Microprocessor controlled leak tester 3925-0050 - Hematech ...

Microprocessor controlled leak tester 3925-0050 - Hematech ...

Microprocessor controlled leak tester 3925-0050 - Hematech ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Prüfmaschinen<br />

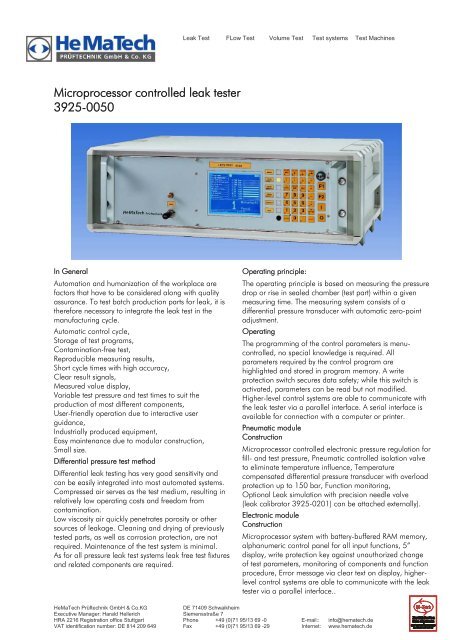

<strong>Microprocessor</strong> <strong>controlled</strong> <strong>leak</strong> <strong>tester</strong><br />

<strong>3925</strong>-<strong>0050</strong><br />

In General<br />

Automation and humanization of the workplace are<br />

factors that have to be considered along with quality<br />

assurance. To test batch production parts for <strong>leak</strong>, it is<br />

therefore necessary to integrate the <strong>leak</strong> test in the<br />

manufacturing cycle.<br />

Automatic control cycle,<br />

Storage of test programs,<br />

Contamination-free test,<br />

Reproducible measuring results,<br />

Short cycle times with high accuracy,<br />

Clear result signals,<br />

Measured value display,<br />

Variable test pressure and test times to suit the<br />

production of most different components,<br />

User-friendly operation due to interactive user<br />

guidance,<br />

Industrially produced equipment,<br />

Easy maintenance due to modular construction,<br />

Small size.<br />

Differential pressure test method<br />

Differential <strong>leak</strong> testing has very good sensitivity and<br />

can be easily integrated into most automated systems.<br />

Compressed air serves as the test medium, resulting in<br />

relatively low operating costs and freedom from<br />

contamination.<br />

Low viscosity air quickly penetrates porosity or other<br />

sources of <strong>leak</strong>age. Cleaning and drying of previously<br />

tested parts, as well as corrosion protection, are not<br />

required. Maintenance of the test system is minimal.<br />

As for all pressure <strong>leak</strong> test systems <strong>leak</strong> free test fixtures<br />

and related components are required.<br />

Leak Test FLow Test Volume Test Test systems Test Machines<br />

Operating principle:<br />

The operating principle is based on measuring the pressure<br />

drop or rise in sealed chamber (test part) within a given<br />

measuring time. The measuring system consists of a<br />

differential pressure transducer with automatic zero-point<br />

adjustment.<br />

Operating<br />

The programming of the control parameters is menu<strong>controlled</strong>,<br />

no special knowledge is required. All<br />

parameters required by the control program are<br />

highlighted and stored in program memory. A write<br />

protection switch secures data safety; while this switch is<br />

activated, parameters can be read but not modified.<br />

Higher-level control systems are able to communicate with<br />

the <strong>leak</strong> <strong>tester</strong> via a parallel interface. A serial interface is<br />

available for connection with a computer or printer.<br />

Pneumatic module<br />

Construction<br />

<strong>Microprocessor</strong> <strong>controlled</strong> electronic pressure regulation for<br />

fill- and test pressure, Pneumatic <strong>controlled</strong> isolation valve<br />

to eliminate temperature influence, Temperature<br />

compensated differential pressure transducer with overload<br />

protection up to 150 bar, Function monitoring,<br />

Optional Leak simulation with precision needle valve<br />

(<strong>leak</strong> calibrator <strong>3925</strong>-0201) can be attached externally).<br />

Electronic module<br />

Construction<br />

<strong>Microprocessor</strong> system with battery-buffered RAM memory,<br />

alphanumeric control panel for all input functions, 5”<br />

display, write protection key against unauthorized change<br />

of test parameters, monitoring of components and function<br />

procedure, Error message via clear text on display, higherlevel<br />

control systems are able to communicate with the <strong>leak</strong><br />

<strong>tester</strong> via a parallel interface..<br />

HeMaTech Prüftechnik GmbH & Co.KG DE 71409 Schwaikheim<br />

Executive Manager: Harald Hellerich Siemensstraße 7<br />

HRA 2216 Registration office Stuttgart Phone +49 (0)71 95/13 69 -0 E-mail:: info@hematech.de<br />

VAT identification number: DE 814 209 649 Fax +49 (0)71 95/13 69 -29 Internet: www.hematech.de

Technical data:<br />

<strong>Microprocessor</strong>: Modular system<br />

Program storage: Battery buffered RAM<br />

Measuring sensor: Temperature compensated<br />

transducer for differential<br />

pressure overload<br />

protection 150 bar/g.<br />

Control panel LCD-Display<br />

(320x240 Pixel),<br />

Alphanumeric control<br />

panel for all input functions<br />

Measuring range: 0 ... 3000 Pa<br />

others on request.<br />

Sensitivity: 1 Pa<br />

Measuring unit: (pressure drop or pressure<br />

rise)<br />

Pa; mm WC; mbar; psi;<br />

mm HG, ml/min.<br />

Parameter sets: 99<br />

Pressure ranges: 0 ... -1.0 bar/g; -0.7 … -0.1 bar/g<br />

0 ... 1.0 bar/g; 0.15... 2.5 bar/g;<br />

0.2 ... 6.0 bar/g;<br />

0.5 ... 10.0 bar/g;<br />

0.5 ... 12.0 bar/g,<br />

others on request.<br />

Test parameters: Filling pressure … bar,<br />

Test pressure … bar,<br />

Fill time 0.1 ... 999.9 sec,<br />

Stabilizing time 0.1 ... 999.9 sec,<br />

Measuring time 0.1 ... 999.9 sec,<br />

Rework from ...<br />

Reject from ...<br />

No. of consecutive rejects<br />

Write protection: Switch lock.<br />

Status indicator: Accept<br />

Rework<br />

Reject<br />

Fault<br />

Leak simulation ON<br />

Interfaces: 1 parallel control I/O-port<br />

Control input:<br />

1 Bit Automatic<br />

1 Bit Program Selection<br />

1 Bit Start<br />

1 Bit Leak simulation<br />

ON/OFF<br />

1 Bit Static Test ON/OFF<br />

8 Bit External Program Select<br />

1 Bit Abort Test<br />

Control output:<br />

1 Bit Ready to operate<br />

1 Bit Ready to test<br />

1 Bit Fault<br />

1 Bit Accept<br />

1 Bit Rework<br />

1 Bit Reject<br />

1 Bit Measuring<br />

Leak Test FLow Test Volume Test Test systems Test Machines<br />

1x Serial Port RS 232<br />

for Parameter down load, Counter and<br />

data logging,<br />

max. 4 Serial ports optional available,<br />

RS 323 and/or RS 485 optional.<br />

Profibus DP is optional available.<br />

Chassis: 19"-rack, 3 HU<br />

Dimensions: 170 x 535 x 400 mm (H x W x D)<br />

Power supply: 115 /230 V ± 10%<br />

50 … 60 Hz (auto select)<br />

Power consumption: Approx. 100 VA<br />

Air supply: Approx. 1, 5 bar > Test pressure,<br />

max. 10 bar/g, filtered, dry and oil free<br />

Pneumatic ports: Air supply G 1/4"<br />

optional test medium port G1/4”<br />

Test port G 1/8"<br />

Reference port G 1/8”<br />

Venting: muffler G 1/4"<br />

Weight: Approx. 15 kg<br />

Standard accessories:<br />

Power cord, length approx. 2.5 m<br />

Spare key for write protection<br />

Operating manual<br />

Leak Tester<br />

Order-No.: 3 925-<strong>0050</strong><br />

Specifications and technical data are subject to change<br />

without notice<br />

HeMaTech Prüftechnik GmbH & Co.KG DE 71409 Schwaikheim<br />

Executive Manager: Harald Hellerich Siemensstraße 7<br />

HRA 2216 Registration office Stuttgart Phone +49 (0)71 95/13 69 -0 E-mail:: info@hematech.de<br />

VAT identification number: DE 814 209 649 Fax +49 (0)71 95/13 69 -29 Internet: www.hematech.de