flywheel tools 8-2 sprocket shaft tools 8-5 inner primary ... - S&S Cycle

flywheel tools 8-2 sprocket shaft tools 8-5 inner primary ... - S&S Cycle

flywheel tools 8-2 sprocket shaft tools 8-5 inner primary ... - S&S Cycle

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Flywheel Tools 8-2<br />

Flywheel Balancing Kits<br />

Flywheel Assembly Fixture & Truing Spanner<br />

Sprocket <strong>shaft</strong> Tools 8-5<br />

Sprocket Shaft Bearing & Seal Installation Kit<br />

Inner Primary Tools 8-6<br />

Inner Primary Bearing Race Installer<br />

Clutch Puller w/ Inner Bearing Race Puller<br />

Top Dead Center Tool<br />

Rocker Cover Wrench Set<br />

Connecting Rod Checking Pins<br />

Compression Release Socket Kit<br />

Main Jet Tool<br />

Manifold Measuring Tools 8-8<br />

X-Wedge Tools 8-10<br />

Bearing Protector Tools<br />

Cam Alignment Tools<br />

Main Bearing Installation Tool<br />

Top End Tools 8-12<br />

Cylinder Torque Plate Kits<br />

Boring Plate Kits<br />

Degree Wheel Kit<br />

Crankpin Nut Clearancing Gauges<br />

Anti-Rotation Bracket<br />

Crankcase Oil Passage Drilling Jig<br />

Shop Supplies 8-16<br />

Mobil 1 ® Synthetic Oil<br />

Oil Filters<br />

Champion ® Spark Plugs<br />

Touch Up Paint, Lubricant, Sealants<br />

Engine Stands

Parts for<br />

Twin Cam 88®<br />

S&S ® Flywheel Balancing Kits<br />

Parts for<br />

Evolution®<br />

Parts for<br />

Sportster® '86-'06<br />

Vintage<br />

Engines<br />

X-Wedge®<br />

Parts for Victory®,<br />

Off-road & Metric<br />

Replacement<br />

Parts<br />

Tools &<br />

Shop Supplies<br />

Racing<br />

Products<br />

Dealer Services<br />

& Promo Items<br />

Warranty &<br />

Company Policy<br />

The S&S Master Flywheel Balancing Kit<br />

Designed to allow the average shop to rebalance stock and S&S <strong>flywheel</strong>s<br />

accurately and quickly. Whether doing a stock rebuild or a performance<br />

upgrade using aftermarket parts, <strong>flywheel</strong> rebalancing is a desirable step in<br />

the engine building process. A complete set of detailed instructions is furnished<br />

with each kit for <strong>flywheel</strong>s with tapered crankpins only.<br />

3<br />

1<br />

19<br />

5<br />

14<br />

4<br />

16<br />

2<br />

15 17<br />

7 8<br />

S&S master <strong>flywheel</strong> balancing kit enables any shop that repairs or builds<br />

v-twin engines to rebalance <strong>flywheel</strong>s from just about any 1936-'99 big<br />

twin or Harley-Davidson® Sportster® model from 1957-'99. This includes all<br />

stock Evolution® engines for big twin and Sportster models with three-piece<br />

crank<strong>shaft</strong>s.<br />

NOTE:<br />

These balancing kits will not work with Harley-Davidson® Twin Cam 88® engines, 2000-<br />

up Sportster models, or any <strong>flywheel</strong> assemblies which use pressed-in crankpins.<br />

13<br />

18<br />

12<br />

6<br />

11<br />

10<br />

9<br />

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53-0027<br />

1. Platform scale, (2610 grams\maximum)<br />

(Includes 51-0021) (1 each) . .....................................53-0011A<br />

2. Replacement balance weight set, (2-500g 1-1000g) . . . . . . . . . . . . . . . . . 53-0021<br />

3. Balance <strong>shaft</strong>, 1957-’71 XL and 1936-’71 OHV BT . . . . . . . . . . . . . . . . . . . . . 53-0090<br />

4. Balance <strong>shaft</strong> nut, (1 each) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53-0092<br />

5. Balance stand, (1 each) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53-0088<br />

6. Rod support stand, (1 each) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53-0089<br />

7. Taper adapter, 1972-Early ‘81 BT (1 each) . . . . . . . . . . . . . . . . . . . . . . . . . . 53-0086<br />

8. Taper adapter, Late 1981-’85 BT and S&S BL, SE, SL style<br />

(1 each) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53-0087<br />

9. Shaft adapter, 1977-up XL driveside (screws on)<br />

(1 each) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53-0093<br />

10. Shaft adapter, 1977-up XL camside (screws on)<br />

(1 each) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53-0095<br />

11. Shaft adapter, 1955-’99 BT driveside (screws on)<br />

(1 each) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53-0091<br />

12. Shaft adapter, 1958-’92 BT camside (LH, screws on)<br />

(1 each) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53-0101<br />

13. Shaft adapter, 1993-’99 BT camside (RH, screws on)<br />

(1 each) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53-0102<br />

14. Shaft adapter, counterweight (1 each)................................ 53-0099<br />

15. Collar spacer, 1970-’99 BT (1 each).. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53-0097<br />

16. Collar spacer, 1986-’90 driveside for XL - .280" (1 each) .. . . . . . . . . . . . . . . 53-0098<br />

17. Collar spacer. 1991-up driveside for XL - .860" (1 each) . . . . . . . . . . . . . . . . 53-0085<br />

18. Bob weight assembly, 1000 gram (Pictured with shims)<br />

(1 each) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53-0094<br />

Repair parts for 53-0094<br />

Screw SHC, 1⁄2”-13 x 3⁄4” ..........................................50-0200 .<br />

Screw SHC, 1⁄2”-13 x 11⁄4” ........................................ 50-0201<br />

19. Shims<br />

2.7 gram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53-0110.<br />

5.4 gram ...................................................... 53-0105.<br />

8.1 gram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53-0115<br />

10.8 gram . ..................................................... 53-0120.<br />

13.4 gram . .....................................................53-0125.<br />

50 gram ....................................................... 53-0150.<br />

100 gram ...................................................... 53-0100<br />

20. Shim Kit ........................................................ 53-0111<br />

Kit includes:<br />

Shims (2 each) 2.7, 5.4, 8.1, 10.8, and 13.4 grams<br />

Shims (1 each) 50 grams and 100 grams<br />

Order toll free 866-244-2673<br />

8-2

Continued –<br />

S&S® Flywheel Balance Kits<br />

5<br />

6<br />

Parts for<br />

Twin Cam 88®<br />

Master Balance Kit Without Balance Scales<br />

Includes: All parts in #53-0027 except balance scales.<br />

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53-0028<br />

4<br />

16 15<br />

7<br />

8<br />

17<br />

18<br />

Parts for<br />

Evolution®<br />

Platform Scale<br />

(2610 grams\maximum) Includes balance weight set #51-0021.<br />

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53-0011<br />

19<br />

14<br />

10<br />

9<br />

Parts for<br />

Sportster® '86-'06<br />

3<br />

12<br />

11<br />

53-0028<br />

Vintage<br />

Engines<br />

5<br />

6<br />

3<br />

19<br />

All Shims<br />

18<br />

53-0012<br />

7<br />

8<br />

4<br />

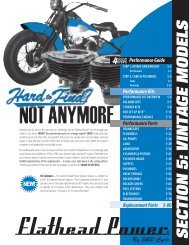

Flywheel Balance Kit For 5-Piece Cranks<br />

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53-0012<br />

Includes:<br />

3. Balance <strong>shaft</strong> ......................................... 53-0090<br />

4. Balance <strong>shaft</strong> nut .................................... 53-0092<br />

5. Balance stand ....................................... 53-0088<br />

6. Rod support stand. ................................... 53-0089<br />

7. Taper adapter ........................................ 53-0086<br />

8. Taper adapter ........................................ 53-0087<br />

18. Bob weight 1000 gram. ............................... 53-0094<br />

19. Shims ..............See previous page for individual part numbers.<br />

13<br />

X-Wedge® Parts for Victory®, Replacement<br />

Off-road & Metric Parts<br />

Flywheel Balance Kit For 3-Piece Cranks<br />

For Harley-Davidson® Evolution® Big Twin and Sportster® Models<br />

16<br />

17<br />

Tools &<br />

Shop Supplies<br />

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53-0015<br />

Includes:<br />

9. Driveside adapter sleeve for 1977-up Sportster ............. 53-0093<br />

10. Camside adapter sleeve for 1977-up Sportster . ........... 53-0095<br />

11. Driveside adapter sleeve for 1955-’99 Big Twin ............ 53-0091<br />

12. Camside adapter for 1958-’92 Big Twin . .................. 53-0101<br />

13. Camside adapter for 1993-’99 Big Twin . ................. 53-0102<br />

14. Shaft counterweight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53-0099<br />

15. Collar spacer for 1970-’99 Big Twin. ...................... 53-0097<br />

16. Collar spacer for 1986-’90 Sportster ...................... 53-0098<br />

17. Collar spacer for 1991-up Sportster. ...................... 53-0085<br />

15<br />

14<br />

53-0015<br />

13<br />

12<br />

11<br />

10<br />

9<br />

Racing<br />

Products<br />

Dealer Services Warranty &<br />

& Promo Items Company Policy<br />

8-3 Visit us at www.sscycle.com

Parts for<br />

Twin Cam 88®<br />

S&S ® Flywheel Assembly Fixture<br />

and Truing spanner<br />

Parts for<br />

Evolution®<br />

Parts for<br />

Sportster® '86-'06<br />

Vintage<br />

Engines<br />

X-Wedge®<br />

Racing<br />

Products<br />

Parts for Victory®,<br />

Off-road & Metric<br />

Replacement<br />

Parts<br />

Tools &<br />

Shop Supplies<br />

By Popular Demand<br />

S&S assembles a lot of <strong>flywheel</strong>s, and we are often asked what we use to<br />

hold them steady during the assembly and truing process. Dealer and<br />

retail customers who have attended our training sessions at the S&S Dealer<br />

Training Center in LaCrosse, WI have repeatedly asked if they can buy one<br />

of our custom <strong>flywheel</strong> fixtures, so we have decided to offer an economical<br />

fixture kit that includes the essentials for <strong>flywheel</strong> assembly and truing –<br />

S&S style. The kit includes a massive fixture to hold the <strong>flywheel</strong>s, <strong>flywheel</strong><br />

clamps and hardware to mount the <strong>flywheel</strong> to the fixture, and a spanner<br />

bar plate to be used with a length of steel pipe to fabricate a long spanner<br />

bar for truing adjustments.<br />

The fixture is mounted to a heavy bench. Flywheels are clamped to the fixture,<br />

allowing the assembler to torque the main<strong>shaft</strong> and crankpin nuts to our<br />

higher than stock torque specs. (We recommend using a torque multiplier.)<br />

Once the <strong>flywheel</strong>s are assembled, the spanner bar (some assembly required)<br />

can be used to shift the <strong>flywheel</strong>s in order to bring the main<strong>shaft</strong>s into true.<br />

This method is much easier, faster, and safer than hitting the <strong>flywheel</strong>s with<br />

a lead or brass hammer to true the assembly.<br />

Works for stock and S&S <strong>flywheel</strong>s for 1936-'99 big twin and 1957-'03<br />

Sportster® models.<br />

The S&S® <strong>flywheel</strong> assembly fixture is massive and rigid. Add a piece of steel<br />

tubing to the included spanner plate to make a tool that positively “plugs<br />

in” to the holes in an S&S <strong>flywheel</strong> and allows you to adjust the alignment<br />

of the <strong>flywheel</strong>s, making the truing process a lot easier.<br />

Flywheel Fixture<br />

Assembly ............................................... 106-0552<br />

Clamp, Flywheel Fixture ................................... 106-0483<br />

Plate, Spanner Bar, Packaged .............................. 106-0783<br />

Hardware Kit, Flywheel Fixture ............................. 106-0782<br />

Dealer Services<br />

& Promo Items<br />

Warranty &<br />

Company Policy<br />

The design of the S&S® <strong>flywheel</strong> assembly fixture is based on this custom made<br />

fixture that has been in daily use in the S&S <strong>flywheel</strong> assembly department<br />

for years. You supply a length of steel pipe to fabricate the spanner bar which<br />

is used to shift the wheels to bring the main<strong>shaft</strong>s into true.<br />

Order toll free 866-244-2673<br />

8-4

Dealer Services<br />

& Promo Items<br />

S&S ® Sprocket Shaft Bearing and<br />

Seal Installation Tool<br />

For Big Twin and Sportster ® Models with Tapered Roller (Timken ® ) Sprocket Shaft Bearings<br />

Say Goodbye To Awkward and Slow Screw Type Installers!<br />

Developed for production shops, this smartly designed tool easily cuts the<br />

time it takes to install <strong>sprocket</strong> <strong>shaft</strong> bearings and seals. The S&S installation<br />

tool uses a smooth operating rack and pinion system to quickly press bearings<br />

and seals into place. The tool is used by itself, without an adapter, to install<br />

<strong>sprocket</strong> <strong>shaft</strong> bearings for big twins. Tool includes four adapters that quickly<br />

convert the tool to install <strong>sprocket</strong> <strong>shaft</strong> bearings for Harley-Davidson®<br />

Sportster® models, or <strong>sprocket</strong> <strong>shaft</strong> seals for big twin and Sportster models.<br />

Simply select the appropriate adapters, screw the installer onto the end of<br />

the <strong>sprocket</strong> <strong>shaft</strong>, and with a few strokes from your 1⁄2" drive ratchet wrench,<br />

the installation is performed quickly and accurately. This tool is built to stand<br />

up to daily shop use, and is covered by a two-year warranty.<br />

Sprocket Shaft Bearing<br />

And Seal Installation Tool<br />

For 1955-’02 Big Twin Engines<br />

(Including 1999-’02 Harley-Davidson® Twin Cam 88® engines<br />

and 1957-present Sportster® Models.) ........................ 53-0060<br />

Replacement Parts:<br />

Adapter, Sprocket Shaft Seal – for big twin engines .............53-0066<br />

Adapter, Sprocket Shaft Bearing – for Sportster Models<br />

(Use with part #53-0068) ................................... 53-0067<br />

Adapter, Sprocket Shaft Bearing Spacer – for Sportster Models<br />

(Use with part #53-0067) ...................................53-0068<br />

Adapter, Sprocket Shaft Seal – for Sportster Models .............53-0069<br />

Replacement installer set screw ............................ 50-0315-S<br />

Parts for<br />

Twin Cam 88®<br />

Parts for<br />

Evolution®<br />

Parts for<br />

Sportster® '86-'06<br />

Vintage<br />

Engines<br />

X-Wedge® Parts for Victory®, Replacement<br />

Off-road & Metric Parts<br />

Tools &<br />

Shop Supplies<br />

Tool kit includes installer and four adapters packaged in a sturdy hard case with foam padding. Adapters are also available individually.<br />

Racing<br />

Products<br />

53-0066 53-0069 53-0068 53-0067 50-3015-S<br />

Warranty &<br />

Company Policy<br />

8-5 Visit us at www.sscycle.com

Parts for Victory®,<br />

Off-road & Metric<br />

Parts for<br />

Twin Cam 88®<br />

Parts for<br />

Evolution®<br />

Parts for<br />

Sportster® '86-'06<br />

Vintage<br />

Engines<br />

Any Job Is Easy With The Right Tools<br />

Saving You a Lot of Money and Trouble<br />

S&S has an elegantly simple, and totally effective solution to the problem of<br />

the <strong>inner</strong> <strong>primary</strong> bearing race moving on the transmission main <strong>shaft</strong> under<br />

high load conditions. A unique modification to the design of the main<strong>shaft</strong><br />

<strong>inner</strong> <strong>primary</strong> bearing race, positively prevents it from "walking" into the<br />

main<strong>shaft</strong> seal and output gear. The S&S bearing race features an extra step<br />

on the inside diameter that acts as a stop on the transmission main<strong>shaft</strong>.<br />

When the race is pressed on to the <strong>shaft</strong>, the step will not allow the race to<br />

move inward toward the main<strong>shaft</strong> seal. The improved S&S bearing race is a<br />

must for any high performance application. It is included as a part of all S&S<br />

high performance clutch kits, and can be retrofitted to stock and aftermarket<br />

transmissions for all 1991-'06 big twins (except '06 Dyna®).<br />

U S A<br />

S&S Inner Primary Bearing Race<br />

All 1991-'06 big twins (except '06 Dyna®) ....................56-5089<br />

X-Wedge®<br />

Replacement<br />

Parts<br />

Tools &<br />

Shop Supplies<br />

Racing<br />

Products<br />

Dealer Services<br />

& Promo Items<br />

Warranty &<br />

Company Policy<br />

S&S Clutch Puller<br />

w/ Inner Bearing Race Puller Attachment<br />

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56-5141<br />

Inner Primary Bearing Race Installer<br />

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56-5145<br />

High performance power trains take a serious beating. That means that<br />

they require more frequent service. Time is money, and in order to allow<br />

you to make better use of your valuable time, S&S offers some new <strong>tools</strong><br />

for clutch and <strong>primary</strong> installation. First there is a <strong>primary</strong> <strong>inner</strong> bearing<br />

race installation tool, with a radial thrust bearing that decreases the effort<br />

required to install a bearing race by 30%. Then there is the new S&S Clutch<br />

Puller that is specifically designed to remove an S&S high performance<br />

clutch. This is also helpful when removing a stock clutch from a damaged<br />

main<strong>shaft</strong>. Finally there is an attachment for the S&S Clutch Puller that<br />

allows easy removal of the <strong>primary</strong> <strong>inner</strong> bearing race.<br />

All of these S&S <strong>tools</strong> are CNC machined from the finest 4140 tool steel and<br />

heat treated for maximum reliability and service life.<br />

Order toll free 866-244-2673<br />

8-6

Continued –<br />

Any Job is Easy with the Right Tools<br />

Parts for<br />

Twin Cam 88®<br />

S&S ® Top Dead Center Tool<br />

Finding top dead center of an engine can be a pretty easy job if you have<br />

the right tool. The S&S Top Dead Center (TDC) Tool makes it easy to find the<br />

exact top dead center of any engine. This is the best way to calibrate your<br />

degree wheel when dialing in cams or performing any number of checks and<br />

modifications based on the position of the crank<strong>shaft</strong>. When you need to<br />

know for sure, you need the S&S TDC tool. Available for engines with 14mm<br />

or 12mm sparkplug holes.<br />

53-0322<br />

Parts for<br />

Evolution®<br />

Parts for<br />

Sportster® '86-'06<br />

14mm ................................................. 53-0321<br />

12mm ................................................. 53-0322<br />

Vintage<br />

Engines<br />

S&S Rocker Cover Wrench Set<br />

Helpful in areas where the motorcycle frame may prevent the use of<br />

conventional <strong>tools</strong>. .........................................53-0040<br />

Connecting Rod Checking Pins<br />

These pins are used to check alignment of connecting rods with crankcase<br />

cylinder decks.<br />

.792" .................................................. 53-0002<br />

.892" .................................................. 53-0001<br />

.927" .................................................. 53-0004<br />

.990" ...................................................53-0022<br />

Special S&S Two-Piece<br />

Compression Release Socket Kit<br />

Allows in-frame installation of S&S compression releases and protects wiring<br />

from damage during installation. .............................53-0045<br />

53-0040<br />

53-0002<br />

X-Wedge® Parts for Victory®, Replacement<br />

Off-road & Metric Parts<br />

Tools &<br />

Shop Supplies<br />

NOTE:<br />

Rocker covers must be removed when installing S&S compression releases. If lack of<br />

frame clearance prevents removal of rocker covers, engine must be removed from<br />

frame for compression release installation.<br />

53-0045<br />

Racing<br />

Products<br />

Main Jet Tool<br />

For changing main jets in all S&S carburetors using #72 series jets.<br />

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53-0452<br />

Dealer Services<br />

& Promo Items<br />

53-0452<br />

Warranty &<br />

Company Policy<br />

8-7 Visit us at www.sscycle.com

Parts for<br />

Twin Cam 88®<br />

S&S ® MANIFOLD MEASURING TOOL<br />

The solution to an old problem<br />

Parts for<br />

Evolution®<br />

Parts for<br />

Sportster® '86-'06<br />

Vintage<br />

Engines<br />

X-Wedge®<br />

Parts for Victory®,<br />

Off-road & Metric<br />

Replacement<br />

Parts<br />

Tools &<br />

Shop Supplies<br />

Racing<br />

Products<br />

Dealer Services<br />

& Promo Items<br />

Warranty &<br />

Company Policy<br />

Get It Right The First Time!<br />

It has always been difficult to accurately measure the distance between the<br />

intake ports of a v-twin engine. In the past this has made ordering intake<br />

manifolds for custom engines somewhat of a gamble. The S&S Manifold<br />

Measuring Tools make it easy to specify the length of a special manifold<br />

with precision, and get it right the first time, every time. That can be really<br />

important when you need to finish an engine in time for an important race.<br />

Here’s How It Works:<br />

S&S offers several special <strong>tools</strong> for measuring engines and manifolds.<br />

The Engine Measuring Tool for Harley-Davidson® Evolution® and Twin Cam<br />

88® engines consists of a pair of measuring fixtures that bolt to the cylinder<br />

heads using the manifold mounting bolt holes. The measuring fixtures for<br />

shovelhead and ironhead Sportster® models simply slip over the intake ports<br />

on the cylinder heads. The fixtures provide convenient parallel surfaces to<br />

measure between and determine the exact distance between the centers of<br />

the intake ports of an assembled or mocked up engine. To measure the length<br />

of an existing manifold, simply slip the manifold measuring fixtures over the<br />

ends of the intake runners of the manifold and measure the distance between<br />

the parallel surfaces of the cone shaped depressions in the fixtures.<br />

The S&S Manifold Measuring Tools eliminate inaccuracies that can be caused<br />

by attempting to measure cylinder heads or manifolds with various port<br />

diameters or shapes, chamfers, and any number of machining variations.<br />

The measurement taken using any of the S&S Manifold Measuring Tools is<br />

the actual distance between the centers of the intake ports of the engine or<br />

manifold. It is important to remember that a manifold for a specific engine<br />

will be about .030" shorter than the distance measured between the intake<br />

ports of that engine. That provides about .015" clearance per side to allow<br />

for manufacturing and assembly tolerances.<br />

S&S has adopted this method of measuring manifolds and has based a<br />

new manifold numbering system on port to port measurements using<br />

the S&S Manifold Measuring Tools. The new manifold size number is the<br />

distance between the port centers of the intended engine, expressed in one<br />

hundredths of an inch. For example, the distance between the intake port<br />

centers of a stock Twin Cam 88 engine is 4.100". That measurement converts<br />

to 410/100" so the manifold size number is 410. All current S&S manifolds<br />

for Evolution and Twin Cam 88 engines are marked in this manner. To<br />

determine the new size number of an older manifold, refer to the manifold<br />

size conversion chart on the next page. To determine the size needed for<br />

an S&S engine, please consult the charts in the appropriate section of this<br />

catalog.<br />

Master Manifold and Head Measuring Tool Kit<br />

The Master Kit contains all the <strong>tools</strong> listed below in a handy plastic storage<br />

case ..................................................... 53-0201<br />

Engine Measuring Tool Kits<br />

for Evolution and Twin Cam 88 Engines<br />

Each kit includes a pair of measuring fixtures for measuring the port center<br />

to port center distance on assembled engines.<br />

Stock Heads .............................................. 53-0070<br />

Heads with Baisley Style – Oval or Round Ports ................ 53-0072<br />

S&S “B” Style Heads with 4-Bolt Flange ..................... 53-0073<br />

Manifold Measuring Tools<br />

for Evolution and Twin Cam 88 Engines<br />

Includes a pair of measuring fixtures for measuring the port center to port<br />

center distance on existing manifolds.<br />

Stock Heads ............................................. 53-0076<br />

S&S Super Stock® Heads .................................... 53-0077<br />

Heads with Baisley Style Oval or Round Ports<br />

S&S B Style SA Manifolds ................................... 53-0079<br />

Engine & Manifold Measuring Tools<br />

for Shovelhead Engines<br />

Includes a pair of fixtures for measuring the port-center to port-center<br />

distance on engines and existing manifolds. Use the same tool for both<br />

engines and manifolds, o-ring and rubberband style. May also be used for<br />

Harley-Davidson® ironhead Sportster® models.<br />

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53-0075<br />

Order toll free 866-244-2673<br />

8-8

Continued –<br />

S&S® Manifold Measuring Tool<br />

Engine Displacement<br />

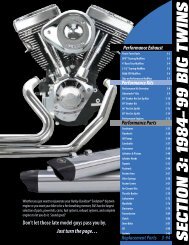

S&S® Manifold Size Conversion Chart<br />

Old Manifold<br />

Size Number<br />

New Manifold<br />

Size Number<br />

Stock 883, 1100, 1200, 79" 0 341<br />

91" Sportster® * 343<br />

79" S&S Retro Big Twin 1 355<br />

100" Sportster 1+ 357<br />

100" S&S Retro Big Twin 2 - 361<br />

89" Sportster 3 374<br />

100" Evolution® 5++ 387<br />

88" & 100" Evolution 6 397<br />

111" S&S 41/8" Bore * 398<br />

100" Twin Cam 88® * 405<br />

93" & 113" Evolution 7 406<br />

117" S&S 41/8" Bore * 408<br />

Stock Evolution & Twin Cam 88 8 410<br />

107" Twin Cam 88 * 414<br />

98" Evolution 9 416<br />

124" S&S 41/8" Bore * 417<br />

103" Evolution & Sportster Models 12 426<br />

116" Twin Cam 88 * 428<br />

Stock Shovelhead & Ironhead Sportster 0 220<br />

93" High Compression Shovelhead 0+ 222<br />

93" Shovelhead * 225<br />

96" Shovelhead 1 228<br />

98" Shovelhead 3 235<br />

103" Shovelhead 5 242<br />

* No old number exists for this manifold length. It was introduced after the new system was initiated.<br />

S&S engine measuring fixtures for Harley-Davidson® Evolution® and Twin<br />

Cam 88® engines, bolt to the heads using manifold mounting bolt holes,<br />

and provide parallel measuring surfaces.<br />

S&S manifold measuring fixtures for Harley-Davidson® Evolution® and<br />

Twin Cam 88® engines slip over the ends of the manifold runners. The<br />

sides of the conical depressions in the fixtures provide parallel surfaces for<br />

measurements.<br />

S&S manifold measuring fixtures for shovelhead engines and Harley-<br />

Davidson® ironhead Sportster® models are used to measure both engines<br />

and manifolds.<br />

Parts for<br />

Twin Cam 88®<br />

Parts for<br />

Evolution®<br />

Parts for<br />

Sportster® '86-'06<br />

Vintage<br />

Engines<br />

X-Wedge® Parts for Victory®, Replacement<br />

Off-road & Metric Parts<br />

Tools &<br />

Shop Supplies<br />

Cylinder Lengths for Stock harley-davidson® engines & models<br />

Measured from head gasket surface to base gasket surface.<br />

88" & 95" Twin Cam 88® , Twin Cam 96 1999-up 4.937"<br />

80" Evolution® Big Twin 1984-'99 5.550"<br />

74" & 80" Shovelhead 1966-'84 5.330"<br />

74" Panhead 1948-'65 5.330"<br />

61" Panhead 1948-'52 5.205"<br />

74" Knucklehead 1936-'47 5.530"<br />

61" Knucklehead 1936-'47 5.405"<br />

Sportster® & Buell® Models 1986-up 4.650"<br />

900cc, 1000cc Ironhead Sportster Models 1957-'85 5.330"<br />

Fixtures slip over the ports of the heads or the ends of manifold. Works for<br />

o-ring and rubber band style heads and manifolds.<br />

Racing<br />

Products<br />

Dealer Services Warranty &<br />

& Promo Items Company Policy<br />

8-9 Visit us at www.sscycle.com

Replacement<br />

Parts<br />

Parts for<br />

Twin Cam 88®<br />

Parts for<br />

Evolution®<br />

Parts for<br />

Sportster® '86-'06<br />

Bearing Protector Tools<br />

For S&S ® X-Wedge ® Engines<br />

Protect Your Crank!<br />

This bearing protector slips over the bearing surface of the X-Wedge<br />

crank<strong>shaft</strong> to prevent damage to the surface of the main bearing journal<br />

when mounting the crank on an S&S <strong>flywheel</strong> assembly fixture. At 42 lbs.,<br />

these cranks are heavy and can be a little awkward to handle. It would be<br />

easy to scratch or dent the journal without the protection of this flanged<br />

sleeve. It can also be used on the <strong>sprocket</strong> side of Victory® crank<strong>shaft</strong>s. Made<br />

of billet aluminum.<br />

Crank<strong>shaft</strong> Main Bearing Protector ...........................106-2858<br />

106-2858<br />

Vintage<br />

Engines<br />

X-Wedge®<br />

Parts for Victory®,<br />

Off-road & Metric<br />

Pictured Above Right: This new bearing protector prevents mishaps<br />

from occurring when mounting an X-Wedge® crank on the S&S Flywheel<br />

assembly fixture. An ounce of prevention is worth 42 pounds of cure. Works<br />

on the <strong>sprocket</strong> side of Victory® crank<strong>shaft</strong>s too!<br />

This bearing protector for the crankcase main bearing inserts not only guides<br />

the crank into the bearing, but prevents sharp surfaces of the <strong>sprocket</strong> <strong>shaft</strong><br />

from contacting the surface of the bearing insert.<br />

Crankcase Main Bearing Insert Protector ......................106-2859<br />

1<br />

Tools &<br />

Shop Supplies<br />

106-2859<br />

Racing<br />

Products<br />

2<br />

Dealer Services<br />

& Promo Items<br />

Warranty &<br />

Company Policy<br />

Pictured Right: Easy as 1-2-3! 106-2859<br />

crankcase bearing protector installs in seconds,<br />

and not only protects the crankcase main<br />

bearing insert from the sharp surfaces on the<br />

<strong>sprocket</strong> <strong>shaft</strong>, but also guides the crank<strong>shaft</strong><br />

into the bearing.<br />

3<br />

Order toll free 866-244-2673<br />

8-10

Dealer Services Warranty &<br />

& Promo Items Company Policy<br />

S&S ® Cam Alignment Tools For X-Wedge ®<br />

Here are some very handy <strong>tools</strong> for aligning the three cams and installing<br />

the cam belt in an S&S X-Wedge engine. The three dowel pins are used to<br />

position each of the three cam belt pulleys with alignment holes in the cam<br />

plate. With the cams correctly positioned, it is a simple job to install the cam<br />

drive belt using the cam belt tensioner socket and a 3/8" ratchet. One more<br />

reason why the X-Wedge engine is so easy to work on!<br />

Cam Alignment Dowels (3 pack) ..............................106-0576<br />

Cam Belt Tensioner Socket ................................ 106-0750<br />

Parts for<br />

Twin Cam 88®<br />

Parts for<br />

Evolution®<br />

Parts for<br />

Sportster® '86-'06<br />

S&S® cam belt tensioner <strong>sprocket</strong> and cam alignment dowels make aligning<br />

the three cams of an X-Wedge® engine and installing a cam belt an easy thing.<br />

Must-have <strong>tools</strong> for any technician servicing X-Wedge engines.<br />

Vintage<br />

Engines<br />

Main Bearing Installation Tool<br />

For X-Wedge ® Engines<br />

This is about the only special tool required to rebuild an S&S® X-Wedge®<br />

engine. This tool consists of a bearing guide that holds the two plain bearing<br />

halves in position and a shouldered press tool that fits through the guide to<br />

press the new bearings into the crankcase. The press tool is also used by itself<br />

to press old bearings out of the crankcase. For cam and driveside bearings in<br />

X-Wedge engines. A hydraulic or arbor press is required to install or remove<br />

bearings.<br />

X-Wedge® Parts for Victory®, Replacement<br />

Off-road & Metric Parts<br />

Tools &<br />

Shop Supplies<br />

Main Bearing Installation Tool<br />

For X-Wedge Engines<br />

Main Bearing Installation Kit ...............................106-0718<br />

Main bearing installation tool for S&S X-Wedge engines installs and removes<br />

plain bearing inserts for camside and driveside main<strong>shaft</strong> bearings.<br />

Racing<br />

Products<br />

8-11 Visit us at www.sscycle.com

Parts for<br />

Twin Cam 88®<br />

Parts for<br />

Evolution®<br />

S&S ® Cylinder Torque Plate Kits<br />

The S&S® cylinder torque plate kits are used to simulate operating stress<br />

conditions when boring and honing aluminum cylinders. These plates are<br />

machined from heat treated chromoly steel, and precision ground on the<br />

working surfaces.<br />

1<br />

Parts for<br />

Sportster® '86-'06<br />

Vintage<br />

Engines<br />

X-Wedge®<br />

Parts for Victory®,<br />

Off-road & Metric<br />

Replacement<br />

Parts<br />

Tools &<br />

Shop Supplies<br />

fitment<br />

❚❚ S&S 41⁄8" bore<br />

❚❚ 4" bore 1999-up big twin<br />

❚❚ 35/8" 1984-'99 big twin<br />

❚❚ Sportster® models in 35⁄8" and 4" bore<br />

❚❚ S&S X-Wedge® 41/8" bore and 41/4" bore*<br />

Features and Benefits<br />

❚❚ S&S torque plates can be used in conjunction with an S&S boring<br />

fixture and a conventional boring bar, and they can be readily<br />

adapted to a Sunnen® type honing machine.<br />

Kit Contents<br />

❚❚ Head end plate<br />

❚❚ Base end plate<br />

❚❚<br />

Four long grade 8 socket head cap screws ( holds the assembly<br />

together and supplies the pressure)<br />

❚ ❚ Stop arm (keeps the cylinder and plates from turning while honing)<br />

* These torque plates are required to bore or hone X-Wedge cylinders. They<br />

have the X-Wedge five bolt pattern and are available for 41/8" bore and 41/4" bore<br />

cylinders.<br />

4<br />

5<br />

Cylinder Torque Plate Replacement Parts<br />

(See chart for specific part numbers.)<br />

1. Base end torque plate<br />

2. Head end torque plate<br />

3. Stop arm<br />

4. Torque bolts<br />

5. Vise tab<br />

6. Tab bolt<br />

6<br />

2<br />

3<br />

Racing<br />

Products<br />

Dealer Services<br />

& Promo Items<br />

Warranty &<br />

Company Policy<br />

Bore<br />

Size<br />

Case Bolt Pattern<br />

Kit<br />

Part No.<br />

S&S® Cylinder Torque Plate Kits and Replacement Parts<br />

Head End<br />

Plate<br />

Base End<br />

Plate<br />

Stop Arm<br />

Bolt<br />

3⁄8"-24 x 6”<br />

Bolt<br />

7⁄16"-20 x 6"<br />

Bolt<br />

7⁄16"-20 x 7"<br />

Vise Tab<br />

Tab Bolt<br />

5⁄16"-18 x 1"<br />

41⁄4" S&S® X-Wedge® 106-0836 106-0837 106-0835 53-0014 106-0840 – – 53-0034 50-0108<br />

43⁄8" S&S 43⁄8" Pattern 53-0055 53-0056 53-0057 53-0014 – – 50-0192 53-0034 50-0108<br />

41⁄8" Stock 1999-up Big Twin 53-0054 106-3190 106-3191 53-0014 – – 50-0192 53-0034 50-0108<br />

41⁄8" S&S 41⁄8" Pattern 53-0051 53-0052 53-0053 53-0014 – 50-0191 – 53-0034 50-0108<br />

4" Stock 1999-up Big Twin 53-0048 53-0049 53-0050 53-0014 – – 50-0192 53-0034 50-0108<br />

4" S&S 4" Pattern 53-0030 53-0031 53-0032 53-0014 – 50-0191 50-0192 53-0034 50-0108<br />

35⁄8" 1984-'99 Big Twin 53-0016 53-0017 53-0018 53-0014 – – 50-0192 53-0034 50-0108<br />

35⁄8" 1984-'03 Sportster® 53-0016 53-0017 53-0018 53-0014 – – 50-0192 53-0034 50-0108<br />

S&S Cylinder torque plate kits are intended for aluminum cylinders including 1984-'99 Harley-Davidson® Evolution® big twin engines, 1986-'03 Sportster models, and 1999-up Twin Cam 88® engines.<br />

Order toll free 866-244-2673<br />

8-12

Warranty &<br />

Company Policy<br />

The S&S boring plates are designed to simplify and reduce the time required to prepare crankcases and cylinder heads for S&S Sidewinder® big bore kit installations.<br />

When adapted to a boring bar such as a Kwik-Way®, it is easy to bolt crankcases or heads to the plate and perform the boring modifications necessary to install<br />

S&S Sidewinder® or Super Sidewinder big bore cylinders. An S&S boring plate and a boring bar may also be used to bore cylinders if desired. The boring plates<br />

Parts for<br />

Twin Cam 88®<br />

53-0006<br />

are machined cast iron with precision ground working surfaces.<br />

Boring Plate Kit for 1936-99 Big Twin<br />

and 1986-'03 Sportster ® Models<br />

This boring plate kit has panhead and shovelhead head bolt patterns in one<br />

end. The other end is machined with the cylinder base patterns of 1936-'99<br />

big twin engines, and 1986-'03 Harley-Davidson® Sportster models. Spacers<br />

are available for Evolution® engines which allow the cases to be bored<br />

without removing the cylinder studs (see below). Spacers are not included<br />

in this kit.<br />

...................................................................................................53-0006<br />

Parts for<br />

Evolution®<br />

Parts for<br />

Sportster® '86-'06<br />

Vintage<br />

Engines<br />

53-0008<br />

53-0007<br />

Includes:<br />

Boring plate (1)<br />

Screw, 7⁄16" -20 x 11⁄4" Sockethead Cap ................... 50-0172<br />

Spacers for Evolution Crankcases<br />

Spacer part #53-0007 is required for 1986-'03 Sportster models.<br />

Spacers part #53-0007 and #53-0008 are both required for 1984-'99 big<br />

twin engines.<br />

Spacer<br />

311/16" tall ............................................... 53-0007<br />

7⁄8" tall .................................................. 53-0008<br />

Boring Plate Kit for Crankcases<br />

& Cylinders For Twin Cam 88 ® Engines<br />

This boring plate kit is designed for boring stock crankcases of Harley-<br />

Davidson® Twin Cam 88® engines to accept S&S Super Sidewinder® 4" and<br />

41/8" bore cylinders. A spacer is included with the kit which allows the cases<br />

to be bored without removing the cylinder studs.<br />

X-Wedge® Parts for Victory®, Replacement<br />

Off-road & Metric Parts<br />

Tools &<br />

Shop Supplies<br />

53-0035<br />

............................................................................................... 53-0035<br />

Includes:<br />

Boring plate ........................................... 53-0036<br />

Spacer, 33⁄4" tall ....................................... 53-0037<br />

Racing<br />

Products<br />

Dealer Services<br />

& Promo Items<br />

8-13 Visit us at www.sscycle.com

Warranty &<br />

Company Policy<br />

Parts for<br />

Twin Cam 88®<br />

Parts for<br />

Evolution®<br />

Parts for<br />

Sportster® '86-'06<br />

Vintage<br />

Engines<br />

X-Wedge®<br />

S&S ® Degree Wheel Kit<br />

The multipurpose S&S® degree wheel can be used to do ignition timing,<br />

crankcase breather timing, cam degreeing, or you name it. The wheel<br />

is designed to fit the <strong>sprocket</strong> <strong>shaft</strong> of any big twin or Harley-Davidson®<br />

Sportster® model simply by using the correct adapter provided. Each kit also<br />

comes with a pointer which is held in place with the center crankcase bolt.<br />

This aid is a must for every well equipped engine building shop.<br />

S&S Degree Wheel Kit .................................... 53-0020<br />

Includes:<br />

1. Adapter for Sportster (1 Each) ........................... 53-0023<br />

2. Adapter for big twin (1 Each) . .......................... 53-0024<br />

3. Pointer (1 Each) ....................................... 53-0025<br />

4. Degree wheel and main adapter assembly (1 Each) ......... 53-0026<br />

53-0020<br />

Parts for Victory®,<br />

Off-road & Metric<br />

Dealer Services<br />

& Promo Items<br />

Replacement<br />

Parts<br />

Racing<br />

Products<br />

Tools &<br />

Shop Supplies<br />

S&S ® CRANKPIN NUT CLEARANCING GAUGES<br />

The S&S crankpin nut clearancing gauges are designed to simplify and<br />

eliminate clearancing problems that may arise when installing stroker<br />

<strong>flywheel</strong>s in stock big twin crankcases. By painting the bosses to be<br />

clearanced and then placing the appropriate gauge on the main bearing race,<br />

the crankcases can be marked with a scribe in the proper hole for the stroke<br />

and style connecting rod crankpin nuts to be used– quickly and precisely.<br />

1937-’57 Big Twin Gauge ................................. 53-0009<br />

1958-’99 Big Twin Gauge ................................ 53-0005 53-0005<br />

Order toll free 866-244-2673<br />

8-14

Dealer Services Warranty &<br />

& Promo Items Company Policy<br />

S&S ® ANTI-ROTATION BRACKET<br />

Useful <strong>tools</strong> don't have to be expensive! This handy bracket slides over<br />

the <strong>sprocket</strong> <strong>shaft</strong> splines of big twin engines and bolts to one of the <strong>primary</strong><br />

bolt holes of the crankcase to keep the crank from rotating. It's like an extra<br />

set of hands while installing pistons and cylinders.<br />

S&S Anti-rotation Bracket .............................. 50-9870<br />

50-9870<br />

Parts for<br />

Twin Cam 88®<br />

Parts for<br />

Evolution®<br />

Parts for<br />

Sportster® '86-'06<br />

S&S ® Crankcase Oil Passage Drilling Jig<br />

The S&S crankcase oil passage drilling jig is used to perform crankcase drilling<br />

modifications when installing an S&S oil pump assembly on early big twin<br />

crankcases. Made of hardened steel for durability, this fixture enables the<br />

builder to do four modifications.<br />

S&S Crankcase Oil Passage Drilling Jig............................... 53-0013<br />

Drill Jig Is Used To Drill...<br />

❚❚ Primary chain oil supply passage from the breather valve gear<br />

cavity to the back side of the oil pump body on late generator<br />

and early alternator crankcases.<br />

❚❚ Pressure relief passage from behind the main oil pressure valve<br />

to the gear cavity on alternator crankcases.<br />

❚❚ Crank<strong>shaft</strong> and main bearings supply passage on generator<br />

crankcases.<br />

❚❚ Crank<strong>shaft</strong> and main bearings supply passage on early<br />

alternator crankcases.<br />

Vintage<br />

Engines<br />

X-Wedge® Parts for Victory®, Replacement<br />

Off-road & Metric Parts<br />

Tools &<br />

Shop Supplies<br />

Racing<br />

Products<br />

8-15 Visit us at www.sscycle.com

Parts for Victory®,<br />

Off-road & Metric<br />

Parts for<br />

Twin Cam 88®<br />

S&S ® and Mobil 1 ® Synthetic Oil<br />

The official oil of S&S ® <strong>Cycle</strong><br />

Parts for<br />

Evolution®<br />

Parts for<br />

Sportster® '86-'06<br />

Vintage<br />

Engines<br />

Racing<br />

Products<br />

X-Wedge®<br />

National account plan<br />

As an authorized S&S dealer, you will have the purchasing power of the S&S<br />

National Account for your Mobil 1 pricing. Through this program, you can<br />

take advantage of local ordering and delivery through the Mobil 1 distributor<br />

in your area, while enjoying centralized billing through S&S.<br />

To set-up your account:<br />

❚❚ Call your S&S sales representative for an application form and<br />

additional information.<br />

❚❚ Mail or fax the form to Mobil 1.<br />

❚❚ After your account has been established, you will be contacted by<br />

a Mobil 1 representative with ordering and delivery procedures.<br />

Future orders will typically be delivered within 72-hours of<br />

placement. Minimum order is 12 cases.<br />

Replacement<br />

Parts<br />

Tools &<br />

Shop Supplies<br />

Mobil 1 V-TWIN 20W-50 synthetic oil has been named the official<br />

oil of S&S <strong>Cycle</strong> engines. This comes after an exhaustive testing<br />

program at our research and development facility in Viola,<br />

Wisconsin.<br />

Dealer Services<br />

& Promo Items<br />

Warranty &<br />

Company Policy<br />

Mobil 1 ® Synthetic Oil TÜV<br />

2,3<br />

Sold in 6 quart cases. Shipped from S&S.<br />

V-Twin 20W-50 ..........................................31-4201<br />

MX4T 10W-40 ............................................31-4203<br />

Order toll free 866-244-2673<br />

8-16

Warranty &<br />

Company Policy<br />

S&S ® Quick OIL CHANGE KITS<br />

Give your engine the good stuff! S&S® recommends that you change<br />

your oil and filter every 2500 miles or six months, which ever comes first.<br />

And to make it easy, we offer S&S Quick Oil Change kits. These kits include<br />

four quarts of Mobil 1® V-Twin 20W-50 full synthetic motor oil, the official<br />

oil of S&S Proven Performance® engines, and a premium chrome S&S oil<br />

filter. Everything you need in one convenient package.<br />

Application<br />

S&S® Quick change oil Kits<br />

Chrome Filter<br />

1984-’99 Evolution® Big Twin 31-4217<br />

1999-up Twin Cam 88®, Twin Cam 96 and X-Wedge® 31-4218<br />

Parts for<br />

Twin Cam 88®<br />

Parts for<br />

Evolution®<br />

Parts for<br />

Sportster® '86-'06<br />

Vintage<br />

Engines<br />

Tech Tip: Use The Right Oil Filter<br />

There are two types of spin-on oil filters available for Harley-Davidson® big<br />

twin engines, and it is important to use the right one for your style of engine.<br />

One type of filter is designed for late shovelhead and all Evolution® engines<br />

up to the 1999 model year. The other type of filter is designed for Twin Cam<br />

88® and Twin Cam 88B engines 1999 and later.<br />

Prior to 1999, the oil filter was located on the return side of the oil system.<br />

Low pressure in the return line, plus the air being pumped along with the oil<br />

made it necessary to use an oil filter media with a relatively open 30 micron<br />

rating. In 1999, the Twin Cam 88® engine was introduced and the oiling<br />

system was updated. In the new system, oil is filtered under higher pressure<br />

before it goes into the engine. This allows the use of an oil filter with finer 10<br />

micron media, which will filter out smaller particles of debris from the oil.<br />

The lower micron rating of filters for 1999-up engines makes it tempting to<br />

use them in earlier engines to give them the same degree of oil filtration.<br />

However, the increased restriction to oil flow of the 10 micron filter media<br />

can cause oil return problems in these engines. These problems may range<br />

from a slight increase in oil mist out the breather, to large amounts of oil<br />

blowing out the breather, generally at sustained high speeds.<br />

Another difference between the two filter types is that the 1999-later style<br />

has an anti-drainback valve or bladder. Since the filter is in the supply line,<br />

it must be full before the engine will get any oil. The anti-drainback valve<br />

keeps the filter full while the engine is not running, ensuring that there is no<br />

delay in oil delivery at startup. If this type of filter is used in 1999 or earlier<br />

engines, the increased restriction to flow from the valve is another factor in<br />

oil return problems.<br />

We recommend that you always use the correct filter for your engine.<br />

It’s easy to tell if your filter has an antidrainback<br />

valve. The valve is a rubber<br />

bladder, which is easily seen through<br />

the inlet holes in the filter. This filter is<br />

for 1999 and later big twin engines.<br />

X-Wedge® Parts for Victory®, Replacement<br />

Off-road & Metric Parts<br />

Tools &<br />

Shop Supplies<br />

Racing<br />

Products<br />

Dealer Services<br />

& Promo Items<br />

8-17 Visit us at www.sscycle.com

Parts for<br />

Twin Cam 88®<br />

Parts for<br />

Evolution®<br />

Parts for<br />

Sportster® '86-'06<br />

Vintage<br />

Engines<br />

X-Wedge®<br />

Parts for Victory®,<br />

Off-road & Metric<br />

Replacement<br />

Parts<br />

S&S ® Oil Filters<br />

Protect your investment. The most important thing you can do to<br />

maximize the life of your engine is to keep your oil clean. Friction-wear<br />

particles and combustion byproducts are picked up by your motor oil.<br />

Regular oil changes are essential to keep contaminants from accumulating,<br />

but from one oil change to the next, your oil filter is your first line of defense<br />

against these wear causing particles. Make sure you have an S&S oil filter<br />

working for you.<br />

Features and benefits<br />

❚❚ Sturdy steel canister houses the finest filtering media and<br />

internal components available<br />

❚❚ Smaller than stock diameter for easier installation and removal<br />

❚❚ Designed with a direct bypass valve that routes bypass oil<br />

directly to the filter exit. Direct bypass minimizes the amount<br />

of contaminants carried to the engine in the unfiltered bypass<br />

oil since the oil is not allowed to pick up contaminants by<br />

flowing over the "dirty" side of the filter media, as it is in some<br />

competitive filters.<br />

❚❚ Filter media traps the smallest possible particles while<br />

maintaining the lowest restriction to oil flow.<br />

❚❚ Available in black or chrome finish<br />

TÜV<br />

4,5,6<br />

USA<br />

1,2,3<br />

U S A<br />

Year Application<br />

1984-'99 Evolution®,<br />

1986-up Xl and 1991-’02 Buell®<br />

1999-Up* Twin Cam 88®,<br />

Twin Cam 96 and X-Wedge®<br />

* Contains an anti-drain back valve<br />

S&S® Oil Filters for 1984-Up Big Twins<br />

Micron<br />

Rating<br />

Chrome<br />

Black<br />

30µ 31-4102 31-4101<br />

10µ 31-4104 31-4103<br />

U S A<br />

U S A<br />

Tools &<br />

Shop Supplies<br />

Racing<br />

Products<br />

Dealer Services<br />

& Promo Items<br />

Warranty &<br />

Company Policy<br />

champion ® spark plugs<br />

Replace Your Spark Plugs For Maximum Performance and Fuel<br />

Economy. S&S® now offers the same high quality Champion® spark plugs<br />

that we include with our engines for replacement in S&S and stock engines<br />

alike. These long reach resistor spark plugs are available in 12mm and 14mm<br />

sizes. They are the correct heat range for all S&S engines and also fit 1977<br />

and later Harley-Davidson® engines. Compatible with any ignition system.<br />

Champion ® Spark Plugs<br />

Size<br />

Part No.<br />

12mm Long Reach (2 Pack) 55-1322<br />

14mm Long Reach (2 Pack) 55-1323<br />

U S A<br />

55-1323<br />

55-1322<br />

TÜV<br />

5,6<br />

USA<br />

2,3<br />

Order toll free 866-244-2673<br />

8-18

Racing<br />

Products<br />

Warranty &<br />

Company Policy<br />

S&S ® Touch Up Paint, Lubricant and sealants<br />

Touch up paint<br />

S&S touch up paint is included with each powdercoated S&S engine, but it’s<br />

handy to have a spare! Keep one in the shop and one in your saddle bag. Sold<br />

in 1⁄2 oz. bottles with applicator cap.<br />

Black 1⁄2 oz. .............................................. 51-9001<br />

Silver 1⁄2 oz ...........................................106-3023<br />

Lubricant and sealants<br />

Use what the pro's use! S&S assembles a lot of engines and customers<br />

often ask what sealants and lubricants we use. We recommend and use the<br />

following:<br />

106-3023<br />

51-9001<br />

Parts for<br />

Twin Cam 88®<br />

Parts for<br />

Evolution®<br />

Parts for<br />

Sportster® '86-'06<br />

Vintage<br />

Engines<br />

Torco® Engine Assembly Lube<br />

Protect engine components during assembly and initial start up!<br />

12 oz. Bottle .........................................51-9012<br />

4 oz. Bottle ...................................... 51-9000<br />

1 oz. Tube ....................................... 51-9002<br />

Gasgacinch® Gasket Sealer<br />

Great for copper head gaskets!<br />

4 oz. (118ml) Can ................................. 51-9009<br />

51-9000<br />

51-9009<br />

X-Wedge® Parts for Victory®, Replacement<br />

Off-road & Metric Parts<br />

ThreeBond® Liquid Gasket 1194<br />

Great for sealing crankcases!<br />

3.5 oz. (100g) Tube ............................... 51-9010<br />

51-9002<br />

Tools &<br />

Shop Supplies<br />

51-9010<br />

Dealer Services<br />

& Promo Items<br />

8-19 Visit us at www.sscycle.com

Parts for<br />

Sportster® '86-'06<br />

Replacement<br />

Parts<br />

Parts for<br />

Twin Cam 88®<br />

Vintage<br />

Engines<br />

Racing<br />

Products<br />

Parts for<br />

Evolution®<br />

S&S ® Engine Stands<br />

S&S now offers an economical way to hold an engine on the work bench, for<br />

shipping, or for display. S&S engine stands are constructed of heavy gauge<br />

stamped steel with "S&S" laser cut in both ends. The bullet proof, blue<br />

powdercoat finish give the stands a professional appearance that is suitable<br />

for display and protects them from corrosion and minor abrasions.<br />

Pictured Right: S&S® engine stands are ideal for use in the workshop or as<br />

display stands for engines or crankcases.<br />

X-Wedge®<br />

Parts for Victory®,<br />

Off-road & Metric<br />

S&S® Engine Stands<br />

Application<br />

Part No.<br />

S&S X-Wedge® Engines 53-0147<br />

1936-'99 Big Twin Engines 53-0141<br />

1999-'09 Unbalanced Big Twin Engines 53-0143<br />

1999-'06 Balanced Big Twin Engines 53-0145<br />

Tools &<br />

Shop Supplies<br />

53-0143<br />

Dealer Services<br />

& Promo Items<br />

53-0145<br />

Warranty &<br />

Company Policy<br />

53-0141<br />

Order toll free 866-244-2673<br />

8-20