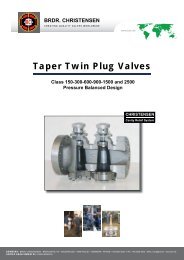

Taper Twin Plug Valves - Brdr. Christensen

Taper Twin Plug Valves - Brdr. Christensen

Taper Twin Plug Valves - Brdr. Christensen

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

BC<br />

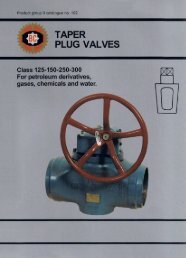

BRDR. CHRISTENSEN<br />

CREATING QUALITY VALVES WORLDWIDE<br />

Cast steel class 600<br />

Rectangular port<br />

Cast steel class 150 rectangular port<br />

port<br />

Class Class<br />

Class Max Max CWP<br />

Max CWP CWP Test Test<br />

Test Pressure<br />

Pressure Pattern<br />

Pattern Connections<br />

Connections Port<br />

Port Materials<br />

Materials<br />

Materials<br />

Body & Cover<br />

<strong>Plug</strong><br />

<strong>Plug</strong><br />

Flanges R.F or R.J.<br />

Body Cover<br />

<strong>Plug</strong><br />

Flanges R.F or or R.J.<br />

ASME B 16.5<br />

Cast Steel<br />

Cast Cast Iron<br />

Iron<br />

ASME B B 16.5<br />

Cast Steel<br />

Cast Iron<br />

Face to Face to ASME<br />

Shell 2225 ASTM A 216<br />

ASTM A A 126<br />

126<br />

ASTM 216 ASTM A 126<br />

600 1480 Shell Shell 450 450 Psi Psi<br />

150 285 Psi<br />

Straight-way<br />

Face Face to to Face<br />

150 285 Psi<br />

B 16.10 Regular and Venturi<br />

Seat Seat 1630 515 Psi<br />

Straightway<br />

See V<br />

Rectangular<br />

Grade WCB<br />

Class B<br />

Seat 515 Psi<br />

See column V<br />

Grade WCB Class B<br />

Pattern<br />

Bleed: See Data or<br />

Cover:<br />

Bleed: See Data Sheet or<br />

Cover:<br />

Bleed: See Data Sheet or<br />

EN 10025-2<br />

specified by by purchaser<br />

EN 10025-2<br />

specified by purchaser<br />

S355J0 or<br />

Steel<br />

S355J2+N<br />

Steel<br />

Operation:<br />

Operation:<br />

Operation:<br />

Manual by wrench.<br />

Manual by wrench.<br />

Manual Type by 8K. wrench.<br />

Type 8K.<br />

Type 8L<br />

Operation:<br />

Operation:<br />

Operation:<br />

Bare stem with mounting flange for actuation.<br />

Bare stem with mounting flange for actuation.<br />

Bare “ISO stem 5211” with mounting flange for actuation.<br />

“ISO 5211”<br />

“ISO 5211”<br />

Operation:<br />

Operation:<br />

Operation: Manual worm gear with vertical handwheel.<br />

Manual worm gear with vertical handwheel.<br />

Manual worm gear with vertical handwheel.<br />

N<br />

N<br />

R Q R<br />

Q<br />

B<br />

C<br />

B<br />

C<br />

K<br />

K<br />

B<br />

B<br />

R Q R<br />

Q<br />

B E<br />

E<br />

R<br />

Q<br />

R<br />

Q<br />

R<br />

Q<br />

B L<br />

B L<br />

F<br />

F<br />

V<br />

V<br />

D<br />

D<br />

<strong>Plug</strong> <strong>Plug</strong> DN DN 1” - 1” 4” – 4” DN DN 1” 1” - 24” – 20” DN 1” –- 4” H<br />

Cast <strong>Plug</strong> Cast Iron Iron 55-AP 55-AP 70164 DN 70124 1” – 4” NN-XXXX 55-AP 55-AP DN 70164 70124 1” – 20” LL-XXXX 55-AP 70164 70124 DN 1” CC-XXXX<br />

– 4”<br />

Cast Steel Iron Steel 55-AP 55-AP 70167 70124 70127 NN-XXXX 55-AP 70167 70124 70127 LL-XXXX 55-AP 55-AP 70167 70127 70124 CC-XXXX<br />

CC-XXXX<br />

Steel 55-AP 70127 NN-XXXX 55-AP 70127 LL-XXXX 55-AP 70127 CC-XXXX<br />

XXXX: See data sheet page 12 or code sheet page 5<br />

XXXX: See data sheet page 12 or code sheet page 5<br />

A<br />

A<br />

A<br />

XXXX: See data sheet page A12 or code sheet page A5<br />

Raise<br />

Ring ISO<br />

d<br />

Raised<br />

Ring Joint Flang<br />

Face<br />

ISO<br />

Face<br />

Joint Ring<br />

e ISO<br />

d<br />

Flange<br />

DN A B C D E F H I J K L M N Q R Face<br />

V Joint V<br />

5211<br />

DN A B C D E F H I J K L M N Q R V V<br />

5211 e<br />

1” 52 88 138 100 89 30 300 124/209 32 40 130 132 50 25 108 229 229 F07<br />

DN A B C D E F H I J K L M N Q R V V<br />

5211<br />

1” 52 88 138 100 89 30 300 124/209 32 40 130 132 50 25 124 *254 *254 F07<br />

2” 65 106 158 115 110 30 300 124/209 32 40 151 132 50 51 152 267 279 F07<br />

1” 52 88 138 100 89 30 300 124/209 32 40 130 132 50 25 108 229 229 F07<br />

2” 65 109 158 115 110 30 300 124/209 32 40 151 132 50 51 165 292 295 F07<br />

3” 80 142 190 165 131 36 300 124/209 32 40 172 132 50 76 191 343 355 F07<br />

2” 65 106 158 115 110 30 300 124/209 32 40 151 132 50 51 152 267 279 F07<br />

3” 76 146 198 137 139 36 300 124/209 32 40 182 132 50 76 210 356 359 F10<br />

4” 86 158 224 170 154 50 300 124/209 32 40 195 132 50 102 229 432 445 F10<br />

3” 80 142 190 165 131 36 300 124/209 32 40 172 132 50 76 191 343 355 F07<br />

4” 95 167 242 170 169 55 300 124/209 42 49 215 165 63 102 273 432 435 F12<br />

6” 116 213 282 232 215 55 152 279 546 558 F14<br />

4” 86 158 224 170 154 50 300 124/209 32 40 195 132 50 102 229 432 445 F10<br />

6” 123 219 232 219 152 356 559 562 F14<br />

8” 147 240 270 249 203 343 622 635 F14<br />

6” 116 213 282 232 215 55 152 279 546 558 F14<br />

8”<br />

10”<br />

152<br />

150<br />

256<br />

266<br />

264<br />

296<br />

260<br />

277<br />

200<br />

254<br />

419<br />

406<br />

660<br />

661<br />

664<br />

674<br />

**F16<br />

F14<br />

8” 147 240 270 249 203 343 622 635 F14<br />

10” 12” 172 175286 303 320 340281 309 248 305 508 483 787 762 791 774 F16 F25<br />

10” 150 266 296 277 254 406 661 674 F14<br />

12” 14” 184 202326 334 343 380359 351 299 337 559 533 838 889 841 902 F25<br />

12” 175 303 340 309 305 483 762 774 F16<br />

14” 16” 202 230345 356 380 415363 386 327 387 603 597 889 991 1004 892 F25 F30<br />

14” 202 334 380 351 337 533 889 902 F25<br />

16” 18” 230 257383 426 415 450385 450 375 438 686 635 1092 991 1104 994 F30<br />

16” 230 356 415 386 387 597 991 1004 F25<br />

18” 20” 257 28440 471 450 494487 503 419 489 743 699 1092 1194 1095 1209 F30 F35<br />

18” 20”<br />

257 284<br />

426 476<br />

450 494<br />

450 504<br />

438 464<br />

635 813<br />

1092 1194<br />

1104 1200<br />

F30<br />

F35<br />

20” 284 471 494 503 489 699 1194 1209 F30<br />

24” 336 566 600 580 559 940 1397 1407 F35<br />

Note: *Not included in the standards.<br />

** With C- and D-gear, the ISO topwork is not according to this size<br />

V<br />

V<br />

D<br />

D<br />

A<br />

A<br />

A<br />

V<br />

V<br />

D<br />

D<br />

I1<br />

I1<br />

I1<br />

J<br />

J<br />

J<br />

H<br />

I M A<br />

I I M A<br />

B 19<br />

B 23<br />

Cast steel class 600 rectangular port<br />

B 19<br />

B.23