Bogie Overhaul Service - Unipart Rail

Bogie Overhaul Service - Unipart Rail

Bogie Overhaul Service - Unipart Rail

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

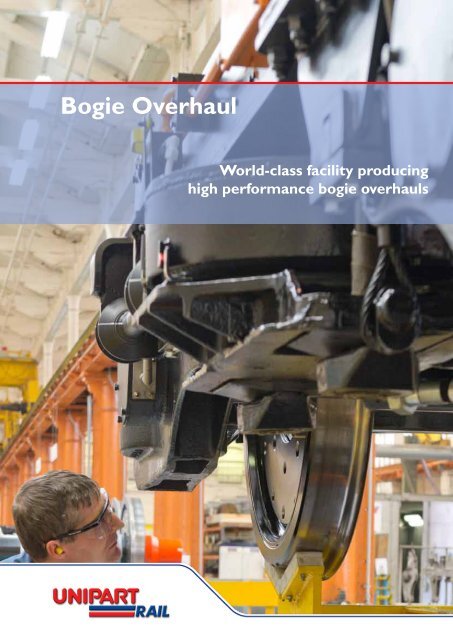

<strong>Bogie</strong> <strong>Overhaul</strong><br />

World-class facility producing<br />

high performance bogie overhauls

<strong>Unipart</strong> <strong>Rail</strong><br />

<strong>Bogie</strong> <strong>Overhaul</strong> <strong>Service</strong><br />

<strong>Unipart</strong> <strong>Rail</strong> provides a complete ‘depot to depot’ bogie overhaul service<br />

to train operators and owners, delivering highly reliable quality bogie<br />

performance across the complete overhaul cycle.<br />

World Class<br />

Facilities and Workforce<br />

Situated at the heart of the UK <strong>Rail</strong> network, our<br />

world-class facility has the capacity to overhaul over<br />

1200 bogies a year.<br />

In 2010 <strong>Unipart</strong> <strong>Rail</strong> overhauled and repaired over<br />

960 bogies. The range of bogies is extensive with<br />

<br />

types to present day high speed new era trains.<br />

Our extensive procurement and bogie overhaul<br />

experience enables us to take responsibility for<br />

managing the entire supply chain to ensure the<br />

overhaul programme meets our customers’<br />

availability requirements and are completed on time<br />

within budget.<br />

Experienced engineers work with our customers<br />

to help solve any technical issues that arise during<br />

the programme. They are further able to add<br />

value, by assessing the condition of the assets and<br />

components with a view of extending life and<br />

maintenance periodicity, as well as re-engineering<br />

obsolete components.<br />

Our workforce is the lifeblood of our business and are key to our success, the strong team ethic helps to produce<br />

a product to be proud of. Our workforce fully embraces our company’s continuous improvement culture and are<br />

totally engaged in providing the best possible service and products to our customers.<br />

<br />

bogie overhaul.<br />

Collaborative Approach<br />

We have the capacity to overhaul all bogie types<br />

working to the exacting standards and engineering<br />

<br />

We believe that the relationship we develop<br />

with our customers should be based on effective<br />

communication, close collaboration and co-operation.<br />

At <strong>Unipart</strong> <strong>Rail</strong> we understand that every customer’s<br />

requirements can be different. It is only by working<br />

collaboratively that we can fully understand their<br />

maintenance needs and respond with a creative solution<br />

<br />

An integrated partnership approach provides the biggest<br />

<br />

jointly agree business aims and projects that will provide<br />

the desired breakthrough of improvements.<br />

Our highly experienced project managers will work<br />

with you to ensure that all your requirements are met.<br />

Our project managers will communicate with you every<br />

step of the way ensuring any issues are resolved in a<br />

proactive, structured and responsive manner allowing<br />

<br />

the knowledge that your project is in capable hands.

Key elements of the <strong>Bogie</strong> <strong>Overhaul</strong> Process<br />

Wash<br />

Oil, grease and soil are removed using two high<br />

pressure, hot water, 1detergent mix pressure<br />

washers enabling two bogies to be cleaned at<br />

once. The working environment is controlled<br />

by ventilation providing sixty air changes per<br />

<br />

for settlement of solids and via a separator to<br />

collect hydrocarbons.<br />

Dismantle<br />

Raised rails facilitate a comfortable effective<br />

working height. <strong>Bogie</strong>s are stripped into<br />

component parts using 2mechanical and hydraulic<br />

pullers to maintain component integrity. All<br />

components are sorted and are placed directly<br />

into appropriate containers eliminating the need<br />

for re-handling and minimising lead-time and<br />

<br />

Shot Blast<br />

Components are blasted 3in our purpose-built<br />

shot blast facility. Two bogie frames can be<br />

processed simultaneously. G17 chilled cast iron<br />

<br />

recycled during operation enabling a continuous<br />

shot blasting process.<br />

Manipulators<br />

<br />

<br />

mounting various bogie types. Manipulators lift<br />

and lower bogie frames to enable the inspection.<br />

Repair and assembly to be carried out safely and<br />

<br />

4<br />

5<br />

Secondary Suspension Air<br />

Bag Tester<br />

6<br />

<br />

<br />

<br />

later assembly stages.<br />

Bracket Alignment<br />

Axle box pivot brackets can be aligned on the<br />

bogie frame to tight tolerances to eliminate axial<br />

load in wheel bearings.<br />

Bolster Jig<br />

7<br />

We use specially designed handling equipment, including the<br />

bolster jig, to ensure that bogie parts travel smoothly through<br />

the process to further protect component integrity.<br />

Dispatch and Delivery<br />

Prior to despatch all bogies are inspected,<br />

strapped and<br />

12<br />

sheeted to prevent damage during<br />

transit. All relevant documentation are provided<br />

in a pack for the convenience of our customers.<br />

Our logistic partner, works in with us to deliver<br />

bogies to our customers’ schedules, ensuring a<br />

<br />

<strong>Bogie</strong> Press and Wheel<br />

Weighting<br />

The bogie press comprises a twin ram hydraulic<br />

<br />

max load.<br />

11<br />

A twin ram and four identical wheel load cells<br />

are used to accurately set the wheel load<br />

distribution and enable the bogie height to be<br />

set to the individual vehicle type.<br />

Assembly<br />

Equipped with<br />

10<br />

a manipulator, raised rails and<br />

a Faro Arm to complete the alignment process,<br />

<br />

dedicated tools. Materials are provided as<br />

kits to reduce the amount of movement and<br />

transportation required during the assembly<br />

process.<br />

Spray Booths<br />

Used for both paint 9application and curing with a<br />

low bake mode, the air assisted paint application<br />

system achieves high volume controlled spraying<br />

with Copon water-based paint. This produces a<br />

<br />

and low environmental impact.<br />

Spring Tester<br />

This equipment is designed 8to measure both<br />

Chevron and Coil springs. With a maximum load<br />

of six tonnes, the force applied is displayed in<br />

kN on a digital readout to accurately determine<br />

spring integrity and packing heights.

Main Features<br />

Scope of Work<br />

In-house engineering support<br />

Provison of specialist support<br />

services<br />

Component <strong>Overhaul</strong><br />

We will work with you from the outset; agreeing<br />

the scope of work in line with your maintenance<br />

requirements.<br />

Our production process is designed to be tailoured<br />

to your requirements. We offer a quick turnaround<br />

of bogies to enable you to minimise the downtime<br />

<br />

requirements.<br />

<br />

you to improve it. If you need to extend your overhaul<br />

periodicity, we will work with you to do so effectively<br />

<br />

Our engineering support teams are able to solve any<br />

technical issues that arise during the programme. They<br />

are further able to add value by assessing the condition<br />

of the assets and components with a view of extending<br />

life, as well as re-engineering obsolete components.<br />

Our Engineers have many years experience working<br />

in the rail industry. This experience as we seek to<br />

implement improvements to the design that increase<br />

reliability, extend maintenance periodicities and extend<br />

the design life; without compromising safety.<br />

We have the skills base to offer any heavy engineering<br />

<br />

<br />

<br />

We have a large and highly trained workforce and<br />

we have invested in a structured apprentice training<br />

program to ensure new talent is brought into the<br />

business.<br />

Our extensive rail industry experience and<br />

comprehensive network of approved suppliers ensures<br />

that the components are overhauled to the latest<br />

industry standards, delivering trouble free and reliable<br />

performance throughout the component life cycle.<br />

Our engineers also make improvements to the design<br />

of components and systems to prevent future failure.<br />

Re-engineering of obsolete<br />

components<br />

Access to a global supply base<br />

A continuous improvement and<br />

Lean philosophy<br />

Integrated depot to depot bogie<br />

transport service<br />

Components that are used in locomotives can rapidly<br />

go out of production or become obsolete (sometimes<br />

<br />

Our specialist in-house engineering team is able to<br />

work with you to identify the origin of a particular part,<br />

even where this is not immediately obvious. We can<br />

work with our specialist supply base to re-engineer<br />

a component, for example if the production of a<br />

particular component has been made obsolete or the<br />

original manufacturer no longer exists.<br />

Our procurement teams source items required to<br />

<br />

<br />

experts have many years’ experience dealing with<br />

major international suppliers building long-standing<br />

relationships.<br />

In many instances where we re-source a component<br />

from a supplier, it is not just a case of ensuring<br />

<br />

improvements in technology to improve both the<br />

materials and the service to our customers.<br />

Every business needs a set of principles that guides it.<br />

Ours is called The <strong>Unipart</strong> Way.<br />

It is more than a set of tools and techniques – it is<br />

a way of working that engages our and your people,<br />

committing them to world-class performance and a<br />

culture of sustained continuous improvement.<br />

Using the ‘Lean’ and continuous improvement expertise,<br />

our bogie overhaul process is designed to place quality<br />

and on-time delivery at the heart of its objectives. This<br />

enables us to supply on time, every time.<br />

Working in partnership with our logistics partner we<br />

offer a full range of integrated bogie transport services.<br />

We help our clients to cut costs, drive year-on-year<br />

continuous improvement, focus on carbon reduction<br />

and create supply chain visibility.<br />

<br />

latest technology providing you with instant visibility of<br />

delivery progress.

About <strong>Unipart</strong><br />

<strong>Unipart</strong> Group is a leading third party logistics provider and a consultant in operational excellence. Operating across<br />

a range of market sectors including automotive, leisure, marine, manufacturing, mobile telecoms, rail, retail and<br />

technology, <strong>Unipart</strong> offers a breadth of services from third party logistics to expert consultancy worldwide.<br />

At the heart of our culture is The <strong>Unipart</strong> Way, our company philosophy.<br />

Walk into any <strong>Unipart</strong> global facility and the difference is clear. In every aspect of our business, teams of people are<br />

using a consistent, integrated Lean toolkit aligned within The <strong>Unipart</strong> Way culture that empowers them to deliver<br />

more for their customers.<br />

Contact us:<br />

For Traction & Rolling Stock information:<br />

<strong>Unipart</strong> <strong>Rail</strong><br />

Jupiter Building, First Point<br />

Balby Carr Bank, Doncaster, DN4 5JQ<br />

<br />

<br />

For information on<br />

Infrastructure:<br />

<strong>Unipart</strong> <strong>Rail</strong><br />

Gresty Road<br />

Crewe<br />

Cheshire, CW2 6EH<br />

<br />

<br />

<br />

<strong>Unipart</strong> <strong>Rail</strong><br />

Leeman Road<br />

York<br />

North Yorkshire, YO26 4ZD<br />

<br />

<br />

enquiries@unipartrail.com<br />

<br />

<strong>Unipart</strong><br />

Sudfeld 7A<br />

59174 Kamen<br />

Deutschland<br />

<br />

<br />

informationen@unipartrail.de<br />

www.unipartrail.de<br />

<br />

<strong>Unipart</strong> <strong>Rail</strong><br />

1 Tyrone Place<br />

Erskine Park NSW 1790<br />

Postal Address<br />

<br />

St. Marys NSW 1790<br />

<br />

<br />

<br />

<br />

209/1 Asoke Road<br />

Klongtoey Nua<br />

Wattana<br />

Bangkok 10110<br />

Thailand<br />

<br />

<br />

<br />

Bath<br />

Ontario<br />

K0H 1G0<br />

Canada<br />

<br />

For information on LED<br />

Signalling & Lighting:<br />

<strong>Unipart</strong> Dorman<br />

Wennington Road<br />

Southport<br />

Merseyside, PR9 7TN<br />

<br />

<br />

dorman.info@uni[partdorman.co.uk<br />

www.unipartdorman.co.uk<br />

<br />

Rivval<br />

Drumconrath Road<br />

Carrickasedge<br />

Carrickmacross<br />

Co. Monaghan<br />

Ireland<br />

<br />

<br />

<strong>Unipart</strong> <strong>Rail</strong><br />

<br />

<br />

<br />

Chancheng District<br />

Foshan<br />

Guangdong<br />

<br />

<br />

Email: trsenquiries@unipartrail.co.uk<br />

UK website: www.unipartrail.co.m<br />

Copyright © <strong>Unipart</strong> <strong>Rail</strong><br />

Issue 1 September 2012<br />

Scan here for<br />

more information