Multi-use air cooled liquid chillers and heat pumps with total heat ...

Multi-use air cooled liquid chillers and heat pumps with total heat ...

Multi-use air cooled liquid chillers and heat pumps with total heat ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Multi</strong>-<strong>use</strong> <strong>air</strong> <strong>cooled</strong> <strong>liquid</strong> <strong>chillers</strong> <strong>and</strong> <strong>heat</strong> <strong>pumps</strong> <strong>with</strong> <strong>total</strong> <strong>heat</strong> recovery<br />

Range: from 195 to 660 kW<br />

• High efficency Semi-hermetic screw compressors<br />

• Refrigerant R134a<br />

• Innovative defrosting system<br />

• 11 size in 4 versions

OPERATING MODES<br />

MULTI-USE “ENERGY RAISER” UNIT<br />

SERIES: ERACS-Q<br />

These units provide automatic <strong>and</strong> simultaneous<br />

<strong>heat</strong>ing <strong>and</strong> cooling throughout the year depending<br />

on the load requirements of buildings.<br />

Units for four-pipe circuits in applications such as:<br />

swimming pools, office blocks, shopping centres <strong>and</strong><br />

buildings <strong>with</strong> glass walls.<br />

<strong>heat</strong>ing<br />

<strong>air</strong>-conditioning<br />

instantaneous <strong>and</strong> simultaneous production<br />

“ENERGY SAVER” HEAT PUMP UNITS<br />

SERIES: ERACS-R<br />

These units are <strong>use</strong>d two-pipe systems <strong>and</strong> provide hot<br />

<strong>and</strong> cold water, depending on the season,<br />

as well as domestic hot water all year round.<br />

The main applications are hotels, sports centres <strong>and</strong> gyms.<br />

domestic<br />

hot water<br />

<strong>heat</strong>ing<br />

<strong>air</strong>-conditioning<br />

instantaneous <strong>and</strong> differentiated production

FLEXIBILITY, INNOVATION AND ENERGY RECOVERY ALL THREE ARE<br />

POSSIBLE WITH ERACS-Q AND ERACS-R<br />

FLEXIBILITY, INNOVATION AND ENERGY RECOVERY<br />

ALL THREE ARE POSSIBLE WITH ERACS-Q AND ERACS-R<br />

-10°C OUTDOOR TEMPERATURES<br />

As operation in the <strong>heat</strong> pump mode is guaranteed<br />

at outdoor temperatures as low as –10°C,<br />

the ERACS-Q ERACS-R range is a valid alternative<br />

to traditional systems.<br />

de <strong>air</strong>e exterior<br />

INNOVATIVE DEFROSTING SYSTEM<br />

(CLIMAVENETA PATENT)<br />

The ERACS-Q ERACS-R units incorporate an innovative cycle reversal<br />

defrosting system whose algorithms can be customised according to<br />

individual requirements.<br />

55°C IN THE HEATING SYSTEM<br />

The ERACS range offers <strong>use</strong>rs <strong>heat</strong>ing<br />

water temperatures of up to 55°C even at low<br />

external <strong>air</strong> temperatures.<br />

This is a valid solution for <strong>heat</strong>ing<br />

<strong>and</strong> domestic hot water production systems.<br />

11 SIZES IN 4 VERSIONS<br />

195 kW TO 660 kW<br />

The large number of sizes ensures the range fully<br />

satisfies all system requirements.<br />

All sizes are present in each of the 4 versions:<br />

B: St<strong>and</strong>ard unit<br />

LT: Low outdoor <strong>air</strong> temperature unit<br />

LN: Low noise unit<br />

SL: Super low noise unit.

COMPRESSORS<br />

An improved generation of screw compressors featuring an extremely compact structure<br />

<strong>and</strong> optimised for R134a has allowed the volumetric displacement to be substantially increased<br />

<strong>with</strong>out modifying the shape of the compressor.<br />

Elevated cooling capacities can thus be achieved <strong>with</strong> improved volumetric efficiency.<br />

• Screw profile: dual rotor design<br />

Compared <strong>with</strong> a traditional screw compressor,<br />

the profile has been modified so that the<br />

increased volumetric flow rate requires just<br />

a 10% increase in size, a fundamental aspect<br />

of rotors. It was therefore possible to modify<br />

the body <strong>with</strong>out affecting the external shape<br />

of the compressor.<br />

• Roller bearings<br />

Thanks to the favourable torque load<br />

<strong>and</strong> the reduced pressure difference,<br />

the bearings work in easier conditions<br />

<strong>and</strong> therefore last longer.<br />

SCREW PROFILE<br />

OIL<br />

SEPARATOR<br />

• Oil separator<br />

The compressors contain<br />

an integrated three-stage oil<br />

separator which can guarantee<br />

extremely high separation levels,<br />

in spite of the increase<br />

in volumetric flow.<br />

This is achieved thanks to the fact that<br />

the limited density of the vapour <strong>and</strong><br />

the outlet temperature of the R134a<br />

allow outst<strong>and</strong>ing oil separation.<br />

ROLLER<br />

BEARINGS<br />

NEW CONTROL UNIT<br />

The main characteristics of the new control unit concern the <strong>use</strong>r interface, unit management,<br />

compatibility <strong>and</strong> Service functions.<br />

User interface<br />

Positioned in an easily accessible area<br />

on the outside of the unit <strong>and</strong> protected<br />

by a transparent cover.<br />

It integrates a graphics display <strong>with</strong><br />

a multilanguage menu for reading <strong>and</strong> setting<br />

parameters, a synoptic panel which,<br />

by now a traditional feature of Climaveneta,<br />

offers an immediate view of compressor<br />

status.

Unit management<br />

Special control algorithms optimise energy saving <strong>and</strong> guarantee maximum system reliability:<br />

compressor starting/stopping management <strong>with</strong> hourly rotation + FIFO, thermoregulator<br />

management of available resources, variation <strong>and</strong> control of operating parameters, monitoring<br />

of critical temperatures <strong>and</strong> phase sequences. The software, especially developed by<br />

Climaveneta, offers modulating control of unit capacity from 100% to a minimum which,<br />

depending on its size, can be as little as 12.5%.<br />

Compatibility<br />

Compatible <strong>with</strong> the supervision systems of Climaveneta, De’Longhi <strong>and</strong> many other BMS<br />

systems present on the market: METASYS ® , MODBUS ® , LONWORKS ® , SIEMENS ® , TREND ® .<br />

FWS supervision<br />

The controller is also compatible <strong>with</strong> the innovative Climaveneta FWS (Field Web Server)<br />

supervision system.<br />

Service<br />

The new “black box” logs data relative to 200 variables,<br />

acquired every 30 seconds during the 10 minutes<br />

preceding an event, for 400 separate events.<br />

The software is compatible <strong>with</strong> the Climaveneta Service<br />

programme: through a remote Internet link it is possible<br />

to monitor the unit, implement preventive <strong>and</strong> corrective<br />

action <strong>and</strong> consequently offer a more effective <strong>and</strong> higher<br />

quality of service.<br />

TOTAL HEAT RECOVERY<br />

The ERACS-R units recover the entire <strong>heat</strong> capacity of the compressor for the production of domestic hot<br />

water. This can be achieved both in summer <strong>and</strong> in winter by assigning operating priorities.<br />

LOW-NOISE VERSIONS<br />

Two noise reduction versions are available for all sizes:<br />

low noise <strong>and</strong> super low noise.<br />

Low noise levels are achieved by reducing fan speed<br />

while the circuitry has been optimised <strong>and</strong> the coils<br />

generously sized to ensure the unit works correctly.<br />

The compressors <strong>and</strong> cooling circuit components<br />

are enclosed in a large soundproofed box.

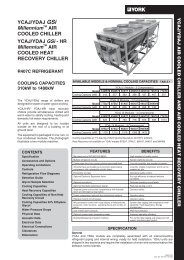

ERACS-Q ERACS-R 1062 1162 1362 1562 1762<br />

Refrigeration <strong>with</strong> <strong>heat</strong> recovery<br />

Cooling capacity (1) kW 195 238 276 307 359<br />

Total power input (1) kW 74 96 109 114 139<br />

Total EER (1) 2,6 2,5 2,5 2,7 2,6<br />

Heating only<br />

Heating capacity (2) kW 212 259 301 332 389<br />

Total power input (2) kW 70 90 102 108 131<br />

Total COP (2) 3,0 3,0 3,0 3,1 3,0<br />

Frío con recuperación<br />

Cooling capacity (1) (3) kW 199 244 284 312 368<br />

Total power input (1) (3) kW 62 78 89 95 115<br />

Heat recovery capacity (1) (3) kW 258 318 368 402 475 518<br />

Sound power level (4) dB(A) 96 97 97 98 98<br />

Sound pressure level (5) dB(A) 77 78 78 78 78<br />

Dimensions A (6) mm 4610 4610 4610 5610 5610<br />

B (6) mm 2220 2220 2220 2220 2220<br />

H mm 2150 2150 2430 2430 2430<br />

Weight Kg 3390 3900 4610 4910 5120<br />

H<br />

H<br />

B<br />

A<br />

B<br />

A<br />

ERACS-Q/ERACS-R 1062-1962 ERACS-Q/ERACS-R 2022-2722

1962 2022 2222 2422 2622 2722<br />

385 454 492 522 585 660<br />

155 170 181 187 215 223<br />

2,5 2,7 2,7 2,8 2,7 3,0<br />

418 491 531 568 613 695<br />

141 163 174 185 195 213<br />

3,0 3,0 3,0 3,1 3,1 3,3<br />

401 461 497 525 601 669<br />

125 141 149 158 176 186<br />

594 638 673 766 843<br />

98 99 101 101 101 101<br />

78 79 80 80 80 80<br />

5610 6300 7200 7200 7200 8800<br />

2220 2260 2260 2260 2260 2260<br />

2430 2350 2350 2350 2350 2350<br />

5700 6990 7470 7620 8030 8630<br />

Data referred to:<br />

1) Refrigeration only:<br />

Evaporator water (in/out) 12/7 °C<br />

Condenser <strong>air</strong> (in) 35 °C<br />

2) Heating only:<br />

Condenser water (in/out) 40/45 °C<br />

Condenser <strong>air</strong> (in)<br />

7 °C / 87% U.R.<br />

3) Refrigeration <strong>and</strong> <strong>total</strong> recovery:<br />

Recovery water (in/out) 40/45 °C<br />

4) Acoustic power measured according to ISO 3744 <strong>and</strong><br />

Eurovent 8/1.<br />

5) Acoustic pressure measured in free field conditions on<br />

a reflecting plane. Average value on the condensing coil side,<br />

1 metre from the outer surface <strong>and</strong> 1 metre above the base<br />

of the unit.<br />

6) Free space required around the unit:<br />

Electrical panel side<br />

1500 mm<br />

Opposite side from electrical panel 1500 mm<br />

Condensation coil side<br />

2000 mm

A 100 AS_107_110_B_CV_06_06_GB (V.01)<br />

CLIMAVENETA S.p.A.<br />

Via Sarson, 57/c<br />

36061 Bassano del Grappa (VI) - Italia<br />

Tel. +39 0424 509 500<br />

Fax +39 0424 509 509<br />

info@climaveneta.it<br />

www.climaveneta.it