KolbTimes March 2012 as PDF - Dr. W. Kolb AG

KolbTimes March 2012 as PDF - Dr. W. Kolb AG

KolbTimes March 2012 as PDF - Dr. W. Kolb AG

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

paper chemicals<br />

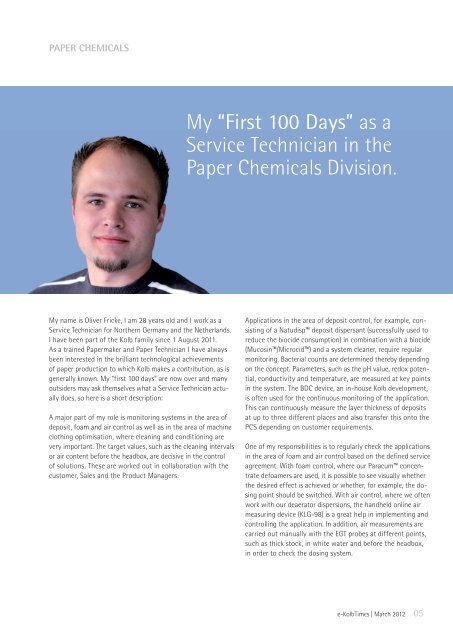

My “First 100 Days” <strong>as</strong> a<br />

Service Technician in the<br />

Paper Chemicals Division.<br />

My name is Oliver Fricke, I am 28 years old and I work <strong>as</strong> a<br />

Service Technician for Northern Germany and the Netherlands.<br />

I have been part of the <strong>Kolb</strong> family since 1 August 2011.<br />

As a trained Papermaker and Paper Technician I have always<br />

been interested in the brilliant technological achievements<br />

of paper production to which <strong>Kolb</strong> makes a contribution, <strong>as</strong> is<br />

generally known. My “first 100 days” are now over and many<br />

outsiders may <strong>as</strong>k themselves what a Service Technician actually<br />

does, so here is a short description:<br />

A major part of my role is monitoring systems in the area of<br />

deposit, foam and air control <strong>as</strong> well <strong>as</strong> in the area of machine<br />

clothing optimisation, where cleaning and conditioning are<br />

very important. The target values, such <strong>as</strong> the cleaning intervals<br />

or air content before the headbox, are decisive in the control<br />

of solutions. These are worked out in collaboration with the<br />

customer, Sales and the Product Managers.<br />

Applications in the area of deposit control, for example, consisting<br />

of a Natudisp deposit dispersant (successfully used to<br />

reduce the biocide consumption) in combination with a biocide<br />

(Mucosin/Microcid) and a system cleaner, require regular<br />

monitoring. Bacterial counts are determined thereby depending<br />

on the concept. Parameters, such <strong>as</strong> the pH value, redox potential,<br />

conductivity and temperature, are me<strong>as</strong>ured at key points<br />

in the system. The BDC device, an in-house <strong>Kolb</strong> development,<br />

is often used for the continuous monitoring of the application.<br />

This can continuously me<strong>as</strong>ure the layer thickness of deposits<br />

at up to three different places and also transfer this onto the<br />

PCS depending on customer requirements.<br />

One of my responsibilities is to regularly check the applications<br />

in the area of foam and air control b<strong>as</strong>ed on the defined service<br />

agreement. With foam control, where our Paracum concentrate<br />

defoamers are used, it is possible to see visually whether<br />

the desired effect is achieved or whether, for example, the dosing<br />

point should be switched. With air control, where we often<br />

work with our deaerator dispersions, the handheld online air<br />

me<strong>as</strong>uring device (KLG-98) is a great help in implementing and<br />

controlling the application. In addition, air me<strong>as</strong>urements are<br />

carried out manually with the EGT probes at different points,<br />

such <strong>as</strong> thick stock, in white water and before the headbox,<br />

in order to check the dosing system.<br />

e-<strong><strong>Kolb</strong>Times</strong> | <strong>March</strong> <strong>2012</strong> 05