CommerCial | GeoTHermal TeCHNoloGY - FHP Manufacturing

CommerCial | GeoTHermal TeCHNoloGY - FHP Manufacturing

CommerCial | GeoTHermal TeCHNoloGY - FHP Manufacturing

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

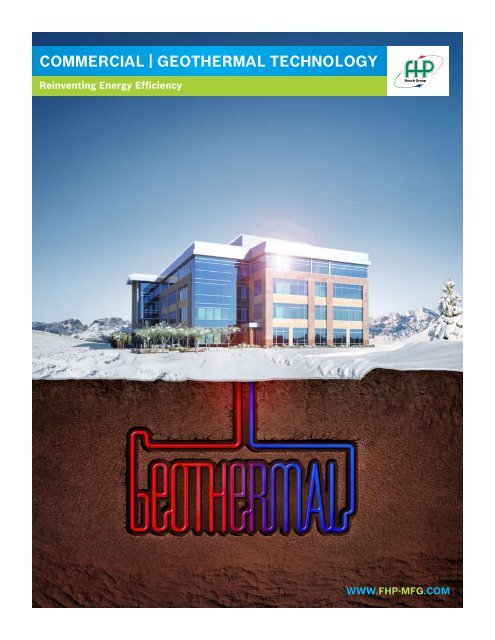

Commercial | GEOTHERMAL TECHNOLOGY<br />

Reinventing Energy Efficiency<br />

www.fhp-mfg.com

<strong>FHP</strong>’s Geothermal And Water Source Systems<br />

Our Heat Pump systems are the most energy and cost efficient systems on the market and therefore the greenest<br />

technology and the smartest investment for commercial heating and cooling applications.<br />

Geothermal Systems<br />

As the cost of energy increases geothermal installations become the system of choice.<br />

The earth has a tremendous capacity of storing thermal energy which can be utilized to heat or cool a building.<br />

Although the initial cost of a geothermal application may be higher, if one considers the life cycle savings in energy<br />

and the reduced maintenance cost then geothermal is the smartest decision for your project.<br />

Geothermal systems are especially recommended in areas that have significant heating and cooling loads.<br />

In areas that are either cooling or heating dominant our hybrid systems could be the perfect solution for your<br />

needs. Using a cooling tower in conjunction with a ground loop in areas that have a cooling dominant load<br />

reduces the cost of the loop field with only a small impact on the efficiency of the system. Conversely in areas<br />

that are heating dominant the addition of a boiler to a geothermal loop reduces the loop field cost with a minimal<br />

effect on the efficiency of the system.<br />

Water Source Cooling Tower/Boiler Systems<br />

A tower/boiler system offers as excellent alternative to a geothermal system where space is limited or initial costs<br />

are a determinant factor.<br />

The tower/boiler system consists of a cooling tower that will reject heat absorbed by the loop when the system<br />

is predominantly in the cooling mode. The boilers function is to add heat to the loop when there is a net heating<br />

demand. In many instances the heat generated by the units in cooling balance the heat loss in the loop for the units<br />

in the heating mode. In this situation neither the tower nor boiler will operate as the system is self balancing.<br />

Environmental stewardship is a core philosophy for <strong>FHP</strong><br />

<strong>Manufacturing</strong> from design to production to the reduction<br />

in our customers’ energy bills. At <strong>FHP</strong>, we are working on a<br />

better future every day.<br />

1 | <strong>FHP</strong> | Bosch Group | Heat Pumps | Commercial | Geothermal Technology

Advantages Of <strong>FHP</strong>’s Technology<br />

Low Installation Costs<br />

<strong>FHP</strong> water source heat pumps systems provide the most flexible and lowest installation costs of virtually any<br />

HVAC system. In a typical installation the water loop remains above the dew point of the ambient air meaning no<br />

insulation is required on piping, a major cost of any installation. To accomplish the same degree of flexibility as a<br />

heat pump system a four pipe system is required. This represents another significant cost saving potential since<br />

heat pumps installations only require a two pipe system for either heating or cooling.<br />

Flexibility and Comfort<br />

<strong>FHP</strong> units come in a wide variety of models, sizes and configurations. This provides the design engineer true<br />

flexibility when designing the system. Should the occupancy of an area change the unit may be changed out for<br />

the appropriate size without major modifications to the layout.<br />

Energy Efficient<br />

<strong>FHP</strong> units operate individually with high efficiency making the complete system extremely efficient. What makes<br />

this system unique is the ability to transfer heat around the building in winter through the common water loop.<br />

In today’s modern buildings, interior zones generally require cooling even in the winter because of the lighting,<br />

occupancy and electronic loading. When cooling these areas heat is transferred to the water loop and utilized by<br />

the units on the perimeter that may require heating. This is the only system with this capability and the net result<br />

is a truly economical operating system. Individual units serve specific zones so that there is no need to operate<br />

large units if there is only a small area calling for heating or cooling.<br />

Redundancy<br />

The building is not dependent on one or two large chillers. With multiple units serving individual zones should<br />

one unit fail, only this area is affected. <strong>FHP</strong> units are designed for convenient, easy and fast service and do not<br />

require specialized training to maintain or repair. Downtime should be minimal. Routine maintenance is limited<br />

to filter replacement and an annual checkup making maintenance cost for water source heat pumps one of the<br />

lowest of any system.<br />

Space Savings<br />

<strong>FHP</strong> horizontal units are designed to be as compact as possible. In a commercial application units are typically<br />

located above a false ceiling meaning that large equipment rooms that would normally house large chillers or air<br />

handlers are not required. This frees up space that can now be used for tenant occupancy generating additional<br />

revenue throughout the life of the building.<br />

Each <strong>FHP</strong> unit will have its own duct system to serve the specific zone. Large central plant ducting is not required<br />

allowing for the possibility of reduced floor to floor height with a corresponding reduction in the mass and cost<br />

of the building.<br />

<strong>FHP</strong> | Bosch Group | Heat Pumps | Commercial | Geothermal Technology | 2

Operation Modes Of A Heat Pump<br />

Cooling Mode<br />

Supply Water<br />

From Thermal Source<br />

Return Air<br />

Thermal Expansion Valve<br />

Water-To-Refrigerant<br />

Heat Exchanger<br />

Compressor<br />

Blower<br />

Hot Gas<br />

Reversing<br />

Valve<br />

Air-To-Refrigerant<br />

Heat Exchanger Coil<br />

Return Water<br />

To Thermal Source<br />

Suction Line<br />

In the COOLING mode, the refrigerant, a hot<br />

gas, is pumped from the compressor to the<br />

water-to-refrigerant heat exchanger via the<br />

reversing valve.<br />

Water, generally with an anti freeze, flowing<br />

through the water-to-refrigerant heat exchanger<br />

removes heat and the hot gas condenses into a<br />

liquid. This liquid then flows through a metering<br />

device to the air-to-refrigerant heat exchanger<br />

coil. In evaporating into a gas, the liquid absorbs<br />

heat and cools and dehumidifies the air that<br />

passes over the coil surface. The cooling cycle is<br />

completed when the refrigerant flows as a low<br />

pressure gas through the reversing valve and<br />

back to the suction side of the compressor.<br />

3 | <strong>FHP</strong> | Bosch Group | Heat Pumps | Commercial | Geothermal Technology

<strong>FHP</strong> | Bosch Group | Heat Pumps | Commercial | Geothermal Technology | 4

Operation Modes Of A Heat Pump<br />

Heating Mode<br />

Supply Water<br />

From Thermal Source<br />

Return Air<br />

Thermal Expansion Valve<br />

Water-To-Refrigerant<br />

Heat Exchanger<br />

Compressor<br />

Blower<br />

Hot Gas<br />

Reversing<br />

Valve<br />

Air-To-Refrigerant<br />

Heat Exchanger Coil<br />

Return Water<br />

To Thermal Source<br />

Suction Line<br />

During the HEATING mode, the refrigerant, a hot<br />

gas, is pumped from the compressor to the air-torefrigerant<br />

heat exchanger coil via the reversing<br />

valve. In the air-to-refrigerant heat exchanger<br />

coil, the heat is removed by the air that passes<br />

over the coil surface, and the hot gas condenses<br />

into a liquid. The air is circuited to the space and<br />

provides heating for the building. The refrigerant<br />

liquid then flows through a metering system to<br />

the water-to-refrigerant heat exchanger. While it<br />

evaporates into a gas, the liquid absorbs heat and<br />

cools the water. The heating cycle is completed<br />

when the refrigerant flows as a low pressure<br />

gas through the reversing valve and back to the<br />

suction side of the compressor.<br />

5 | <strong>FHP</strong> | Bosch Group | Heat Pumps | Commercial | Geothermal Technology

<strong>FHP</strong> | Bosch Group | Heat Pumps | Commercial | Geothermal Technology | 6

Earth Coupling Options<br />

Geothermal systems use the earth as a heat source and heat sink. In order to transfer heat to or from the house<br />

heat exchangers (ground loops) are installed in the ground. These consist of high density polyethylene plastic<br />

pipes. The loops are then connected to the heat pump and fluid circulated between them transferring the heat<br />

between the heat pump and the earth.<br />

Vertical Ground<br />

Loop System<br />

Horizontal Ground<br />

Loop System<br />

Pond/Lake<br />

Loop System<br />

Well Water<br />

System<br />

7 | <strong>FHP</strong> | Bosch Group | Heat Pumps | Commercial | Geothermal Technology

Vertical Ground Loop System<br />

This type is used mainly in commercial buildings or where space is limited.<br />

Vertical holes 100 to 400 feet deep are drilled in the ground, and a single loop of pipe with a U-tube at the<br />

bottom is installed. The borehole is then sealed with grout to ensure good contact with the soil. The vertical<br />

ground loops are then connected to a horizontal underground header pipe that carries fluid to the unit. The<br />

Earth’s temperature is more stable farther below the surface which is an advantage for the system. Vertical<br />

ground loop fields may be located under buildings or parking lots. The life expectancy is in excess of 50 years.<br />

<strong>FHP</strong> | Bosch Group | Heat Pumps | Commercial | Geothermal Technology | 8

Horizontal Ground Loop System<br />

This type is cost effective on smaller projects or where there is sufficient space for the loop. Trenches, three<br />

to six feet deep are dug in which a series of parallel plastic pipes are laid. These loops are manifolded and<br />

connected to the heat pump. The fluid is then circulated absorbing or rejecting heat to the earth depending<br />

on the mode of operation. A typical horizontal loop will be 400 to 600 feet long for each ton of heating and<br />

cooling but will vary according to the soil type and the layout of the piping.<br />

9 | <strong>FHP</strong> | Bosch Group | Heat Pumps | Commercial | Geothermal Technology

Pond/Lake Loop System<br />

This type of design is economical when a project is located near a body of water. Fluid circulates through<br />

polyethylene piping in a closed system, just as it does through ground loops but in this case underwater.<br />

The pipes may be coiled in a slinky to fit more surfaces into a given amount of space. The lake needs to be a<br />

minimum size and depth depending on the load. Lake loops have no adverse impact on the aquatic system.<br />

<strong>FHP</strong> | Bosch Group | Heat Pumps | Commercial | Geothermal Technology | 10

Well Water System<br />

This type of installation is only possible if there is sufficient ground water available in a well, a lake or river in the<br />

area. The water must be of good quality. Local codes may limit the use of this system in certain areas.<br />

The system is open which means that water is pumped directly into the geothermal unit and then discharged<br />

either into a return well or a body of water. The water quality is unaffected other than a change in the temperature.<br />

11 | <strong>FHP</strong> | Bosch Group | Heat Pumps | Commercial | Geothermal Technology

How To Benefit From Geothermal Heat Pumps<br />

Heating In The Winter<br />

Groundwater or a fluid circulating inside a sealed piping loop absorbs heat from the earth. In the heat pump,<br />

refrigerant is compressed to raise source heat to a higher temperature and heat the air or hot water for<br />

distribution throughout your building.<br />

Cooling In The Summer<br />

The system reverses and expels heat from your building to the cooler earth via the loop system or ground water.<br />

This heat exchange process is not only natural, but is a truly ingenious way to create a comfortable climate in<br />

your building.<br />

Hot Water Year-Round<br />

Plentiful hot water provides added capacity for cafeterias, locker rooms, restrooms, etc. In the summer hot water<br />

is virtually free—produced by the waste heat extracted from interior air during the cooling cycle.<br />

Safety<br />

Geothermal heat pumps have no flame, no flue, no odor and no danger of fumes.<br />

Warranty Protection<br />

Ground loop pipes have warranties of 50+ years.<br />

These systems are dependable, reliable and have a long service life.<br />

<strong>FHP</strong> | Bosch Group | Heat Pumps | Commercial | Geothermal Technology | 12

www.fhp-mfg.com<br />

601 N.W. 65th Court, Ft. Lauderdale, FL 33309<br />

Phone: 954-776-5471 | Fax: 954-776-5529<br />

www.boschtaxcredit.com | www.fhp-mfg.com<br />

970-348