx-EN_2-3 Page 1/2 Rev. 2.3<br />

■<br />

Filtration of heating oil<br />

■ Design Pressure: 6,0 bar<br />

■ Max. Differential Pressure: 1.5 bar<br />

Element Typ<br />

Micro Filter<br />

Element<br />

Absorption<br />

Element<br />

nominal Micron Rating in µm<br />

1 5 25 5 10 15 20 25 40 1 5 25<br />

l/min 19 15 12 39 39 39 40 40 40 39 39 39<br />

MPF1-210 10<br />

usgpm 5.0 3.9 3.1 10.3 10.3 10.3 10.6 10.6 10.6 10.3 10.3 10.3<br />

l/min 29 24 19 58 60 60 63 63 63 58 58 58<br />

MPF1-215 15<br />

usgpm 7.6 6.3 5.0 15.3 15.9 15.9 16.6 16.6 16.6 15.3 15.3 15.3<br />

l/min 60 50 40 115 120 120 130 130 130 115 115 115<br />

MPF1-230 30<br />

usgpm 15.8 13.2 10.5 30.4 31.7 31.7 34.4 34.4 34.4 30.4 30.4 30.4<br />

* -<br />

-<br />

-<br />

only in combination with a separator element with identical length!<br />

these flow rates are based on fuels with minimum interfacial tension of ≥ 36 mN/m<br />

and a maximale water content of 0.1 Vol.% in the inlet<br />

maximale 50 ppm free water in outlet<br />

Y-Adaptor<br />

(for parallel combination)<br />

3 011 504<br />

Reducing<br />

(R 1½‟ to G ½‟)<br />

3 010 778<br />

MULTI PURPOSE FILTER

MULTI PURPOSE FILTER<br />

MPF Series<br />

Sample of marking<br />

Articel Code:<br />

Combinations of Elements<br />

MPF1-215-A<br />

Vessel Series<br />

Fitted Element Type<br />

Multi Purpose Filter C Coalescer Element FDC-2xx-x<br />

S Separator Element FDS-2xx-x<br />

Qty. of installed element A Absorbtion Element FDA-2xx-x<br />

1 element F Micro Filter Element FDF-2xx-x<br />

Outer Diameter (Element)<br />

Nominal Length L N<br />

in inch (Element)<br />

2” (50 mm) 10 15 30<br />

Coalescer<br />

10 inch 15 inch 30 inch<br />

or<br />

Separator<br />

or<br />

MPF1-210<br />

Micro Filter<br />

or<br />

Absorbtion Filter<br />

Coalescer<br />

Separator<br />

Micro Filter<br />

or or or<br />

MPF1-215<br />

Absorbtion Filter<br />

Coalescer<br />

or<br />

Separator<br />

or<br />

MPF1-230<br />

Micro Filter<br />

or<br />

Absorbtion Filter<br />

EXTENSIONS<br />

(optional)<br />

MPF-230<br />

FILTER MONITOR<br />

MPF-220<br />

Combinations of Housings (samples)<br />

Combinations<br />

1<br />

1<br />

1 2<br />

2 3<br />

1 2 3 4<br />

FAUDI Aviation GmbH<br />

Scharnhorststrasse 7 B<br />

D-35260 Stadtallendorf<br />

Germany<br />

Coalescer<br />

Separator<br />

Micro Filter<br />

Absorbtion<br />

Filter<br />

1<br />

1<br />

1 2<br />

1 2<br />

2 3 1<br />

1 2 3<br />

2 3 1 4<br />

3 4 1 & 2<br />

Phone: +49 6428 4465-275<br />

Fax: +49 6428 4465-231<br />

E-Mail: contact@faudi-aviation.com<br />

Web: www.faudi-aviation.com<br />

Combinations<br />

diesel<br />

DS-MPF1-2xx-EN_2-3 Page 2/2 Rev. 2.3<br />

1<br />

1<br />

1 2<br />

1 2<br />

2 3<br />

2 3<br />

Micro Filter<br />

Coalescer<br />

Separator<br />

1 2<br />

1 2<br />

1 2 3<br />

1 2 3

MPF1-6xx-x-Series<br />

Description<br />

The multi-functional filter can be used with a micro or absorption<br />

filter element. Thus, simple and quick solutions are possible as prefilters<br />

upstream of a filter/water separator or as standalone solutions<br />

for particle filtration or absorption of water from fuel. There are two<br />

housing sizes to reach different flow rates. Increase of the maximum<br />

flow rate can be reached by additional parallel circuit(s).<br />

The MPF1-6xx-x-series is used to improve the quality of diesel fuels<br />

when fuelling diesel-operated vehicles and systems.<br />

Applications<br />

■<br />

Fuels<br />

Filtration and/or Absorbtion at small and medium flow rates<br />

■ Diesel ■ Heating oil<br />

Technical Details<br />

■ Temperature range: -10°C to +50°C<br />

■ Connections: 2‟ BSP<br />

Flow Rates<br />

Vessel Type<br />

Element length<br />

(Inch)<br />

MPF1-614 14<br />

MPF1-629 29<br />

Flow Rate<br />

■ Design Pressure: 145 psi / 10 bar<br />

■ Max. Differential Pressure: 24,6 psi / 1,7 bar<br />

Microfilter Element<br />

FDF-6xx-xxC<br />

Element Type<br />

Absorbtion Element<br />

FDA-6xx-xxC<br />

nominal Micron Rating in µm<br />

5 25 40 1 5 25<br />

l/min 205 205 205 190 190 190<br />

usgpm 54 54 54 50 50 50<br />

l/min 424 424 424 394 394 394<br />

usgpm 112 112 112 104 104 104<br />

MULTI PURPOSE FILTER<br />

Available Accessories<br />

dp-Indicator<br />

3 002 531<br />

Vent<br />

8 808 651<br />

Ball Valve<br />

3 007 551<br />

FAUDI Aviation GmbH<br />

Scharnhorststrasse 7 B<br />

D-35260 Stadtallendorf<br />

Germany<br />

Phone: +49 6428 4465-275<br />

Fax: +49 6428 4465-231<br />

E-Mail: contact@faudi-aviation.com<br />

Web: www.faudi-aviation.com<br />

diesel<br />

DS-MPF1-6xx-x-EN_2-1 Page 1/2 Rev. 2.1

MULTI PURPOSE FILTER<br />

MPF1-6xx-x-Series<br />

Sample of marking<br />

Article Code:<br />

Vessel Series<br />

Fitted Element Type<br />

Multi Purpose Filter A Absorbtion Element<br />

F Microfilter Element<br />

Quantity of Element<br />

1 ea<br />

Outer Diameter (Element)<br />

6 inch 14 29<br />

Abmessungen<br />

Dimensions & Connections<br />

L t<br />

106<br />

L C<br />

4 17/100˝<br />

N1<br />

Ø221 / 8 14/20˝<br />

146 / 5 3/4˝<br />

N4<br />

Øext.<br />

168,3 / 6 31/50˝<br />

MPF1-614-A<br />

N2<br />

Vessel Type<br />

Nominal Length L N<br />

in inch (Element)<br />

L T<br />

(inch / mm)<br />

Dimensions<br />

Connections<br />

L C<br />

(inch / mm)<br />

Ref. Position Ø Type Usage<br />

N1 270° 2“ BSP Inlet<br />

N2 90° 2“ BSP Outlet<br />

N3 180° 1/2“ BSP Drain<br />

N4 0° 3/8“ BSP Vent<br />

Volume<br />

l<br />

MPF-1-614 23 / 585 /0 18 17/20 / 479 9<br />

MPF-1-629 37 1/2 / 953 33 17/50 / 847 17<br />

N3<br />

FAUDI Aviation GmbH<br />

Scharnhorststrasse 7 B<br />

D-35260 Stadtallendorf<br />

Germany<br />

Phone: +49 6428 4465-275<br />

Fax: +49 6428 4465-231<br />

E-Mail: contact@faudi-aviation.com<br />

Web: www.faudi-aviation.com<br />

diesel<br />

DS-MPF1-6xx-x-EN_2-1 Page 2/2 Rev. 2.1

Sieve Basket Strainer Series 11<br />

Product Describtion<br />

The FAUDI Aviation Single Sieve basket strainer Type 11 is used for the filtration of fluids and gases.<br />

The Sieve basket strainer consists of a perforated sieve basket made of Carbon steel, Stainless Steel or<br />

other materials, depending on the fuels or gases being filtered.<br />

Installations<br />

■ The Sieve basket strainer can be installed as a suction or pressure filter<br />

■ Verticale or horizontal applications possible<br />

■ For both installations a shut-off valve must be fitted at the inlet/outlet connection and the drain point.<br />

Applications<br />

■ As a strainer in pipework systems for the separation of unwanted contaminations (rust, dirt)<br />

■ Prefilter for oil and gas pipelines<br />

■ Protection Filter for meters, valves, pumps and safety devices<br />

Technical Details<br />

■ Change out differential pressure:<br />

■ Operating temperature:<br />

■ Design pressure:<br />

1 bar (higher in case of special designs)<br />

-10 / +50 °C (depending on model type)<br />

depending on model type<br />

Standard Design<br />

■ Vertical or horizontal cylindrical housing with a dished bottom<br />

■ Depending on the size and pressure rating, Type 11 is fitted with a flat or dished cover<br />

■ Standard flange joint fastened with hexagonal bolts and nuts to secure the cover<br />

■ Alternative cover closures are possible (See page 2)<br />

SIEVE BASKET STRAINER<br />

FAUDI Aviation GmbH<br />

Scharnhorststrasse 7 B<br />

D-35260 Stadtallendorf<br />

Germany<br />

Phone: +49 6428 4465-275<br />

Fax: +49 6428 4465-231<br />

E-Mail: contact@faudi-aviation.com<br />

Web: www.faudi-aviation.com<br />

DS-SKF-11-EN_2-2b Page 1/2 Rev. 2.2b

SIEVE BASKET STRAINER<br />

Sieve Basket Strainer Series 11<br />

Sample of Identification<br />

Model<br />

No.<br />

Connections<br />

DN<br />

Filterarea<br />

(cm²)<br />

11.10 40 300<br />

11.13 65 640<br />

11.19 100 1.250<br />

11.27 150 3.200<br />

11.36 200 4.800<br />

11.45 250 5.800<br />

11.55 300 10.000<br />

11.60 350 14.000<br />

11.70 400 18.000<br />

11.85 500 26.500<br />

11.00 600 33.500<br />

11.01 700 37.500<br />

Cover Closure Material Pressure Range<br />

(bar)<br />

Connections<br />

DN<br />

1 Standard 0 Carbon steel 0 6 02 20 1 1.4541 0 Without<br />

3 Eye swing bolts 1 1.4541 1 10 03 32 2 1.4571 1 1.4541<br />

4 Segmential bolt closure 2 1.4571 2 16 04 40 3 Monel 2 1.4571<br />

7 Patent quick opening<br />

closure with cover davit<br />

Insert<br />

Mesh<br />

3 Carbon steel (coated) 3 25 05 50 4 Special 3 Monel<br />

6 Special materials 4 40 06 65<br />

materials<br />

4 Special<br />

5 64 08 80<br />

materials<br />

6 100** 10 100<br />

7 160** 12 125<br />

15 150<br />

20 200<br />

25 250<br />

30 300<br />

35 350<br />

40 400<br />

50 500<br />

11.13 1. 0 1. 05 1 1<br />

Sample of Article Code = Model 11.131.01.0511<br />

FAUDI Aviation GmbH<br />

Scharnhorststrasse 7 B<br />

D-35260 Stadtallendorf<br />

Germany<br />

Phone: +49 6428 4465-275<br />

Fax: +49 6428 4465-231<br />

E-Mail: contact@faudi-aviation.com<br />

Web: www.faudi-aviation.com<br />

DS-SKF-11-EN_2-2b Page 2/2 Rev. 2.2b

Sieve Basket Strainer Series 21<br />

Product Describtion<br />

The FAUDI Aviation Single Sieve basket strainer Type 21 is used for the filtration of fluids and gases.<br />

The Sieve basket strainer consists of a perforated sieve basket made of Carbon steel, Stainless Steel or<br />

other materials, depending on the fuels or gases being filtered<br />

Installations<br />

■<br />

■<br />

■<br />

The Sieve basket strainer can be installed as a suction or pressure filter<br />

Verticale or horizontal applications possible<br />

For both installations a shut-off valve must be fitted<br />

at the inlet/outlet connection and the drain point<br />

Applications<br />

■<br />

■<br />

■<br />

As a strainer in pipework systems for the separation of unwanted contaminations (rust, dirt)<br />

Prefilter for oil and gas pipelines<br />

Protection Filter for meters, valves, pumps and safety devices<br />

Technical Details<br />

■ Change out on a differential pressure of 1 bar (higher in case of special designs)<br />

■ Operating temperature: -10C / +50°C (depending on model type)<br />

■ Design pressure: depending on model type<br />

Standard Design<br />

■<br />

■<br />

■<br />

Vertical or horizontal cylindrical housing with a dished bottom<br />

Depending on the size and pressure rating, Type 11 is fitted with a flat or dished cover<br />

flange joint on housing opening (cover)<br />

SIEVE BASKET STRAINER<br />

FAUDI Aviation GmbH<br />

Scharnhorststrasse 7 B<br />

D-35260 Stadtallendorf<br />

Germany<br />

Phone: +49 6428 4465-275<br />

Fax: +49 6428 4465-231<br />

E-Mail: contact@faudi-aviation.com<br />

Web: www.faudi-aviation.com<br />

DS-SKF-21-EN_2-2b Page 1/2 Rev. 2.2b

SIEVE BASKET STRAINER<br />

Sieve Basket Strainer Series 21<br />

Sample of Identification<br />

Model<br />

No.<br />

Connections<br />

DN<br />

Filterarea<br />

(m²)<br />

21.08 40 0,04<br />

21.10 50 0,07<br />

21.13 80 0,14<br />

21.19 100 0,22<br />

21.27 150 0,48<br />

21.36 200 0,80<br />

21.45 250 1,20<br />

21.55 300 1,60<br />

FAUDI Aviation GmbH<br />

Scharnhorststrasse 7 B<br />

D-35260 Stadtallendorf<br />

Germany<br />

Cover Closure Material Press. Range<br />

bar<br />

Connections<br />

DN<br />

1 Standard 0 Carbon steel 0 6 02 20 1 1.4541 0 Without<br />

3 Eye swing bolts 1 1.4541 1 10 03 32 2 1.4571 1 1.4541<br />

4 Segmential bolt closure 2 1.4571 2 16 04 40 3 Monel 2 1.4571<br />

7 Patent quick opening<br />

closure with cover davit<br />

Phone: +49 6428 4465-275<br />

Fax: +49 6428 4465-231<br />

E-Mail: contact@faudi-aviation.com<br />

Web: www.faudi-aviation.com<br />

DS-SKF-21-EN_2-2b Page 2/2 Rev. 2.2b<br />

Insert<br />

Mesh<br />

3 Carbon steel (coated) 3 25 05 50 4 Special 3 Monel<br />

6 Special materials 4 40 06 65<br />

materials<br />

4 Special<br />

5 64 08 80<br />

materials<br />

6 100** 10 100<br />

7 160** 12 125<br />

15 150<br />

20 200<br />

25 250<br />

30 300<br />

21.13 1. 0 1. 05 1 1<br />

Sample of Article Code = Model 21.131.01.0511

2” diesel Coalescer Element<br />

On One View<br />

Function Water Separation / Particulate Retention from Hydrocarbons<br />

Media Diesel, biodiesel blends<br />

Norms/Specs n.a.<br />

Applications Filter Water Separators fixed fuelling installations<br />

Range of use Refineries, petrochemical plants, mining and petrol stations<br />

Micron Ratings 1, 5 & 25 µm<br />

Features & Benefits ● High efficiency filtration and separation<br />

● Improved diesel engine performance and life time<br />

● Reduce fuel contamination problems<br />

● Economical period of use<br />

Technical Details<br />

Change-out differential pressure 15 psi (1.1 bar)<br />

Test- /berst pressure<br />

75 psi (5.2 bar)<br />

Recommended storage time (max.) 24 months 1&2<br />

Recommended service time (max.) 24 months 1<br />

Operating temperature min. -30°C / max. 80°C<br />

Flow direction<br />

In to Out<br />

Outside diameter<br />

2 inch (50 mm)<br />

Material of inner tube<br />

Stainless steel (reinforced)<br />

Material of seals NBR (Buna-N ® )<br />

Material of end caps<br />

Conductive Polyamid<br />

Labeling of end cap<br />

Type, date of manufacturing &<br />

ID-Number<br />

1<br />

Manufacturer recommendation<br />

2<br />

Original packaging, 20°C and max. 50% humidity<br />

after date of shipment out of manufacturer‘s stock<br />

diesel COALESCER ELEMENT<br />

Sample of Marking<br />

Article Code:<br />

FDC-215-5<br />

Element Series Nominal Micron Rating in µm<br />

FAUDI Diesel Coalescer 1 5 25<br />

Outer Diameter<br />

Nominal Length L N<br />

in inch<br />

2” (50 mm) 10 15 30<br />

FAUDI Aviation GmbH Phone: +49 6428 4465-275<br />

Scharnhorststrasse 7 B Fax: +49 6428 4465-231<br />

D-35260 Stadtallendorf E-Mail: contact@faudi-aviation.com<br />

Germany Web: www.faudi-aviation.com<br />

diesel<br />

DS-FDC-2-EN_1-3 Page 1/1 Rev. 1.3

6” diesel Coalescer Element<br />

On One View<br />

Function Water Separation / Particulate Retention from Hydrocarbons<br />

Media Diesel, biodiesel blends<br />

Norms/Specs n.a.<br />

Applications Filter Water Separators fixed fuelling installations<br />

Range of use Refineries, petrochemical plants, mining and petro stations<br />

Micron Ratings 5, 10, 15, 20 & 25 µm<br />

Features & Benefits ● High efficiency filtration and separation<br />

● Improved diesel engine performance and life time<br />

● Reduce fuel contamination problems<br />

● Economical period of use<br />

Technical Details<br />

Change-out differential pressure 15 psi (1.1 bar)<br />

Test- /berst pressure<br />

75 psi (5.2 bar)<br />

Recommended storage time (max.) 12 months 1&2<br />

Recommended service time (max.) 12 months 1<br />

Operating temperature min. -30°C / max. 80°C<br />

Flow direction<br />

In to Out<br />

Outside diameter<br />

6 inch (152 mm)<br />

Material of inner tube<br />

Epoxy coated steel<br />

Material of seals NBR (Buna-N ® )<br />

Material of end caps<br />

Epoxy coated steel<br />

Labeling of end cap<br />

Type, date of manufacturing &<br />

ID-Number<br />

1<br />

Manufacturer recommendation<br />

2<br />

Original packaging, 20°C and max. 50% humidity<br />

after date of shipment out of manufacturer‘s stock<br />

diesel COALESCER ELEMENT<br />

FAUDI Aviation GmbH Phone: +49 6428 4465-275<br />

Scharnhorststrasse 7 B Fax: +49 6428 4465-231<br />

D-35260 Stadtallendorf E-Mail: contact@faudi-aviation.com<br />

Germany Web: www.faudi-aviation.com<br />

diesel<br />

DS-FDC-EN_1-7 Page 1/2 Rev. 1.7

L<br />

diesel COALESCER ELEMENT<br />

6” diesel Coalescer Element<br />

Sample of Marking<br />

Element Series<br />

Torques<br />

Ø 3 1/2 ” (89 mm)<br />

Ø 6” (152 mm)<br />

flat sealed<br />

Articel Code:<br />

Ø 1/2” - 13 UNC<br />

FDC-614-5TB<br />

L<br />

1” (25 mm)<br />

Ø 4 9/64 ” (105 mm)<br />

Ø 6” (152 mm)<br />

threaded based<br />

End Cap Version<br />

FAUDI Diesel Coalescer - flat sealed<br />

Outer Diameter<br />

6” (152 mm)<br />

TB<br />

threaded based<br />

Nominal Length L N<br />

in inch Nominal Micron Rating in µm<br />

flat sealed threaded based 5 10 15 20 25<br />

inch mm inch mm<br />

14 14 1/4 362 13 9/11 351<br />

29 28 31/50 727 27 3/4 705<br />

33 33 3/20 842 32 5/6 834<br />

44 43 1/32 1,093 43 17/25 1,114<br />

56 56 63/64 1,422 56 41/50 1,418<br />

34 Nm (for center rod) 15 Nm<br />

flat sealed<br />

threaded based<br />

22 Nm<br />

27 Nm<br />

Conversation Table<br />

ft/lbs inch/lbs kg/m Nm<br />

5 62 0.71 7<br />

11 128 1.50 15<br />

16 193 2.25 22<br />

20 240 2.80 27<br />

25 300 3.50 34<br />

FAUDI Aviation GmbH Phone: +49 6428 4465-275<br />

Scharnhorststrasse 7 B Fax: +49 6428 4465-231<br />

D-35260 Stadtallendorf E-Mail: contact@faudi-aviation.com<br />

Germany Web: www.faudi-aviation.com<br />

diesel<br />

DS-FDC-EN_1-7 Page 2/2 Rev. 1.7

2” FAUDI diesel Separator Element<br />

On One View<br />

Function Water Separation from Hydrocarbons<br />

Media Diesel, biodiesel blends<br />

Norms/Specs n.a.<br />

Applications Filter Water Separators on fixed fuelling installations<br />

Range of use Refineries, petrochemical plants, mining, marine and<br />

petrol stations<br />

Micron Ratings n.a.<br />

Features & Benefits ● High efficiency separation / effective water barrier<br />

● Optimum 2 nd stage water removal<br />

● Field proven performance<br />

Technical Details<br />

Recommended storage time (max.) 24 months 1&2<br />

Recommended service time (max.) 24 months 1<br />

Operating temperature min. -30°C / max. 80°C<br />

Flow direction<br />

Out to In<br />

Outside diameter<br />

2 inch (50 mm)<br />

Material of separator screen Synthetic mesh<br />

Material of inner tube<br />

Stainless steel (reinforced)<br />

Material of seals NBR (Buna-N ® )<br />

Material of end caps<br />

Conductive Polyamid<br />

Labeling of end cap<br />

Type, date of manufacturing<br />

& ID-Number<br />

1<br />

Manufacturer recommendation<br />

2<br />

Original packaging, 20°C and max. 50% humidity<br />

after date of shipment out of manufacturer‘s stock<br />

diesel SEPARATOR ELEMENT<br />

Sample of Marking<br />

Article Code:<br />

FDS-215-S<br />

Element Series<br />

Type of Screen<br />

FAUDI Diesel Separator S Synthetic mesh<br />

Outer Diameter<br />

Nominal Length L N<br />

in inch<br />

2” (50 mm) 10 15 30<br />

FAUDI Aviation GmbH Phone: +49 6428 4465-275<br />

Scharnhorststrasse 7 B Fax: +49 6428 4465-231<br />

D-35260 Stadtallendorf E-Mail: contact@faudi-aviation.com<br />

Germany Web: www.faudi-aviation.com<br />

diesel<br />

DS-FDS-2-EN_1-4 Page 1/1 Rev. 1.4

6” diesel Separator Element<br />

On One View<br />

Function Water Separation from Hydrocarbons<br />

Media Diesel, biodiesel blends<br />

Norms/Specs n.a.<br />

Applications Filter Water Separators on fixed fuelling installations<br />

Range of use Refineries, petrochemical plants, mining, marine and<br />

petrol stations<br />

Micron Ratings n.a.<br />

Features & Benefits ● High efficiency separation / effective water barrier<br />

● Permanent Reusable (only with teflonised screen 1&2 )<br />

● Optimum 2nd stage water removal<br />

● Field proven performance<br />

1<br />

Depending regular cleaning and inspection on each replacement of 1st stage elements! Please see our datasheet „handling<br />

separators“ for further information.<br />

2<br />

Small defects on the screen could repair with our Separator Repair Kit. Please see datasheet „DS-Z-15.1 for further information<br />

Technical Details<br />

Operating temperature min. -30°C / max. 80°C<br />

Flow direction<br />

Out to in<br />

Outside diameter<br />

6 inch (152 mm)<br />

Material of separator screen Teflon ® coated stainless steel mesh<br />

Material of seals NBR (Buna-N ® )<br />

Material of end caps see page 2<br />

Labeling of end cap<br />

Type, date of manufacturing &<br />

ID-Number<br />

diesel SEPARATOR ELEMENT<br />

FAUDI Aviation GmbH Phone: +49 6428 4465-275<br />

Scharnhorststrasse 7 B Fax: +49 6428 4465-231<br />

D-35260 Stadtallendorf E-Mail: contact@faudi-aviation.com<br />

Germany Web: www.faudi-aviation.com<br />

diesel<br />

DS-FDS-EN_1-6 Page 1/2 Rev. 1.6

L N<br />

L N<br />

diesel SEPARATOR ELEMENT<br />

6” diesel Separator Element<br />

Sample of marking<br />

Element Series<br />

Ø 3 1/2 ” (89 mm)<br />

Ø 1/2” - 13 mm<br />

Ø 3 1/2 ” (89 mm)<br />

Ø 6” (152 mm) Ø 6” (152 mm) Ø 6” (152 mm)<br />

Articel Code:<br />

FDS-614-TBC<br />

Addition<br />

Ø 1/2” - 13 UNC<br />

L N<br />

1” (25 mm)<br />

Ø 4 9/64 ” (105 mm)<br />

FAUDI Diesel Separator - Flat sealed open end caps<br />

Outer Diameter TB Threaded based<br />

6” (152 mm)<br />

flat sealed blind end cap threaded based<br />

Nominale Length L N<br />

in inch<br />

BC<br />

Blind end cap (closed with hole Ø 13 mm)<br />

Type of screen<br />

flat sealed threaded based T teflonized stainless steel mesh<br />

inch mm inch mm S Synthetic mesh<br />

14 14 1/2 368 14 13/16 376<br />

27 27 3/4 705 27 3/4 705<br />

33 33 3/8 848 32 7/8 835<br />

44 43 1/4 1,099 43 7/8 1,114<br />

56 56 1/4 1,429 56 7/8 1,445<br />

Material of end caps<br />

Polyamide<br />

Carbon steel (epoxy coated)<br />

Torques<br />

34 Nm (for center rod) 15 Nm<br />

flat sealed<br />

34 Nm (for center rod) 7 Nm<br />

blind end cap<br />

Threaded<br />

based<br />

22 Nm<br />

27 Nm<br />

Conversation Table<br />

ft/lbs inch/lbs kg/m Nm<br />

5 62 0.71 7<br />

11 128 1.50 15<br />

16 193 2.25 22<br />

20 240 2.80 27<br />

25 300 3.50 34<br />

FAUDI Aviation GmbH Phone: +49 6428 4465-275<br />

Scharnhorststrasse 7 B Fax: +49 6428 4465-231<br />

D-35260 Stadtallendorf E-Mail: contact@faudi-aviation.com<br />

Germany Web: www.faudi-aviation.com<br />

diesel<br />

DS-FDS-EN_1-6 Page 2/2 Rev. 1.6

2” diesel Microfilter Element<br />

On One View<br />

Function Particulate Filtration of solids from hydrocarbons<br />

Media Diesel, biodiesel blends<br />

Norms/Specs n.a.<br />

Applications Micro Filter on fixed fuelling installations<br />

Range of use Refineries, petrochemical plants, mining, marine &<br />

petrol stations<br />

Micron Ratings 5, 10, 15, 20, 25 & 40 µm<br />

Features & Benefits ● High efficiency filtration<br />

● Improved diesel engine performance and life time<br />

● Reduce fuel contamination problems<br />

● Economical period of use<br />

Technical Details<br />

Efficiency 99% (acc. to ISO 19438)<br />

Change-out differential pressure 21 psi (1.5 bar)<br />

Recommended storage time (max.) 24 months 1&2<br />

Recommended service time (max.) 24 months 1<br />

Operating temperature min. -30°C / max. 80°C<br />

Flow direction<br />

Out to In<br />

Outside diameter<br />

2 inch (50 mm)<br />

Material of inner tube<br />

Stainless steel<br />

Material of seals NBR (Buna-N ® )<br />

Material of end caps<br />

Conductive Polyamid (reinforced)<br />

Labeling of end cap<br />

Type, date of manufacturing<br />

& ID-Number<br />

1<br />

Manufacturer recommendation<br />

2<br />

Original packaging, 20°C and max. 50% humidity<br />

after date of shipment out of manufacturer‘s stock<br />

diesel MICROFILTER ELEMENT<br />

Sample of Marking<br />

Article Code:<br />

FDF-215-5<br />

Element Series Nominal Micron Rating in µm<br />

FAUDI Diesel Filter 5 10 15 20 25 40<br />

Outer Diameter<br />

Nominal Length L N<br />

in inch<br />

2” (50 mm) 10 15 30<br />

FAUDI Aviation GmbH Phone: +49 6428 4465-275<br />

Scharnhorststrasse 7 B Fax: +49 6428 4465-231<br />

D-35260 Stadtallendorf E-Mail: contact@faudi-aviation.com<br />

Germany Web: www.faudi-aviation.com<br />

diesel<br />

DS-FDF-2-EN_1-4 Page 1/1 Rev. 1.4

6” diesel Microfilter Element<br />

On One View<br />

Function Particulate Filtration of solids from hydrocarbons<br />

Media Diesel, biodiesel blends<br />

Norms/Specs n.a.<br />

Applications Micro Filter on fixed fuelling installations<br />

Range of use Refineries, petrochemical plants, mining, marine &<br />

petro stations<br />

Micron Ratings 5, 10, 15, 20, 25 & 40 µm<br />

Features & Benefits ● High efficiency filtration<br />

● Improved diesel engine performance and life time<br />

● Reduce fuel contamination problems<br />

● Economical period of use<br />

Technical Details<br />

Efficiency 99% (acc. to ISO 19438)<br />

Change-out differential pressure 21 psi (1.5 bar)<br />

Test- /berst pressure<br />

75 psi (5.2 bar)<br />

Recommended storage time (max.) 12 months 1&2<br />

Recommended service time (max.) 12 months 1<br />

Operating temperature min. -30°C / max. 80°C<br />

Flow direction<br />

Out to In<br />

Outside diameter<br />

6 inch (152 mm)<br />

Material of inner tube<br />

Epoxy coated steel<br />

Material of seals NBR (Buna-N ® )<br />

Material of end caps<br />

Epoxy coated steel<br />

Labeling of end cap<br />

Type, date of manufacturing<br />

& ID-Number<br />

1<br />

Manufacturer recommendation<br />

2<br />

Original packaging, 20°C and max. 50% humidity<br />

after date of shipment out of manufacturer‘s stock<br />

diesel MICROFILTER ELEMENT<br />

FAUDI Aviation GmbH Phone: +49 6428 4465-275<br />

Scharnhorststrasse 7 B Fax: +49 6428 4465-231<br />

D-35260 Stadtallendorf E-Mail: contact@faudi-aviation.com<br />

Germany Web: www.faudi-aviation.com<br />

diesel<br />

DS-FDF-EN_1-7 Page 1/2 Rev. 1.7

diesel MICROFILTERER ELEMENT<br />

6” diesel Microfilter Element<br />

Sample of Marking<br />

Torques<br />

flat sealed<br />

L<br />

Articlel Code:<br />

Ø 3 1/2 ” (89 mm)<br />

Ø 6” (152 mm)<br />

flat sealed<br />

FDF-614-5<br />

Element Series Nominal Micron Rating in µm<br />

FAUDI Diesel Filter 5 10 15 20 25 40<br />

Outer Diameter<br />

Nominale Length L N<br />

in inch<br />

6” (152 mm) inch mm<br />

34 Nm (for rod) 15 Nm<br />

14 14 1/2 368<br />

27 27 3/4 705<br />

33 33 3/8 848<br />

44 43 1/4 1,099<br />

56 56 1/4 1,429<br />

Conversion table<br />

ft/lbs inch/lbs kg/m Nm<br />

5 62 0.71 7<br />

11 128 1.50 15<br />

16 193 2.25 22<br />

20 240 2.80 27<br />

25 300 3.50 34<br />

FAUDI Aviation GmbH Phone: +49 6428 4465-275<br />

Scharnhorststrasse 7 B Fax: +49 6428 4465-231<br />

D-35260 Stadtallendorf E-Mail: contact@faudi-aviation.com<br />

Germany Web: www.faudi-aviation.com<br />

diesel<br />

DS-FDF-EN_1-7 Page 2/2 Rev. 1.7

2” diesel Absorbtion Element<br />

On One View<br />

Function Free Water Removal & Particulate Filtration from hydrocarbons<br />

Media Diesel, biodiesel blends<br />

Norms/Specs n.a.<br />

Applications Absorber on fixed fuelling installations<br />

Range of use Refineries, petrochemical plants, mining and marine<br />

Micron Ratings 1, 5 & 25 µm<br />

Features &<br />

Benefits<br />

Technical Details<br />

● High efficiency absorbtion of free water<br />

● Improved diesel engine performance and life time<br />

● Reduce fuel contamination problems<br />

● Economical period of use<br />

● Easy replaceable with other brands<br />

Efficiency 99% (acc. to ISO 19438)<br />

Change-out differential pressure 21 psi (1.5 bar)<br />

Test- /berst pressure<br />

75 psi (5.2 bar)<br />

Recommended storage time (max.) 12 months 1&2<br />

Recommended service time (max.) 12 months 1<br />

Operating temperature min. -30°C / max. 80°C<br />

Flow direction<br />

Out to In<br />

Outside diameter<br />

2 inch (50 mm)<br />

Material of inner tube<br />

Conductive Polyamid (reinforced)<br />

Material of seals NBR (Buna-N ® )<br />

Material of end caps<br />

Conductive Polyamid<br />

Labeling of end cap<br />

Type, date of manufacturing<br />

& ID-Number<br />

1<br />

Manufacturer recommendation<br />

2<br />

Original packaging, 20°C and max. 50% humidity<br />

after date of shipment out of manufacturer‘s stock<br />

diesel ABSORBTION ELEMENT<br />

Sample of Marking<br />

Article Code:<br />

FDA-215-5<br />

Element Series Nominal Micron Rating in µm<br />

FAUDI Diesel Absorber 1 5 25<br />

Outer Diameter<br />

Nominal Length L N<br />

in inch<br />

2” (50 mm) 10 15 30<br />

FAUDI Aviation GmbH Phone: +49 6428 4465-275<br />

Scharnhorststrasse 7 B Fax: +49 6428 4465-231<br />

D-35260 Stadtallendorf E-Mail: contact@faudi-aviation.com<br />

Germany Web: www.faudi-aviation.com<br />

diesel<br />

DS-FDA-2-EN_1-3 Page 1/1 Rev. 1.3

6” diesel Absorbtion Element<br />

On One View<br />

Function Free Water Removal & Particulate Filtration from hydrocarbons<br />

Media Diesel, biodiesel blends<br />

Norms/Specs n.a.<br />

Applications Absorber on fixed fuelling installations<br />

Range of use Refineries, petrochemical plants, mining and marine<br />

Micron Ratings 5, 10, 15, 20, 25 & 40 µm<br />

Features &<br />

Benefits<br />

Technical Details<br />

● High efficiency absorbtion of free water<br />

● Improved diesel engine performance and life time<br />

● Reduce fuel contamination problems<br />

● Economical period of use<br />

Efficiency 99% (acc. to ISO 19438)<br />

Change-out differential pressure 21 psi (1.5 bar)<br />

Test- /berst pressure<br />

75 psi (5.2 bar)<br />

Recommended storage time (max.) 12 months 1&2<br />

Recommended service time (max.) 12 months 1<br />

Operating temperature min. -30°C / max. 80°C<br />

Flow direction<br />

Out to In<br />

Outside diameter<br />

6 inch (152 mm)<br />

Material of inner tube<br />

Epoxy coated steel<br />

Material of seals NBR (Buna-N ® )<br />

Material of end caps<br />

Epoxy coated steel<br />

Labeling of end cap<br />

Type, date of manufacturing<br />

& ID-Number<br />

1<br />

Manufacturer recommendation<br />

2<br />

Original packaging, 20°C and max. 50% humidity<br />

after date of shipment out of manufacturer‘s stock<br />

diesel ABSORBTION ELEMENT<br />

FAUDI Aviation GmbH Phone: +49 6428 4465-275<br />

Scharnhorststrasse 7 B Fax: +49 6428 4465-231<br />

D-35260 Stadtallendorf E-Mail: contact@faudi-aviation.com<br />

Germany Web: www.faudi-aviation.com<br />

diesel<br />

DS-FDA-EN_1-5 Page 1/2 Rev. 1.5

diesel ABSORBTION ELEMENT<br />

6” diesel Absorbtion Element<br />

Sample of Marking<br />

Torques<br />

flat sealed<br />

Article Code:<br />

L<br />

Ø 3 1/2 ” (89 mm)<br />

Ø 6” (152 mm)<br />

flat sealed<br />

FDA-614-5<br />

Element Series Nominal Micron Rating in µm<br />

FAUDI Diesel Absorber 5 10 15 20 25 40<br />

Outer Diameter<br />

Nominal Length L N<br />

in inch<br />

6” (152 mm) inch mm<br />

14 14 1/2 368<br />

27 27 3/4 705<br />

33 33 3/8 848<br />

44 43 1/4 1,099<br />

56 56 1/4 1,429<br />

34 Nm (for rod) 15 Nm<br />

Conversion table<br />

ft/lbs inch/lbs kg/m Nm<br />

5 62 0.71 7<br />

11 128 1.50 15<br />

16 193 2.25 22<br />

20 240 2.80 27<br />

25 300 3.50 34<br />

FAUDI Aviation GmbH Phone: +49 6428 4465-275<br />

Scharnhorststrasse 7 B Fax: +49 6428 4465-231<br />

D-35260 Stadtallendorf E-Mail: contact@faudi-aviation.com<br />

Germany Web: www.faudi-aviation.com<br />

diesel<br />

DS-FDA-EN_1-5 Page 2/2 Rev. 1.5

Z-3.1 Water Level Gauge<br />

1<br />

2<br />

4<br />

guard bar<br />

3<br />

5<br />

4<br />

FWE<br />

FW 6<br />

FW 7<br />

FW10-H<br />

FW 8<br />

ACCESSORIES<br />

2<br />

armature open<br />

1<br />

armature closed<br />

FW 8-S<br />

FW10-V<br />

Construction<br />

The water level indicator consists of shutoff instruments (1) and a glass tube (3). The<br />

shutoff cocks (1) are tightened by means of an o-ring (2) which can be retightened by<br />

a screw cap. Between the cocks the glass tube (3) is inserted. The seals (4) can be retightened<br />

by means of screw caps. Inside the sight glass is the ball (5), which floats on<br />

the water / fuel interface and indicates the water level. Two guard bars protect the glass<br />

tube.<br />

Maintenance<br />

Retighten the cap nut respectively replace the seals on leaks.<br />

Pos. Qty. Designation Material Article no. Spare<br />

part<br />

1 2 Shut off instrument R ½“ Stainless Steel 300 589 1 X<br />

2 2 Seal for shut off cock (package) TEFLON ® 300 855 6 X<br />

3 1 Sight glass Ø13 mm, lenght = 265 mm Perspex 300 595 0 X<br />

4 2 Seal NBR Laminum 885 217 0 X<br />

5 1 Ball Ø 7 mm, colored PP-H 886 570 1 X<br />

Subject<br />

to wear<br />

FAUDI Aviation GmbH<br />

Scharnhorststrasse 7 B<br />

D-35260 Stadtallendorf<br />

Germany<br />

Phone: +49 6428 4465-275<br />

Fax: +49 6428 4465-231<br />

E-Mail: contact@faudi-aviation.com<br />

Web: www.faudi-aviation.com<br />

DS-Z-3.1-EN_2-2 Page 1/1 Rev. 2.2

Z-3.2 Water Level Indicator<br />

3<br />

1<br />

5<br />

6<br />

4<br />

FWE<br />

FW 6<br />

FW 7<br />

FW 8<br />

ACCESSORIES<br />

5<br />

2<br />

3<br />

FW 8S<br />

Construction<br />

The water level indicator consists of reception and shutoff instruments (1) and (2). The shutoff cocks (3)<br />

are tightened and can be retightened by a screw cap. Between the cocks the sight glass (4) is inserted.<br />

The seals (5) can be retightened by means of a screw cap. Inside the glass tube is the ball (6), which floats<br />

on the water/fuel interface and indicates the water level. A slot tube protects the glass tube.<br />

Maintenance<br />

Retighten the cap nut respectively replace the seals on leaks.<br />

Pos. Qty. Designation Material Article no. Spare<br />

part<br />

1 Water Level Gauge (compl.) - 300 119 6 X<br />

1 2 Shut off instrument R ½“ Stainless Steel 887 421 6 X<br />

2 1 Angle Profil Edelstahl 300 256 1 X<br />

Subject to<br />

wear<br />

3 2 Seal for shut off cock (package) FAW 205 898 246 4 X<br />

4 1 Sight glass Ø16 mm DURAN 50 887 418 2 X<br />

5 2 Seal for sight glass VITON ® 941 813 8 X<br />

6 1 Ball Ø7 mm, coloured PP-H 886 570 1 X<br />

FAUDI Aviation GmbH<br />

Scharnhorststrasse 7 B<br />

D-35260 Stadtallendorf<br />

Germany<br />

Phone: +49 6428 4465-275<br />

Fax: +49 6428 4465-231<br />

E-Mail: contact@faudi-aviation.com<br />

Web: www.faudi-aviation.com<br />

DS-Z-3.2-EN_2-1 Page 1/1 Rev. 2.1

Z-3.5 Water Level Indicator<br />

Applications<br />

Water level indicator for mobile and stationary applications. For indicating the fluid level<br />

in tanks or vessels with a design pressure up to 40 bar.<br />

Total length<br />

Sight length<br />

Center<br />

ACCESSORIES<br />

Designed with sockets (Ø 20 mm) on the back side. Other sizes on request.<br />

The indicator is consisting of the support frame with a closed base, deck frame, sheet,<br />

seal, screws and sockets.<br />

Technical Details<br />

■ Temperatur Range: -20°C to +160°C, resp. -50°C to +200°C<br />

■ Sealing: - Klingersil C 4400 (for -20°C - +160°C)<br />

- Graphite/Tanged Steel (for -50°C - +200°C)<br />

■ Max. Design pressure: 16/40 bar<br />

■ Support Frame: Stainless Steel (1.4571)<br />

■ Deck Frame: Stainless Steel (1.4571)<br />

■ Fastening:<br />

Stud, Nut (Stainless Steel)<br />

■ Sheet:<br />

Borosilicate Glas DIN 7081, reflex<br />

Dimensions and Ordering Details<br />

Total Length<br />

in mm<br />

Sight Length<br />

in mm<br />

Center<br />

in mm *1<br />

Quantity of<br />

Screws<br />

Temperatur Range<br />

in °C<br />

*1<br />

Must be minimum 50 mm less than total length<br />

FAUDI Aviation GmbH Phone: +49 6428 4465-275<br />

Scharnhorststrasse 7 B Fax: +49 6428 4465-231<br />

D-35260 Stadtallendorf E-Mail: contact@faudi-aviation.com<br />

Germany<br />

Web: www.faudi-aviation.com<br />

Article Code<br />

(16 bar)<br />

Article Code<br />

(40 bar)<br />

170 120 120 8 -20 to +160 300 57 32 300 68 02<br />

170 120 120 8 -50 to +200 300 57 33 300 68 03<br />

250 200 200 12 -20 to +160 300 57 35 300 68 05<br />

250 200 200 12 -50 to +200 300 57 34 300 68 04<br />

DS-Z-3.5-EN_2-2 Page 1/1 Rev. 2.2

Z-4.1 Automatic High Efficiency Air Eliminator<br />

7<br />

2<br />

3<br />

6<br />

4<br />

8<br />

1<br />

FWE<br />

FW 6<br />

FW 8-S<br />

FW10-V<br />

FW 7<br />

FW10-H<br />

FW 8<br />

ACCESSORIES<br />

Construction<br />

The air eliminator consist of a casing (1) welded to the pressure vessel, cover (2), cover<br />

seal (3), main valve (6) with seal (7), servovalve (4) with seal (5) and bridge with rods<br />

and float ball (8).<br />

Function<br />

In an unfilled condition the float is in the low position. The servo valve and the main valve<br />

is opened filling the unit, the displaced air is discharged, the float shuts the servo and<br />

the main valve by means of the rods. In case of presences of air or gas bubbles during<br />

operation, the float of this double stage first opens the servo-valve and at high quantities<br />

of air the main valve with an opening diameter of 18 mm.<br />

Maintenance<br />

When the operation instruction is disregarded, troubles can occur. The interior of the unit<br />

is accessible for cleaning after removal of the cover. In case of malfunction the seals<br />

have to be renewed.<br />

Pos. Qty. Designation Material Article no. Spare<br />

part<br />

8 1 Rods with float ball GALSi/1.4571 900 725 3 X<br />

3 1 Cover seal (sealing ring) VITON ® 886 994 3 X<br />

5 1 O-ring for main valve VITON ® 920 822 4 X<br />

7 1 O.ring for servo valve VITON ® 920 827 3 X<br />

Subject<br />

to wear<br />

FAUDI Aviation GmbH<br />

Scharnhorststrasse 7 B<br />

D-35260 Stadtallendorf<br />

Germany<br />

Phone: +49 6428 4465-275<br />

Fax: +49 6428 4465-231<br />

E-Mail: contact@faudi-aviation.com<br />

Web: www.faudi-aviation.com<br />

DS-Z-4.1-EN_2-1 Page 1/1 Rev. 2.1

Z-4.3 Aeration and Deaeration Valve<br />

ACCESSORY<br />

Construction<br />

The aeration and deaeration valve consists of a housing completeley welded and a float ball made of<br />

stainless steel.<br />

Function<br />

In unfilled condition the float is in lower position and the deaeration valve is opened. When filling the<br />

pressure vessel the air escapes. When the liquid rises in the deaeration housing, the ball floats and the<br />

deaeration valve is closed. If air present during the operation process and thus descending of the ball, the<br />

valve opens for a short time so that the air can escape.<br />

Pos. Qty. Designation Material Article No.<br />

Spare<br />

Part<br />

1 1 Automatic Aeration Valve type 11-AV Stainless Steel 897 280 4 X<br />

2 1 Double nipple R¾“ Stainless Steel 884 778 2 X<br />

Subject to<br />

wear<br />

FAUDI Aviation GmbH<br />

Scharnhorststrasse 7 B<br />

D-35260 Stadtallendorf<br />

Germany<br />

Phone: +49 6428 44652 - 75<br />

Fax: +49 6428 44652 - 31<br />

E-Mail: contact@faudi-aviation.com<br />

Web: www.faudi-aviation.com<br />

DS-Z-4.3-EN_2-2 Page 1/1 Rev. 2.2

PSI<br />

bar<br />

2,0<br />

28<br />

1,8<br />

24<br />

1,6<br />

20<br />

1,4<br />

16<br />

1,2<br />

12<br />

1,0<br />

8<br />

0,8<br />

4<br />

0,4<br />

0<br />

0<br />

PSI<br />

bar<br />

2,0<br />

28<br />

1,8<br />

24<br />

1,6<br />

20<br />

1,4<br />

16<br />

1,2<br />

12<br />

1,0<br />

8<br />

0,8<br />

4<br />

0,4<br />

0<br />

0<br />

PSI<br />

bar<br />

2,0<br />

28<br />

1,8<br />

24<br />

1,6<br />

20<br />

1,4<br />

16<br />

1,2<br />

12<br />

1,0<br />

8<br />

0,8<br />

4<br />

0,4<br />

0<br />

0<br />

28<br />

24<br />

20<br />

16<br />

12<br />

8<br />

4<br />

0<br />

2,0<br />

1,8<br />

1,6<br />

1,4<br />

1,2<br />

1,0<br />

0,8<br />

0,4<br />

0<br />

Z-5.1 Piston Type Differential Pressure Gauge<br />

28<br />

24<br />

20<br />

16<br />

12<br />

8<br />

4<br />

0<br />

PSI<br />

bar<br />

2,0<br />

1,8<br />

1,6<br />

1,4<br />

1,2<br />

1,0<br />

0,8<br />

0,4<br />

0<br />

1<br />

4<br />

5<br />

FWE<br />

FW6<br />

3<br />

FW10-H<br />

FW10-H-T<br />

FW7-H<br />

3<br />

3<br />

3<br />

ACCESSORIES<br />

DD 3B<br />

FW10-V<br />

FW8-S<br />

FW9-S<br />

PSI bar 3<br />

2<br />

3<br />

3<br />

3<br />

Construction<br />

The differential pressure measuring device consists of the precision differential pressure<br />

gauge (1) with built in protective filter (2), the shutoff valves (3) and the connecting pipes.<br />

The unit allows the reading of the entire differential pressure (1st and 2nd stage) of a<br />

filter/water separator. In order to avoid a possible bursting of the glass cylinder by pressure<br />

formation due to heat influence, at least one shutoff valve must always be open.<br />

The device vents automatically. With the 3 way ball valve you can check the function of<br />

the differential pressure gauge.<br />

Maintenance<br />

If necessary, replace filter elements (2). Before opening and cleaning shut off the ball<br />

valves (3).<br />

Pos. Qty. Designation Material Article no. Spare<br />

part<br />

1 1 Piston differential pressure gauge AL 887 667 4 X<br />

2 1 Filter element for item (1) - 887 669 0 X<br />

3 2 Ball valve MS/VE/PTFE 300 320 6 X<br />

-<br />

4 1 Sight glass 300 307 3 X<br />

5 1 3-way ball valve MS/VE/PTFE 300 351 7 X<br />

FAUDI Aviation GmbH<br />

Scharnhorststrasse 7 B<br />

D-35260 Stadtallendorf<br />

Germany<br />

Phone: +49 6428 4465-275<br />

Fax: +49 6428 4465-231<br />

E-Mail: contact@faudi-aviation.com<br />

Web: www.faudi-aviation.com<br />

Subject<br />

to wear<br />

DS-Z-5.1-EN_2-1 Page 1/1 Rev. 2.1

28<br />

24<br />

20<br />

16<br />

12<br />

8<br />

4<br />

0<br />

PSI<br />

bar<br />

2,0<br />

1,8<br />

1,6<br />

1,4<br />

1,2<br />

1,0<br />

0,8<br />

0,4<br />

0<br />

28<br />

24<br />

20<br />

16<br />

12<br />

8<br />

4<br />

0<br />

PSI<br />

bar<br />

2,0<br />

1,8<br />

1,6<br />

1,4<br />

1,2<br />

1,0<br />

0,8<br />

0,4<br />

0<br />

28<br />

24<br />

20<br />

16<br />

12<br />

8<br />

4<br />

0<br />

PSI<br />

bar<br />

2,0<br />

1,8<br />

1,6<br />

1,4<br />

1,2<br />

1,0<br />

0,8<br />

0,4<br />

0<br />

28<br />

24<br />

20<br />

16<br />

12<br />

8<br />

4<br />

0<br />

PSI<br />

bar<br />

2,0<br />

1,8<br />

1,6<br />

1,4<br />

1,2<br />

1,0<br />

0,8<br />

0,4<br />

0<br />

Z-5.2 Piston Type Differential Pressure Gauge<br />

4<br />

~100<br />

PSI<br />

bar<br />

28<br />

2,0<br />

1,8<br />

24<br />

1,6<br />

20<br />

1,4<br />

16<br />

1,2<br />

12<br />

1,0<br />

8<br />

0,8<br />

4<br />

0,4<br />

0<br />

0<br />

3<br />

6<br />

1<br />

5<br />

3<br />

3<br />

3<br />

ACCESSORIES<br />

DD 3B<br />

2<br />

3 3<br />

3<br />

3<br />

Construction<br />

The differential pressure gauge measuring device consists of the precision differential<br />

pressure gauge (1) with protective filter (2), the built on proximity switch (4), the ball valves<br />

(3) and the connecting pipes. The device allows the reading of the total differential<br />

(1 st and 2 nd stage). In order to avoid the bursting of the glass cylinder by pressure formation<br />

due to heat influence, at least one ball valve must always be open. The device vents<br />

automatically. The proximity switch allows an automatic switching off or<br />

signaling when reaching or exceeding the maximum differential pressure. With the 3<br />

way ball valve you can check the function of the differential pressure gauge.<br />

Maintenance<br />

If necessary, replace filter elements (2). Before opening and cleaning shut the ball<br />

valves.<br />

Pos. Qty. Designation Material Article no. Spare<br />

part<br />

1 1 Piston differential pressure gauge AL 887 668 2 X<br />

2 1 Filter element for item (1) - 887 669 0 X<br />

3 2 Ball valve MS/VE/PTFE 300 320 6 X<br />

4 1 Proximity switch - 890 786 7 X<br />

5 1 Sight glass - X<br />

6 1 3-way ball valve MS/VE/PTFE 300 351 7<br />

Subject<br />

to wear<br />

FAUDI Aviation GmbH<br />

Scharnhorststrasse 7 B<br />

D-35260 Stadtallendorf<br />

Germany<br />

Phone: +49 6428 4465-275<br />

Fax: +49 6428 4465-231<br />

E-Mail: contact@faudi-aviation.com<br />

Web: www.faudi-aviation.com<br />

DS-Z-5.2-EN_2-0 Page 1/1 Rev. 2.0

28<br />

24<br />

20<br />

16<br />

12<br />

8<br />

4<br />

0<br />

PSI<br />

bar<br />

2,0<br />

1,8<br />

1,6<br />

1,4<br />

1,2<br />

1,0<br />

0,8<br />

0,4<br />

0<br />

28<br />

24<br />

20<br />

16<br />

12<br />

8<br />

4<br />

0<br />

PSI<br />

bar<br />

2,0<br />

1,8<br />

1,6<br />

1,4<br />

1,2<br />

1,0<br />

0,8<br />

0,4<br />

0<br />

28<br />

24<br />

20<br />

16<br />

12<br />

8<br />

4<br />

0<br />

PSI<br />

bar<br />

2,0<br />

1,8<br />

1,6<br />

1,4<br />

1,2<br />

1,0<br />

0,8<br />

0,4<br />

0<br />

Z-5.3 Piston Type Differential Pressure Gauge<br />

28<br />

24<br />

20<br />

16<br />

12<br />

8<br />

4<br />

0<br />

PSI<br />

bar<br />

2,0<br />

1,8<br />

1,6<br />

1,4<br />

1,2<br />

1,0<br />

0,8<br />

0,4<br />

0<br />

5<br />

1<br />

4<br />

FWE<br />

FW6<br />

FW10-H<br />

FW10-H-T<br />

FW 7<br />

-2<br />

+2<br />

+2<br />

3 3<br />

-1<br />

-1<br />

+1<br />

3<br />

-2<br />

+1<br />

3<br />

ACCESSORIES<br />

DD 3B<br />

FW10-V<br />

FW 8-S<br />

2<br />

-1<br />

Switching Shut-off valves<br />

open<br />

1 st stage +1 -1<br />

3<br />

+2<br />

+1 -2<br />

3<br />

2 nd stage +2 -2<br />

1 st & 2 nd stage +1 -2<br />

Construction<br />

The differential pressure measuring device consists of a precision differential pressure<br />

gauge (1) with built in protective filter (2), the ball valves (3) as well as the connection<br />

pipes. The unit allows measuring according to chart. In order to avoid a possible bursting<br />

of the glass cylinder by pressure formation due to heat influence, at least one ball valve<br />

must always be open. The advice vents automatically. With the 3 way ball valve you can<br />

check the function of the differential pressure gauge.<br />

Maintenance<br />

If necessary, replace filter element (2). Before opening and cleaning shut the ball valves<br />

(3).<br />

Pos. Qty. Designation Material Article no. Spare<br />

part<br />

1 1 Piston differential pressure gauge AL 887 667 4 X<br />

2 1 Filter element for item (1) - 887 669 0 X<br />

3 4 Ball valve MS/VE/PTFE 300 320 6 X<br />

4 1 Sight glass - 300 307 3 X<br />

5 1 3-way ball valve MS/VE/PTFE 300 351 7 X<br />

Subject<br />

to wear<br />

FAUDI Aviation GmbH<br />

Scharnhorststrasse 7 B<br />

D-35260 Stadtallendorf<br />

Germany<br />

Phone: +49 6428 4465-275<br />

Fax: +49 6428 4465-231<br />

E-Mail: contact@faudi-aviation.com<br />

Web: www.faudi-aviation.com<br />

DS-Z-5.3-EN_2-0 Page 1/1 Rev. 2.0

28<br />

24<br />

20<br />

16<br />

12<br />

8<br />

4<br />

0<br />

PSI<br />

bar<br />

2,0<br />

1,8<br />

1,6<br />

1,4<br />

1,2<br />

1,0<br />

0,8<br />

0,4<br />

0<br />

28<br />

24<br />

20<br />

16<br />

12<br />

8<br />

4<br />

0<br />

PSI<br />

bar<br />

2,0<br />

1,8<br />

1,6<br />

1,4<br />

1,2<br />

1,0<br />

0,8<br />

0,4<br />

0<br />

28<br />

24<br />

20<br />

16<br />

12<br />

8<br />

4<br />

0<br />

PSI<br />

bar<br />

2,0<br />

1,8<br />

1,6<br />

1,4<br />

1,2<br />

1,0<br />

0,8<br />

0,4<br />

0<br />

Z-5.4 Piston Type Differential Pressure Gauge<br />

4<br />

~100<br />

PSI<br />

bar<br />

28<br />

2,0<br />

1,8<br />

24<br />

1,6<br />

20<br />

1,4<br />

16<br />

1,2<br />

12<br />

1,0<br />

8<br />

0,8<br />

4<br />

0,4<br />

0<br />

0<br />

3<br />

6<br />

1<br />

5<br />

3<br />

3<br />

3<br />

ACCESSORIES<br />

DD 3B<br />

Switching Shut-off valves<br />

1 st stage +1 -1<br />

2 nd stage +2 -2<br />

1 st & 2 nd stage +1 -2<br />

2<br />

3 3<br />

Construction<br />

The differential pressure measuring device consists of a precision differential pressure<br />

gauge (1) withbuilt in protective filter (2), the built on approximation initiator (4), the ball<br />

valves (3) as well as the connecting pipe lines. The unit allows measuring according to<br />

chart. In order to avoid a possible bursting of the glass cylinder by pressure formation<br />

due to heat influence, at least one ball valve must always be open. The device vents<br />

automatically. The approximation initiator allows an automatic switching off or signaling<br />

when reaching or exceeding the maximum differential pressure. With the 3 way ball valve<br />

you can check the function of the differential pressure gauge.<br />

Maintenance<br />

If necessary, replace filter element (2). Before opening and cleaning shut the ball valves<br />

(3).<br />

Pos. Qty. Designation Material Article no. Spare<br />

part<br />

1 1 Piston differential pressure gauge AL 887 668 2 X<br />

2 1 Filter element for item (1) - 887 669 0 X<br />

3 4 Ball valve MS/VE/PTFE 887 610 4 X<br />

4 1 Proximity switch 890 786 7<br />

5 1 Sight glass - 300 320 6 X<br />

6 1 3-way ball valve MS/VE/PTFE 300 351 7 X<br />

Subject<br />

to wear<br />

FAUDI Aviation GmbH<br />

Scharnhorststrasse 7 B<br />

D-35260 Stadtallendorf<br />

Germany<br />

Phone: +49 6428 4465-275<br />

Fax: +49 6428 4465-231<br />

E-Mail: contact@faudi-aviation.com<br />

Web: www.faudi-aviation.com<br />

DS-Z-5.4-EN_2-0 Page 1/1 Rev. 2.0

0<br />

1<br />

2<br />

3<br />

4.1<br />

5<br />

10<br />

15<br />

20<br />

25<br />

30<br />

psi<br />

DD 3B<br />

0<br />

0,1<br />

0,2<br />

0,28<br />

0,5<br />

1<br />

1,5<br />

2<br />

bar<br />

0<br />

1<br />

2<br />

3<br />

4.1<br />

5<br />

10<br />

15<br />

20<br />

25<br />

30<br />

psi<br />

DD 3B<br />

0<br />

0,1<br />

0,2<br />

0,28<br />

0,5<br />

1<br />

1,5<br />

2<br />

bar<br />

0<br />

1<br />

2<br />

3<br />

4.1<br />

5<br />

10<br />

15<br />

20<br />

25<br />

30<br />

psi<br />

DD 3B<br />

0<br />

0,1<br />

0,2<br />

0,28<br />

0,5<br />

1<br />

1,5<br />

2<br />

bar<br />

Z-5.5 Piston Type Differential Pressure Gauge<br />

2 1<br />

2<br />

0<br />

1<br />

2<br />

3<br />

4.1<br />

5<br />

10<br />

15<br />

20<br />

25<br />

30<br />

psi<br />

DD 2B<br />

0<br />

0,1<br />

0,2<br />

0,28<br />

0,5<br />

1<br />

1,5<br />

2 1<br />

2<br />

bar<br />

3<br />

6<br />

1<br />