apr APCO 600 - Summit Valve and Controls

apr APCO 600 - Summit Valve and Controls

apr APCO 600 - Summit Valve and Controls

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

2008<br />

Edition<br />

®<br />

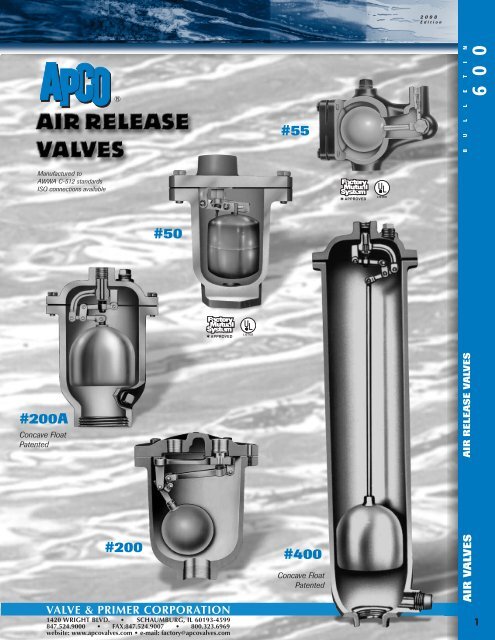

#55<br />

6 0 0<br />

B U L L E T I N<br />

Manufactured to<br />

AWWA C-512 st<strong>and</strong>ards<br />

ISO connections available<br />

#50<br />

#200A<br />

Concave Float<br />

Patented<br />

AIR RELEASE VALVES<br />

#200<br />

VALVE & PRIMER CORPORATION<br />

1420 WRIGHT BLVD. • SCHAUMBURG, IL 60193-4599<br />

847.524.9000 • FAX:847.524.9007 • 800.323.6969<br />

website: www.apcovalves.com • e-mail: factory@apcovalves.com<br />

#400<br />

Concave Float<br />

Patented<br />

AIR VALVES<br />

1151

AIR RELEASE VALVES<br />

WHY <strong>and</strong> WHERE to use An Air Release <strong>Valve</strong> has a small venting orifice <strong>and</strong> is used wherever<br />

air is entrained in water under pressure. These pockets of air increase the resistance to the flow of water. In critical<br />

installations, air can reduce the capacity of a line down to zero. More common is an increased resistance of 10 to 15%.<br />

The increased resistance must be overcome by the pump using more power than necessary to move the required<br />

amount of water. Such a loss can continue unnoticed for years creating excessive power consumption costs. This is a<br />

major reason why all points where air can collect should be equipped with an <strong>APCO</strong> Air Release <strong>Valve</strong>.<br />

HOW TO OPERATE These valves have much smaller orifices than the Air/Vacuum <strong>Valve</strong>s. Their function<br />

is to release small pockets of air which gather at the high points of a system after it is filled <strong>and</strong> under pressure.<br />

The Air Release <strong>Valve</strong> has the ability to open against internal pressure because it has a small orifice <strong>and</strong> a leverage<br />

mechanism which multiplies the force of the float. This force must be greater than the internal pressure across the<br />

orifice in order to open the orifice when a pocket of air needs to be vented. This explains why, as the internal pressure<br />

increases, the orifice decreases in size to facilitate the valve opening.<br />

S I M P L E L E V E R<br />

All <strong>APCO</strong> Air Release <strong>Valve</strong>s<br />

are 100% Hydrostatically factory<br />

tested for ANSI/AWWA<br />

C512 st<strong>and</strong>ards.<br />

#50<br />

1/2, 3/4, 1” Inlet<br />

PHYSICAL DIMENSIONS<br />

Height . . . . . . . . 5 7 ⁄8”<br />

Width . . . . . . . . . 3 3 ⁄4”<br />

Weight . . . . . . . . 6 lbs.<br />

#55<br />

1/2” Inlet<br />

PHYSICAL DIMENSIONS<br />

Height . . . . . . . . 5 ”<br />

Length . . . . . . . . 6 3 ⁄8”<br />

Width . . . . . . . . . 3 5 ⁄16”<br />

Weight . . . . . . . . 5 1 ⁄2 lbs.<br />

#65 MATERIALS OF<br />

3/4” Inlet<br />

CONSTRUCTION<br />

PHYSICAL DIMENSIONS<br />

Height . . . . . . . . 7”<br />

Length . . . . . . . . 8 1 ⁄2”<br />

Width . . . . . . . . . 4 1 ⁄2”<br />

Weight . . . . . . . . 9 lbs.<br />

Body <strong>and</strong> Cover<br />

Cast Iron<br />

Float<br />

Stainless Steel<br />

Seat<br />

Brass-Stainless or Buna-N<br />

St<strong>and</strong>ard pressures up to 175 psi<br />

<strong>and</strong> up to 300 psi with special<br />

orifice.<br />

Specify if operating pressure is<br />

below 20 psi.<br />

St<strong>and</strong>ard pressures up to 175 psi.<br />

<strong>APCO</strong> Uses Stainless Steel Floats Exclusively!<br />

Examine these QUALITY features provided at no extra cost!<br />

1. ASTM QUALITY materials guaranteed throughout<br />

2. Stainless Steel Floats<br />

3. Conserve pumping power — eliminate restricted high points<br />

4. Create maximum pipeline efficiency<br />

Use <strong>APCO</strong> Air Release <strong>Valve</strong>s.<br />

St<strong>and</strong>ard pressures up to 150 psi<br />

Needle<br />

Brass or Stainless Steel<br />

Linkage<br />

Delrin, Bronze or<br />

Stainless Steel<br />

Other internal parts —<br />

Lever Pins, Retaining Rings,<br />

Screws are Stainless Steel,<br />

Bronze or Brass.<br />

NOTE:<br />

Great care is taken in<br />

the choice of materials to<br />

avoid galvanic action!<br />

116 2

WHERE TO INSTALL...<br />

TYPICAL PIPELINE AND POSITION OF NECESSARY<br />

AIR VALVES.<br />

Also install on:<br />

1. Centrifugal pumps<br />

2. Hydropneumatic Tanks<br />

3. Enclosed Systems<br />

4. Sewage Lines<br />

B U L L E T I N<br />

6 0 0<br />

AIR/VACUUM VALVE on pump discharge before check valve (not necessary for pumps with positive suction head) or HYDRAULICALLY<br />

CONTROLLED AIR/VACUUM VALVE where a discharge central valve is normally closed during pump start-up to develop head.<br />

NOTE: INSTALLING MANWAYS AT INTERVALS IN LARGER SIZE PIPELINES PROVIDES AN EXCELLENT POINT TO INSTALL AIR VALVES.<br />

C O M P O U N D L E V E R<br />

#200A<br />

1”, 2” Inlet<br />

PHYSICAL DIMENSIONS<br />

Height . . . . . . . . 10”<br />

Width . . . . . . . . . 7”<br />

Weight . . . . . . . . 20 lbs.<br />

Inlet— 1” or 2” pipe thread<br />

St<strong>and</strong>ard pressures up to 150 psi<br />

<strong>and</strong> up to 300 psi with special<br />

orifice.<br />

Concave float is patented.<br />

#200<br />

2” Inlet<br />

PHYSICAL DIMENSIONS<br />

Height . . . . . . . . 12 1 ⁄2”<br />

Width . . . . . . . . . 9 1 ⁄2”<br />

Weight . . . . . . . . 45 lbs.<br />

Inlet— 2” pipe thread<br />

St<strong>and</strong>ard pressures up to 150 psi<br />

<strong>and</strong> up to 300 psi with special<br />

orifice.<br />

#205<br />

2” Inlet<br />

PHYSICAL DIMENSIONS<br />

Height . . . . . . . . 13”<br />

Width . . . . . . . . . 12”<br />

Weight . . . . . . . . 75 lbs.<br />

Inlet— 2” pipe thread<br />

Flanged inlet available<br />

150 or 300 lb. class<br />

St<strong>and</strong>ard pressures up to 500 psi<br />

<strong>and</strong> up to 800 psi with special<br />

orifice.<br />

#206<br />

#207<br />

6” Inlet<br />

PHYSICAL DIMENSIONS<br />

Height . . . . . . . . 28”<br />

Width . . . . . . . . . 13 1 ⁄2”<br />

Weight . . . . . . . .200 lbs.<br />

Inlet— 6” 125# flange<br />

Discharge orifice . . 1” dia.<br />

HIGH VENTING CAPACITY<br />

St<strong>and</strong>ard pressures up to 150 psi<br />

<strong>and</strong> up to 300 psi with special<br />

orifice.<br />

AIR RELEASE VALVES<br />

FOR SELECTION AND SIZING<br />

OF ALL THE ABOVE AIR VALVES,<br />

SEE BACK PAGE OF THIS BULLETIN<br />

OR ASK FOR <strong>APCO</strong> AIR VALVE<br />

SIZING SOFTWARE.<br />

2” Inlet<br />

PHYSICAL DIMENSIONS<br />

Height . . . . . . . . 14”<br />

Width . . . . . . . . . 12”<br />

Weight . . . . . . . .115 lbs.<br />

Flanged inlet available<br />

400 or <strong>600</strong> lb. class<br />

St<strong>and</strong>ard pressures up to 800 psi<br />

<strong>and</strong> up to 1,500 psi with special<br />

orifice.<br />

AIR VALVES<br />

117 3

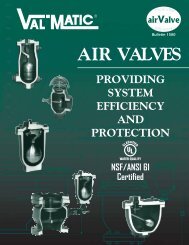

HOW TO SELECT . . .<br />

. . . AND SIZE AN AIR RELEASE<br />

VALVE WHEN A SPECIFIC<br />

VENTING CAPACITY IS<br />

REQUIRED.<br />

A. Enter GRAPH with pressure in system <strong>and</strong><br />

venting capacity required.<br />

B. Read off nearest orifice diameter to intersection<br />

of pressure <strong>and</strong> capacity lines on GRAPH.<br />

C. Enter TABLE BELOW with orifice diameter<br />

<strong>and</strong> select valve which can use this orifice<br />

diameter at the pressure involved.<br />

1500<br />

1000<br />

PRESSURE DIFFERENTIAL ACROSS VALVE IN P.S.I.<br />

500<br />

200<br />

150<br />

100<br />

50<br />

20<br />

10<br />

5<br />

2<br />

VENTING CAPACITY GRAPH FOR AIR RELEASE VALVES<br />

ORIFICE SIZES<br />

1<br />

⁄32<br />

1<br />

0.1 0.2 0.5 1.0 2.0 5.0 10 20 50 100 200 500 1000 2000 5000<br />

VENTING CAPACITY IN CUBIC FEETOFFREEAIRPERMINUTE<br />

1<br />

⁄16<br />

3 ⁄32<br />

1 ⁄8<br />

5 ⁄32 3 ⁄16 7 ⁄32 1 ⁄4 5 ⁄16 3 ⁄8 7 ⁄16 1 ⁄2<br />

3 ⁄4<br />

1<br />

1/2” SHUT-OFF<br />

VALVE<br />

QUICK<br />

DISCONNECT<br />

COUPLING<br />

S E W A G E A I R R E L E A S E<br />

STANDARD OPERATING PRESSURE 175 PSI.<br />

HIGHER PRESSURES AVAILABLE.<br />

#400<br />

#450<br />

CONCAVE<br />

FLOAT<br />

PATENTED<br />

2”<br />

SHUT-OFF<br />

VALVE<br />

BACK<br />

FLUSHING<br />

HOSE<br />

1”<br />

BLOW-OFF<br />

VALVE<br />

2, 3, 4”<br />

PHYSICAL DIMENSIONS<br />

Height . . . . . . . . . . 17 1 ⁄2”<br />

Max. Diameter . . . 7 1 ⁄2”<br />

Weight . . . . . . . . . . 41 lbs.<br />

VALVE WITH ACCESSORIES<br />

Height . . . . . . . . . . 24”<br />

Weight . . . . . . . . . . 55 lbs.<br />

Inlet— 2”, 3” or 4” pipe thread<br />

2, 3, 4”<br />

PHYSICAL DIMENSIONS<br />

Height . . . . . . . . . . 20”<br />

Max. Diameter . . . 9 1 ⁄2”<br />

Weight . . . . . . . . . . 85 lbs.<br />

VALVE WITH ACCESSORIES<br />

Height . . . . . . . . . . 27”<br />

Weight . . . . . . . . . . 118 lbs.<br />

Inlet— 2”, 3” or 4” pipe thread<br />

MODEL INLET<br />

MAXIMUM ORIFICE SIZES WHICH CAN BE USED WITH THE FOLLOWING PRESSURES<br />

SIZE 10 25 50 75 100 125 150 200 250 300 500 800 1500<br />

50<br />

55<br />

65<br />

200A<br />

200<br />

205<br />

206<br />

207<br />

400<br />

450<br />

1<br />

⁄2, 3 ⁄4,1” 3/32 3/32 3/32 3/32 3/32 3/32 3/32 1/16 1/16 1/16 x x x<br />

1/2” 3/32 3/32 3/32 3/32 3/32 3/32 3/32 x x x x x x<br />

3/4” 7/32 7/32 7/32 7/32 1/8 1/8 1/8 x x x x x x<br />

1”,2” 5/16 5/16 5/16 1/4 3/16 3/16 3/16 5/32 5/32 5/32 x x x<br />

2” 1/2 1/2 1/2 1/2 3/8 3/8 3/8 7/32 7/32 7/32 x x x<br />

2” x x x x 1/2 3/8 3/8 7/32 7/32 7/32 7/32 1/8 x<br />

2” x x x x x x x x x x x x 3/32<br />

6” 1 1 1 1 1 1 1 3/4 3/4 3/4 x x x<br />

2”,3”,4”<br />

2”,3”,4”<br />

5/16 5/16 5/16 1/4 1/4 1/4 1/4 3/16 5/32 5/32 x x x<br />

1/2 1/2 1/2 1/2 1/2 1/2 1/2 7/16 7/16 7/16 x x x<br />

STANDARD ORIFICES ON CHART ARE SHADED IN BLUE<br />

118 4<br />

VALVE & PRIMER CORPORATION<br />

1420 WRIGHT BLVD. • SCHAUMBURG, IL 60193-4599<br />

847.524.9000 • FAX:847.524.9007 • 800.323.6969<br />

website: www.apcovalves.com • e-mail: factory@apcovalves.com<br />

VALVE & PRIMER CORPORATION HEREBY RESERVES THE RIGHT TO CHANGE ANY<br />

COMPONENT PARTS WHICH, IN THE OPINION OF ITS ENGINEERING DEPARTMENT,<br />

WILL IMPROVE THE PRODUCT OR INCREASE ITS SERVICEABILITY.<br />

DIMENSIONS ARE FOR ILLUSTRATIVE PURPOSES ONLY. PLEASE CONFIRM ALL DIMENSIONAL<br />

INFORMATION WITH VALVE & PRIMER CORPORATION ENGINEERING DEPARTMENT.