You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PRODUCT DATA SHEET<br />

<strong>ACTUATOR</strong><br />

<strong>LA27</strong><br />

Features:<br />

• 24V DC permanent magnet motor.<br />

• Thrust up to 8000N (in a push application)<br />

• Thrust up to 4000N (in a pull application)<br />

• Elegant and compact design with small<br />

installation dimensions<br />

• Protection class: IPX4, IPX6<br />

• Colour: Dark grey or light grey<br />

• Built-in end stop switches (not adjustable)<br />

• Possible to mount on control box CB6 with a<br />

special mounting clip (article no. 009271002 is<br />

delivered with CB6 )<br />

• Scratch and wear resistent powder painted<br />

steel inner tube.<br />

• Brake ensures the self-locking<br />

ability in either push or pull<br />

directions.There will always<br />

be a reduction of the selflock<br />

characteristic when the<br />

actuator is run in the opposite direction to the<br />

brake direction<br />

• Thrust up to 3500N in push with Quick Release<br />

• <strong>LA27</strong> with Quick Release can have ratchet spline<br />

it can only pull with max.100N (anti-squeeze).<br />

• <strong>LA27</strong> with QR can be combined with std. spline<br />

function, it can only push.<br />

• Compatible with CB9C (only with the versions AC,<br />

AD, AE or AH), CB6, CB6S OBL/OBF, CB6S OBM,<br />

CB16 OBL/OBF, CB20)<br />

• Noise level 50dB (A), actuator not loaded<br />

Usage:<br />

• Duty cycle: 2/18; 2 minutes continuous use<br />

followed by 18 minutes not in use<br />

• Duty cycle: Max 5% or 1 min. continuous use<br />

followed by 19 minutes not in use - with 8000N<br />

version.<br />

• Lifetime limited to only 3000 cycles according to<br />

EN1970 - with 8000N version<br />

• Ambient temperature: +5 o to +40 o C (the<br />

actuator must also be at this temp.)<br />

• <strong>LA27</strong> is approved according to EN 60601-1 /<br />

UL60601-1<br />

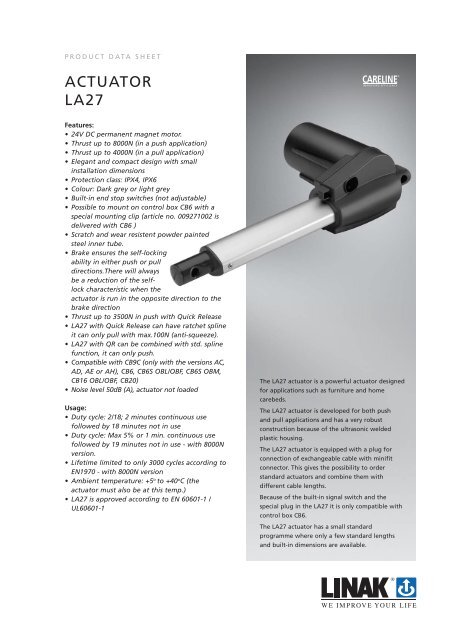

The <strong>LA27</strong> actuator is a powerful actuator designed<br />

for applications such as furniture and home<br />

carebeds.<br />

The <strong>LA27</strong> actuator is developed for both push<br />

and pull applications and has a very robust<br />

construction because of the ultrasonic welded<br />

plastic housing.<br />

The <strong>LA27</strong> actuator is equipped with a plug for<br />

connection of exchangeable cable with minifit<br />

connector. This gives the possibility to order<br />

standard actuators and combine them with<br />

different cable lengths.<br />

Because of the built-in signal switch and the<br />

special plug in the <strong>LA27</strong> it is only compatible with<br />

control box CB6.<br />

The <strong>LA27</strong> actuator has a small standard<br />

programme where only a few standard lengths<br />

and built-in dimensions are available.

....continous<br />

Usage:<br />

NOTE: re. <strong>LA27</strong> with 6.000N specification (274x3xxx1xxx0xZ; Z = A or B i.e with Bouverat worm axle*) for<br />

OpenBus:<br />

I.e. to use such combination a preceding test MUST be carried out.<br />

This combination reduces the self-lock ability because of lower friction from the Bouverat worm which has a<br />

rolled axle. The Bouverat worm is however needed because of the OpenBus output power.<br />

The alternative is a milled worm axle, but this may mean reduced lifetime of the worm.<br />

The problem related to an application:<br />

The self-lock ability may be reduced in cases where the load curve is 6.000N in both minimum and maximum<br />

stroke length - see (A). Further such load distribution may reduce the lifetime of actuator.<br />

A reduced load curve e.g. as in illustration (B) may also result in reduced self-lock, however it may have less<br />

impact on the lifetime of the actuator.<br />

Required test to ensure compatibility:<br />

(only needed for <strong>LA27</strong> with 6.000N for OpenBus (274x3xxx1xxx0xZ; Z = A or B))<br />

The purpose is:<br />

• to observe the actual load curve distribution (comparison to above curves). If load curve results are better<br />

than the above you can proceed. If in doubt about evaluating the load curves please contact your<br />

LINAK A/S sales engineer.<br />

• to observe the self-lock ability in the actual application. In fact the application design may support the<br />

self-lock ability in such a way so that <strong>LA27</strong> no longer sinks. Normally the actuator is not allowed to sink,<br />

however it is the customer who decides if it can be accepted (depends on the application type).<br />

• a lifetime test MUST be carried out by the LINAK Subsidiary or be documented by the customer to ensure<br />

that mutual expectations are met.<br />

I.e. All <strong>LA27</strong> with 6.000 N load specification (all 4 mm spindle types) MUST be tested as described before they<br />

can be accepted for running production. However samples for test are available.<br />

FOOTNOTE:<br />

* REMARK: Z as type ‘0’ does not use the Bouverat worm. However type ‘0’ is NOT compatible with the<br />

transformer used for OpenBus CB’s

Technical specifications<br />

Combi code<br />

Generel<br />

Max load<br />

Typical amp.<br />

Speed<br />

Selocking<br />

Type seleon<br />

Actuator type<br />

Spindle type<br />

Back xture<br />

Piston rod eye<br />

Opon posion<br />

Colour<br />

<br />

Brake<br />

Stroke Length<br />

Motor type<br />

IP Degree<br />

Motor PCBA<br />

PITCH<br />

MAX STROKE<br />

MIN STROKE<br />

PUSH<br />

PULL<br />

27 X X X X Z X X BBB Z Z Z<br />

27 1 F M 0 B Z 4 1 BBB Z Z Z 3 200 50 8000 2000 5,7 4,9 2,7 3,8 8000 push, 4000 pull X<br />

Max current at<br />

max load<br />

Average<br />

current at max<br />

load<br />

Minimum<br />

speed at max<br />

load<br />

Average speed,<br />

max load<br />

Short-circuit ON<br />

Std.<br />

8000N<br />

QR<br />

0 2000<br />

1<br />

0<br />

2000<br />

2<br />

-<br />

3<br />

27 2 S Z 0 B Z 0 BBB Z Z Z 5 300 50<br />

3.8 3.3 4,5 5,5<br />

1<br />

2<br />

3<br />

0<br />

1<br />

2<br />

3500<br />

-<br />

-<br />

3500<br />

27 2 F<br />

C E<br />

M<br />

C E<br />

F<br />

Z<br />

0<br />

1<br />

2<br />

3<br />

0<br />

1 BBB Z Z Z 5 250 50 3500 -<br />

750<br />

3.5 3.1 4,5 5,5<br />

27 3 S Z 0 B<br />

Z<br />

1<br />

2<br />

3<br />

0<br />

1<br />

2<br />

3<br />

1500 -<br />

0 2 - 1500<br />

0 3000<br />

1<br />

0<br />

3000<br />

2<br />

-<br />

3<br />

250<br />

0<br />

6000<br />

1<br />

1 -<br />

2<br />

27 4 S Z 0 B Z BBB Z Z Z 4 50<br />

5<br />

3<br />

0<br />

251<br />

1<br />

4000<br />

1<br />

-<br />

2<br />

300<br />

3<br />

-<br />

0<br />

1<br />

0<br />

2<br />

250 - 4000<br />

1000<br />

1<br />

0<br />

1000<br />

2<br />

-<br />

3<br />

27 7 S Z 0 B Z 0 BBB Z Z Z 6 300 50<br />

3,5<br />

1<br />

2<br />

3<br />

0<br />

1<br />

2<br />

2500<br />

-<br />

-<br />

2500<br />

C E<br />

0<br />

1<br />

27 7 F M Z 1 BBB Z Z Z 6<br />

C E 2<br />

250 50 2500 - 3,5<br />

F 3<br />

Z<br />

3,5 2,7 10 11<br />

4,6<br />

2,9<br />

3<br />

5<br />

3,4<br />

2,9 5 6,8<br />

6,8<br />

2000<br />

3500*<br />

3500*<br />

0 750 750<br />

-<br />

1<br />

BBB<br />

Z<br />

Z 9 405 50<br />

1500*<br />

3000<br />

6000*<br />

4000<br />

4000<br />

1000<br />

2500*<br />

2500*<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

Z = No iuence on technical data<br />

X = Iuence on technical data<br />

S = Standard<br />

BBB = Look max stroke in table<br />

F = Flexible<br />

M = Massive/Solid<br />

* = See tabel 1 for selocking running opposite direon of brake direon<br />

Max BID (Build in Dimension) is 700 mm<br />

Spindle<br />

type<br />

Pitch<br />

(mm)<br />

3 9 1000<br />

4 4 2000<br />

7 6 1500<br />

2 5 -<br />

1 3 2000<br />

Max.<br />

self-lock (N)<br />

Table 1.<br />

Reduced self-lock characteristics when the<br />

actuator is run in the opposite direction.

Built-in Dimensions (standard)<br />

Standard<br />

S + 170 mm<br />

Standard + Mechanical Spline<br />

S + 170 mm<br />

Built-in Dimensions (Options)<br />

QR ver. 2 + ratchet<br />

spline<br />

QR ver. 2<br />

QR ver. 2 +<br />

mechanical spline<br />

8000 N<br />

S < 150 mm<br />

8000 N<br />

S > = 150 mm<br />

S + 180 mm S + 186 mm S + 186 mm S + 210 mm S + 260 mm<br />

The maximum allowed Built-in Dimension may not exceed the standard BID by more than 100 mm.<br />

Contact LINAK A/S if more than 100 mm is wanted.<br />

If mechanical spline and eye options 1, 3 or 4 are chosen, then the Built-in Dimension is increased by<br />

10 mm.<br />

“HALL” has no influence on the Built-in Dimensions.

<strong>LA27</strong><br />

Ordering example:<br />

2 7 0 4 0 1 0 0 0 0 0 3 B 4 - 2 1 2 0 1 0 2 7 0 1 D 0 0<br />

0 0<br />

Not used<br />

Not used<br />

Safety Factor:<br />

Cable:<br />

Plug Type:<br />

Fire Category:<br />

Install. Dim.:<br />

Brake:<br />

Option/Position:<br />

Piston Rod Eye:<br />

Back fixture:<br />

Colour:<br />

IP:<br />

Motor Type:<br />

Interface:<br />

0 = None<br />

0 = None<br />

0 = 2.0<br />

1 = 1.5<br />

2 = 2.5<br />

0 = None<br />

D = Mini-fit<br />

X = Special<br />

1 = V0<br />

2 = V2<br />

XXXX = mm<br />

0 = None<br />

1 = Brake PUSH<br />

2 = Brake PULL<br />

0 = None<br />

A = Internal QR<br />

K = High Load<br />

X = Other<br />

1 = With slot<br />

2 = Without slot<br />

X = Special<br />

1 = 0 degrees<br />

2 = 90 degrees<br />

X = Special<br />

2 = Grey RAL7035<br />

3 = Dark grey RAL7016<br />

X = Special<br />

-<br />

4 = IPX4<br />

6 = IPX6<br />

B = 24VDC. Normal<br />

X = Other<br />

Description<br />

01 = Analog<br />

02 = OpenBus<br />

XX = Special<br />

Positionering:<br />

Safety :<br />

Stroke Length:<br />

Spindle Pitch:<br />

Actuator Type:<br />

0 = None<br />

H = Hall<br />

X = Special<br />

0 = None<br />

A = Safety nut<br />

C = Mec.Spline<br />

D = Mec.Spline+Safety nut.<br />

J = Ratchet Spline<br />

K = Ratchet Spline + Safety nut<br />

X = Special<br />

XXX = mm.<br />

030 = 3 mm<br />

040 = 4 mm<br />

050 = 5 mm<br />

060 = 6 mm<br />

090 = 9 mm<br />

27 = <strong>LA27</strong><br />

It is possible to order <strong>LA27</strong> with individual stroke lengths (in steps of 5 mm) and installation dimensions. This<br />

requires a minimum quantity of 200 pcs per order.

Dimensions <strong>LA27</strong><br />

Drawing no.:<strong>LA27</strong>001B<br />

Dimensions <strong>LA27</strong> with CB6:<br />

Drawing no.: CB6_<strong>LA27</strong>001B

Dimension for <strong>LA27</strong>C with Quick Release:<br />

Quick release unit<br />

Bowden cable<br />

10.2<br />

93.8<br />

35.2<br />

6.8<br />

15<br />

10.3<br />

28<br />

26<br />

38.7<br />

60.2<br />

19.1<br />

18<br />

15<br />

35.7<br />

125.5<br />

12.5<br />

92.4<br />

128.6<br />

18.9<br />

29.5<br />

25<br />

1.8<br />

Detail A<br />

5.3<br />

Detail A<br />

Drawing no.:277131-k1500041<br />

Dimension for <strong>LA27</strong>C with 8000 N:<br />

26<br />

25<br />

38<br />

28<br />

93.8<br />

35.2<br />

34.7<br />

15<br />

19.1<br />

92.4<br />

125.5<br />

12.5<br />

29.5<br />

10.3<br />

Cable<br />

128.6<br />

29<br />

7.5<br />

10.3±0.1<br />

1.5<br />

Drawing no. 0279020-10

Back fixtures:<br />

SECTION<br />

A-A<br />

A<br />

Type 06<br />

Type 05<br />

Type 01 Type 02<br />

Current v’s Thrust (typical values) Push with push brake<br />

Speed v’s Thrust (typical values) Push with push brake<br />

Copyright © LINAK 2012.12 . MA M9-02-041-M . Chapter 5.4<br />

Terms of use<br />

The user is responsible for determining the suitability of LINAK products for specific application.<br />

LINAK takes great care in providing accurate and up-to-date information on its products.<br />

However, due to continuous development in order to improve its products, LINAK products are<br />

subject to frequent modifications and changes without prior notice. Therefore, LINAK cannot<br />

guarantee the correct and actual status of said information on its products.<br />

While LINAK uses its best efforts to fulfil orders, LINAK cannot, for the same reasons as<br />

mentioned above, guarantee the availability of any particular product. Therefore, LINAK reserves<br />

the right to discontinue the sale of any product displayed on its website or listed in its catalogues<br />

or other written material drawn up by LINAK.<br />

All sales are subject to the Standard Terms of Sale and Delivery for LINAK. For a copy hereof,<br />

please contact LINAK.<br />

FOR MOUNTING INSTRUCTIONS AND GUIDANCE IN USAGE, PLEASE SEE THE RELEVANT USER’S MANUALS