Technical Data - Power Stow

Technical Data - Power Stow

Technical Data - Power Stow

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

info@powerstow.com • www.powerstow.com • +45 46 31 10 32<br />

S. 1<br />

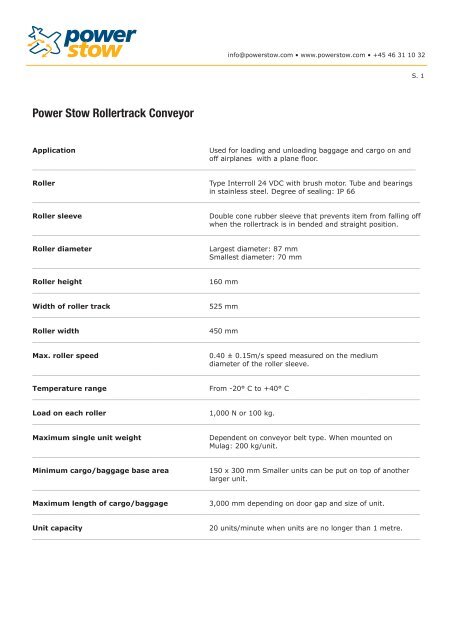

<strong>Power</strong> <strong>Stow</strong> Rollertrack Conveyor<br />

Application<br />

Used for loading and unloading baggage and cargo on and<br />

off airplanes with a plane floor.<br />

________________________________________________________________________________________<br />

Roller<br />

Type Interroll 24 VDC with brush motor. Tube and bearings<br />

in stainless steel. Degree of sealing: IP 66<br />

_________________________________________________________________________________________<br />

Roller sleeve<br />

Double cone rubber sleeve that prevents item from falling off<br />

when the rollertrack is in bended and straight position.<br />

_________________________________________________________________________________________<br />

Roller diameter<br />

Largest diameter: 87 mm<br />

Smallest diameter: 70 mm<br />

_________________________________________________________________________________________<br />

Roller height<br />

160 mm<br />

_________________________________________________________________________________________<br />

Width of roller track<br />

525 mm<br />

_________________________________________________________________________________________<br />

Roller width<br />

450 mm<br />

_________________________________________________________________________________________<br />

Max. roller speed<br />

0.40 ± 0.15m/s speed measured on the medium<br />

diameter of the roller sleeve.<br />

_________________________________________________________________________________________<br />

Temperature range<br />

From -20° C to +40° C<br />

_________________________________________________________________________________________<br />

Load on each roller<br />

1,000 N or 100 kg.<br />

_________________________________________________________________________________________<br />

Maximum single unit weight<br />

Dependent on conveyor belt type. When mounted on<br />

Mulag: 200 kg/unit.<br />

_________________________________________________________________________________________<br />

Minimum cargo/baggage base area<br />

150 x 300 mm Smaller units can be put on top of another<br />

larger unit.<br />

_________________________________________________________________________________________<br />

Maximum length of cargo/baggage<br />

3,000 mm depending on door gap and size of unit.<br />

_________________________________________________________________________________________<br />

Unit capacity<br />

20 units/minute when units are no longer than 1 metre.<br />

_________________________________________________________________________________________

info@powerstow.com • www.powerstow.com • +45 46 31 10 32<br />

S. 2<br />

Rollertrack Conveyor chain link<br />

Speed in/out<br />

0.35 m/s<br />

_________________________________________________________________________________________<br />

Chain link<br />

Stainless steel<br />

Hollow chain links. Protect all wires. Every chain link can be<br />

individually replaced.<br />

_________________________________________________________________________________________<br />

Distance between links<br />

139.7 mm<br />

_________________________________________________________________________________________<br />

Rollers per link 1<br />

_________________________________________________________________________________________<br />

Horizontal angle between links 11.3°<br />

_________________________________________________________________________________________<br />

Vertical angle up between links 35.0°<br />

_________________________________________________________________________________________<br />

Vertical angle down between links 38.0°<br />

_________________________________________________________________________________________

info@powerstow.com • www.powerstow.com • +45 46 31 10 32<br />

S. 3<br />

Loading/unloading head<br />

Length<br />

600 mm<br />

_________________________________________________________________________________________<br />

Height from nose roller to floor<br />

45 mm above floor<br />

_________________________________________________________________________________________<br />

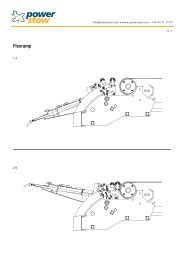

Flexramp<br />

Angular slope of door sill ± 10.0°<br />

_________________________________________________________________________________________<br />

Maximum angular slope of belt conveyer + 25.0°<br />

_________________________________________________________________________________________<br />

Minimum angular slope of belt conveyer - 5.0°<br />

_________________________________________________________________________________________

info@powerstow.com • www.powerstow.com • +45 46 31 10 32<br />

S. 4<br />

Control<br />

Roller track sections<br />

Sections of maximum 15 rollers start individually when<br />

needed.<br />

_________________________________________________________________________________________<br />

Roller fusing<br />

Each roller is connected to a thermal fuse to protect the<br />

roller motors.<br />

_________________________________________________________________________________________<br />

Roller control<br />

The rollers are controlled by pulse wide modulation for<br />

acceleration and deceleration and current limiting.<br />

_________________________________________________________________________________________<br />

Roller track in/out controls<br />

The roller tracks are controlled by pulse wide modulation for<br />

acceleration and deceleration and current limiting<br />

_________________________________________________________________________________________<br />

Roller track and conveyer stop<br />

To save power the roller track and the conveyer will stop if<br />

no baggage or cargo has passed a sensor in one minute.<br />

_________________________________________________________________________________________<br />

Display<br />

Shows the number of pieces or cargo that have passed the<br />

conveyor sensor, both when loading and unloading.<br />

_________________________________________________________________________________________<br />

Level sensing<br />

Automatic adjustment of conveyer height to make sure the<br />

flexramp between the conveyer and the aircraft is horizontal.<br />

_________________________________________________________________________________________<br />

Conveyor and roller controls<br />

Single-switch control of start, stop, direction and speed of<br />

the roller and the conveyer. Speed can only be adjusted in<br />

the baggage / cargo receiving end.<br />

_________________________________________________________________________________________