New Danfoss VLT® Decentral Drive E cient, reliable and powerful

New Danfoss VLT® Decentral Drive E cient, reliable and powerful

New Danfoss VLT® Decentral Drive E cient, reliable and powerful

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

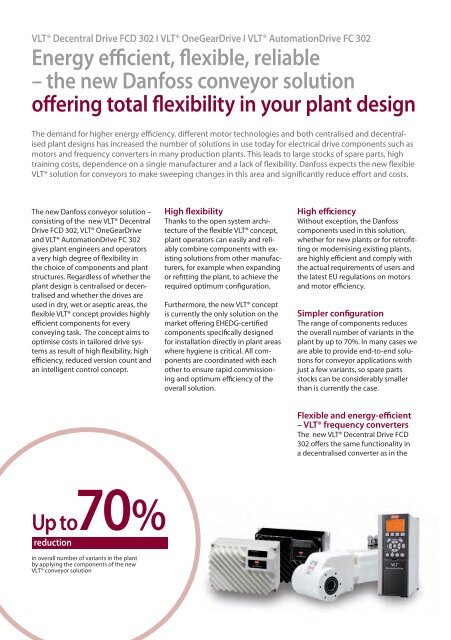

VLT® <strong>Decentral</strong> <strong>Drive</strong> FCD 302 I VLT® OneGear<strong>Drive</strong> I VLT® Automation<strong>Drive</strong> FC 302<br />

Energy effi<strong>cient</strong>, flexible, <strong>reliable</strong><br />

– the new <strong>Danfoss</strong> conveyor solution<br />

offering total flexibility in your plant design<br />

The dem<strong>and</strong> for higher energy efficiency, different motor technologies <strong>and</strong> both centralised <strong>and</strong> decentralised<br />

plant designs has increased the number of solutions in use today for electrical drive components such as<br />

motors <strong>and</strong> frequency converters in many production plants. This leads to large stocks of spare parts, high<br />

training costs, dependence on a single manufacturer <strong>and</strong> a lack of flexibility. <strong>Danfoss</strong> expects the new flexible<br />

VLT® solution for conveyors to make sweeping changes in this area <strong>and</strong> significantly reduce effort <strong>and</strong> costs.<br />

The new <strong>Danfoss</strong> conveyor solution –<br />

consisting of the new VLT® <strong>Decentral</strong><br />

<strong>Drive</strong> FCD 302, VLT® OneGear<strong>Drive</strong><br />

<strong>and</strong> VLT® Automation<strong>Drive</strong> FC 302<br />

gives plant engineers <strong>and</strong> operators<br />

a very high degree of flexibility in<br />

the choice of components <strong>and</strong> plant<br />

structures. Regardless of whether the<br />

plant design is centralised or decentralised<br />

<strong>and</strong> whether the drives are<br />

used in dry, wet or aseptic areas, the<br />

flexible VLT® concept provides highly<br />

effi<strong>cient</strong> components for every<br />

conveying task. The concept aims to<br />

optimise costs in tailored drive systems<br />

as result of high flexibility, high<br />

efficiency, reduced version count <strong>and</strong><br />

an intelligent control concept.<br />

High flexibility<br />

Thanks to the open system architecture<br />

of the flexible VLT® concept,<br />

plant operators can easily <strong>and</strong> reliably<br />

combine components with existing<br />

solutions from other manufacturers,<br />

for example when exp<strong>and</strong>ing<br />

or refitting the plant, to achieve the<br />

required optimum configuration.<br />

Furthermore, the new VLT® concept<br />

is currently the only solution on the<br />

market offering EHEDG-certified<br />

components specifically designed<br />

for installation directly in plant areas<br />

where hygiene is critical. All components<br />

are coordinated with each<br />

other to ensure rapid commissioning<br />

<strong>and</strong> optimum efficiency of the<br />

overall solution.<br />

High efficiency<br />

Without exception, the <strong>Danfoss</strong><br />

components used in this solution,<br />

whether for new plants or for retrofitting<br />

or modernising existing plants,<br />

are highly effi<strong>cient</strong> <strong>and</strong> comply with<br />

the actual requirements of users <strong>and</strong><br />

the latest EU regulations on motors<br />

<strong>and</strong> motor efficiency.<br />

Simpler configuration<br />

The range of components reduces<br />

the overall number of variants in the<br />

plant by up to 70%. In many cases we<br />

are able to provide end-to-end solutions<br />

for conveyor applications with<br />

just a few variants, so spare parts<br />

stocks can be considerably smaller<br />

than is currently the case.<br />

Flexible <strong>and</strong> energy-effi<strong>cient</strong><br />

– VLT® frequency converters<br />

The new VLT® <strong>Decentral</strong> <strong>Drive</strong> FCD<br />

302 offers the same functionality in<br />

a decentralised converter as in the<br />

Up to70%<br />

reduction<br />

in overall number of variants in the plant<br />

by applying the components of the new<br />

VLT® conveyor solution