Fire-fighting Units

Fire-fighting Units

Fire-fighting Units

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

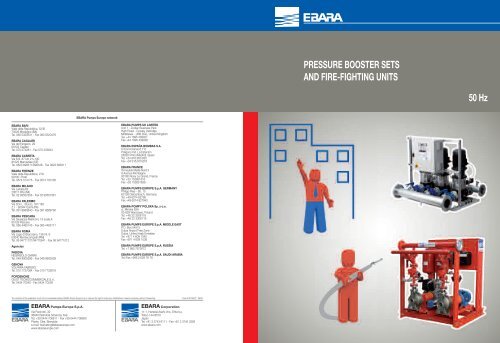

PRESSURE BOOSTER SETS<br />

AND FIRE-FIGHTING UNITS<br />

50 Hz<br />

EBARA Pumps Europe network<br />

EBARA BARI<br />

Viale della Repubblica, 52/B<br />

70026 Modugno (BA)<br />

Tel. 080 5320531 - Fax 080 5320478<br />

EBARA CAGLIARI<br />

Via del Fangario, 29<br />

09122 Cagliari<br />

Tel. 070 274281 - Fax 070 253643<br />

EBARA CASERTA<br />

Via S.S. 87 km 21+100<br />

81025 Marcianise (CE)<br />

Tel. 0823 696511/696346 - Fax 0823 696411<br />

EBARA FIRENZE<br />

Viale della Repubblica, 279<br />

59100 Prato<br />

Tel. 0574 514175 - Fax 0574 700126<br />

EBARA MILANO<br />

Via Lainate,62<br />

20017 Rho (MI)<br />

Tel. 02 93507358 - Fax 02 93507361<br />

EBARA PALERMO<br />

Via Don L. Sturzo, 181/183<br />

Z.I. - 90044 Carini (PA)<br />

Tel. 091 8680840 - Fax 091 8669790<br />

EBARA PESCARA<br />

Via Giuseppe Misticoni, 13 scala A<br />

65129 Pescara<br />

Tel. 085 4465145 - Fax 085 4465171<br />

EBARA ROMA<br />

Via Lago di Bracciano, 138 Int. 6<br />

00040 Montecompatri (RM)<br />

Tel. 06 94771127/94770541 - Fax 06 94771012<br />

Agencies<br />

PADOVA<br />

NEGRISOLO GIANNI<br />

Tel. 049 9900296 - Fax 049 9903539<br />

GENOVA<br />

VOLPARA FABRIZIO<br />

Tel. 010 7727084 - Fax 010 7729018<br />

PORDENONE<br />

GIUST TECNOCOMMERCIALE S.r.l.<br />

Tel. 0434 70040 - Fax 0434 70239<br />

EBARA PUMPS UK LIMITED<br />

Unit 7 - Zodiac Business Park<br />

High Road - Cowley Uxbridge<br />

Middlesex - UB8 2GU, United Kingdom<br />

Tel. +44 1895 439027<br />

Fax +44 1895 439028<br />

EBARA ESPAÑA BOMBAS S.A.<br />

C/Cormoranes 6 Y 8<br />

Poligono Ind. La Estación<br />

28320 Pinto (Madrid), Spain<br />

Tel. +34 916.953.630<br />

Fax +34 916.910.818<br />

EBARA FRANCE<br />

Immeuble Maille Nord II<br />

8 Avenue Montaigne<br />

93160 Noisy Le Grand, France<br />

Tel. +33 155851616<br />

Fax +33 155851639<br />

EBARA PUMPS EUROPE S.p.A. GERMANY<br />

Philipp-Reis - Str. 15<br />

63128 Dietzenbach, Germany<br />

Tel. +49 6074 82790<br />

Fax +49 6074 827942<br />

EBARA POMPY POLSKA Sp. z o.o.<br />

ul. Minska 63A<br />

03-828 Warszawa, Poland<br />

Tel. +48 22 3308118<br />

Fax +48 22 3308119<br />

EBARA PUMPS EUROPE S.p.A. MIDDLE EAST<br />

P.O. Box 54515<br />

Dubai Airport Free Zone<br />

Dubai, United Arab Emirates<br />

Tel. +971 4 609 1040<br />

Fax +971 4 609 1038<br />

EBARA PUMPS EUROPE S.p.A. RUSSIA<br />

Tel. +7 985 7672672<br />

EBARA PUMPS EUROPE S.p.A. SAUDI ARABIA<br />

Tel./Fax +966 2 629 76 78<br />

The contents of this publication must not be considered binding. EBARA Pumps Europe S.p.A. reserves the right to make any modifications it deems necessary without forewarning. Code 479705422 09/09<br />

EBARA Pumps Europe S.p.A.<br />

Via Pacinotti, 32<br />

36040 Brendola (Vicenza), Italy<br />

Tel. +39 0444 706811 - Fax +39 0444 706950<br />

Plants: Cles, Brendola<br />

e-mail: marketing@ebaraeurope.com<br />

www.ebaraeurope.com<br />

EBARA Corporation<br />

11-1, Haneda Asahi-cho, Ohta-ku,<br />

Tokyo 144-8510<br />

Japan<br />

Tel. +81 3 3743 6111 - Fax +81 3 3745 3356<br />

www.ebara.com

INDEX<br />

PRESSURE BOOSTING<br />

DOMESTIC PRESSURE BOOSTING at fixed speed (GP)<br />

Introduction 2<br />

2GP AGA 6<br />

2GP CDA 9<br />

2GP 2CDX 12<br />

2GP COMPACT 15<br />

2GP MATRIX 18<br />

2GP CVM 22<br />

2GP HVM 26<br />

3GP CVM 29<br />

3GP HVM 33<br />

DOMESTIC PRESSURE BOOSTING at variable speed (GPE)<br />

2GPE COMPACT 36<br />

2GPE MATRIX 39<br />

2GPE CVM 43<br />

2GPE HVM 47<br />

INDUSTRIAL PRESSURE BOOSTING at fixed speed (GP)<br />

2GP 3M 50<br />

2GP EVMG 57<br />

3GP 3M 69<br />

3GP EVMG 76<br />

INDUSTRIAL PRESSURE BOOSTING at variable speed (GPE)<br />

2GPE 3M 88<br />

2GPE EVMG 95<br />

3GPE 3M 107<br />

3GPE EVMG 114<br />

Electric control panels 126<br />

FIRE-FIGHTING<br />

PUMPS BASE-JOINT (3PS - ENRS)<br />

General considerations regarding the UNI EN 12845 Standard 130<br />

<strong>Fire</strong>-<strong>fighting</strong> introduction 132<br />

FFS-FFBE electric pump 140<br />

FFBD motor pump 151<br />

FFBD electric pump + motor pump 156<br />

VERTICAL MULTISTAGE PUMPS (EVMG)<br />

FFS electric pump 159<br />

SUBMERSED PUMPS (SF6 - WINNER 4N15 - BHE)<br />

FFS-S hydraulic elements kit 168<br />

Electric control panels 177<br />

Technical appendix 184<br />

Your Life, our Quality. Worldwide. 1 Booster & <strong>Fire</strong>-Fighting

GP - GPE<br />

PRESSURE BOOSTER UNITS<br />

use of the same.<br />

N.B. By connecting a float or minimum pressure pressure switch to<br />

the control panel (whether for withdrawal from the primary<br />

collection reservoir or from the hydraulic circuit), the most frequent<br />

cause of electric pump breakdown is prevented: the lack of water at<br />

suction.<br />

DEFINITION AND USE<br />

OF THE PRESSURE BOOSTER UNITS<br />

If the public water distribution system is inexistent or insufficient for<br />

correct functioning of the utilities, it is necessary to install a<br />

pressure boosting unit in order to guarantee an acceptable pressure<br />

and amount of water also in the most unfavourable points of use.<br />

The pressure boosting unit is applied every time the pressure must<br />

be increases or where the mains water must be pressurised.<br />

The GPs, EBARA pressure boosting units, are small automatic<br />

systems with 2 or more pumps in parallel, studied and realised<br />

simply and reliably to satisfy the most recurrent pressure<br />

maintenance requests in the water supply of condominiums, hotels,<br />

centres, offices, schools, auxiliary services in the industrial and<br />

agricultural ambit. They are distinguished for the construction<br />

strength, compactness, high efficiency and silence.<br />

The GP units are set-up for the membrane autoclaves or air pocket<br />

connection.<br />

Start-up of the individual pumps is caused by the activation of<br />

pressure switches, appropriately calibrated via an electric control<br />

panel. In the units controlled with electric control panel with<br />

INVERTER, as well as pressure switches, one of the pumps is started<br />

via the calibration of a pressure transducer.<br />

FUNCTIONING PRINCIPLE<br />

OF THE PRESSURE BOOSTER UNIT GP<br />

If water is requested, this is initially withdrawn from the autoclave<br />

reservoir, whenever the system is provided.<br />

This consumption of water or, however, the escape of water from<br />

the system, with pumps off, determines the lowering of the<br />

pressure to a value such to trip the closure of the pressure switch<br />

contact with higher calibration, which determines the ignition of<br />

the first electric pump.<br />

If the outlet discharge exceeds the flow rate of a pump, the<br />

pressure continues to drop until it causes the closure of the contact<br />

of the second pressure switch and the start-up of the second pump.<br />

This takes place for all of the electric pumps that make up the unit.<br />

The end of the distribution of the reduction of the outlet discharge<br />

leads to the pressure in the system rising, with opening of the<br />

pressure switch contacts and staggered pumps stops. The inversion<br />

of the ignition order of the motors reduces the number of hourly<br />

start-ups of the individual pumps and consequently a homogenous<br />

FUNCTIONING PRINCIPLE<br />

OF THE PRESSURE BOOSTING UNIT GPE<br />

The GPE unit is designed to function with a pump governed by a<br />

frequency converter “INVERTER” inserted into the electric control<br />

panel and the others with direct intervention.<br />

This unit, thus constructed, allows to maintain constant pressure in<br />

the water network.<br />

On variation of the network pressure, the INVERTER governed pump<br />

varies its own rotation speed, stating the pressure of the set value.<br />

Whenever the water withdrawal should exceed the pump flow rate,<br />

the second pump intervenes directly and, in the meantime, that<br />

governed by the INVERTER goes into regulation mode in order to<br />

keep the water pressure at the set value. This takes place for all of<br />

the pumps making up the unit.<br />

When the withdrawal has been closed, the pump governed by the<br />

INVERTER reaches the minimum rotation value and, after a few<br />

minutes, stops allowing to obtain a large energy saving.<br />

It is possible to have various versions of the GPE units:<br />

• With an individual INVERTER, which governs just one pump, but<br />

different from the previous start-up (Standard EFC Version).<br />

• With multi-inverter, where every pump is controlled by an inverter<br />

(MFC versions and HERTZ TWIN versions).<br />

Contolling a unit via SP EFC control panels<br />

The SP EFC for controlling units with several pumps envision<br />

powering the pump n°1 via inverter in order to modulate<br />

performance of the system depending on the reference signal,<br />

while the other electric pumps are made to work at maximum<br />

nominal speed (about 2900 min-1) with insertion and<br />

disconnection in sequence on variation of the request.<br />

This implies the presence of two distinct primary electric<br />

circuits:<br />

1st- pump start-up via inverter, 2nd- start-up (direct of deltatriangle)<br />

of the other pumps, by contactors.<br />

The system is governed by the “SYSTEM CONTROLLER” control<br />

unit on the basis of the reference signal, which derives from a<br />

pressure transmitter, flow rate measuring device or other<br />

unified control signal (4÷20 mA passive).<br />

• In the case of water distribution with constant start pressure<br />

(Fig.1), the control unit is connected to the pressure<br />

transmitter positioned in the discharge manifold of the unit<br />

that will send a proportional signal to the network pressure.<br />

The lowering of the network pressure, following water<br />

withdrawal, causes a reduction of the pressure transmitter<br />

signal, which, via the control unit, will control start-up, via<br />

inverter, of the first pump regulating its speed in a way to reestablish<br />

the reference/work pressure. If the flow rate of the<br />

pump is lower than that requested, the network pressure will<br />

tend to decrease and the system will react by increasing the<br />

pump rotation speed. Once the maximum speed of pump n°1<br />

Your Life, our Quality. Worldwide. 2 Booster & <strong>Fire</strong>-Fighting

GP - GPE<br />

PRESSURE BOOSTER UNITS<br />

has been reached, if the pump flow rate is still lower than that<br />

requested, the control unit will control the start-up of the<br />

second pump, which will work at constant speed.<br />

Pump n°1 will be immediately positioned in the conditions to<br />

modulate the rotation speed in order to take the pressure back<br />

to the work value. If the network pressure should drop even<br />

further, once the maximum rotation speed on pump n°1 has<br />

been reached again, the control unit will control start-up of<br />

pump n°3 and successively of any pump n°4. When there is a<br />

reduction of water withdrawal, the pressure tends to increase<br />

as does the pressure signal transmitter. The control unit will<br />

reduce the rotation speed of the pump n°1 in order to reestablish<br />

the reference/work pressure. If the pump flow rate<br />

exceeds that requested, the network pressure will tend to<br />

increase and the system will react by decreasing the pump<br />

rotation speed until the minimum value set is reached. At this<br />

point, the control unit will control stopping of pump n°4,<br />

while pump n°1 will be put in the conditions to modulate the<br />

rotation speed in order to take the pressure back to the work<br />

value On further decrease of the request for flow rate with<br />

consequent tendency on increase in network pressure, once<br />

the minimum rotation speed has been reached again on pump<br />

n°1, the control unit will stop pump n°3 and successively<br />

pump n°2. When the demand for water ceases, the control<br />

unit will reduce the rotation speed of pump n°1 to the<br />

minimum value and after the re-set time (about 1 minute) it<br />

will also stop this pump.<br />

• The case of functioning with increasing set pressure is shown<br />

in an example, for a unit with two pumps, in Fig. 2. While the<br />

system controls just one pump the reference pressure is SET1.<br />

The transmitter pressure signal is compared with SET1, a<br />

lowering or increase in active pressure, through the control<br />

unit, pump rotation speed modulation. Once the maximum<br />

speed of pump n°1 has been reached, if the pressure is below<br />

the work value, the control unit will control start-up of pump<br />

n°2 and the reference pressure becomes SET2.<br />

The reference pressure will remain SET2 while the control unit<br />

keeps pumps n°1 and n°2 running. It will go back to the SET1<br />

value when the control unit controls shutdown of pump n°2.<br />

Contolling a unit via TWIN and SP MFC control panels<br />

The SP MFC and TWIN control panels for controlling units with<br />

several pumps, envision powering each pump via an inverter in<br />

order to modulate system performance depending on the reference<br />

signal. From a construction point of view, the two types of control<br />

panel are different while from a functional point of view ruling is<br />

similar and always takes place by the SYSTEM CONTROLLER control<br />

unit. This acts on the basis of the reference signal, which is derived<br />

from a pressure transmitter, flow rate measuring device or other<br />

unified control signal (4÷20 mA passive).On these control panels,<br />

every pump is powered by the respective inverter and whenever a<br />

fault occurs on the control unit or pressure transducer, if connected,<br />

a system of pressure switches sub-enters, which controls the inviters<br />

directly.<br />

Fig. 1 - UNIT WITH TWO PUMPS WITH CONSTANT PRESSURE REGULATION<br />

Reference<br />

pressure<br />

Head H[m]<br />

1 Pump 2 Pumps<br />

Flow rate Q [%]<br />

Fig. 2 - UNIT WITH TWO PUMPS WITH REGULATION SET AT TWO LEVELS<br />

System<br />

curve<br />

Head H[m]<br />

1 Pump 2 Pumps<br />

Flow rate Q [%]<br />

Your Life, our Quality. Worldwide. 3 Booster & <strong>Fire</strong>-Fighting

GP - GPE<br />

PRESSURE BOOSTER UNITS<br />

• In the case of water distribution with constant start pressure<br />

(Fig.1), the control unit is connected to the pressure transmitter<br />

positioned in the discharge manifold of the unit that will send a<br />

proportional signal to the network pressure. The lowering of the<br />

network pressure following water withdrawal causes a reduction of<br />

the pressure transmitter signal, which, via the control unit, will<br />

control start-up, via inverter, of the first pump regulating its speed<br />

in a way to re-establish the reference/work pressure.<br />

If the flow rate of the pump is lower than that requested, the<br />

network pressure will tend to decrease and the system will react by<br />

increasing the pump rotation speed. Once the maximum speed of<br />

pump n°1 has been reached, if the pump flow rate is still lower<br />

than the request, the control unit will control start-up of the second<br />

pump, which will also work with various speeds. The two pumps<br />

will be immediately placed in conditions to modulate the rotation<br />

speed in order to take the pressure to the work value. The<br />

modulation frequency is the same for both pumps, therefore, as<br />

noted in Fig.1, when both pumps operate, the curves are different<br />

with respect to that highlighted in Fig.1. If the network pressure<br />

should lower further, once the maximum rotation speed on pump<br />

n°1 is reached again, the control unit will control the start-up of<br />

pump n°3 and successively also pump n°4. When there is a<br />

reduction of the withdrawal of water the pressure tends to increase<br />

as does the pressure transmitter signal. The control unit will reduce<br />

the rotation speed of pumps n°1, n°2, n°3 and n°4 (the four pumps<br />

are modulated in parallel) in order to re-establish the<br />

reference/work pressure. If the pump flow rate exceeds that<br />

requested, the network pressure will tend to increase and the<br />

system will react by decreasing the rotation speed of the pumps<br />

until the minimum value set for pump n° 4. At this point, the<br />

control unit will control stopping of pump n°4 while pumps n°1,<br />

n°2 and n°3 will be put in the conditions to modulate the speed of<br />

rotation in order to take the pressure back to the work value. On<br />

further decrease of the flow rate request, with consequent<br />

tendency of increase of the network pressure, once the minimum<br />

rotation speed set for pump n°3 has been reached, the control unit<br />

will control the stopping of pump n°3 while the rotation speed on<br />

pumps n°1 and n°2 will be modulated. On successive decrease of<br />

the request, the control unit will also stop pump n°2 and will<br />

modulate the speed of pump n°1. When the demand for water<br />

stops, the control unit will reduce the rotation speed of pump n°1<br />

to the minimum value and after the pre-set time (about 1 minute)<br />

will also stop this pump.<br />

• Also for these types of control panels there is functioning with<br />

incremental pressure set in order to compensate the pressure drops<br />

(pressure transmitter positioned at start). The control unit operates<br />

in steps with two pressure steps; when just pump n°1 is started, the<br />

reference set is SET1 and becomes SET2 when both pumps are<br />

started, as represented in Fig.2. Both pumps are modulated in<br />

parallel.<br />

CONDITIONS FOR USE<br />

The GP-GPE EBARA pressure boosting units, can be used, in the<br />

standard versions, for civil, industrial and agricultural applications,<br />

in particular for:<br />

• lifting or moving water<br />

• air conditioning<br />

• heating<br />

• irrigation<br />

• washing systems<br />

The liquid conveyed can be: clean water, drinkable, rain, sheet,<br />

mixed or however without solid bodies or fibres in suspension and<br />

without aggressive chemical substances.<br />

The units must be installed in environments that are covered and<br />

protected from weather conditions and freezing.<br />

• Temperature of the conveyed water is 0°÷50°C (according to the<br />

types of pumps installed).<br />

• Environmental functioning area is 0°÷40°C at a height not<br />

exceeding 1000 m a.s.l.<br />

• Max. relative humidity 50% at +40°C.<br />

N.B. The available system NPSH must be greater than the NPSH<br />

requested by the pump.<br />

For applications with different technical features, uses, climatic<br />

conditions (type of liquid conveyed, marine environment, aggressive<br />

industrial environment) contact our sales network .<br />

TESTS AND INSPECTIONS<br />

All EBARA pressure boosting units undergo hydraulic, mechanical<br />

and electrical tests before packaging.<br />

HYDRAULIC MECHANICAL TESTS<br />

Pressure switch calibration Verification of the pump rotation<br />

direction<br />

• Mechanical test of moving parts and noise test (on every pump)<br />

• Sealing test at closed discharge inlet and verification of plate head<br />

• Functioning test in MANUAL (via button on electric control panel)<br />

of each individual pump<br />

• Functioning test in AUTOMATIC (via switch on electric control<br />

panel) of the unit<br />

ELECTRIC TESTS<br />

• Verification of continuity of the earth circuit<br />

• Test at applied voltage (dielectric strength).<br />

• Isolation resistance test<br />

Your Life, our Quality. Worldwide. 4 Booster & <strong>Fire</strong>-Fighting

GP - GPE<br />

PRESSURE BOOSTER UNITS<br />

PRESSURE BOOSTING UNIT HYDRAULIC LAYOUT WITH PUMPS IN PARALLEL<br />

KEY<br />

1 Electric pump<br />

2 Suction manifold<br />

3 Shut-off valve in suction<br />

4 Non-return valve<br />

5 Shut-off valve in discharge<br />

6 Discharge manifold<br />

7 Shut-off valve<br />

8 Pump control/regulation pressure switches<br />

9 Pressure gauge<br />

10 Membrane vessel (Optional*)<br />

USE<br />

UNDERHEAD<br />

OVERHEAD<br />

SUPPLY SYSTEM UPSTREAM FROM THE UNIT<br />

AT THE DISCRETION OF THE CUSTOMER<br />

OF THE SYSTEM DESIGNER<br />

PRESSURE BOOSTING UNIT LAYOUT AND COMPONENTS<br />

KEY<br />

1 Electric pump<br />

2 Suction manifold<br />

3 Ball shut-off valve<br />

4 Non-return valve<br />

5 Air vent nipple<br />

6 Ball shut-off valve<br />

7 Discharge manifold<br />

8 Ball shut-off valve<br />

9 Pump control/regulation pressure switches<br />

10 Pressure gauge<br />

11 Membrane vessel (Optional*)<br />

12 Control panel<br />

13 Pressure transducer (on request)<br />

14 Bracket/sleeve set-up<br />

manifold anchorage<br />

*<br />

Your Life, our Quality. Worldwide. 5 Booster & <strong>Fire</strong>-Fighting

2GP AGA<br />

DOMESTIC PRESSURE BOOSTING<br />

TYPICAL APPLICATIONS<br />

The base of the group is in galvanised steel as are the manifolds. The<br />

discharge manifold is set-up to gather two vertical membrane<br />

reservoirs. Mounted on them find two pressure switches, the electric<br />

control panel and a pressure gauge. On suction, each electric pump has<br />

an isolating valve and a non-return valve, with the possibility of<br />

connection to an air supply unit and has another isolating valve in<br />

discharge mode.<br />

<strong>Units</strong> with two horizontal self-priming single impeller pumps with cast<br />

iron hydraulic parts.<br />

PUMP FEATURES<br />

FIELD OF USE<br />

• Maximum working pressure:<br />

6 bar (AGA 1.00)<br />

10 bar for the rest of the range<br />

• Maximum temperature of the liquid: 45°C<br />

• Maximum suction depth: 8 m<br />

MATERIALS<br />

• Cast iron pump body<br />

• Seal housing disc AISI 304<br />

• Shaft in AISI 416<br />

• Impeller and nozzle in PPO reinforced with fibreglass<br />

• Mechanical seal in Carbon/Ceramic/NBR<br />

TECHNICAL DATA<br />

• Self-ventilated 2 pole asynchronous motor<br />

• Class of insulation F<br />

• IP44 Protection rating<br />

• 230V ± 10% 50Hz single phase voltage<br />

230/400V ± 10% 50Hz three phase voltage<br />

• Permanent capacitor inserted and thermo-amperometric protection<br />

with automatic reset incorporated for the single phase motor<br />

• Protection under user's responsibility for the three phase version<br />

Protection and control panel with CE mark<br />

• IMQ and VDE marked components<br />

• Very low voltage auxiliary circuit<br />

• Motor switch-on and switch-off are controlled by two pressure<br />

switches<br />

• The connection to a float of minimum pressure pressure switch is<br />

possible in order to prevent functioning in conditions when there is no<br />

suction water<br />

• A device is present that inverts the insertion order of the pumps at<br />

every start-up<br />

• Power supply:<br />

- 230V, 50Hz single phase<br />

- 400V, 50 Hz three phase<br />

• Direct start-up<br />

• Power circuit protection fuse<br />

• Auxiliary circuit protection fuse<br />

• Protection rating IP 55<br />

• Line general isolating switch with door lock<br />

• Aut. - 0 - man. switches for each pump<br />

• Circuit breaker protection reset<br />

• LED indicator: - network presence<br />

- motor running<br />

- level alarm<br />

- motor in protection mode (for three phase version only)<br />

• Alarm output set-up<br />

• On request, special version control panels can be used<br />

FUNCTIONING PRINCIPLES<br />

The withdrawal or however the escape of water from the system with<br />

the pumps at a standstill, causes the pressure to drop and the<br />

consequent closure of the pressure switch contact with highest<br />

calibration, which determines start-up of the first electric pump. If the<br />

outlet discharge exceeds the flow rate of a pump, the pressure<br />

continues to drop until it causes the closure of the contact of the<br />

second pressure switch and the start-up of the second pump. The end<br />

of the distribution of the reduction of the outlet discharge leads to the<br />

pressure in the system rising, with opening of the pressure switch<br />

contacts and staggered pumps stops. The inversion of the ignition order<br />

of the two motors reduces the number of hourly start-ups of the<br />

individual pumps and consequently allows a homogenous use of the<br />

same. By connecting a float or minimum pressure pressure switch to the<br />

control panel (whether for withdrawal from the primary collection<br />

reservoir or from the hydraulic circuit), the most frequent cause of<br />

electric pump breakdown is prevented: the lack of water at suction.<br />

Your Life, our Quality. Worldwide. 6 Booster & <strong>Fire</strong>-Fighting

2GP AGA<br />

DOMESTIC PRESSURE BOOSTING<br />

2GP AGA 1.00 range PERFORMANCE CURVES<br />

(according to ISO 9906 Attachment A)<br />

2GP AGA 1.50 - 2.00 - 3.00 range PERFORMANCE CURVES<br />

(according to ISO 9906 Attachment A)<br />

PERFORMANCE TABLE AND ELECTRIC DATA OF THE TWO PUMPS FUNCTIONING SIMULTANEOUSLY<br />

Model Max absorption Q=Flow rate<br />

230V 400V [A] l/min 10 20 40 60 90 100 120 160 200<br />

single phase three-phase [kW] 230V 400V m 3 /h 0,6 1,2 2,4 3,6 5,4 6 7,2 9,6 12<br />

single phase three-phase<br />

H=Head [m]<br />

AGA 1.00 M AGA 1.00 T 0.75+0.75 11 4,2 47,5 45 40,3 35,7 29,1 27 23 - -<br />

AGA 1.50 M AGA 1.50 T 1.1+1.1 16,2 6 - 48 45,1 42,4 38,6 37,4 35,1 30,8 27<br />

AGA 2.00 M AGA 2.00 T 1.5+1.5 19,6 7,2 - 59 55,6 52,2 47,3 45,7 42,5 36,4 30,5<br />

- AGA 3.00 T 2.2+2.2 - 9,4 - 68 64,3 60,8 55,9 54,4 51,6 46,4 42<br />

Your Life, our Quality. Worldwide. 7 Booster & <strong>Fire</strong>-Fighting

2GP AGA<br />

DOMESTIC PRESSURE BOOSTING<br />

DIMENSIONS<br />

DIMENSIONS TABLE<br />

Model Dimensions [mm] Weight<br />

A B B1 C D M R Q HQ DNA DNM [kg]<br />

[2] [1] [2] [1]<br />

2GP AGA 1.00 (M) 485 210 275 415 770 770 370 1090 - - 560 G2 G1½ 51,0<br />

2GP AGA 1.50 (M) 525 230 295 495 870 870 470 1130 - - 600 G2½ G1½ 78,0<br />

2GP AGA 2.00 (M) 525 230 295 495 885 870 470 1130 15 - 600 G2½ G1½ 78,0<br />

2GP AGA 3.00 525 230 295 495 - 885 470 1130 - 15 600 G2½ G1½ 80,0<br />

[1]= Three-phase only<br />

[2]= Single phase only<br />

Your Life, our Quality. Worldwide. 8 Booster & <strong>Fire</strong>-Fighting

2GP CDA<br />

DOMESTIC PRESSURE BOOSTING<br />

TYPICAL APPLICATIONS<br />

The base of the group is in galvanised steel as are the manifolds. The<br />

discharge manifold is set-up to gather any two vertical type membrane<br />

reservoirs; two pressure switches, the electric control panel and a<br />

pressure gauge are mounted on it.<br />

On inlet, each electric pump has an isolating valve and a non-return<br />

valve, with the possibility of connection to an air supply unit and has<br />

another isolating valve in discharge mode.<br />

<strong>Units</strong> with two horizontal dual impeller pumps with cast iron hydraulic<br />

parts.<br />

PUMP FEATURES<br />

FIELD OF USE<br />

• Maximum working pressure:<br />

- 6 bar for CDA 0.75 - 1.00<br />

- 10 bar for the rest of the range<br />

• Maximum temperature of the liquid:<br />

- 40°C for CDA 0.75 - 1.00<br />

- 90°C for the rest of the range<br />

MATERIALS<br />

• Cast iron pump body<br />

• Mechanical seal in Carbon/Ceramic/NBR<br />

• Impeller: - in technopolymer for CDA 0.75 - 1.00<br />

- in brass for the rest of the range<br />

• Shaft: - in AISI 303 for CDA 1.50 - 2.00 - 3.00<br />

- in AISI 304 for CDA 4.00 - 5.50<br />

- in AISI 416 for the rest of the range<br />

• Support: - in aluminium for CDA 0.75 - 1.00<br />

- in cast iron for the rest of the range<br />

• Seal housing disc: - in AISI 304 for CDA 0.75 - 1.00<br />

- in cast iron for the rest of the range<br />

TECHNICAL DATA<br />

• Self-ventilated 2 pole asynchronous motor<br />

• Class of insulation F<br />

• Protection rating IP44<br />

• 230V ± 10% 50Hz, single phase voltage<br />

230/400V ± 10% 50Hz three phase voltage<br />

• Permanent capacitor inserted and<br />

thermo-amperometric protection with automatic reset incorporated<br />

for the single phase motor<br />

• Protection under user's responsibility for the three phase version<br />

Protection and control panel with CE mark<br />

• IMQ and VDE marked components<br />

• Very low voltage auxiliary circuit<br />

• Motor switch-on and switch-off are controlled by two pressure<br />

switches<br />

• The connection to a float of minimum pressure pressure switch is<br />

possible in order to prevent functioning in conditions when there is no<br />

suction water<br />

• A device is present that inverts the insertion order of the pumps at<br />

every start-up<br />

• Power supply:<br />

- 230V, 50Hz single phase<br />

- 400V, 50 Hz three phase<br />

• Direct start-up<br />

• Power circuit protection fuses<br />

• Auxiliary circuit protection fuses<br />

• Protection rating IP 55<br />

• Line main isolating device with door lock<br />

• Aut - 0 - man. switches for each pump<br />

• Reset circuit breaker protection<br />

• Indicator LED:<br />

- network presence<br />

- motor running<br />

- level alarm<br />

- motor in protection mode (for three phase version only)<br />

• Alarm output set-up<br />

• On request, special version control panels can be used<br />

FUNCTIONING PRINCIPLES<br />

The withdrawal or however the escape of water from the system with<br />

the pumps at a standstill, causes the pressure to drop and the<br />

consequent closure of the pressure switch contact with highest<br />

calibration, which determines start-up of the first electric pump. If the<br />

outlet discharge exceeds the flow rate of a pump, the pressure<br />

continues to drop until it causes the closure of the contact of the<br />

second pressure switch and the start-up of the second pump. The end<br />

of the distribution of the reduction of the outlet discharge leads to the<br />

pressure in the system rising, with opening of the pressure switch<br />

contacts and staggered pumps stops. The inversion of the ignition order<br />

of the two motors reduces the number of hourly start-ups of the<br />

individual pumps and consequently allows a homogenous use of the<br />

same. By connecting a float or minimum pressure pressure switch to the<br />

control panel (whether for withdrawal from the primary collection<br />

reservoir or from the hydraulic circuit), the most frequent cause of<br />

electric pump breakdown is prevented: the lack of water at suction.<br />

Your Life, our Quality. Worldwide. 9 Booster & <strong>Fire</strong>-Fighting

2GP CDA<br />

DOMESTIC PRESSURE BOOSTING<br />

2GP CDA range PERFORMANCE CURVES<br />

(according to ISO 9906 Attachment A)<br />

PERFORMANCE TABLE AND ELECTRIC DATA OF THE TWO PUMPS FUNCTIONING SIMULTANEOUSLY<br />

Model Max absorption Q=Flow rate<br />

230V 230/400V [A] l/min 40 80 100 160 180 200 220 240 280 380 420<br />

single phase three-phase [kW] 230V 230/400V m 3 /h 2,4 4,8 8 9,6 10,8 12 13,2 14,4 16,8 22,8 25,2<br />

single phase three-phase<br />

H=Head [m]<br />

CDA 1,00M CDA 1,00T 0,75 + 0,75 12,2 4,6 39,5 37,0 35,2 27,0 21,0 - - - - - -<br />

CDA 1,50M CDA 1,50T 1,1 + 1,1 18 6,8 50,8 49,0 47,0 38,4 33,4 27,5 - - - - -<br />

CDA 2,00M CDA 2,00T 1,5 + 1,5 21,6 8,6 60,5 58,5 57,0 50,0 46,5 40,5 32,5 - - - -<br />

- CDA 3,00T 2,2 + 2,2 - 10,2 - 60,5 59,5 54,0 51,5 48,5 44,5 40,5 32,0 - -<br />

- CDA 4,00T 3 + 3 - 15 - - 67,0 65,0 64,0 62,5 62,0 61,0 58,0 48,0 -<br />

- CDA 5,50T 4 + 4 - 19 - - 76,5 74,0 73,0 72,0 70,5 69,0 67,0 58,5 54,0<br />

Your Life, our Quality. Worldwide. 10 Booster & <strong>Fire</strong>-Fighting

2GP CDA<br />

DOMESTIC PRESSURE BOOSTING<br />

DIMENSIONS<br />

DIMENSIONS TABLE<br />

Model Dimensions [mm] Weight<br />

A B B1 C C1 D DNA DNM HQ M Q R [kg]<br />

2GP CDA 100 530 160 370 425 395 730 G2 G1½ 600 350 - 1135 66,0<br />

2GP CDA 150 565 170 395 420 385 730 G2 G1½ 640 340 10 1170 90,0<br />

2GP CDA 200 585 170 415 420 385 745 G2 G2 650 340 25 1185 94,0<br />

2GP CDA 300 625 170 455 490 445 815 G2½ G2½ 705 405 30 1245 98,0<br />

2GP CDA 400 635 195 440 475 430 845 G2½ G2½ 715 390 75 1255 130,0<br />

2GP CDA 550 635 195 440 475 430 845 G2½ G2½ 715 390 75 1255 138,0<br />

Your Life, our Quality. Worldwide. 11 Booster & <strong>Fire</strong>-Fighting

2GP 2CDX<br />

DOMESTIC PRESSURE BOOSTING<br />

TYPICAL APPLICATIONS<br />

The base of the group is in galvanised steel as are the manifolds. The<br />

discharge manifold is set-up to gather two vertical membrane<br />

reservoirs. Mounted on them find two pressure switches, the electric<br />

control panel and a pressure gauge. On suction, each electric pump has<br />

an isolating valve and a non-return valve, with the possibility of<br />

connection to an air supply unit and has another isolating valve in<br />

discharge mode.<br />

<strong>Units</strong> with two horizontal dual impeller pumps with stainless steel<br />

hydraulic parts.<br />

PUMP FEATURES<br />

FIELD OF USE<br />

• Maximum working pressure: 8 bar<br />

• Maximum temperature of the liquid: 60°C<br />

MATERIALS<br />

• Pump body, impeller, shaft, nozzle and seal housing disc<br />

in AISI 304<br />

• Motor support in aluminium (up to 1.5 kW included), in cast iron<br />

(2.2 kW and over).<br />

TECHNICAL DATA<br />

• Self-ventilated 2 pole asynchronous motor<br />

• Class of insulation F<br />

• Protection rating IP55<br />

• 230V ± 10% 50Hz, single phase voltage<br />

230/400V ±10% 50Hz three phase voltage<br />

• Permanent capacitor inserted and<br />

thermo-amperometric protection with automatic reset incorporated<br />

for the single phase motor<br />

Protection and control panel with CE mark<br />

• IMQ and VDE marked components<br />

• Very low voltage auxiliary circuit<br />

• Motor switch-on and switch-off are controlled by two pressure<br />

switches<br />

• The connection to a float of minimum pressure pressure switch is<br />

possible in order to prevent functioning in conditions when there is no<br />

suction water<br />

• A device is present that inverts the insertion order of the pumps at<br />

every start-up<br />

• Power supply: - 230V, 50Hz single phase<br />

- 400V, 50 Hz three phase<br />

• Direct start-up<br />

• Power circuit protection fuses<br />

• Auxiliary circuit protection fuses<br />

• Protection rating IP 55<br />

• Line main isolating device with door lock<br />

• Aut - 0 - man. switches for each pump<br />

• Reset circuit breaker protection<br />

• Indicator LED:<br />

- network presence<br />

- motor running<br />

- level alarm<br />

- motor in protection mode (for three phase version only)<br />

• Alarm output set-up<br />

• On request, special version control panels can be used<br />

FUNCTIONING PRINCIPLES<br />

The withdrawal or however the escape of water from the system with<br />

the pumps at a standstill, causes the pressure to drop and the<br />

consequent closure of the pressure switch contact with highest<br />

calibration, which determines start-up of the first electric pump. If the<br />

outlet discharge exceeds the flow rate of a pump, the pressure<br />

continues to drop until it causes the closure of the contact of the<br />

second pressure switch and the start-up of the second pump. The end<br />

of the distribution of the reduction of the outlet discharge leads to the<br />

pressure in the system rising, with opening of the pressure switch<br />

contacts and staggered pumps stops. The inversion of the ignition order<br />

of the two motors reduces the number of hourly start-ups of the<br />

individual pumps and consequently allows a homogenous use of the<br />

same. By connecting a float or minimum pressure pressure switch to the<br />

control panel (whether for withdrawal from the primary collection<br />

reservoir or from the hydraulic circuit), the most frequent cause of<br />

electric pump breakdown is prevented: the lack of water at suction.<br />

Your Life, our Quality. Worldwide. 12 Booster & <strong>Fire</strong>-Fighting

2GP 2CDX<br />

DOMESTIC PRESSURE BOOSTING<br />

2GP 2CDX 70 range PERFORMANCE CURVES<br />

(according to ISO 9906 Attachment A)<br />

2GP 2CDX 120 range PERFORMANCE CURVES<br />

(according to ISO 9906 Attachment A)<br />

2GP 2CDX 200 range PERFORMANCE CURVES<br />

(according to ISO 9906 Attachment A)<br />

Your Life, our Quality. Worldwide. 13 Booster & <strong>Fire</strong>-Fighting

2GP 2CDX<br />

DOMESTIC PRESSURE BOOSTING<br />

PERFORMANCE TABLE AND ELECTRIC DATA OF THE TWO PUMPS FUNCTIONING SIMULTANEOUSLY<br />

Model Max absorption Q=Flow rate<br />

230V 400V [A] l/min 40 80 120 160 200 240 300 360 420<br />

single phase three-phase [kW] 230V 400V m 3 /h 2,4 4,8 7,2 9,6 12 14,4 18 21,6 25,2<br />

single phase three-phase<br />

H=Head [m]<br />

2CDXM 70/10 2CDX 70/10 0,75 + 0,75 12 4,6 38,5 35,0 31,5 27,0 - - - - -<br />

2CDXM 70/12 2CDX 70/12 0,9 + 0,9 14 5,8 44,5 40,3 35,2 29,0 - - - - -<br />

2CDXM 70/15 2CDX 70/15 1,1 + 1,1 16,2 6,6 52,5 48,0 42,8 36,5 - - - - -<br />

2CDXM 70/20 2CDX 70/20 1,5 + 1,5 20 8 60,0 55,6 50,0 44,0 - - - - -<br />

2CDXM 120/15 2CDX 120/15 1,1 + 1,1 16,6 6,6 - 42,0 41,5 39,5 37,5 35,0 30,0 - -<br />

2CDXM 120/20 2CDX 120/20 1,5 + 1,5 20,4 8 - 51,5 49,5 47,0 45 42,0 36,5 - -<br />

- 2CDX 120/30 2,2 + 2,2 - 10 - 59,0 57,0 54,6 52 49,0 44,0 - -<br />

- 2CDX 120/40 3 + 3 - 12,4 - 68,5 66,5 64,0 61 57,5 52,0 - -<br />

- 2CDX 200/30 2,2 + 2,2 - 12 - - 52,0 51,0 49,5 48,0 45,5 42,6 39,5<br />

- 2CDX 200/40 3 + 3 - 13,2 - - 62,5 61,0 59,5 58,0 55,0 52,2 49,0<br />

- 2CDX 200/50 3,7 + 3,7 - 17,4 - - 71,5 70,0 68,5 67,0 64,0 61,3 57,5<br />

DIMENSIONS<br />

DIMENSIONS TABLE<br />

Model Dimensions [mm] Weight<br />

A B B1 C C1 D DNA DNM HQ M R [kg]<br />

2GP 2CDX 70/10 525 165 360 420 385 800 G2 G1½ 625 400 1130 53,0<br />

2GP 2CDX 70/12 525 165 360 420 385 800 G2 G1½ 625 400 1130 54,0<br />

2GP 2CDX 70/15 550 180 370 420 385 800 G2 G1½ 650 400 1155 60,0<br />

2GP 2CDX 70/20 550 180 370 420 385 800 G2 G1½ 650 400 1155 64,0<br />

2GP 2CDX 120/15 535 165 370 485 445 880 G2½ G2 635 465 1145 60,0<br />

2GP 2CDX 120/20 535 165 370 485 445 880 G2½ G2 635 465 1145 63,0<br />

2GP 2CDX 120/30 555 180 375 485 445 880 G2½ G2 685 480 1165 76,0<br />

2GP 2CDX 120/40 555 180 375 485 445 880 G2½ G2 685 480 1165 83,0<br />

2GP 2CDX 200/30 585 165 420 465 425 860 G2½ G2½ 690 460 1205 80,0<br />

2GP 2CDX 200/40 610 180 430 465 425 860 G2½ G2½ 715 460 1230 80,0<br />

2GP 2CDX 200/50 610 180 430 465 425 860 G2½ G2½ 715 460 1230 95,0<br />

Your Life, our Quality. Worldwide. 14 Booster & <strong>Fire</strong>-Fighting

2GP COMPACT<br />

DOMESTIC PRESSURE BOOSTING<br />

TYPICAL APPLICATIONS<br />

The base of the group is in galvanised steel as are the manifolds. The<br />

discharge manifold is set-up to gather any two vertical type membrane<br />

reservoirs. Two pressure switches, the electric control panel and a<br />

pressure gauge are mounted on it. On suction, each electric pump has<br />

an isolating valve and a non-return valve, with the possibility of<br />

connection to an air supply unit and has another isolating valve in<br />

discharge mode.<br />

<strong>Units</strong> with two horizontal multistage pumps.<br />

PUMP FEATURES<br />

FIELD OF USE<br />

• Maximum working pressure: 10 bar<br />

• Maximum temperature of the liquid: 40°C<br />

MATERIALS<br />

• Cast iron pump body and support<br />

• External casing in AISI 304<br />

• Technopolymer impeller and nozzle<br />

• Shaft in AISI 416<br />

TECHNICAL DATA<br />

• Self-ventilated 2 pole asynchronous motor<br />

• Class of insulation F<br />

• IP44 Protection rating<br />

• 230V ±10%, 50Hz single phase voltage,<br />

230/400V ±10%, 50Hz three phase voltage<br />

• Permanent capacitor inserted and thermo-amperometric protection<br />

with automatic reset incorporated for the single phase motor<br />

• Protection under user's responsibility for the three phase version<br />

Protection and control panel with CE mark<br />

• IMQ and VDE marked components<br />

• Very low voltage auxiliary circuit<br />

• Motor switch-on and switch-off are controlled by two pressure<br />

switches<br />

• The connection to a float of minimum pressure pressure switch is<br />

possible in order to prevent functioning in conditions when there is no<br />

suction water<br />

• A device is present that inverts the insertion order of the pumps at<br />

every start-up<br />

• Power supply:<br />

- 230V, 50Hz single phase<br />

- 400V, 50 Hz three phase<br />

• Direct start-up<br />

• Power circuit protection fuse<br />

• Auxiliary circuit protection fuse<br />

• Protection rating IP 55<br />

• Line general isolating switch with door lock<br />

• Aut. - 0 - man. switches for each pump<br />

• Circuit breaker protection reset<br />

• LED indicator:<br />

- network presence<br />

- motor running<br />

- level alarm<br />

- motor in protection mode (for three phase version only)<br />

• Alarm output set-up<br />

• On request, special version control panels can be used<br />

FUNCTIONING PRINCIPLES<br />

The withdrawal or however the escape of water from the system with<br />

the pumps at a standstill, causes the pressure to drop and the<br />

consequent closure of the pressure switch contact with highest<br />

calibration, which determines start-up of the first electric pump. If the<br />

outlet discharge exceeds the flow rate of a pump, the pressure<br />

continues to drop until it causes the closure of the contact of the<br />

second pressure switch and the start-up of the second pump. The end<br />

of the distribution of the reduction of the outlet discharge leads to the<br />

pressure in the system rising, with opening of the pressure switch<br />

contacts and staggered pumps stops. The inversion of the ignition order<br />

of the two motors reduces the number of hourly start-ups of the<br />

individual pumps and consequently allows a homogenous use of the<br />

same. By connecting a float or minimum pressure pressure switch to the<br />

control panel (whether for withdrawal from the primary collection<br />

reservoir or from the hydraulic circuit), the most frequent cause of<br />

electric pump breakdown is prevented: the lack of water at suction.<br />

Your Life, our Quality. Worldwide. 15 Booster & <strong>Fire</strong>-Fighting

2GP COMPACT<br />

DOMESTIC PRESSURE BOOSTING<br />

2GP COMPACT A range PERFORMANCE CURVES<br />

(according to ISO 9906 Attachment A)<br />

2GP COMPACT B range PERFORMANCE CURVES<br />

(according to ISO 9906 Attachment A)<br />

PERFORMANCE TABLE AND ELECTRIC DATA OF THE TWO PUMPS FUNCTIONING SIMULTANEOUSLY<br />

Model Max absorption Q=Flow rate<br />

230V 400V [A] l/min 40 80 120 160 200 240<br />

single phase three-phase [kW] 230V 400V m 3 /h 2,4 4,8 7,2 9,6 12 14,4<br />

single phase three-phase H=Head [m]<br />

COMPACT AM 8 COMPACT A 8 0,60 + 0,6 8 3 39,7 32,0 22,4 10,5 - -<br />

COMPACT AM 10 COMPACT A 10 0,75 + 0,75 12 4,8 56,5 48,6 37,1 20,0 - -<br />

COMPACT AM 12 COMPACT A 12 0,88 + 0,88 12,4 5,4 67,5 58,4 44,9 24,0 - -<br />

COMPACT AM 15 COMPACT A 15 1,1 + 1,1 14,6 6,6 79,0 69,1 54,0 28,0 - -<br />

COMPACT BM 12 COMPACT B 12 0,88 + 0,88 11,6 5,4 - 45,9 41,3 35,2 27,6 18,0<br />

COMPACT BM 15 COMPACT B 15 1,1 + 1,1 14,6 6,8 - 56,0 51,5 44,5 34,5 22,0<br />

Your Life, our Quality. Worldwide. 16 Booster & <strong>Fire</strong>-Fighting

2GP COMPACT<br />

DOMESTIC PRESSURE BOOSTING<br />

DIMENSIONS<br />

DIMENSIONS TABLE<br />

Model Dimensions [mm] Weight<br />

B B1 C C1 D DNA M Q [kg]<br />

2GP COMPACT A(M)8 190 285 525 490 815 G2 270 65 52,0<br />

2GP COMPACT A(M)10 185 290 555 520 840 G2 295 105 61,0<br />

2GP COMPACT A(M)12 185 290 580 545 865 G2 320 105 63,0<br />

2GP COMPACT A(M)15 185 290 605 570 890 G2 345 120 65,0<br />

2GP COMPACT B(M)12 185 290 575 530 860 G2½ 315 105 64,0<br />

2GP COMPACT B(M)15 185 290 600 560 890 G2½ 345 120 66,0<br />

Your Life, our Quality. Worldwide. 17 Booster & <strong>Fire</strong>-Fighting

2GP MATRIX<br />

DOMESTIC PRESSURE BOOSTING<br />

TYPICAL APPLICATIONS<br />

The base of the group is in galvanised steel as are the manifolds. The<br />

discharge manifold is set-up to gather any two vertical type membrane<br />

reservoirs; two pressure switches, the electric control panel and a<br />

pressure gauge are mounted on it. On inlet, each electric pump has an<br />

isolating valve and a non-return valve, with the possibility of connection<br />

to an air supply unit and has another isolating valve in discharge mode.<br />

<strong>Units</strong> with two horizontal multistage pumps with stainless steel<br />

hydraulic parts.<br />

PUMP FEATURES<br />

FIELD OF USE<br />

• Maximum temperature of the liquid: 110°C<br />

• Maximum working pressure: 10 bar<br />

• Maximum chlorine content: 500 ppm<br />

MATERIALS<br />

• Pump body, impeller, intermediate body, and seal housing disc and<br />

shaft in AISI 304<br />

• Mechanical sealing in Carbon/Ceramic/EPDM<br />

• Support and motor casing in aluminium<br />

TECHNICAL DATA<br />

• Self-ventilated 2 pole asynchronous motor<br />

• Class of insulation F<br />

• IP55 Protection rating<br />

• 230V ±10%, 50Hz single phase voltage,<br />

230/400V ±10%, 50Hz three phase voltage<br />

• Permanent capacitor inserted and thermo-amperometric protection<br />

with automatic reset incorporated for the single phase motor<br />

Protection and control panel with CE mark<br />

• IMQ and VDE marked components<br />

• Very low voltage auxiliary circuit<br />

• Motor switch-on and switch-off are controlled by two pressure<br />

switches<br />

• The connection to a float of minimum pressure pressure switch is<br />

possible in order to prevent functioning in conditions when there is no<br />

suction water<br />

• A device is present that inverts the insertion order of the pumps at<br />

every start-up<br />

• Power supply: 230V, 50Hz single phase<br />

400V, 50 Hz three phase<br />

• Direct start-up<br />

• Power circuit protection fuses<br />

• Auxiliary circuit protection fuses<br />

• Protection rating IP 55<br />

• Line main isolating device with door lock<br />

• Aut - 0 - man. switches for each pump<br />

• Reset circuit breaker protection<br />

• Indicator LED:<br />

- network presence<br />

- motor running<br />

- level alarm<br />

- motor in protection mode (for three phase version only)<br />

• Alarm output set-up<br />

• On request, special version control panels can be used<br />

FUNCTIONING PRINCIPLES<br />

The withdrawal or however the escape of water from the system with<br />

the pumps at a standstill, causes the pressure to drop and the<br />

consequent closure of the pressure switch contact with highest<br />

calibration, which determines start-up of the first electric pump. If the<br />

outlet discharge exceeds the flow rate of a pump, the pressure<br />

continues to drop until it causes the closure of the contact of the<br />

second pressure switch and the start-up of the second pump. The end<br />

of the distribution of the reduction of the outlet discharge leads to the<br />

pressure in the system rising, with opening of the pressure switch<br />

contacts and staggered pumps stops. The inversion of the ignition order<br />

of the two motors reduces the number of hourly start-ups of the<br />

individual pumps and consequently allows a homogenous use of the<br />

same. By connecting a float or minimum pressure pressure switch to the<br />

control panel (whether for withdrawal from the primary collection<br />

reservoir or from the hydraulic circuit), the most frequent cause of<br />

electric pump breakdown is prevented: the lack of water at suction.<br />

Your Life, our Quality. Worldwide. 18 Booster & <strong>Fire</strong>-Fighting

2GP MATRIX<br />

DOMESTIC PRESSURE BOOSTING<br />

2GP MATRIX 3 range PERFORMANCE CURVES<br />

(according to ISO 9906 Attachment A)<br />

2GP MATRIX 5 range PERFORMANCE CURVES<br />

(according to ISO 9906 Attachment A)<br />

2GP MATRIX 10 range PERFORMANCE CURVES<br />

(according to ISO 9906 Attachment A)<br />

2GP MATRIX 18 range PERFORMANCE CURVES<br />

(according to ISO 9906 Attachment A)<br />

Your Life, our Quality. Worldwide. 19 Booster & <strong>Fire</strong>-Fighting

2GP MATRIX<br />

DOMESTIC PRESSURE BOOSTING<br />

PERFORMANCE TABLE AND ELECTRIC DATA OF THE TWO PUMPS FUNCTIONING SIMULTANEOUSLY<br />

Model Max absorption Q=Flow rate<br />

230V 400V [A] l/min 40 60 120 160 200 260 320 400 500 600 700 800 900<br />

single phase three-phase [kW] 230V 400V m 3 /h 2,4 3,6 7,2 9,6 12 15,6 19,2 24 30 36 42 48 54<br />

single phase three-phase<br />

H=Head [m]<br />

MATRIX 3-4/0.65M MATRIX 3-4/0.65 0,65+0,65 9 3,2 42,0 39,1 27,2 16,0 - - - - - - - - -<br />

MATRIX 3-5/0.75M MATRIX 3-5/0.75 0,75+0,75 10,8 5 52,5 49,0 34,0 20,0 - - - - - - - - -<br />

MATRIX 3-6/0.9M MATRIX 3-6/0.9 0,9+0,9 11,4 5,2 62,5 58,5 41,0 24,0 - - - - - - - - -<br />

MATRIX 3-7/1.3M MATRIX 3-7/1.3 1,3+1,3 15,6 7 73,0 68,5 47,5 28,0 - - - - - - - - -<br />

MATRIX 3-8/1.3M MATRIX 3-8/1.3 1,3+1,3 15,6 7 83,5 78,0 54,5 32,0 - - - - - - - - -<br />

MATRIX 3-9/1.5M MATRIX 3-9/1.5 1,5+1,5 17,4 6,8 94,0 88,0 61,0 36,0 - - - - - - - - -<br />

MATRIX 5-4/0.9M MATRIX 5-4/0.9 0,9+0,9 11,4 5,2 - 43,0 38,6 34,7 29,4 17,6 - - - - - - -<br />

MATRIX 5-5/1.3M MATRIX 5-5/1.3 1,3+1,3 15,6 7 - 54,0 48,5 43,5 36,7 22,0 - - - - - - -<br />

MATRIX 5-6/1.3M MATRIX 5-6/1.3 1,3+1,3 15,6 7 - 64,5 58,0 52,0 44,0 26,4 - - - - - - -<br />

MATRIX 5-7/1.5M MATRIX 5-7/1.5 1,5+1,5 17,4 6,8 - 75,5 67,5 61,0 51,5 30,8 - - - - - - -<br />

MATRIX 5-8/2.2M MATRIX 5-8/2.2 2,2+2,2 26 9,2 - 86,0 77,0 69,5 58,5 35,2 - - - - - - -<br />

MATRIX 5-9/2.2M MATRIX 5-9/2.2 2,2+2,2 26 9,2 - 97,0 87,0 78,0 66,0 39,6 - - - - - - -<br />

MATRIX 10-3/1.3M MATRIX 10-3/1.3 1,3+1,3 15,6 7 - - 33,3 32,1 30,9 28,6 25,5 19,3 8,7 - - - -<br />

MATRIX 10-4/1.5M MATRIX 10-4/1.5 1,5+1,5 17,4 6,8 - - 44,5 43,0 41,0 38,1 34,0 25,7 11,6 - - - -<br />

MATRIX 10-5/2.2M MATRIX 10-5/2.2 2,2+2,2 26 9,2 - - 55,5 53,5 51,5 47,5 42,5 32,1 14,5 - - - -<br />

MATRIX 10-6/2.2M MATRIX 10-6/2.2 2,2+2,2 26 9,2 - - 66,5 64,5 62,0 57,0 51,0 38,5 17,4 - - - -<br />

MATRIX 18-3/2.2M MATRIX 18-3/2.2 2,2+2,2 26 9,2 - - - - - 33,0 31,9 30,4 28,1 25,2 21,3 15,5 7,8<br />

- MATRIX 18-4/3.0 3+3 - 12,6 - - - - - 44,0 42,5 40,5 37,4 33,6 28,4 20,6 10,4<br />

- MATRIX 18-5/4.0 4+4 - 16,2 - - - - - 55,0 53,0 50,5 47,0 42,0 35,5 25,8 13,0<br />

- MATRIX 18-6/4.0 4+4 - 16,2 - - - - - 66,0 64,0 60,5 56,0 50,5 42,5 30,9 15,6<br />

DIMENSIONS<br />

Your Life, our Quality. Worldwide. 20 Booster & <strong>Fire</strong>-Fighting

2GP MATRIX<br />

DOMESTIC PRESSURE BOOSTING<br />

DIMENSIONS TABLE<br />

Model Dimensions [mm] Weight<br />

A B C C1 D DNA DNM HQ L R S [kg]<br />

[2] [1] [2] [1]<br />

2GP MATRIX 3-4M/0,65 2GP MATRIX 3-4T/0,65 490 340 255 450 740 50 40 550 565 520 1100 380 54,0 54,0<br />

2GP MATRIX 3-5M/0,75 2GP MATRIX 3-5T/0,75 490 340 255 475 765 50 40 550 565 520 1100 380 58,0 58,0<br />

2GP MATRIX 3-6M/0,9 2GP MATRIX 3-6T/0,9 490 340 255 500 790 50 40 550 565 520 1100 380 61,0 61,0<br />

2GP MATRIX 3-7M/1,3 2GP MATRIX 3-7T/1,3 490 340 295 520 850 50 40 550 565 520 1100 550 68,0 68,0<br />

2GP MATRIX 3-8M/1,3 2GP MATRIX 3-8T/1,3 490 340 295 545 875 50 40 550 565 520 1100 550 68,0 69,0<br />

2GP MATRIX 3-9M/1,5 2GP MATRIX 3-9T/1,5 490 340 295 570 900 50 40 550 565 520 1100 550 72,0 71,0<br />

2GP MATRIX 5-4M/0,9 2GP MATRIX 5-4T/0,9 500 350 295 490 825 65 50 560 575 520 1110 380 62,0 62,0<br />

2GP MATRIX 5-5M/1,3 2GP MATRIX 5-5T/1,3 500 350 295 515 850 65 50 560 575 520 1110 380 67,0 66,0<br />

2GP MATRIX 5-6M/1,3 2GP MATRIX 5-6T/1,3 500 350 295 535 875 65 50 560 575 520 1110 380 70,0 69,0<br />

2GP MATRIX 5-7M/1,5 2GP MATRIX 5-7T/1,5 500 350 295 560 895 65 50 560 575 520 1110 550 75,0 74,0<br />

2GP MATRIX 5-8M/2,2 2GP MATRIX 5-8T/2,2 500 350 305 585 935 65 50 575 575 520 1110 550 86,0 78,0<br />

2GP MATRIX 5-9M/2,2 2GP MATRIX 5-9T/2,2 500 350 305 610 960 65 50 575 575 520 1110 550 86,0 78,0<br />

2GP MATRIX 10-3M/1,3 2GP MATRIX 10-3T/1,3 515 365 300 510 855 80 65 585 600 520 1135 380 72,0 70,0<br />

2GP MATRIX 10-4M/1,5 2GP MATRIX 10-4T/1,5 515 365 300 540 885 80 65 585 600 520 1135 380 73,0 73,0<br />

2GP MATRIX 10-5M/2,2 2GP MATRIX 10-5T/2,2 515 365 310 570 930 80 65 600 600 520 1135 380 85,0 78,0<br />

2GP MATRIX 10-6M/2,2 2GP MATRIX 10-6T/2,2 515 365 310 600 960 80 65 600 600 520 1135 550 89,0 81,0<br />

2GP MATRIX 18-3M/2,2 2GP MATRIX 18-3T/2,2 575 425 315 520 895 100 80 660 660 620 1200 380 94,0 87,0<br />

- 2GP MATRIX 18-4T/3,0 575 425 350 555 965 100 80 660 660 620 1200 550 - 98,0<br />

- 2GP MATRIX 18-5T/3,8 575 425 385 595 1000 100 80 660 660 620 1200 550 - 109,0<br />

- 2GP MATRIX 18-6T/4,0 575 425 385 630 1075 100 80 660 660 620 1200 550 - 111,0<br />

[1]= Three-phase<br />

[2]= Single phase<br />

Your Life, our Quality. Worldwide. 21 Booster & <strong>Fire</strong>-Fighting

2GP CVM<br />

DOMESTIC PRESSURE BOOSTING<br />

TYPICAL APPLICATIONS<br />

The base of the group is in galvanised steel as are the manifolds. The<br />

discharge manifold is set-up to gather any two vertical type membrane<br />

reservoirs. Two pressure switches, the electric control panel and a<br />

pressure gauge are mounted on it. On suction, each electric pump has<br />

an isolating valve and a non-return valve, with the possibility of<br />

connection to an air supply unit and has another isolating valve in<br />

discharge mode.<br />

<strong>Units</strong> with two vertical multistage pumps.<br />

PUMP FEATURES<br />

FIELD OF USE<br />

• Maximum working pressure: 11 bar<br />

• Maximum temperature of the liquid: 40°C<br />

MATERIALS<br />

• Cast iron pump body and motor support<br />

• External casing in AISI 304<br />

• Impeller and nozzle in PPE+PS reinforced with fibreglass<br />

• Shaft in AISI 416<br />

TECHNICAL DATA<br />

• Self-ventilated 2 pole asynchronous motor<br />

• Class of insulation F<br />

• IP44 Protection rating<br />

• 230V ±10%, 50Hz single phase voltage,<br />

230/400V ±10%, 50Hz three phase voltage<br />

• Permanent capacitor inserted and thermo-amperometric protection<br />

with automatic reset incorporated for the single phase motor<br />

Protection and control panel with CE mark<br />

• IMQ and VDE marked components<br />

• Very low voltage auxiliary circuit<br />

• Motor switch-on and switch-off are controlled by two pressure<br />

switches<br />

• The connection to a float of minimum pressure pressure switch is<br />

possible in order to prevent functioning in conditions when there is no<br />

suction water<br />

• A device is present that inverts the insertion order of the pumps at<br />

every start-up<br />

• Power supply: - 230V, 50Hz single phase<br />

- 400V, 50 Hz three phase<br />

• Direct start-up<br />

• Power circuit protection fuse<br />

• Auxiliary circuit protection fuse<br />

• Protection rating IP 55<br />

• Line general isolating switch with door lock<br />

• Aut. - 0 - man. switches for each pump<br />

• Circuit breaker protection reset<br />

• LED indicator:<br />

- network presence<br />

- motor running<br />

- level alarm<br />

- motor in protection mode (for three phase version only)<br />

• Alarm output set-up<br />

• On request, special version control panels can be used<br />

FUNCTIONING PRINCIPLES<br />

The withdrawal or however the escape of water from the system with<br />

the pumps at a standstill, causes the pressure to drop and the<br />

consequent closure of the pressure switch contact with highest<br />

calibration, which determines start-up of the first electric pump. If the<br />

outlet discharge exceeds the flow rate of a pump, the pressure<br />

continues to drop until it causes the closure of the contact of the<br />

second pressure switch and the start-up of the second pump. The end<br />

of the distribution of the reduction of the outlet discharge leads to the<br />

pressure in the system rising, with opening of the pressure switch<br />

contacts and staggered pumps stops. The inversion of the ignition order<br />

of the two motors reduces the number of hourly start-ups of the<br />

individual pumps and consequently allows a homogenous use of the<br />

same. By connecting a float or minimum pressure pressure switch to the<br />

control panel (whether for withdrawal from the primary collection<br />

reservoir or from the hydraulic circuit), the most frequent cause of<br />

electric pump breakdown is prevented: the lack of water at suction.<br />

Your Life, our Quality. Worldwide. 22 Booster & <strong>Fire</strong>-Fighting

2GP CVM<br />

DOMESTIC PRESSURE BOOSTING<br />

2GP CVM A 8 range PERFORMANCE CURVES<br />

(according to ISO 9906 Attachment A)<br />

2GP CVM A 10 - A 12 - A 15 range PERFORMANCE CURVES<br />

(according to ISO 9906 Attachment A)<br />

EFFICIENCY<br />

EFFICIENCY<br />

HEAD<br />

HEAD<br />

2GP CVM A 18 range PERFORMANCE CURVES<br />

(according to ISO 9906 Attachment A)<br />

Your Life, our Quality. Worldwide. 23 Booster & <strong>Fire</strong>-Fighting

2GP CVM<br />

DOMESTIC PRESSURE BOOSTING<br />

2GP CVM B 10 - B 12 - B 15 range PERFORMANCE CURVES<br />

(according to ISO 9906 Attachment A)<br />

2GP CVM B 20 - B 23 - B 25 range PERFORMANCE CURVES<br />

(according to ISO 9906 Attachment A)<br />

EFFICIENCY<br />

HEAD<br />

PERFORMANCE TABLE AND ELECTRIC DATA OF THE TWO PUMPS FUNCTIONING SIMULTANEOUSLY<br />

Model Max absorption Q=Flow rate<br />

230V 400V [A] l/min 40 60 80 100 120 160 200 240<br />

single phase three-phase [kW] 230V 400V m 3 /h 2,4 3,6 4,8 6 7,2 9,6 12 14,4<br />

single phase three-phase H=Head [m]<br />

CVM AM/8 CVM A/8 0,6+0,6 8 3,2 42,5 39,4 35,6 31,1 25,9 12,8 - -<br />

CVM AM/10 CVM A/10 0,75+0,75 12 4,6 57,5 54,0 49,5 43,5 36,6 19,5 - -<br />

CVM AM/12 CVM A/12 0,9+0,9 13 5,6 69,0 65,0 59,5 52,5 44,0 23,4 - -<br />

CVM AM/15 CVM A/15 1,1+1,1 14,4 6,6 80,5 75,5 69,5 61,0 51,0 27,3 - -<br />

CVM AM/18 CVM A/18 1,3+1,3 15,6 6,2 94,5 88,0 80,0 70,0 58,5 28,8 - -<br />

CVM BM/10 CVM B/10 0,75+0,75 11,2 4,8 - 36,2 35,1 33,7 32,0 27,5 21,6 14,7<br />

CVM BM/12 CVM B/12 0,9+0,9 12,4 5,4 - 48,0 46,8 45,0 42,6 36,6 28,8 19,6<br />

CVM BM/15 CVM B/15 1,1+1,1 14,8 6,4 - 60,5 58,5 56,2 53,3 45,8 36,0 24,5<br />

CVM BM/20 CVM B/20 1,5+1,5 16,6 6,6 - 74,0 72,0 69,0 65,5 56,0 44,5 30,6<br />

CVM BM/23 CVM B/23 1,7+1,7 19,2 8,6 - 86,0 84,0 80,5 76,5 65,5 51,5 35,7<br />

- CVM B/25 1,85+1,85 - 8,6 - 98,5 96,0 92,0 87,0 74,5 59,0 41,0<br />

Your Life, our Quality. Worldwide. 24 Booster & <strong>Fire</strong>-Fighting

2GP CVM<br />

DOMESTIC PRESSURE BOOSTING<br />

DIMENSIONS<br />

DIMENSIONS TABLE<br />

Model Dimensions [mm] Weight<br />

A B R DNA DNM [kg]<br />

2GP CVM A(M)8 260 165 865 G2 G2 61,0<br />

2GP CVM A(M)10 285 190 890 G2 G2 65,0<br />

2GP CVM A(M)12 310 215 915 G2 G2 66,0<br />

2GP CVM A(M)15 335 240 940 G2 G2 67,0<br />

2GP CVM A(M)18 365 270 970 G2 G2 73,0<br />

2GP CVM B(M)10 235 140 840 G2 G2 64,0<br />

2GP CVM B(M)12 260 165 865 G2 G2 65,0<br />

2GP CVM B(M)15 285 190 890 G2 G2 66,0<br />

2GP CVM B(M)20 310 215 915 G2 G2 72,0<br />

2GP CVM B(M)23 335 240 940 G2 G2 76,0<br />

2GP CVM B25 365 270 970 G2 G2 78,0<br />

Your Life, our Quality. Worldwide. 25 Booster & <strong>Fire</strong>-Fighting

2GP HVM<br />

DOMESTIC PRESSURE BOOSTING<br />

TYPICAL APPLICATIONS<br />

The base of the group is in galvanised steel as are the manifolds. The<br />

discharge manifold is set-up to gather any two vertical type membrane<br />

reservoirs. Two pressure switches, the electric control panel and a<br />

pressure gauge are mounted on it. On suction, each electric pump has<br />

an isolating valve and a non-return valve, with the possibility of<br />

connection to an air supply unit and has another isolating valve in<br />

discharge mode.<br />

<strong>Units</strong> with two vertical multistage pumps with stainless steel hydraulic<br />

parts.<br />

PUMP FEATURES<br />

FIELD OF USE<br />

• Maximum working pressure: 10 bar<br />

• Maximum temperature of the liquid: 90°C<br />

MATERIALS<br />

• Cast iron pump body<br />

• External casing, impellers, intermediate stage, seal housing disc and<br />

shaft in AISI 304<br />

• Mechanical seal in Carbon/Ceramic/NBR<br />

TECHNICAL DATA<br />

• T.E.F.C. 2 pole motor<br />

• Class of insulation F<br />

• IP55 Protection rating<br />

• 230V ±10%, 50Hz single phase voltage,<br />

230/400V ±10%, 50Hz three phase voltage<br />

• Permanent capacitor inserted and thermo-amperometric protection<br />

with automatic reset incorporated for the single phase motor<br />

• Circuit breaker protection under user's responsibility for the three<br />

phase version<br />

Protection and control panel with CE mark<br />

• IMQ and VDE marked components<br />

• Very low voltage auxiliary circuit<br />

• Motor switch-on and switch-off are controlled by two pressure<br />

switches<br />

• The connection to a float of minimum pressure pressure switch is<br />

possible in order to prevent functioning in conditions when there is no<br />

suction water<br />

• A device is present that inverts the insertion order of the pumps at<br />

every start-up<br />

• Power supply:<br />

- 230V, 50Hz single phase<br />

- 400V, 50 Hz three phase<br />

• Direct start-up<br />

• Power circuit protection fuse<br />

• Auxiliary circuit protection fuse<br />

• Protection rating IP 55<br />

• Line general isolating switch with door lock<br />

• Aut. - 0 - man. switches for each pump<br />

• Circuit breaker protection reset<br />

• LED indicator:<br />

- network presence<br />

- motor running<br />

- level alarm<br />

- motor in protection mode (for three phase version only)<br />

• Alarm output set-up<br />

• On request, special version control panels can be used<br />

FUNCTIONING PRINCIPLES<br />

The withdrawal or however the escape of water from the system with<br />

the pumps at a standstill, causes the pressure to drop and the<br />

consequent closure of the pressure switch contact with highest<br />

calibration, which determines start-up of the first electric pump. If the<br />

outlet discharge exceeds the flow rate of a pump, the pressure<br />

continues to drop until it causes the closure of the contact of the<br />

second pressure switch and the start-up of the second pump. The end<br />

of the distribution of the reduction of the outlet discharge leads to the<br />

pressure in the system rising, with opening of the pressure switch<br />

contacts and staggered pumps stops. The inversion of the ignition order<br />

of the two motors reduces the number of hourly start-ups of the<br />

individual pumps and consequently allows a homogenous use of the<br />

same. By connecting a float or minimum pressure pressure switch to the<br />

control panel (whether for withdrawal from the primary collection<br />

reservoir or from the hydraulic circuit), the most frequent cause of<br />

electric pump breakdown is prevented: the lack of water at suction.<br />

Your Life, our Quality. Worldwide. 26 Booster & <strong>Fire</strong>-Fighting

2GP HVM<br />

DOMESTIC PRESSURE BOOSTING<br />

2GP HVM 3 range PERFORMANCE CURVES<br />

(according to ISO 9906 Attachment A)<br />

2GP HVM 5 range PERFORMANCE CURVES<br />

(according to ISO 9906 Attachment A)<br />

2GP HVM A 10 range PERFORMANCE CURVES<br />

(according to ISO 9906 Attachment A)<br />

Your Life, our Quality. Worldwide. 27 Booster & <strong>Fire</strong>-Fighting

2GP HVM<br />

DOMESTIC PRESSURE BOOSTING<br />

PERFORMANCE TABLE AND ELECTRIC DATA OF THE TWO PUMPS FUNCTIONING SIMULTANEOUSLY<br />

Model Max absorption Q=Flow rate<br />

230V 400V [A] l/min 40 60 90 120 160 200 260 320 400 500<br />

single phase three-phase [kW] 230V 400V m 3 /h 2,4 3,6 5,4 7,2 9,6 12 15,6 19,2 24 30<br />

single phase three-phase<br />

H=Head [m]<br />

HVM 3-5N/0.9M HVM 3-5N/0.9 0,9+0,9 11,4 5,2 52,5 49,0 42,5 34,0 20,0 - - - - -<br />

HVM 3-6N/0.9M HVM 3-6N/0.9 0,9+0,9 11,4 5,2 62,5 58,5 51,0 41,0 24,0 - - - - -<br />

HVM 3-7N/1.5M HVM 3-7N/1.5 1,5+1,5 17,4 6,8 73,0 68,5 59,5 47,5 28,0 - - - - -<br />

HVM 3-8N/1.5M HVM 3-8N/1.5 1,5+1,5 17,4 6,8 83,5 78,0 68,0 54,5 32,0 - - - - -<br />

HVM 3-9N/1.5M HVM 3-9N/1.5 1,5+1,5 17,4 6,8 94,0 88,0 76,5 61,0 36,0 - - - - -<br />

HVM 5-6N/1.5M HVM 5-6N/1.5 1,5+1,5 17,4 6,8 - 64,5 61,5 58,0 52,0 44,0 26,4 - - -<br />

HVM 5-7N/1.5M HVM 5-7N/1.5 1,5+1,5 17,4 6,8 - 75,5 71,5 67,5 61,0 51,5 30,8 - - -<br />

HVM 5-8N/2.2M HVM 5-8N/2.2 2,2+2,2 26 9,2 - 86,0 82,0 77,0 69,5 58,5 35,2 - - -<br />

HVM 5-9N/2.2M HVM 5-9N/2.2 2,2+2,2 26 9,2 - 97,0 92,0 87,0 78,0 66,0 39,6 - - -<br />

HVM 10-4N/1.5M HVM 10-4N/1.5 1,5+1,5 17,4 6,8 - - - 44,5 43,0 41,0 38,1 34,0 25,7 11,6<br />

HVM 10-5N/2.2M HVM 10-5N/2.2 2,2+2,2 26 9,2 - - - 55,5 53,5 51,5 47,5 42,5 32,1 14,5<br />

HVM 10-6N/2.2M HVM 10-6N/2.2 2,2+2,2 26 9,2 - - - 66,5 64,5 62,0 57,0 51,0 38,5 17,4<br />

- HVM 10-7N/3 3+3 - 12,6 - - - 77,5 75,0 72,0 66,5 59,5 45,0 20,3<br />

- HVM 10-8N/3 3+3 - 12,6 - - - 89,0 85,5 82,5 76,0 68,0 51,5 23,2<br />

DIMENSIONS<br />

DIMENSIONS TABLE<br />

Model Dimensions [mm] Weight [kg]<br />

L H H1 H2 P P1 L1 DNA-DNM<br />

[2] [1] [2] [1] [2] [1] [2] [1]<br />

2GP HVM 3-5N/0.9 805 835 110 570 570 740 800 860 695 660 G2 82,0 84,0<br />

2GP HVM 3-6N/0.9 805 835 110 595 595 740 800 860 695 660 G2 84,0 86,0<br />

2GP HVM 3-7N/1.5 805 835 110 655 655 740 800 860 695 660 G2 90,0 92,0<br />

2GP HVM 3-8N/1.5 805 835 110 680 680 740 800 860 695 660 G2 90,0 93,0<br />

2GP HVM 3-9N/1.5 805 835 110 705 705 740 800 860 695 660 G2 94,0 95,0<br />

2GP HVM 5-6N/1.5 775 805 110 635 635 740 800 800 635 660 G2 88,0 91,0<br />

2GP HVM 5-7N/1.5 775 805 110 655 655 740 800 800 635 660 G2 92,0 93,0<br />

2GP HVM 5-8N/2.2 775 805 110 730 695 740 800 800 635 660 G2 103,0 97,0<br />

2GP HVM 5-9N/2.2 775 805 110 750 720 740 800 800 635 660 G2 104,0 97,0<br />

2GP HVM 10-4N/1.5 815 845 140 640 640 740 800 920 740 670 G3 97,0 99,0<br />

2GP HVM 10-5N/2.2 845 845 140 715 680 800 800 920 740 670 G3 109,0 104,0<br />

2GP HVM 10-6N/2.2 845 845 140 745 710 800 800 920 740 670 G3 112,0 105,0<br />

2GP HVM 10-7N/3 - 845 140 - 775 - 800 920 740 670 G3 - 113,0<br />

2GP HVM 10-8N/3 - 845 140 - 805 - 800 920 740 670 G3 - 115,0<br />

[1]= Three-phase only<br />

[2]= Single phase only<br />

Your Life, our Quality. Worldwide. 28 Booster & <strong>Fire</strong>-Fighting

3GP CVM<br />

DOMESTIC PRESSURE BOOSTING<br />

TYPICAL APPLICATIONS<br />

The base of the group is in galvanised steel as are the manifolds. The<br />

discharge manifold is set-up to gather any three vertical type membrane<br />

reservoirs. Three pressure switches, the electric control panel and a<br />

pressure gauge are mounted on it. On suction, each electric pump has<br />

an isolating valve and a non-return valve, with the possibility of<br />

connection to an air supply unit and has another isolating valve in<br />

discharge mode.<br />

<strong>Units</strong> with three vertical multistage pumps.<br />

PUMP FEATURES<br />

FIELD OF USE<br />

• Maximum working pressure: 11 bar<br />

• Maximum temperature of the liquid: 40°C<br />

MATERIALS<br />

• Cast iron pump body and motor support<br />

• External casing in AISI 304<br />

• Impeller and nozzle in PPE+PS reinforced with fibreglass<br />

• Shaft in AISI 416<br />

TECHNICAL DATA<br />

• Self-ventilated 2 pole asynchronous motor<br />

• Class of insulation F<br />

• IP44 Protection rating<br />

• 230V ±10%, 50Hz single phase voltage,<br />

230/400V ±10%, 50Hz three phase voltage<br />

• Permanent capacitor inserted and thermo-amperometric protection<br />

with automatic reset incorporated for the single phase motor<br />

Protection and control panel with CE mark<br />

• IMQ and VDE marked components<br />

• Very low voltage auxiliary circuit<br />

• Motor switch-on and switch-off are controlled by two pressure<br />

switches<br />

• The connection to a float of minimum pressure pressure switch is<br />

possible in order to prevent functioning in conditions when there is no<br />

suction water<br />

• A device is present that inverts the insertion order of the pumps at<br />

every start-up<br />

• Power supply:<br />

- 230V, 50Hz single phase<br />

- 400V, 50 Hz three phase<br />

• Direct start-up<br />

• Power circuit protection fuse<br />

• Auxiliary circuit protection fuse<br />

• Protection rating IP 55<br />

• Line general isolating switch with door lock<br />

• Aut. - 0 - man. switches for each pump<br />

• Circuit breaker protection reset<br />

• LED indicator:<br />

- network presence<br />

- motor running<br />

- level alarm<br />

- motor in protection mode (for three phase version only)<br />

• Alarm output set-up<br />

• On request, special version control panels can be used<br />

FUNCTIONING PRINCIPLES<br />

The withdrawal or however the escape of water from the system with<br />

the pumps at a standstill, causes the pressure to drop and the<br />

consequent closure of the pressure switch contact with highest<br />

calibration, which determines start-up of the first electric pump. If the<br />

outlet discharge exceeds the flow rate of a pump, the pressure<br />

continues to drop until it causes the closure of the contact of the<br />

second pressure switch and the start-up of the second pump. The end<br />

of the distribution of the reduction of the outlet discharge leads to the<br />

pressure in the system rising, with opening of the pressure switch<br />

contacts and staggered pumps stops. The inversion of the ignition order<br />

of the two motors reduces the number of hourly start-ups of the<br />

individual pumps and consequently allows a homogenous use of the<br />

same. By connecting a float or minimum pressure pressure switch to the<br />

control panel (whether for withdrawal from the primary collection<br />

reservoir or from the hydraulic circuit), the most frequent cause of<br />

electric pump breakdown is prevented: the lack of water at suction.<br />

Your Life, our Quality. Worldwide. 29 Booster & <strong>Fire</strong>-Fighting

3GP CVM<br />

DOMESTIC PRESSURE BOOSTING<br />

3GP CVM A 8 range PERFORMANCE CURVES<br />

(according to ISO 9906 Attachment A)<br />

3GP CVM A 10 - A 12 - A 15 range PERFORMANCE CURVES<br />

(according to ISO 9906 Attachment A)<br />

3GP CVM A 18 range PERFORMANCE CURVES<br />

(according to ISO 9906 Attachment A)<br />

Your Life, our Quality. Worldwide. 30 Booster & <strong>Fire</strong>-Fighting

3GP CVM<br />

DOMESTIC PRESSURE BOOSTING<br />

3GP CVM B 10 - B 12 - B 15 range PERFORMANCE CURVES<br />

(according to ISO 9906 Attachment A)<br />

3GP CVM B 20 - B 23 - B 25 range PERFORMANCE CURVES<br />

(according to ISO 9906 Attachment A)<br />

PERFORMANCE TABLE AND ELECTRIC DATA OF THE TWO PUMPS FUNCTIONING SIMULTANEOUSLY<br />

Model Max. abs. Q=Flow rate<br />

[A] l/min 60 90 120 150 180 240 300 360<br />

[kW] m 3 /h 3,6 5,4 7,2 9 10,8 14,4 18 21,6<br />

H=Head [m]<br />

CVM A/8 0,6+0,6+0,6 4,8 42,5 39,4 35,6 31,1 25,9 12,8 - -<br />

CVM A/10 0,75+0,75+0,75 6,9 57,5 54,0 49,5 43,5 36,6 19,5 - -<br />

CVM A/12 0,9+0,9+0,9 8,4 69,0 65,0 59,5 52,5 44,0 23,4 - -<br />

CVM A/15 1,1+1,1+1,1 9,9 80,5 75,5 69,5 61,0 51,0 27,3 - -<br />