Synthesis of large surface area LaFeO3 nanoparticles by SBA-16 ...

Synthesis of large surface area LaFeO3 nanoparticles by SBA-16 ...

Synthesis of large surface area LaFeO3 nanoparticles by SBA-16 ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

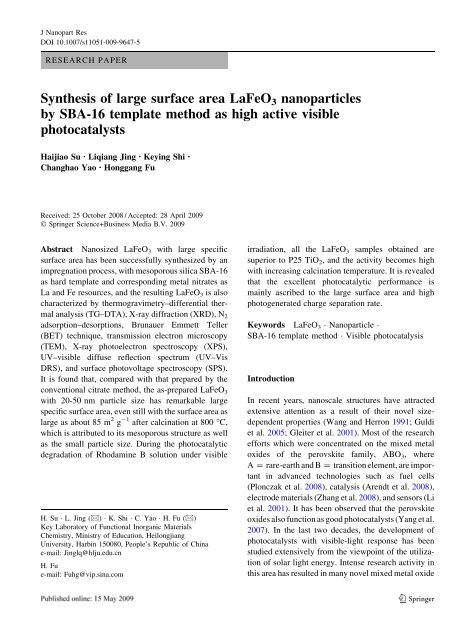

J Nanopart Res<br />

DOI 10.1007/s11051-009-9647-5<br />

RESEARCH PAPER<br />

<strong>Synthesis</strong> <strong>of</strong> <strong>large</strong> <strong>surface</strong> <strong>area</strong> LaFeO 3 <strong>nanoparticles</strong><br />

<strong>by</strong> <strong>SBA</strong>-<strong>16</strong> template method as high active visible<br />

photocatalysts<br />

Haijiao Su Æ Liqiang Jing Æ Keying Shi Æ<br />

Changhao Yao Æ Honggang Fu<br />

Received: 25 October 2008 / Accepted: 28 April 2009<br />

Ó Springer Science+Business Media B.V. 2009<br />

Abstract Nanosized LaFeO 3 with <strong>large</strong> specific<br />

<strong>surface</strong> <strong>area</strong> has been successfully synthesized <strong>by</strong> an<br />

impregnation process, with mesoporous silica <strong>SBA</strong>-<strong>16</strong><br />

as hard template and corresponding metal nitrates as<br />

La and Fe resources, and the resulting LaFeO 3 is also<br />

characterized <strong>by</strong> thermogravimetry–differential thermal<br />

analysis (TG–DTA), X-ray diffraction (XRD), N 2<br />

adsorption–desorptions, Brunauer Emmett Teller<br />

(BET) technique, transmission electron microscopy<br />

(TEM), X-ray photoelectron spectroscopy (XPS),<br />

UV–visible diffuse reflection spectrum (UV–Vis<br />

DRS), and <strong>surface</strong> photovoltage spectroscopy (SPS).<br />

It is found that, compared with that prepared <strong>by</strong> the<br />

conventional citrate method, the as-prepared LaFeO 3<br />

with 20-50 nm particle size has remarkable <strong>large</strong><br />

specific <strong>surface</strong> <strong>area</strong>, even still with the <strong>surface</strong> <strong>area</strong> as<br />

<strong>large</strong> as about 85 m 2 g -1 after calcination at 800 °C,<br />

which is attributed to its mesoporous structure as well<br />

as the small particle size. During the photocatalytic<br />

degradation <strong>of</strong> Rhodamine B solution under visible<br />

H. Su L. Jing (&) K. Shi C. Yao H. Fu (&)<br />

Key Laboratory <strong>of</strong> Functional Inorganic Materials<br />

Chemistry, Ministry <strong>of</strong> Education, Heilongjiang<br />

University, Harbin 150080, People’s Republic <strong>of</strong> China<br />

e-mail: Jinglq@hlju.edu.cn<br />

H. Fu<br />

e-mail: Fuhg@vip.sina.com<br />

irradiation, all the LaFeO 3 samples obtained are<br />

superior to P25 TiO 2 , and the activity becomes high<br />

with increasing calcination temperature. It is revealed<br />

that the excellent photocatalytic performance is<br />

mainly ascribed to the <strong>large</strong> <strong>surface</strong> <strong>area</strong> and high<br />

photogenerated charge separation rate.<br />

Keywords LaFeO 3 Nanoparticle <br />

<strong>SBA</strong>-<strong>16</strong> template method Visible photocatalysis<br />

Introduction<br />

In recent years, nanoscale structures have attracted<br />

extensive attention as a result <strong>of</strong> their novel sizedependent<br />

properties (Wang and Herron 1991; Guldi<br />

et al. 2005; Gleiter et al. 2001). Most <strong>of</strong> the research<br />

efforts which were concentrated on the mixed metal<br />

oxides <strong>of</strong> the perovskite family, ABO 3 , where<br />

A = rare-earth and B = transition element, are important<br />

in advanced technologies such as fuel cells<br />

(Plonczak et al. 2008), catalysis (Arendt et al. 2008),<br />

electrode materials (Zhang et al. 2008), and sensors (Li<br />

et al. 2001). It has been observed that the perovskite<br />

oxides also function as good photocatalysts (Yang et al.<br />

2007). In the last two decades, the development <strong>of</strong><br />

photocatalysts with visible-light response has been<br />

studied extensively from the viewpoint <strong>of</strong> the utilization<br />

<strong>of</strong> solar light energy. Intense research activity in<br />

this <strong>area</strong> has resulted in many novel mixed metal oxide<br />

123

J Nanopart Res<br />

photocatalysts for water splitting such as SrTiO 3 ,<br />

NaTaO 3 , etc. (Subramanian et al. 2006; Kato and Kudo<br />

2003; Maeda and Domen 2007; Penä and Fierro 2001),<br />

and the photocatalytic decompositions <strong>of</strong> organic<br />

compounds have been widely studied, but all the<br />

performance need to be advanced.<br />

The specific <strong>surface</strong> <strong>area</strong> and crystal structure are<br />

the most important two factors influencing catalytic<br />

activity. During several conventional synthetic processes<br />

<strong>of</strong> perovskites, such as citrate method and<br />

solid state reactions, the high-temperature thermal<br />

treatments needed usually lead to the sintering <strong>of</strong> the<br />

resulting particles, consequently decreasing greatly<br />

the specific <strong>surface</strong> <strong>area</strong>, which will <strong>large</strong>ly influence<br />

the performance <strong>of</strong> the resulting perovskites and<br />

hinder their widespread use as catalysts. Thus, novel<br />

synthetic methods to obtain materials with <strong>large</strong><br />

specific <strong>surface</strong> <strong>area</strong> are greatly desired.<br />

Among various preparation methods <strong>of</strong> nanosized<br />

materials, the template method, which provides a<br />

good choice for the synthesis <strong>of</strong> <strong>nanoparticles</strong> with<br />

controllable size and shape because <strong>of</strong> being in a<br />

confined three-dimensional (3D) space, has recently<br />

sparked great research interests (Lu and Schüth 2006;<br />

Schüth 2003). Unlike conventional surfactant templates,<br />

the hard template could effectively maintain<br />

the local strain caused <strong>by</strong> the crystallization <strong>of</strong><br />

precursors. Zhao et al. synthesized highly dispersed<br />

TiO 2 <strong>nanoparticles</strong> using <strong>SBA</strong>-15 as hard template<br />

(Zhao and Yu 2006). Valdés-Solís et al. prepared<br />

nanosized perovskites and spinels through a silica<br />

xerogel template route (Valdés-Solís et al. 2005).<br />

However, so far the articles on the use <strong>of</strong> the <strong>SBA</strong>-<strong>16</strong><br />

as hard template to synthesize nanosized solid<br />

materials are seldom reported. <strong>SBA</strong>-<strong>16</strong> is a kind <strong>of</strong><br />

3D, ‘‘cage-like’’ mesoporous silica, and its pores are<br />

connected <strong>by</strong> some mesoporous windows, so as to be<br />

beneficial for the substance transportation. Thus, it<br />

can be deduced that its negative replica is 3D<br />

connected structure (Shi et al. 2005a, b; Schüth and<br />

Schmid 2002; Kärger and Freude 2002), so that the<br />

<strong>SBA</strong>-<strong>16</strong> as template to prepare porous solid materials<br />

with <strong>large</strong> <strong>surface</strong> <strong>area</strong> is feasible. It has been<br />

demonstrated that mesoporous structure is highly<br />

desirable for effective photocatalysis, since such<br />

structures enable more light to be harvested and also<br />

possess continuous pore channels that facilitate the<br />

transfer <strong>of</strong> reactant molecules.<br />

As a kind <strong>of</strong> important functional material, LaFeO 3<br />

with a typical ABO 3 -type perovskite structure has<br />

many applications, such as catalytic oxidation, electrode<br />

materials, and chemical sensors for the humidity<br />

and alcohols, and it also is an ideal potential semiconductor<br />

material for visible photocatalyst because <strong>of</strong> its<br />

small band gap energy (Wang et al. 2006; Li et al.<br />

2007). Herein, nanosized LaFeO 3 with <strong>large</strong> <strong>surface</strong><br />

<strong>area</strong> was synthesized with mesoporous silica <strong>SBA</strong>-<strong>16</strong><br />

as hard template for the first time. The as-prepared<br />

LaFeO 3 exhibits excellent visible-light photocatalytic<br />

activity, which is attributed to the <strong>large</strong> <strong>surface</strong> <strong>area</strong>, as<br />

well as to the high photoinduced charge separation rate<br />

mainly based on the SPS responses. This should be<br />

valuable for the practical application <strong>of</strong> LaFeO 3 and<br />

also provides a new strategy to prepare other highperformance<br />

nanostructured oxide composite materials<br />

with <strong>large</strong> <strong>surface</strong> <strong>area</strong>.<br />

Experimental<br />

Preparation <strong>of</strong> the template <strong>SBA</strong>-<strong>16</strong><br />

The <strong>SBA</strong>-<strong>16</strong> was synthesized <strong>by</strong> a sol–gel process as<br />

described elsewhere (Shi et al. 2005a, b). The F127<br />

(EO 106 PO 70 EO 106 , BASF) and Ethyl silicate<br />

(C 8 H 20 O 4 Si) were used as surfactant and silicon<br />

sources, respectively. After the resulting xerogel was<br />

calcined at 550 °C with a heating rate <strong>of</strong> 1 °C min -1<br />

and ground, the mesoporous silica <strong>SBA</strong>-<strong>16</strong> was<br />

obtained eventually.<br />

<strong>Synthesis</strong> <strong>of</strong> the samples<br />

Nanosized LaFeO 3 was synthesized according to the<br />

flowchart shown in Fig. 1. First, 1 g <strong>of</strong> freshly<br />

as-synthesized <strong>SBA</strong>-<strong>16</strong> was dispersed in 2 mL <strong>of</strong><br />

ethanol solution, containing 0.0041 mol <strong>of</strong> La(NO 3 ) 3 <br />

6H 2 O and 0.0041 mol <strong>of</strong> Fe(NO 3 ) 3 9H 2 O. After<br />

ultrasonication for 10 min, the mixture obtained was<br />

kept at 60 °C under stirring until the solvent was<br />

evaporated completely. Subsequently, the LaFeO 3 –<br />

<strong>SBA</strong>-<strong>16</strong> composite was obtained after the above<br />

mixture was dried in a vacuum at 80 °C and calcined<br />

in air at needed temperature for 2 h. Finally, the<br />

template-free LaFeO 3 nanopowder was gained <strong>by</strong><br />

washing, drying, grinding, and heat-treatment at<br />

123

J Nanopart Res<br />

La(NO 3 ) 3·6H 2 O<br />

Fe(NO 3 ) 3·9H 2 O<br />

Ethanol<br />

Nitrate ethanol solution<br />

Adding<br />

Fresh <strong>SBA</strong>-<strong>16</strong><br />

Mixed solution<br />

Drying and grinding<br />

precursor<br />

Calcining<br />

Template-containing LaFeO 3<br />

Washing, drying and calcining<br />

after treatment with NaOH<br />

Template-free LaFeO 3<br />

Fig. 1 Flowchart <strong>of</strong> the synthetic processes <strong>of</strong> nanosized<br />

LaFeO 3<br />

500 °C after the silica in the composite was dissolved<br />

in the 2 M NaOH solution.<br />

Characterization <strong>of</strong> the samples<br />

The thermogravimetry–differential thermal analysis<br />

(TG–DTA) <strong>of</strong> the dry mixtured precursor was<br />

performed using a Rigaku TAS 100 thermal analyzer,<br />

with the temperature rate <strong>of</strong> 10 °C min -1 in air,<br />

referenced to a-Al 2 O 3 . The crystal structure <strong>of</strong> the<br />

samples was determined <strong>by</strong> X-ray diffraction (XRD)<br />

method (Rigaku D/MAX-rA powder diffractometer,<br />

Japan). N 2 adsorption–desorption isotherm <strong>of</strong> the<br />

sample was carried out at the temperature <strong>of</strong> liquid<br />

nitrogen <strong>by</strong> using a Micromeritics ASAP 2020 M<br />

system, outgassed for 10 h at 300 °C prior to the<br />

measurements. Transmission electron microscopy<br />

(TEM) observation <strong>of</strong> the sample was performed on<br />

a JEM-3010 electron microscope (JEOL, Japan), with<br />

an acceleration voltage <strong>of</strong> 300 kV. The BET <strong>surface</strong><br />

<strong>area</strong> was evaluated <strong>by</strong> a ST-2000 constant volume<br />

adsorption apparatus. The <strong>surface</strong> composition and<br />

elemental chemical state <strong>of</strong> the samples were examined<br />

<strong>by</strong> X-ray photoelectron spectroscopy (XPS)<br />

using a Model VG ESCALAB apparatus with AlKa<br />

X-ray source. The binding energies were calibrated<br />

with respect to the signal for adventitious carbon<br />

(binding energy = 284.6 eV). The UV–visible diffuse<br />

reflection spectrum (UV–vis DRS) <strong>of</strong> the<br />

samples was recorded with Shimadzu UV-2550<br />

Spectrophotometer, using BaSO 4 as reference. The<br />

SPS measurement <strong>of</strong> the samples was carried out with<br />

a home-built apparatus that had been described<br />

elsewhere (Jing et al. 2003).<br />

Photocatalytic activity measurement<br />

Rhodamine B (C 28 H 31 ClN 2 O 3 ) is a common dye that is<br />

extensively used in a variety <strong>of</strong> industrial applications<br />

(Wang et al. 2008; Huang et al. 2003). Therefore, the<br />

photocatalytic activity <strong>of</strong> the as-synthesized samples<br />

was evaluated <strong>by</strong> photodegradation <strong>of</strong> Rhodamine B<br />

under irradiation <strong>of</strong> visible light (k [ 400 nm). The<br />

light source was a high-pressure Xe lamp (150 W).<br />

Light passed through a cut<strong>of</strong>f filter and then was<br />

focused onto a 100-mL beaker. The reaction was<br />

maintained at ambient temperature. In a typical<br />

experiment, aqueous suspensions <strong>of</strong> Rhodamine B<br />

and 0.10 g <strong>of</strong> the photocatalyst powder were placed in<br />

the beaker. Prior to irradiation, the suspension was<br />

magnetically stirred in the dark to ensure the establishment<br />

<strong>of</strong> an adsorption/desorption equilibrium. At<br />

given irradiation time, 10 mL <strong>of</strong> the suspension was<br />

collected and centrifuged to remove the particles; then,<br />

the dye concentration was determined <strong>by</strong> measuring<br />

the UV–Vis absorbance <strong>of</strong> the dye aqueous solution.<br />

Results and discussion<br />

Measurements <strong>of</strong> TG–DTA and XRD<br />

Figure 2 is the TG–DTA curves <strong>of</strong> the dry mixed<br />

powder obtained. There are three stages during the<br />

weight loss process, one is at the temperature range<br />

from the room temperature to 250 °C, with endothermic<br />

phenomenon, mainly attributed to desorption<br />

<strong>of</strong> water that is physically adsorbed. The next is from<br />

300 to 500 °C, with three maximum exothermic<br />

peaks, accompanied <strong>by</strong> drastic weight loss which was<br />

attributed to vaporization <strong>of</strong> inner water and autocombustion<br />

during the nitrate decomposition <strong>of</strong> the<br />

dried powder. There is a slight loss process at the<br />

temperature higher than 500 °C, which is mainly<br />

caused <strong>by</strong> desorption <strong>of</strong> residual hydroxyl (OH)<br />

group (Nosaka et al. 1998). In this case, the slight<br />

exothermic phenomenon can be seen, which is<br />

possibly attributed to the gradual crystallization <strong>of</strong><br />

LaFeO 3 .<br />

123

J Nanopart Res<br />

Mass loss (%)<br />

Fig. 2<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

TG<br />

DTA<br />

Exo<br />

0<br />

Endo<br />

-2<br />

200 400 600 800 1000<br />

Temperature (°C)<br />

The XRD patterns <strong>of</strong> the as-prepared LaFeO 3<br />

samples calcined at different temperature are shown<br />

in Fig. 3. For the sample calcined at 500 °C, no<br />

obvious XRD peaks can be seen, indicating that there<br />

is mainly amorphous. When the calcination temperature<br />

is higher than 500 °C, the marked XRD peaks,<br />

which can be indexed to the ABO 3 -type LaFeO 3 as<br />

shown in the standard JCPDS No. 15-0148, display,<br />

and the XRD intensity gradually increases with<br />

enhancing the calcination temperature, implying that<br />

the crystallinity becomes much high.<br />

Measurements <strong>of</strong> N 2 adsorption–desorption,<br />

TEM, and BET<br />

In order to reveal the structure <strong>of</strong> the as-prepared<br />

LaFeO 3 , we took the measurements <strong>of</strong> N 2 adsorption–desorption<br />

and TEM observation <strong>of</strong> the sample<br />

10<br />

TG–DTA curves <strong>of</strong> the dry mixed powder obtained<br />

8<br />

6<br />

4<br />

2<br />

Heat flow (mV)<br />

calcined at 700 °C. Figure 4 shows the N 2 adsorption–desorption<br />

isotherm <strong>of</strong> the LaFeO 3 and pore size<br />

distributions (inset) calculated from desorption<br />

branch <strong>by</strong> the BJH method. The isotherm exhibits a<br />

long and narrow hysteresis loop, which is due to the<br />

nonstandard porous structure (Jin et al. 2006; Zapilko<br />

et al. 2007), and it can be seen that the template-free<br />

LaFeO 3 has disordered porous structure from the low<br />

values <strong>of</strong> dV/dR at BJH pore size distributions. The<br />

isotherm which starts a sharp capillary condensation<br />

step at low relative pressures must be caused <strong>by</strong> the<br />

pore size centered between 2 and 5 nm and has the<br />

hysteresis loop taken at high relative pressures<br />

attributed to its having <strong>large</strong> slit-like pores, size <strong>of</strong><br />

which extended to above 10 nm, between the particles<br />

rather than a mesostructure. The TEM image<br />

reported in Fig. 5 confirms the monodisperse <strong>nanoparticles</strong><br />

<strong>of</strong> LaFeO 3 with the particle sizes ranging<br />

from 20 to 50 nm.<br />

Table 1 reflects the specific <strong>surface</strong> <strong>area</strong>s <strong>of</strong> the<br />

LaFeO 3 prepared <strong>by</strong> the template method and the<br />

citrate method in our group (Li et al. 2007),<br />

respectively. By comparison, two main points can<br />

be found. One is that, at the same calcination<br />

temperature, the LaFeO 3 prepared <strong>by</strong> the template<br />

method has much <strong>large</strong>r <strong>surface</strong> <strong>area</strong> than that<br />

prepared via the citrate method and the other is that<br />

the <strong>surface</strong> <strong>area</strong> <strong>of</strong> the LaFeO 3 gradually decreases<br />

with increasing calcination temperature, which is<br />

mainly attributed to the increase in the particle size.<br />

However, compared with the LaFeO 3 prepared via<br />

the citrate method at the low temperature, the LaFeO 3<br />

Intensity (a.u.)<br />

900°C<br />

800°C<br />

700°C<br />

600°C<br />

500°C<br />

Absorbed volume (cm 3 / g)<br />

80<br />

60<br />

40<br />

20<br />

dV/dR (cm 3 g -1 nm -1 )<br />

0.002<br />

0.001<br />

0.000<br />

0 5 10 15 20 25 30<br />

Pore diameter (nm)<br />

20 30 40 50 60<br />

2θ (degree)<br />

Fig. 3 XRD patterns <strong>of</strong> LaFeO 3 samples calcined at different<br />

temperature<br />

0.0 0.2 0.4 0.6 0.8 1.0<br />

Relative pressure (p / p o<br />

)<br />

Fig. 4 N 2 adsorption–desorption isotherm for the templatefree<br />

LaFeO 3 calcined at 700 °C and pore size distributions<br />

calculated from desorption branch <strong>by</strong> the BJH method<br />

123

J Nanopart Res<br />

Fig. 5 TEM image <strong>of</strong> LaFeO 3 calcined at 700 °C<br />

Table 1 BET <strong>surface</strong> <strong>area</strong> <strong>of</strong> the LaFeO 3 samples prepared<br />

<strong>by</strong> different methods<br />

Calcination<br />

temperature (°C)<br />

prepared <strong>by</strong> the template method still can have a high<br />

<strong>surface</strong> <strong>area</strong>, even after calcination at 900 °C. Based<br />

on the above analyses <strong>of</strong> the N 2 adsorption–desorption,<br />

BET, and TEM observation, it can be deduced<br />

that the disordered porous structure in the particles<br />

and the relative small particle size are responsible for<br />

the high <strong>surface</strong> <strong>area</strong> <strong>of</strong> the resulting LaFeO 3 .<br />

Measurement <strong>of</strong> XPS<br />

BET <strong>surface</strong> <strong>area</strong> (m 2 g -1 )<br />

By the template<br />

method<br />

500 – 15.0<br />

600 129.6 9.2<br />

700 101.1 6.3<br />

800 85.4 4.3<br />

900 34.5 3.2<br />

By the citrate<br />

method<br />

The XPS spectra <strong>of</strong> La3d, Fe2p, and O1s <strong>of</strong> the<br />

resulting LaFeO 3 after calcination at 700 and 800 °C<br />

were performed, as shown in Fig. 6. The binding<br />

energies obtained in the XPS analysis are standardized<br />

for specimen charging using C1s as the reference<br />

at 284.6 eV. The XPS peak positions <strong>of</strong> La3d 5/2<br />

(Fig. 6a) and Fe2p 3/2 (Fig. 6b) are at about 834.8 and<br />

710.5 eV, respectively, demonstrating that the main<br />

chemical valences <strong>of</strong> La and Fe in the two samples<br />

both are ?3 according to the method principle and<br />

handbook <strong>of</strong> the XPS instrument and the literature<br />

(Yang et al. 2006). The two O1s XPS spectra<br />

(Fig. 6c) are wide and asymmetric, demonstrating<br />

that there are at least two kinds <strong>of</strong> O chemical states<br />

according to the binding energy range from about<br />

526.0 to 534.0 eV, including crystal lattice oxygen<br />

(O L ) and hydroxyl oxygen (O H ) with increasing<br />

binding energy (Zhang et al. 2006; Jing et al. 2006).<br />

Thus, the O1s XPS spectrum is fitted to two kinds <strong>of</strong><br />

chemical states with the Origin s<strong>of</strong>tware <strong>by</strong> Gaussian<br />

rule. The O L XPS signal is attributed to the contribution<br />

<strong>of</strong> La–O and Fe–O in LaFeO 3 crystal lattice,<br />

and its peak position is at about 529.5 eV. The O H<br />

XPS is close related to the hydroxyl groups resulting<br />

mainly from the chemisorbed water, and its peak<br />

position is at about 531.5 eV. As seen from Fig. 6c,<br />

the amount <strong>of</strong> hydroxyl oxygen (O H ) decreases as the<br />

thermal treatment is enhanced.<br />

Measurements <strong>of</strong> UV–Vis DRS and SPS<br />

Figure 7 shows the UV–Vis DRS spectra <strong>of</strong> LaFeO 3<br />

samples calcined at different temperature; it can be seen<br />

that the DRS spectra <strong>of</strong> all LaFeO 3 samples are similar,<br />

and upon the calcination temperature increasing, the<br />

absorption <strong>of</strong> the spectra above 550 nm is decreased<br />

gradually, which is the cause that the LaFeO 3 crystallinity<br />

increases with the calcination temperature<br />

increasing on the basis <strong>of</strong> XRD measurement. According<br />

to the energy band structure <strong>of</strong> LaFeO 3 similar to<br />

that <strong>of</strong> a-Fe 2 O 3 (Lu et al. 2005), it can be concluded that<br />

the DRS spectra <strong>of</strong> LaFeO 3 <strong>nanoparticles</strong> are ascribed<br />

to the electronic transitions from the valence band to<br />

conduction band (O 2p ? Fe 3d ) (Li et al. 2000). In<br />

addition, it can be ascertained that the as-prepared<br />

LaFeO 3 samples can be excited <strong>by</strong> the light with the<br />

wavelength <strong>of</strong> equal to or smaller than 550 nm.<br />

The SPS technique can provide a rapid, nondestructive<br />

test <strong>of</strong> semiconductor solid <strong>surface</strong> property,<br />

and is also a very effective way to study the separation<br />

and transfer behavior <strong>of</strong> photoinduced charge carriers at<br />

a <strong>surface</strong> or interface (Jing et al. 2006). Figure 8 shows<br />

the SPS response <strong>of</strong> LaFeO 3 <strong>nanoparticles</strong> calcined at<br />

different temperature. It can be found that all <strong>of</strong> these<br />

samples display obvious SPS response in the<br />

123

J Nanopart Res<br />

a<br />

La3d<br />

50<br />

Intensity (a.u.)<br />

800°C<br />

3d 5/2<br />

3d 3/2<br />

DRS (%)<br />

40<br />

30<br />

20<br />

10<br />

900°C<br />

800°C<br />

700°C<br />

600°C<br />

b<br />

Intensity (a.u.)<br />

Intensity (a.u.)<br />

820 830 840 850 860<br />

Binding energy (eV)<br />

c<br />

700°C<br />

800°C<br />

700°C<br />

2p 3/2<br />

2p 1/2<br />

700 710 720 730<br />

Binding energy (eV)<br />

800°C<br />

700°C<br />

524 528 532 536<br />

Binding energy (eV)<br />

Fe2p<br />

wavelength range from 300 to 550 nm, with a SPS peak<br />

at about 390 nm, which can be attributed to the<br />

photoinduced electronic transitions from the valence<br />

band to conduction band (O 2p ? Fe 3d ) (Li et al. 2000).<br />

O L<br />

O L<br />

O H<br />

O H<br />

O1s<br />

Fig. 6 XPS spectra <strong>of</strong> La3d (a), Fe2p (b), and O1s (c) <strong>of</strong><br />

LaFeO 3 samples calcined at 700 and 800 °C<br />

0<br />

300 350 400 450 500 550 600 650 700<br />

Wavelength (nm)<br />

Fig. 7 UV–Vis DRS spectra <strong>of</strong> LaFeO 3 samples calcined at<br />

different temperature<br />

Moreover, the SPS response becomes much stronger<br />

with increasing calcination temperature, which is close<br />

related to the increase in the crystallinity <strong>of</strong> the LaFeO 3 .<br />

The high crystallinity makes electronic band perfect so<br />

as to enhance the built-in field strength, which can<br />

promote charge separation, meanwhile leading to the<br />

decrease <strong>of</strong> the defect amounts, which is also favorable<br />

for charge separation (Jing et al. 2006). According to the<br />

SPS method principles, it can be expected that the<br />

stronger is the SPS signal, the higher is the photoinduced<br />

charge separation rate. Thus, it can be supposed<br />

that the high crystallinity is favorable for the photoinduced<br />

charge separation and then improve the photocatalytic<br />

activity further.<br />

Photocatalytic activity evaluation<br />

The activity <strong>of</strong> the as-prepared LaFeO 3 was evaluated<br />

<strong>by</strong> photocatalytic degradation <strong>of</strong> Rhodamine B solution<br />

under visible light. Figure 9 shows the RhB<br />

degradation rate <strong>of</strong> photocatalytic reaction under<br />

visible irradiation and adsorption in the dark on the<br />

different LaFeO 3 samples and internationally commercial<br />

P-25 TiO 2 . As the calcination temperature is<br />

enhanced, it can be noticed that the photocatalytic<br />

activity <strong>of</strong> the as-prepared LaFeO 3 gradually increases,<br />

and the LaFeO 3 calcined at 900 °C exhibits excellent<br />

photocatalytic activity. Interestingly, all the LaFeO 3<br />

samples display higher visible activity than P25 TiO 2<br />

and those LaFeO 3 samples prepared via the citrate<br />

method (Li et al. 2007). Based on the above discussion,<br />

the high photocatalytic activity is mainly explained<br />

from the following two aspects. One is the <strong>large</strong> <strong>surface</strong><br />

123

J Nanopart Res<br />

Photovoltage (a.u.)<br />

0.00008<br />

0.00006<br />

0.00004<br />

0.00002<br />

0.00000<br />

<strong>area</strong> <strong>of</strong> the as-prepared LaFeO 3 , which is favorable for<br />

the adsorption <strong>of</strong> RhB. This can be proved <strong>by</strong> the<br />

adsorption rate in Fig. 9, even still with a <strong>large</strong> RhB<br />

adsorption rate after calcination at 900 °C. The other is<br />

the high crystallinity <strong>of</strong> the as-prepared LaFeO 3 caused<br />

<strong>by</strong> calcined at the high temperature. The high crystallinity<br />

can promote the photoinduced charge separation<br />

(Jing et al. 2006). In addition, a certain amount <strong>of</strong><br />

<strong>surface</strong> hydroxyl group is also beneficial for photocatalytic<br />

reactions.<br />

Conclusions<br />

900°C<br />

800°C<br />

700°C<br />

600°C<br />

300 350 400 450 500 550 600<br />

Wavelength (nm)<br />

Fig. 8 SPS responses <strong>of</strong> LaFeO 3 samples calcined at different<br />

temperature<br />

On the basis <strong>of</strong> the above systematical investigations,<br />

the following conclusions can be drawn: (1) nanosized<br />

LaFeO 3 with <strong>large</strong> <strong>surface</strong> <strong>area</strong> has been<br />

successfully fabricated <strong>by</strong> using mesoporous silica<br />

<strong>SBA</strong>-<strong>16</strong> as hard template, still with 85 m 2 g -1<br />

<strong>surface</strong> <strong>area</strong> after calcination at 800 °C. At the same<br />

thermal treatment temperature, the <strong>surface</strong> <strong>area</strong> <strong>of</strong> the<br />

LaFeO 3 prepared <strong>by</strong> the template method is much<br />

<strong>large</strong>r than that prepared via the citrate method; (2)<br />

the as-prepared LaFeO 3 , especially for those calcined<br />

at high temperature, exhibits high visible activity; (3)<br />

the high activity <strong>of</strong> the as-prepared LaFeO 3 is<br />

attributed to the <strong>large</strong> <strong>surface</strong> <strong>area</strong> and high charge<br />

separation rate resulting from the high crystallinity,<br />

as well as to a certain amount <strong>of</strong> <strong>surface</strong> hydroxyl<br />

group. It can be suggested that the SPS method is an<br />

effective tool to reveal the processes <strong>of</strong> separation<br />

and transfer <strong>of</strong> photoinduced charges. This study<br />

provides a new route to design and synthesize other<br />

metal composite oxides with <strong>large</strong> <strong>surface</strong> <strong>area</strong>, and<br />

RhB degradation rate (%)<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

would broaden the scope <strong>of</strong> the application <strong>of</strong><br />

perovskite-type materials.<br />

Actually, compared with porous TiO 2 and other<br />

oxide nano-materials routinely with hundreds <strong>of</strong><br />

meters squared per gram, the as-prepared nanosized<br />

LaFeO 3 has still low specific <strong>surface</strong> <strong>area</strong>. However,<br />

the superior visible photocatalytic performance <strong>of</strong><br />

this LaFeO 3 over international P25 TiO 2 is confirmed,<br />

implying that the porous perovskite-based<br />

nanomaterials, as non-TiO 2 -based visible-driven<br />

photocatalysts, are feasible and promising.<br />

Acknowledgments We gratefully acknowledge the fundings<br />

received from the National Nature Science Foundation <strong>of</strong><br />

China (No. 20501007, 20676027), the program for New<br />

Century Excellent Talents in universities (NCET-07-259), the<br />

Key project <strong>of</strong> Science & Technology Research <strong>of</strong> Ministry <strong>of</strong><br />

Education <strong>of</strong> China (No. 207027), the Science Foundation <strong>of</strong><br />

Excellent Youth <strong>of</strong> Heilongjiang Province <strong>of</strong> China<br />

(JC200701), and the Science Foundation <strong>of</strong> Harbin City <strong>of</strong><br />

China (No. 2005AFQXJ060), for the completion <strong>of</strong> this study.<br />

References<br />

600°C<br />

Adsorption in the dark<br />

Under visible irradation<br />

700°C<br />

800°C<br />

Samples<br />

900°C<br />

P-25<br />

Fig. 9 Photocatalytic degradation rate <strong>of</strong> RhB solution on<br />

different LaFeO 3 samples and P-25 TiO 2<br />

Arendt E, Maione A, Klisinska A, Sanz O, Montes M, Suarez<br />

S, Blanco J, Ruiz P (2008) Structuration <strong>of</strong> LaMnO 3<br />

perovskite catalysts on ceramic and metallic monoliths:<br />

physico-chemical characterisation and catalytic activity in<br />

methane combustion. Appl Catal A 339:1–14. doi:<br />

10.10<strong>16</strong>/j.apcata.2008.01.0<strong>16</strong><br />

Gleiter H, Weissmüller J, Wollersheim O, Würschum R (2001)<br />

Nanocrystalline materials: a way to solids with tunable<br />

electronic structures and properties. Acta Mater 49:737–<br />

745. PII:S1359-6454(00)00221-4<br />

Guldi DM, Zerbetto F, Georgakilas V, Prato M (2005)<br />

Ordering fullerene materials at nanometer dimensions.<br />

Acc Chem Res 38:8–43. doi:10.1021/ar040222s<br />

123

J Nanopart Res<br />

Huang Y, Ma W, Li J, Cheng M, Zhao J, Wan L, Yu JC (2003)<br />

A novel b-CD-Hemin complex photocatalyst for efficient<br />

degradation <strong>of</strong> organic pollutants at neutral pHs under<br />

visible irradiation. J Phys Chem B 107:9409–9414. doi:<br />

10.1021/jp034854s<br />

Jin HX, Wu QY, Chen C, Zhang DL, Pang WQ (2006) Facile<br />

synthesis <strong>of</strong> crystal like shape mesoporous silica <strong>SBA</strong>-<strong>16</strong>.<br />

Microporous Mesoporous Mater 97:141–144. doi:<br />

10.10<strong>16</strong>/j.micromeso.2006.08.008<br />

Jing LQ, Sun XJ, Shang J, Cai WM, Xu ZL, Du YG, Fu HG<br />

(2003) Review <strong>of</strong> <strong>surface</strong> photovoltage spectra <strong>of</strong> nanosized<br />

semiconductor and its applications in heterogeneous<br />

photocatalysis. Sol Energy Mater Sol Cells 79:133–151.<br />

doi:10.10<strong>16</strong>/S0927-0248(02)00393-8<br />

Jing LQ, Fu HG, Wang BQ (2006) Effects <strong>of</strong> Sn dopant on the<br />

photoinduced charge property and photocatalytic activity<br />

<strong>of</strong> TiO 2 <strong>nanoparticles</strong>. Appl Catal B 62:282–291. doi:<br />

10.10<strong>16</strong>/j.apcatb.2005.08.012<br />

Kärger J, Freude D (2002) Mass transfer in micro-and mesoporous<br />

materials. Chem Eng Technol 25:769–778. doi:<br />

0930-75<strong>16</strong>/02/0808-0769<br />

Kato H, Kudo A (2003) Photocatalytic water splitting into H 2<br />

and O 2 over various tantalate photocatalysts. Catal Today<br />

78:561–569. PII:S0920-5861(02)00355-3<br />

Li KY, Wang DJ, Wu FQ, Xie TF, Li TJ (2000) Surface<br />

electronic states and photovoltage gas-sensitive characters<br />

<strong>of</strong> nanocrystalline LaFeO 3 . Mater Chem Phys 64:269–<br />

272. PII:S0254-0584(99)00265-5<br />

Li KY, Wu FQ, Wang DJ, Xie TF, Li TJ (2001) Electron<br />

behavior and photoelectric gas-sensitive characters <strong>of</strong><br />

nanocrystalline La 1-x Sr x FeO 3 . Mater Chem Phys 71:34–<br />

39. PII:S0254-0584(00)00524-1<br />

Li SD, Jing LQ, Fu W, Yang LB, Xin BF, Fu HG (2007)<br />

Photoinduced charge property <strong>of</strong> nanosized perovskitetype<br />

LaFeO 3 and its relationships with photocatalytic<br />

activity under visible irradiation. Mater Res Bull 42:203–<br />

212. doi:10.10<strong>16</strong>/j.materresbull.2006.06.010<br />

Lu AH, Schüth F (2006) Nanocasting: a versatile strategy for<br />

creating nanostructured porous materials. Adv Mater<br />

18:1793–1805. doi:10.1002/adma.200600148<br />

Lu L, Wang X, Li L, Li G (2005) Understanding <strong>of</strong> the finite<br />

size effects on lattice vibrations and electronic transitions<br />

<strong>of</strong> nano a-Fe 2 O 3 . J Phys Chem B 109:17151–17156. doi:<br />

10.1021/jp052780?<br />

Maeda K, Domen K (2007) New non-oxide photocatalysts<br />

designed for overall water splitting under visible light. J<br />

Phys Chem C 111:7851–7861. doi:10.1021/jp070911w<br />

Nosaka Y, Kishimoto M, Nishino J (1998) Factors governing<br />

the initial process <strong>of</strong> TiO 2 photocatalysis studied <strong>by</strong><br />

means <strong>of</strong> in situ electron spin resonance measurements. J<br />

Phys Chem B 102:10279–10283. doi:10.1021/jp982886n<br />

Penä MA, Fierro JLG (2001) Chemical structures and performance<br />

<strong>of</strong> perovskite oxides. Chem Rev 101:1981–2017.<br />

doi:10.1021/cr980129f<br />

Plonczak P, Gazda M, Kusz B, Jasinski P (2008) Fabrication <strong>of</strong><br />

solid oxide fuel cell supported on specially performed<br />

ferrite-based perovskite cathode. J Power Sources 181:1–<br />

7. doi:10.10<strong>16</strong>/j.jpowsour.2007.12.019<br />

Schüth F (2003) Endo- and exotemplating to create high-<strong>surface</strong>-<strong>area</strong><br />

inorganic materials. Angew Chem Int Ed<br />

42:3604–3622. doi:10.1002/anie.200300593<br />

Schüth F, Schmid W (2002) Microporous and mesoporous<br />

materials. Adv Eng Mater 4:269–279. doi:1438-<strong>16</strong>56/02/<br />

0505-0269<br />

Shi KY, Chi YJ, Jin XQ, Xu M, Yuan FL, Fu HG (2005a)<br />

<strong>Synthesis</strong> and characterization <strong>of</strong> modified mesoporous<br />

silica <strong>SBA</strong>-<strong>16</strong> film. Acta Chimi Sin 63:885–890<br />

Shi KY, Peng LM, Chen Q, Wang RH, Zhou WZ (2005b)<br />

Porous crystalline iron oxide thin films templated <strong>by</strong><br />

mesoporous silica. Microporous Mesoporous Mater<br />

83:219–224. doi:10.10<strong>16</strong>/j.micromeso.2005.01.020<br />

Subramanian V, Roeder RK, Wolf EE (2006) <strong>Synthesis</strong> and<br />

UV–visible-light photoactivity <strong>of</strong> noble-metal-SrTiO 3<br />

composites. Ind Eng Chem Res 45:2187–2193. doi:<br />

10.1021/ie050693y<br />

Valdés-Solís T, Marbán G, Fuertes AB (2005) Preparation <strong>of</strong><br />

nanosized perovskites and spinels through a silica xerogel<br />

template route. Chem Mater 17:1919–1922. doi:10.1021/<br />

cm0477321<br />

Wang Y, Herron N (1991) Nanometer-sized semiconductor<br />

clusters: materials synthesis, quantum size effects, and<br />

photophysical properties. J Phys Chem 95:525–532. doi:<br />

10.1021/j100155a009<br />

Wang YP, Yang XJ, Lu LD, Wang X (2006) Experimental<br />

study on preparation <strong>of</strong> LaMO 3 (M = Fe, Co, Ni) nanocrystals<br />

and their catalytic activity. Thermochim Acta<br />

443:225–230. doi:10.10<strong>16</strong>/j.tca.2006.01.030<br />

Wang J, Jiang Z, Zhang ZH, Xie YP, Wang XF, Xing ZQ, Xu<br />

R, Zhang XD (2008) Sonocatalytic degradation <strong>of</strong> acid<br />

red B and rhodamine B catalyzed <strong>by</strong> nano-sized ZnO<br />

powder under ultrasonic irradiation. Ultrason Sonochem<br />

15:768–774. doi:10.10<strong>16</strong>/j.ultsonch.2008.02.002<br />

Yang Z, Huang Y, Dong B, Li HL (2006) Controlled synthesis<br />

<strong>of</strong> highly ordered LaFeO 3 nanowires using a citrate-based<br />

sol–gel route. Mater Res Bull 41:274–281. doi:10.10<strong>16</strong>/<br />

j.materresbull.2005.08.022<br />

Yang Y, Jiang YS, Wang YW, Sun YB (2007) Photoinduced<br />

decomposition <strong>of</strong> BaFeO 3 during photodegradation <strong>of</strong><br />

methyl orange. J Mol Catal A 270:56–60. doi:10.10<strong>16</strong>/<br />

j.molcata.2007.01.033<br />

Zapilko C, Liang YC, Nerdal W, Anwander R (2007) A general<br />

strategy for the rational design <strong>of</strong> size-selective<br />

mesoporous catalysts. Chem Eur J 13:3<strong>16</strong>9–3176. doi:<br />

10.1002/chem.200601598<br />

Zhang J, Li M, Feng Z, Chen J, Li C (2006) UV Raman<br />

spectroscopic study on TiO 2 . I. Phase transformation at<br />

the <strong>surface</strong> and in the bulk. J Phys Chem B 110:927–935.<br />

doi:10.1021/jp0552473<br />

Zhang JC, Wen ZY, Huang SH, Wu JG, Han JD, Xu XX (2008)<br />

High-temperature proton conductor Sr(Ce 0.6 Zr 0.4 ) 0.9 Y 0.1 O 3 :<br />

preparation, sintering and electrical properties. Ceram Int<br />

34:1273–1278. doi:10.10<strong>16</strong>/j.ceramint.2007.03.007<br />

Zhao L, Yu JG (2006) Controlled synthesis <strong>of</strong> highly dispersed<br />

TiO 2 <strong>nanoparticles</strong> using <strong>SBA</strong>-15 as hard template. J<br />

Colloid Interface Sci 304:84–91. doi:10.10<strong>16</strong>/j.jcis.2006.<br />

08.042<br />

123