Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

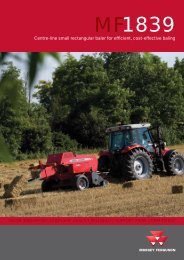

The Power Feed Roller at the front<br />

of the main crop elevator gives a<br />

consistent crop flow from the table<br />

into the main crop elevator. As a<br />

result of the more even crop flow,<br />

less power is needed to thresh<br />

the crop. The crop is distributed<br />

across the full width of the<br />

elevator by the Power Feed Roller<br />

to maximise the potential of the<br />

threshing unit.<br />

In addition, as the crop is readily<br />

prepared for optimum threshing,<br />

both power requirement and more<br />

importantly fuel consumption<br />

is reduced.<br />

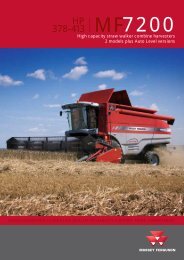

The key to performance!<br />

Equipped with a robust, highinertia<br />

cylinder and a heavy-duty<br />

concave, these machines are able<br />

to effectively thresh the majority of<br />

crops with ease.<br />

The threshing drum has added<br />

weight in the form of ballast bars<br />

to increase the weight around the<br />

cylinder as they thresh the heads.<br />

This reduces load on the drives,<br />

power requirement and<br />

fuel consumption.<br />

The concave has differentiated<br />

wire spacing, i.e. the rear section<br />

of the concave has half as many<br />

wires as the front section. This<br />

principle provides the optimum<br />

balance between high threshing<br />

capacity and good grain flow<br />

through the concave.<br />

Independent adjustment of the<br />

front and rear of the concave is via<br />

electric controls in the cab. This<br />

makes it possible for the operator<br />

to set the concave to the optimum<br />

position to suit the conditions. For<br />

example, using the concave in the<br />

parallel position allows output to<br />

be maximised and straw damage<br />

minimised.<br />

01 PowerFlow table. 02 The immensely strong<br />

FreeFlow header frame.<br />

03 Schumacher knife system. 04 MF BETA combines are fitted with<br />

an Auto Level table as standard.<br />

05 Power Feed Roller is located at the<br />

front of the main crop elavator.<br />

04 05<br />

06 Heavy duty cylinder with ballast bars<br />

and differential wire spacing on concave.<br />

06 05