PG 8527 - 12 Page - web - 12-10-2007.qxp

PG 8527 - 12 Page - web - 12-10-2007.qxp

PG 8527 - 12 Page - web - 12-10-2007.qxp

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

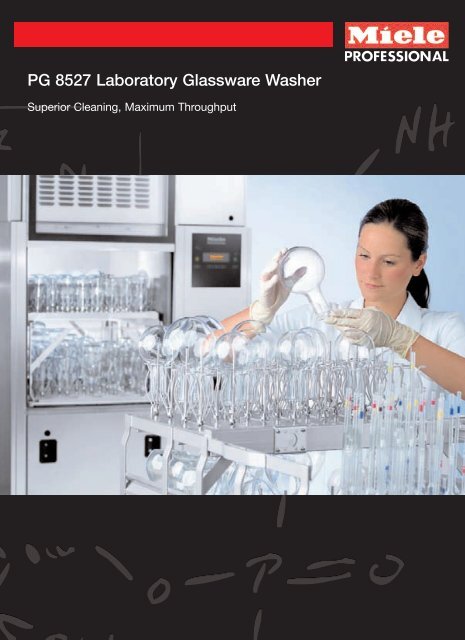

<strong>PG</strong> <strong>8527</strong> Laboratory Glassware Washer<br />

Superior Cleaning, Maximum Throughput

2<br />

Miele Professional:<br />

Advancing the Science of Clean

<strong>PG</strong> <strong>8527</strong>:<br />

Advancing the Science of Clean<br />

Miele <strong>PG</strong> <strong>8527</strong> Overview<br />

Miele's largest and most sophisticated<br />

glassware washer, the all new <strong>PG</strong> <strong>8527</strong> is<br />

designed for high-throughput cleaning in<br />

centralized wash areas. This unit is ideal<br />

for cleaning both large volumes of small<br />

items, and difficult to clean large items.<br />

The <strong>PG</strong> <strong>8527</strong> features a wide array of<br />

innovations and unique functions such as<br />

the new Profitronic+ controller with<br />

PerfectTouch control, the patented<br />

maintenance-free conductivity meter, an<br />

improved hygienic wash chamber, a<br />

unique spray arm monitoring system, a<br />

highly accurate detergent dispensing<br />

monitor using ultrasound technology, an<br />

improved HEPA-filtered forced air drying<br />

system, and a full-view glass door with<br />

chamber lighting.<br />

<strong>PG</strong> <strong>8527</strong> Key Features<br />

• Optional HEPA-filtered forced-air drying<br />

• Profitronic+ controller<br />

• <strong>12</strong> standard wash programs<br />

• 35 additional custom program spaces<br />

• Freely programmable<br />

• Spray arm monitoring system<br />

• Standard liquid dispensing<br />

• Bellows-type detergent pumps<br />

• 1 on-board <strong>10</strong>L liquid detergent<br />

dispenser<br />

• 1 on-board <strong>10</strong>L liquid neutralizer<br />

dispenser<br />

• 3 optional off-board <strong>10</strong>L dispensers<br />

• Dispensing volume control system<br />

using ultrasound technology<br />

• Modular basket system<br />

• 1-3 levels of injection cleaning<br />

• 1-5 levels of standard cleaning<br />

• Adjustable main wash and DI rinse<br />

• Adjustable from ambient to 93° C<br />

• 264 combined gpm high-flow circulation<br />

• Separate drain & circulation pumps<br />

• 4 standard RS-232 ports<br />

• Optional maintenance free<br />

conductivity meter<br />

• Optional automatic basket recognition<br />

• Standard stainless steel exterior<br />

• Optional dual-door model, <strong>PG</strong> 8528<br />

Superior Cleaning Results<br />

Miele washers employ a delicate balance<br />

of four factors to ensure exemplary<br />

cleaning results. Through a careful balance<br />

of wash time, water temperatures, water<br />

circulation, and specific detergents, Miele<br />

systems provide reliable wash results.<br />

Advanced wash programs, precise<br />

sensors, and leading componentry; Miele<br />

truly is advancing the science of clean.<br />

PerfectVision<br />

Miele’s new Profitronic+ controller ushers<br />

in a new era of streamlined, user-friendly<br />

machine interfaces that maintain great<br />

depths of customability and data logging.<br />

The <strong>PG</strong> <strong>8527</strong> comes standard with<br />

<strong>12</strong> wash programs and 17 utility<br />

programs plus the ability to store 35<br />

additional custom wash programs as<br />

your requirements dictate.<br />

Operation is straight<br />

forward. Controlled<br />

through a flat glass<br />

screen display for<br />

simplified cleaning,<br />

program selection is<br />

via capacitive touch<br />

controls, providing an extremely durable<br />

and elegantly streamlined set of controls<br />

that are not hindered by any protrusions.<br />

Through 15 selectable languages, minimal<br />

controls, and a modular CAN-BUS design<br />

for future scalability, the <strong>PG</strong> <strong>8527</strong> allows<br />

central wash areas to be up and running<br />

comfortably in a short time frame.<br />

PerfectVision<br />

Beyond validation, the <strong>PG</strong> <strong>8527</strong> offers a<br />

new patented conductivity meter to ensure<br />

proper cleaning.<br />

The sensor measures the conductivity<br />

inductively, with no sensors exposed to<br />

water. Your benefit? The system is<br />

absolutely maintenance free and no<br />

calibration is required.<br />

Upon setting the<br />

permissible water<br />

conductivity, the <strong>PG</strong><br />

<strong>8527</strong>’s meter then<br />

monitors accurately<br />

within the ranges of<br />

0-<strong>10</strong>0 mS/cm and<br />

0.1-<strong>12</strong>0 mS/cm. The controller can be set<br />

to add additional rinses until the target<br />

conductivity level is reached. You are<br />

assured residual-free rinses with<br />

reliable, repeatable wash results.<br />

Hygienic Wash Chamber Design<br />

The <strong>PG</strong> <strong>8527</strong> features a self-draining wash<br />

chamber with coved corners and sloped<br />

ceiling for superior hygienic operation.<br />

To withstand the<br />

rigors present in<br />

your workplace, the<br />

<strong>PG</strong> <strong>8527</strong>’s entire<br />

wash chamber is<br />

constructed of<br />

high-grade 316L<br />

stainless steel for extra corrosion<br />

resistance. And, with with no internal<br />

heater elements, the <strong>PG</strong> <strong>8527</strong> presents<br />

a truly well engineered wash chamber<br />

for years of worry-free operation.

Engineered Perfection,<br />

Miele’s Solution for Perfect Cleaning<br />

PerfectVision<br />

The <strong>PG</strong> <strong>8527</strong> comes standard with<br />

on-board, color-coded liquid detergent<br />

and neutralizer dispensers for increased<br />

safety and simplicity. Chemical dispensing<br />

is monitored through Miele’s revolutionary<br />

PerfectFlow Sensor system.<br />

This advanced system employs ultrasound<br />

technology, producing precise readings<br />

irrespective of ambient temperature and<br />

fluid viscosity conditions.<br />

Highly reliable and<br />

entirely automatic,<br />

its liquid dispensing<br />

provides high levels<br />

of accuracy while<br />

eliminating potential<br />

user error in the<br />

chemical dosing<br />

process. In addition,<br />

the included reservoir means less refilling,<br />

freeing valuable staff time.<br />

Choice of Machine Base Selection<br />

Miele offers both a stationary and a<br />

mobile base, both manufactured by Miele<br />

of high-grade stainless steel.<br />

Optional Pass-Through Model<br />

The <strong>PG</strong> 8528, Miele’s optional dual-door<br />

model, is designed for critical applications<br />

where a pass-through washer is needed.<br />

Profitronic+ control panels are featured<br />

on both the clean- and dirty-sides, with<br />

specific functions for simple operation.<br />

Miele also offers a stainless steel trim kit<br />

for flush, in-wall installations.<br />

PerfectVision<br />

The <strong>PG</strong> <strong>8527</strong> spray arm monitoring system<br />

employs a sensor strip located outside of<br />

the chamber to monitor spray arm rotation.<br />

Rotation speed of<br />

all spray arms is<br />

monitored within<br />

the out-of-range<br />

values above or<br />

below 45 rpm or 25<br />

rpm respectively,<br />

and is customizable to 15-55 rpm.<br />

When the value is found to be out of the<br />

specified range, or if the spray arm<br />

movement is blocked entirely, the <strong>PG</strong> <strong>8527</strong><br />

automatically creates an alarm condition.<br />

This system prevents improper machine<br />

loading while assuring a good wash result.<br />

PerfectVision<br />

The <strong>PG</strong> <strong>8527</strong> offers an all-glass door<br />

option with interior cabinet lighting to<br />

allow optimal visual monitoring of the<br />

wash process.<br />

Cabinet lighting<br />

time lengths can be<br />

user defined, and<br />

the lift door can<br />

open automatically<br />

after program end<br />

if required.<br />

The door adheres to Miele’s strict<br />

engineering guidelines, and is extremely<br />

shatter resistant and has been designed,<br />

tested, and manufactured to minimize<br />

unwanted heat transfer.<br />

PerfectVision<br />

Miele’s optional HEPA drying system<br />

with a 1,000-hour maintenance cycle<br />

provides a faster, more complete drying .<br />

Combined with<br />

Miele’s assortment<br />

of direct-injection<br />

baskets, forced-air<br />

drying blows air<br />

both around the<br />

chamber and into<br />

each individual piece of glassware for<br />

complete drying, even in difficult,<br />

restrictive narrow-neck items.<br />

The <strong>PG</strong> <strong>8527</strong> features an improved air<br />

path for particulate-free drying, with the<br />

HEPA filter positioned directly behind the<br />

entrance to the wash cabinet to ensure<br />

that particulate contamination from the<br />

heating system, fan, and silencers cannot<br />

enter the cabinet.<br />

Drying times and temperatures (ambient<br />

to 115° C) are fully adjustable to meet the<br />

demands of objects being dried.<br />

Modular Design<br />

The Miele <strong>PG</strong> <strong>8527</strong> is available for your<br />

specific wash requirements thanks to a<br />

highly flexible modular design. This allows<br />

customization down to an impressive level,<br />

ensuring the machine you order and<br />

receive is exactly what your facility will best<br />

benefit from.<br />

Contact Miele today to find out how to<br />

best kit your <strong>PG</strong> <strong>8527</strong>.

Profitronic Leading Machine Controller: Features,<br />

Superior The Ultimate Cleaning Cleaning ResultsFlexibility<br />

Superior DurabilityControl<br />

The In addition Miele Profitronic to the many control new system features, offers the<br />

unprecedented <strong>PG</strong> <strong>8527</strong> includes levels one of characteristic programmability that<br />

in all a Miele powerful, Labwashers user-friendly are well interface. known for:<br />

durability. This machine is tested to run<br />

Through 15,000 cycles, the expertise which equals of the a Miele life<br />

Application expectancy of Laboratory, nearly <strong>10</strong> the years <strong>PG</strong> (based <strong>8527</strong> on is<br />

equipped heavy usage with of 6 wash an array cycles of per standard day cleaning 260 working programs days per to deftly year). handle a large<br />

variety of laboratory cleaning challenges.<br />

The new HEPA filter has an extended<br />

Beyond durability that, of 1,000 the Profitronic hours, requiring features less a<br />

generous changing amount than the of previous storage for version. additional And<br />

customized since the cleaning new conductivity programs. Thanks meter to is<br />

tremendous absolutely maintenance flexibility, free, operators it eliminates are<br />

presented service and calibration with easy concerns design common and<br />

programming with most conductivity of custom meters. wash protocols,<br />

including full control of time, temperature,<br />

detergent Electric and and Steam neutralizer Heating dosing, Options water fill<br />

volume, To customize and drying. installation for your facility,<br />

the <strong>PG</strong> <strong>8527</strong> can be heated by either<br />

Should electric your only cleaning or a combination application of require steam<br />

special and electric. attention, This our greatly application reduces<br />

specialists electrical demand, will work resulting with you to in an guarantee energy<br />

the cost best savings. programming for your specific,<br />

unique needs.<br />

Advanced Filter System<br />

The <strong>PG</strong> <strong>8527</strong> features a triple filtration<br />

system in the bottom of the wash<br />

chamber, ensuring only clean, particle-free<br />

water is circulated.<br />

Additional filters protecting the incoming<br />

water lines stop external particles from<br />

entering the water path.<br />

The multiple sump filters help prevent<br />

debris from the wash load from<br />

recirculating, while filters upstream of<br />

the circulation pumps protect and<br />

extend pump life.<br />

Validation-Ready Optional Steam Condenser Design<br />

The steam Profitronic condenser system's eliminates built-in the relays need<br />

allow for external the unit to machine interface seamlessly venting while with<br />

many eliminating external potentially components hazardous helping steam the<br />

washer from venting integrate into the into lab during large operation. facilities.<br />

Some examples include visual or audible<br />

signal Using cold systems, water,<br />

external this system detergent deftly<br />

dispensers,<br />

condenses water or<br />

HVAC vapors and system flushes<br />

switches. them down the<br />

drain. This ensures<br />

The minimal controller radiant heat also<br />

features and a more advanced pleasant<br />

self-diagnostics,<br />

work environment.<br />

stopping Installation the is also wash greatly program simplified. at the first<br />

occurrence of an error code. The controller<br />

then High-Volume displays Pumps the fault message in plain<br />

English, At near ensuring twice the valid circulation wash results power and of a<br />

fast some service manufacturers, response. the <strong>PG</strong> <strong>8527</strong><br />

features a low pressure, 264 gallon/<br />

The minute 4-line, combined full-text circulation navigation rate. display This<br />

with provides selection a high of turnover six languages rate<br />

makes of water, direct while programming remaining<br />

simple, gentle enough and an not optical to<br />

interface damage allows or break programming<br />

glassware. delicate and<br />

For ensured cleaning performance,<br />

the <strong>PG</strong> <strong>8527</strong> also features<br />

separate circulation pumps for the<br />

upper and lower spray arms and the injectors.<br />

The pumps feature speed sensors and a<br />

gentle start for maximum pump longevity.<br />

The <strong>PG</strong> <strong>8527</strong> features separate pumps<br />

for its circulation and drainage, greatly<br />

simplifying installation and reducing any<br />

cross-contamination concerns.<br />

archiving Adjustable on High a PC Wash or Temperatures<br />

laptop. Using the<br />

optional Hotter water internal provides printer better module, cleaning or and<br />

external rinsing. printer The <strong>PG</strong> via <strong>8527</strong> the on-board can heat RS-232 wash<br />

port, water the and Profitronic DI water up system to 93° can C, accurately providing<br />

document thorough cleaning select program results parameters,<br />

in a short<br />

including amount of date, time. machine Separate number, wash program, and DI<br />

detergent, rinse temperatures pump status, are user-configurable.<br />

and temperatures.<br />

Simplified Operation<br />

The Profitronic <strong>PG</strong> <strong>8527</strong> controller<br />

dual sensors features to<br />

has<br />

clearly ensure consistent displayed<br />

operator wash temperatures prompts<br />

on and a high bright, cleaning fourline,<br />

levels, full-text allowing LCDa<br />

navigation greater degree display of<br />

with cleaning a accuracy. choice of<br />

multiple languages including English and<br />

Spanish. Flow Meters Programs & Heated can DI be Rinse easily Cycles selected<br />

Complete via the rotary elimination selector of residue dial. is best<br />

accomplished by one or more heated DI<br />

A rinse four-level cycles. The security <strong>PG</strong> <strong>8527</strong> system features allows a DI<br />

strict water connection control over and machine the ability access. to heat The the<br />

following DI water up levels to 93° can C. be selected:<br />

• Optional Limited in program the <strong>PG</strong> access <strong>8527</strong> is a 35L tank for<br />

• pre-heating Full program DI access water prior to the final<br />

• rinse, Full program ensuring access high plus throughput programming and<br />

proper temperatures.<br />

Miele combines this<br />

with flow meters on<br />

all incoming water<br />

lines. This feature<br />

allows extremely<br />

precise filling, and<br />

varying of fill volume<br />

by program step.<br />

The ability to vary fill volumes helps to save<br />

water by allowing the use of less water in<br />

certain wash or rinse steps.<br />

1 8

Miele’s Profitronic+ Controller:<br />

Capacitive Touch for Wash Precision<br />

Superior Control<br />

Miele’s Profitronic+ control system offers<br />

unprecedented levels of programmability<br />

in a powerful, user-friendly interface.<br />

Through the expertise of the Miele<br />

Application Laboratory, the <strong>PG</strong> <strong>8527</strong> is<br />

equipped with an array of standard<br />

cleaning programs to deftly handle a large<br />

variety of laboratory cleaning challenges.<br />

Beyond that, the Profitronic+ features a<br />

generous amount of storage for additional<br />

customized cleaning programs. Thanks to<br />

tremendous flexibility, operators are<br />

presented with easy design and<br />

programming of custom wash protocols,<br />

including full control of time, temperature,<br />

detergent and neutralizer dosing, water fill<br />

volume, and drying.<br />

Should your cleaning application require<br />

special attention, our application<br />

specialists will work with you to guarantee<br />

the best programming for your specific,<br />

unique needs.<br />

Flexible Design<br />

The Profitronic+ system's built-in relays<br />

allow the unit to interface seamlessly with<br />

many external components helping the<br />

washer integrate into large facilities. Some<br />

examples include visual or audible signal<br />

systems, external detergent dispensers, or<br />

HVAC system switches.<br />

The controller also features advanced<br />

self-diagnostics, stopping the wash<br />

program at the first occurrence of an error<br />

code. The controller then displays the fault<br />

message in plain English, ensuring valid<br />

wash results and a fast service response.<br />

The full-text navigation display with 15<br />

selectable languages makes direct<br />

programming simple, and an optical<br />

interface allows programming and digital<br />

archiving. Using the optional internal<br />

printer module, or an external printer via<br />

the on-board RS-232 port, the<br />

Profitronic+ system can document select<br />

program parameters, including date,<br />

machine number, program, detergent,<br />

pump status, and temperatures.<br />

As with the Profitronic+ controller, the<br />

entire <strong>PG</strong> <strong>8527</strong> is designed to be validation<br />

friendly. Featuring spray arm monitoring,<br />

conductivity metering, and a sample test<br />

port, the <strong>PG</strong> <strong>8527</strong> is ideally suited for<br />

facilities requiring documented, valid<br />

cleaning results.<br />

Simplified Operation<br />

The Profitronic+ controller features clearly<br />

displayed operator prompts on a bright,<br />

flush glass full-text capacitive touch LCD<br />

navigation display with a choice of<br />

multiple languages including English and<br />

Spanish. Additionally, the capacitive touch<br />

controller works even with gloved hands.<br />

A four-level security system allows<br />

strict control over machine access. The<br />

following levels can be selected:<br />

• Limited program access<br />

• Full program access<br />

• Full program access plus programming<br />

• Automatic Basket Recognition System<br />

This level is the ultimate safeguard,<br />

allowing only the program specified on the<br />

magnetic basket-coding strip to be run.<br />

Although highly advanced, the Profitronic+<br />

is not difficult to master. These superior<br />

features simply enable you to maximize<br />

efficiency in your wash area. Another way<br />

Miele is advancing the science of clean.<br />

1 Electronic door lock<br />

2 On/Off button<br />

3 LCD display<br />

4 Switch between selections<br />

5 Entry acceptance button<br />

6 Program selector button<br />

7 Cancel selection button<br />

8 Optical PC interface<br />

1 2 3 4 5 6 7 8

Miele Professional:<br />

Service and Customization at Your Fingertips<br />

The Exclusive Application Laboratory<br />

Drawing on a library of knowledge<br />

constructed over <strong>10</strong>0 years through<br />

cleaning innovation and expertise,<br />

Miele provides world-class application<br />

assistance and consultation.<br />

A key component of this is the exclusive<br />

Miele Application Laboratory, housed in<br />

Princeton, NJ, with a sister lab in<br />

Gütersloh, Germany.<br />

Through these<br />

active working labs,<br />

Miele continually<br />

surveys the horizon<br />

for unique cleaning<br />

challenges. This<br />

ensures you a truly<br />

competent and uniquely tailored cleaning<br />

system. Miele will also guide you, through<br />

testing, to the proper basket system.<br />

Whether cleaning narrow-necked<br />

Erlenmeyer flasks containing solvents on<br />

an injection insert, orthopedic knee<br />

implants covered in titanium dust in the<br />

proper wash rack, or loose stainless steel<br />

gears coated in cutting oils in a fine mesh<br />

basket, you are ensured consistent results.<br />

Wide Array of Baskets & Detergents<br />

Through the largest collection of washer<br />

baskets and detergents in the industry,<br />

you are ensured a specific, automated<br />

washing solution to your unique<br />

cleaning requirements.<br />

And, should your needs change, rest<br />

assured in knowing that Miele baskets and<br />

inserts are highly interchangeable,<br />

meaning that your new cleaning<br />

procedure, including detergents and wash<br />

baskets, is only a phone call away.<br />

Comprehensive Validation Services<br />

Miele is proud to offer renowned<br />

validation documentation and services<br />

for Miele Professional laboratory<br />

glassware washers.<br />

Miele validation<br />

services include<br />

extensive Mieledeveloped<br />

IQ/OQ<br />

documentation, fully<br />

trained validation<br />

technicians, and<br />

convenient set pricing to eliminate cost<br />

concerns associated with hourly billing by<br />

independent consultants.<br />

Miele Professional Technical Service<br />

Place your trust in Miele, and you are<br />

incorporating an industry-leading cleaning<br />

system into your facility. A network of<br />

dedicated and highly specialized Miele<br />

Professional Technical Service personnel<br />

guarantees that on-site assistance is close<br />

at hand.<br />

To ensure a robust<br />

operating life, Miele<br />

produces spare<br />

parts for at least 15<br />

years from the<br />

discontinuation of<br />

series production<br />

for every model. Coupled with industryleading<br />

engineering, you have a rock-solid,<br />

reliable cleaning solution.<br />

Miele sets the standard in terms of<br />

knowledge, application support, and<br />

training. Beyond comprehensive machine<br />

service, Miele Professional Technical<br />

Service also excels in installation and<br />

application-related issues, supplying you<br />

with the flexibility needed to deftly handle<br />

evolving goals and application issues.<br />

<strong>10</strong>

Laboratory Glassware Washer<br />

Technical Data<br />

Machine <strong>PG</strong> <strong>8527</strong>/<strong>PG</strong> 8528<br />

Control Unit<br />

Profitronic+:<br />

Standard:<br />

Utility:<br />

Custom:<br />

Temperatures<br />

Wash:<br />

Final Rinse:<br />

Cleaning Mechanism<br />

Rotary:<br />

Spray Arm Monitoring:<br />

Direct Injection:<br />

Drying<br />

Water Softener<br />

Profitronic+ control system with programmable wash options, available automatic basket recognition (AWK),<br />

1 Ethernet interface, 4 RS 232 serial interface for connection to printer or PC, 15 selectable languages on<br />

an easy to use glass screen touch screen display<br />

<strong>12</strong> standard wash programs<br />

17 utility programs<br />

35 available spaces for custom wash programs to be created and stores<br />

Freely adjustable up to 93° C<br />

Freely adjustable up to 93° C<br />

Dual spray arms located at the top and bottom of chamber, additional spray arm(s) on modular baskets<br />

For upper and lower spray arms and spray arms on baskets<br />

Injection cleaning possible on 1, 1.5, 2, and 3 levels<br />

Optional; HEPA-filtered forced-air drying system w/ freely adjustable time and temp. settings w/ cool-down step<br />

Temp adj.: 140-239° F (60-115° C), 1° C increments; time adj.: 1-240 min., 1 minute increments<br />

Optional; Built-in softener with easily programmed water hardness control<br />

Steam Condenser<br />

Optional; no external venting required<br />

Detergent & Neutralizer Dispensing<br />

Detergent:<br />

1 bellows-type dosing connection for <strong>10</strong>L container, stored on-board<br />

Neutralizer:<br />

1 bellows-type dosing connection for <strong>10</strong>L container, stored on-board<br />

3 additional bellows-type dosing connections for <strong>10</strong>L containers optional<br />

Main Circulation Pump<br />

Circulation:<br />

264 gal/min (<strong>10</strong>00 l/min) total; Spray arm pump <strong>10</strong>6 gal/min (400 l/min), Injection pump 158 gal/min (600 l/min)<br />

Pump includes sensor to protect against overheating<br />

Cabinet and Chamber Construction<br />

Exterior:<br />

Brush finish type 304 stainless steel top, front, sides and bottom<br />

Interior:<br />

Type 316L stainless steel chamber sides, back and top<br />

Type 316L stainless steel chamber floor and door<br />

Plumbing Connections<br />

Tap (2 connections):<br />

DI (1 connection):<br />

a) Hot water for wash cycles: One 1/2” ID pressure hose, 5’ 7” long with 3/4” hose thread<br />

Input pressure: 30 - 147 PSI, min. flow rate of 3.9 gal/min (15 l/min)<br />

Max incoming water temperature: 158° F (70° C)<br />

b) Cold water for wash cycles: One 1/2” ID pressure hose, 5’ 7” long w/ 3/4” hose thread<br />

Input pressure: 30 - 147 PSI, min. flow rate of 3.9 gal/min (15 l/min)<br />

Max incoming water temperature: 158° F (70° C)<br />

c) DI water for rinse cycles: One 1/2” ID pressure hoses, 5’ 7” long with 3/4” hose thread<br />

Input pressure: 30 - 147 PSI, min. flow rate of 3.9 gal/min (15 l/min)<br />

Max incoming water temperature: 158° F (70° C)<br />

Drain Connections<br />

Connection: Two 1” OD, one 3/8” OD flexible drain hoses, 4’ 11” long; max drain height = 3’. Max drain length = 13’<br />

If steam condenser installed, optional 1/2” ID drain line provided; 3” min. floor drain or standpipe required<br />

Flow Rate:<br />

Maximum amount of water a drain needs to accept would be both numbers at the same time: <strong>10</strong>.8 gal/min<br />

9.2 gal/min (35 l/min) for chamber fill<br />

1.6 gal/min (6 l/min) for steam condenser fill<br />

Electrical Requirements<br />

Electric Only: 3 AC 208 V, 60 Hz, 3 x 60 Amps<br />

Steam/Electric: 3 AC 208 V, 60 Hz, 3 x 15 Amps<br />

Steam Drying Option<br />

A more efficient solution than heating with electric alone<br />

36 - 145 PSI required; two 1/2” threaded connections provided for steam connection and condensate/return<br />

Requires compressed air option (see below)<br />

Compressed Air (req w/ Steam) 85 - 175 PSI required<br />

Noise Level, Cleaning<br />

61.5 dBA<br />

Noise Level, Drying<br />

61.5 dBA<br />

Dimensions<br />

Exterior:<br />

95.3” H (inc. Base, TA drying unit, MAV enclosure) x 45.3” W x 34.3” D<br />

Interior (Chamber):<br />

26.6” H x 25.6” W x 31.5” D<br />

Net Weight:<br />

1,256.6 lbs

Miele Professional<br />

9 Independence Way<br />

Princeton, NJ 08540<br />

USA<br />

& 800.991.9380<br />

609.419.4241<br />

labwasher.com<br />

Miele Limited<br />

161 Four Valley Drive<br />

Vaughan, ON L4K 4V8<br />

Canada<br />

& 800.643.5381<br />

905.532.2290<br />

miele.ca<br />

Miele S.A. de C.V.<br />

Av. Santa Fe 170, German Centre: 0-4-2<br />

Col. Lomas de Santa Fe<br />

C.p. 0<strong>12</strong><strong>10</strong>. Mexico, D.F.<br />

& (+5255) - 8503 9870 al 73<br />

(+5255) - 8503 9874<br />

miele-professional.com.mx<br />

Every effort has been made to ensure that<br />

the information given in this brochure is<br />

correct at the time of printing. However,<br />

due to continuous product improvement,<br />

Miele reserves the right to make changes<br />

to products and technical data without<br />

prior notice.<br />

©2008 Miele, Inc.<br />

B999690