FSAW 0301 - Generic MPM R1 - Jamaica Civil Aviation Authority

FSAW 0301 - Generic MPM R1 - Jamaica Civil Aviation Authority

FSAW 0301 - Generic MPM R1 - Jamaica Civil Aviation Authority

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

GENERIC AVIATION SERVICES LIMITED<br />

Maintenance Procedures Manual<br />

MAINTENANCE PROCEDURES MANUAL<br />

COPY No:<br />

(ADDRESS PAGE)<br />

Name of Operator:<br />

Address:<br />

Tel:<br />

Fax:<br />

Maintenance Base:<br />

JAMAICAN AIRLINES (OR AIRCRAFT) USING FACILITY<br />

1) _________________________<br />

2) _________________________<br />

3) _________________________

GENERIC AVIATION SERVICES LIMITED<br />

Maintenance Procedures Manual<br />

4) _________________________<br />

INDEX<br />

[For <strong>Generic</strong> Manual]<br />

Use of individualsection page numbers recommended for Company Manuals<br />

e.g. ‘Page 6-5’being 5 th page of Section 6<br />

Cover-page ......................................................................... 1<br />

Index................................................................................. 2 & 3<br />

Compliance Statement/Certification Page...................................... 4<br />

Distribution List ................................................................... 5<br />

Amendment Record ............................................................... 6<br />

List of Effective Pages............................................................ 7<br />

Abbreviations & Glossary........................................................ 8<br />

Section 1 Introduction and Description ............................... 9<br />

1.1 Manualamendment Procedure ........................ 10<br />

Section 2 OrganisationalStructure............................. 11<br />

2.1 OrganisationalCharts................................... 11<br />

2.2 Responsibilities and Duties ............................ 12<br />

2.3 List of Certifying Staff................................. 13<br />

Section 3 <strong>Aviation</strong> Maintenance Resources ................... 14<br />

3.1 Maintenance Facility.................................... 14<br />

3.2 Maintenance Equipment................................ 14<br />

3.3 TechnicalPublications.................................. 15<br />

Revision: 12 Page 2<br />

08/09/02August 21, 2002<br />

<strong>FSAW</strong> <strong>0301</strong>

GENERIC AVIATION SERVICES LIMITED<br />

Maintenance Procedures Manual<br />

Section 4 Maintenance Procedures ............................. 16<br />

4.1 Aircraft Maintenance Programme Compliance ..... 16<br />

4.2 Airworthiness Directives Compliance................ 16<br />

4.3 Repairs and Modifications ............................. 17<br />

4.4 Use of Maintenance Documentation.................. 17<br />

4.5 Airworthiness Certification and Authorisation...... 18<br />

4.6 Rectification of Defects [Sched. Mtce] .............. 19<br />

4.7 Human Factors .......................................... 19<br />

Section 5 Products and Materials Control.................... 20<br />

5.1 Supplier Evaluation Procedure ........................ 20<br />

5.2 Acceptance of Aircraft Components & Materials .. 20<br />

5.3 Storage, Tagging & Release of A/C Parts........... 21<br />

5.4 Acceptance of Tools and Equipment................. 21<br />

5.5 Calibration of Tools and Equipment.................. 21<br />

5.6 Use of Tooling and Equipment........................ 21<br />

5.7 Return of Defective Components to Stores.......... 22<br />

5.8 Return of Def. Components to Contractors ......... 22<br />

5.9 Aircraft Parts Scrap Programme...................... 22<br />

5.10 Return Of Components To Customers -owners… ….22<br />

Section 6 Quality Assurance ..................................... 23<br />

6.1 Policy ..................................................... 23<br />

6.2 Auditing .................................................. 23<br />

6.3 Training................................................... 24<br />

6.4 Records of Certifying Staff............................ 25<br />

6.5 Extension of Quality System .......................... 25<br />

6.6 Deviation from Procedures ............................ 26<br />

6.7 Reporting to the JCAA/Operator/Manufacturer .... 26<br />

Section 7 TechnicalRecords Controland Storage........... 27<br />

7.1 Primary Maintenance Records ........................ 27<br />

7.2 Computer Based Maintenance Recording System .. 27<br />

7.3 Third Party Records Maintenance .................... 27<br />

Section 8 Maintenance Agreements/Sub-Contracting ...... 28<br />

Appendix A Forms ..................................................... 29 - 30<br />

Appendix B Contracts/Agreements .................................. 31<br />

Appendix C Capability listing ........................................ 32<br />

Revision: 12 Page 3<br />

08/09/02August 21, 2002<br />

<strong>FSAW</strong> <strong>0301</strong>

GENERIC AVIATION SERVICES LIMITED<br />

Maintenance Procedures Manual<br />

COMPLIANCE STATEMENT<br />

This Maintenance Procedure Manual(<strong>MPM</strong>) contains information and instructions on the manner<br />

in which maintenance and inspection, procedures and practices wi lbe conducted, and defines<br />

personnelresponsibilities.<br />

The standards, practices and procedures reflect company maintenance and inspection policies and<br />

are in accordance with the <strong>Civil</strong><strong>Aviation</strong> (Air Navigation) Regulations 1995. Any error or<br />

omission in this regard does not relieve personnelof the responsibility of observing <strong>Jamaica</strong> <strong>Civil</strong><br />

<strong>Aviation</strong> <strong>Authority</strong> (JCAA) requirements at a ltimes. This manualwi lbe made available to a l<br />

personnelconcerned with the maintenance and inspection of company aircraft and aeronautical<br />

products.<br />

A lcompany personnelconcerned with the maintenance and inspection of aircraft and components<br />

wi lbe familiar with and comply with the contents of this manual.<br />

Economic requirements sha lnot take precedence over safety in the inspection and maintenance<br />

function.<br />

No aircraft sha lbe released for flight unless it has been maintained and certified in accordance<br />

with this manualand the operators approved maintenance program.<br />

Accountable Manager Certification: ______________________________ _______________<br />

(Signature/Title)<br />

(Date)<br />

********************************************************************************************<br />

JCAA Certification<br />

This Maintenance Procedures Manualhas been accepted by the <strong>Jamaica</strong> <strong>Civil</strong><strong>Aviation</strong> <strong>Authority</strong>.<br />

________________________________________________<br />

Airworthiness Inspector for Director <strong>Civil</strong> <strong>Aviation</strong> <strong>Authority</strong><br />

___________________<br />

(Date)<br />

(JCAA Stamp/Insp. No)<br />

Revision: 12 Page 4<br />

08/09/02August 21, 2002<br />

<strong>FSAW</strong> <strong>0301</strong>

GENERIC AVIATION SERVICES LIMITED<br />

Maintenance Procedures Manual<br />

Revision: 12 Page 5<br />

08/09/02August 21, 2002<br />

<strong>FSAW</strong> <strong>0301</strong>

GENERIC AVIATION SERVICES LIMITED<br />

Maintenance Procedures Manual<br />

MANUAL DISTRIBUTION LIST<br />

Serial/Copy Number<br />

Holder<br />

1. Quality Assurance<br />

2. Director of Maintenance<br />

3. Library<br />

4. JCAA<br />

5. ???<br />

6. ???<br />

7. ???<br />

8. ???<br />

Revision: 12 Page 6<br />

08/09/02August 21, 2002<br />

<strong>FSAW</strong> <strong>0301</strong>

GENERIC AVIATION SERVICES LIMITED<br />

Maintenance Procedures Manual<br />

AMENDMENT RECORD<br />

Revision Date Date Inserted Inserted By<br />

Original<br />

# 1<br />

# 2<br />

Revision: 12 Page 7<br />

08/09/02August 21, 2002<br />

<strong>FSAW</strong> <strong>0301</strong>

GENERIC AVIATION SERVICES LIMITED<br />

Maintenance Procedures Manual<br />

LIST OF EFFECTIVE PAGES<br />

PAGE # REV. # DATE PAGE # REV. # DATE<br />

Company Representative:<br />

____________________________________ ____________________<br />

(Signature/Title) (Date)<br />

(<br />

S<br />

i<br />

g<br />

n<br />

THIS MANUAL HAS BEEN ACCEPTED BY THE<br />

JAMAICAN CIVIL AVIATION AUTHORITY.<br />

_______________________________<br />

for The Director General <strong>Civil</strong> <strong>Aviation</strong> <strong>Authority</strong><br />

Date:__________________________<br />

Revision: 12 Page 8<br />

08/09/02August 21, 2002<br />

<strong>FSAW</strong> <strong>0301</strong>

GENERIC AVIATION SERVICES LIMITED<br />

Maintenance Procedures Manual<br />

ABBREVIATIONS & GLOSSARY<br />

A list of a lterms used that may be unknown or mis-understood by ANY person that may have<br />

reason to use this manualfor the purpose of obtaining information so as to be able to comply with,<br />

or maintain compliance with the “approved”procedures.<br />

Revision: 12 Page 9<br />

08/09/02August 21, 2002<br />

<strong>FSAW</strong> <strong>0301</strong>

GENERIC AVIATION SERVICES LIMITED<br />

Maintenance Procedures Manual<br />

SECTION 1 - INTRODUCTION AND DESCRIPTION<br />

(A brief description of the Organisation including type and scope of operation, customers of the<br />

AMO, geographic location and generallayout of the facilities, etc.)<br />

Revision: 12 Page 10<br />

08/09/02August 21, 2002<br />

<strong>FSAW</strong> <strong>0301</strong>

GENERIC AVIATION SERVICES LIMITED<br />

Maintenance Procedures Manual<br />

SECTION 1.1 –MANUAL AMENDMENT PROCEDURE<br />

(Sample only)<br />

A lamendments wi lbe properly inserted by the person in the position as indicated on the<br />

distribution list. As the holder, he wi lbe responsible for the safe custody and maintenance<br />

of the manual.<br />

(1) Amendments wi lbe drafted by the (???), then submitted to the (???) for company<br />

approval.<br />

(2) A verticalline in the right hand column wi lindicate amended areas for the current<br />

submission only (except where an entire section or chapter is replaced). Failure<br />

to remove previous revision indicator lines wi l result in the amendment being<br />

rejected by the JCAA.<br />

(3) Each amended page sha lshow the amendment number and the date in the lower<br />

left hand corner.<br />

(4) If an amendment requires additionalpages, these pages sha lbear the page number<br />

of the preceding page in the manualand be suffixed alphabetica ly.<br />

(5) A copy of the amendment wi lbe forwarded to the JCAA along with a revised List<br />

of Effective Pages (LEP) and Amendment ControlSheet.<br />

(6) Once accepted by the JCAA, amendments sha lbe issued to manualholders with<br />

copies of the LEP's and Amendment ControlSheet.<br />

(7) Confirmation that amendment action has been accomplished wi lbe provided within<br />

30 days to the Accountable Manager by return of the amendment controlpage<br />

signed and dated by the individualmaking the amendment.<br />

Revision: 12 Page 11<br />

08/09/02August 21, 2002<br />

<strong>FSAW</strong> <strong>0301</strong>

GENERIC AVIATION SERVICES LIMITED<br />

Maintenance Procedures Manual<br />

SECTION 2 –ORGANISATIONAL STRUCTURE<br />

SECTION 2.1 –ORGANISATIONAL CH ART(S)<br />

MUST reflect specific organisation as in simple example below<br />

ACCOUNTABLE<br />

MANAGER<br />

General Manager, Managing Director etc<br />

DIRECTOR MAINTENANCE<br />

Type title here<br />

Cheif Engineer, Maintenance Manager etc<br />

STORES/Materials<br />

DIRECTOR QUALITY<br />

Chief Inspector, Manager Quality etc.<br />

Revision: 12 Page 12<br />

08/09/02August 21, 2002<br />

<strong>FSAW</strong> <strong>0301</strong>

GENERIC AVIATION SERVICES LIMITED<br />

Maintenance Procedures Manual<br />

SECTION 2.2 - RESPONSIBILITIES AND DUTIES<br />

The responsibilities and duties wi lbe as defined in the fo lowing sections. A lCompany personnel<br />

are required to become familiar with the positions and duties as reflected in this manual.<br />

(Detailthe responsibilities and duties of management personnel)<br />

2.2.1 Accountable Manager<br />

2.2.2 Director of Maintenance (Or Chief Engineer)<br />

2.2.3 Director of Quality Assurance (Or Chief Inspector)<br />

2.2.4 (Other Manager/Supervisor as Applicable)<br />

2.2.5 (Materials Manager or Storekeeper)<br />

ETC. ETC. ETC.<br />

Revision: 12 Page 13<br />

08/09/02August 21, 2002<br />

<strong>FSAW</strong> <strong>0301</strong>

GENERIC AVIATION SERVICES LIMITED<br />

Maintenance Procedures Manual<br />

SECTION 2.3 –LIST OF CERTIFYING STAFF….[if applicable]<br />

2.3.1 Certifying Staff - Mechanic/Avionics [MCRS, CRS]<br />

2.3.2 CMR Certifying Staff<br />

2.3.3 Component Certifying Staff [CRS on Authorised Release Certificates]<br />

2.3.4 Contract Certifying Staff …[Details As Applicable]<br />

Revision: 12 Page 14<br />

08/09/02August 21, 2002<br />

<strong>FSAW</strong> <strong>0301</strong>

GENERIC AVIATION SERVICES LIMITED<br />

Maintenance Procedures Manual<br />

SECTION 3 –AVIATION MAINTENANCE RESOURCES<br />

Resources available to the Company to facilitate the performance of maintenance functions<br />

include facilities, equipment and publications as described in the fo lowing sections.<br />

SECTION 3.1 - MAINTENANCE FACILITY<br />

3.1.1 Base Maintenance Facilities<br />

3.1.1.1 Hangar Accommodation<br />

3.1.1.2 Specialised Workshops<br />

3.1.1.3 EnvironmentalProvisions<br />

3.1.1.4 Office Accommodation<br />

3.1.1.5 Stores/Storage<br />

3.1.1.6 Layout of facility & premises<br />

3.1.2 Sate lite Maintenance Facilities [at each location as applicable]<br />

[Same format as Base Facilities]<br />

3.1.3 Component Maintenance Facilities<br />

3.1.3.1 Specialised Workshops<br />

3.1.3.2 Environmental Provisions<br />

3.1.3.3 Office Accommodation<br />

3.1.3.4 Stores/Storage<br />

3.1.3.5 Layout of facility & premises<br />

3.1.4 Cleanliness Standards of Maintenance Facilities<br />

3.1.4.1 “Foreign Object” exclusion programme<br />

3.1.4.2 Cleaning programme [– individual responsibilities – Timescales]<br />

3.1.4.3 Waste material disposal<br />

SECTION 3.2 - MAINTENANCE EQUIPMENT<br />

List available support equipment and special tools necessary and available for the<br />

operation of the Maintenance Facility.<br />

Revision: 12 Page 15<br />

08/09/02August 21, 2002<br />

<strong>FSAW</strong> <strong>0301</strong>

GENERIC AVIATION SERVICES LIMITED<br />

Maintenance Procedures Manual<br />

SECTION 3.3 - TECH NICAL PUBLICATIONS<br />

3.3.1 Contro led Manuals<br />

3.3.1.1 Mechanism for Review of Amendment Status of Contro led Manuals<br />

State mechanism for the periodic review of the amendment status of ALL<br />

“controlled documentation” [preferably done by the Technical library] i.e. Legal<br />

Documents from Airworthiness Authorities, MPDs/MRBs & MMELs [including<br />

current Temporary Revisions], and MMs, IPCs, WDMs, Procedures Manuals, etc<br />

etc. provided by customers.<br />

3.3.1.2 List of Controlled Publications.<br />

List the Technicaland Regulatory publications on hand [or distributed], and how<br />

maintained to the latest amendment status. Include the fo lowing:<br />

(1) The <strong>Jamaica</strong> <strong>Civil</strong><strong>Aviation</strong> Regulations (JCAR's) and Directives, as we l<br />

as the Personnel Licensing Standards Handbook Volume II+ JCAA<br />

Airworthiness Policy Letters<br />

(2) Manuals provided by customers [Procedures Manuals, MELs, MM, CMMs]<br />

(3) Airworthiness Directives of country of manufacture [or holder of original<br />

Type Certificate if applicable]<br />

(4) FAA AC 43.13 Parts 1 and 2 ???????<br />

(5) Manufacturers SB’s, SL’s & SI’s<br />

(6) For the types of aircraft/engines/components/tools maintained by the<br />

organisation, the relevant manufacturers manuals for:<br />

a) Maintenance<br />

b) Troubleshooting<br />

c) Parts Listing<br />

d) Manufacturers Information updates [e.g. SB’s, SL’s & SI’s etc]<br />

e) Tools and required equipment<br />

f) Manuals required for operating/maintaining specialised equipment<br />

in (e)<br />

3.3.2 Uncontro led Manuals<br />

3.3.2.1 Differentiation from contro led manuals and storage.<br />

3.3.2.2 List of UN-Contro led Publications [as required].<br />

3.3.3 InternalDistribution Of CriticalReading Information<br />

3.3.3.1 Method of distribution [incl. routing to Tech. Lib from source]<br />

Revision: 12 Page 16<br />

08/09/02August 21, 2002<br />

<strong>FSAW</strong> <strong>0301</strong>

GENERIC AVIATION SERVICES LIMITED<br />

Maintenance Procedures Manual<br />

3.3.3.2 Reading record [confirmation of having read and understood material]<br />

SECTION 4 - MAINTENANCE PROCEDURES<br />

Describe the system that wi lbe used to ensure a lmaintenance is completed in accordance<br />

with the relevant <strong>Civil</strong><strong>Aviation</strong> Regulations, (i.e.<strong>Jamaica</strong>n Regulations), manufacturer's<br />

requirements and recommendations, the approved inspection program and the customers<br />

requirements and approved procedures.<br />

SECTION 4.1 - PROGRAMME COMPLIANCE<br />

4.1.1 Obtaining and maintaining current Maintenance Programme from Operator.<br />

4.1.2 Mechanism for cross-checking validity of Maintenance Programme<br />

4.1.3 Reserved<br />

4.1.4 Reserved<br />

4.1.4<br />

4.1.5<br />

SECTION 4.2 AIRWORTH INESS DIRECTIVES COMPLIANCE<br />

4.2.1 Airworthiness directive response procedure –(termination action/inspection)<br />

4.2.2 Records of AD compliance and certification<br />

4.2.3 Repetitive AD requirements –(inspection control)<br />

4.2.4 Continued Airworthiness Information – (assessment procedure and methods of<br />

response)<br />

Revision: 12 Page 17<br />

08/09/02August 21, 2002<br />

<strong>FSAW</strong> <strong>0301</strong>

GENERIC AVIATION SERVICES LIMITED<br />

Maintenance Procedures Manual<br />

SECTION 4.3 - REPAIRS & MODIFICATIONS<br />

Describe the standards and procedures that wi lbe used to perform repairs and modifications,<br />

both minor and major. Ref.: SRM’s, AD’s, TC’s, STC’s, manufacturers repair schemes, Design<br />

ApprovalOrganisations, etc.<br />

Note 1:<br />

Note 2:<br />

Note 3:<br />

A lrepairs and modifications to aircraft sha lbe made to data accepted or approved<br />

by the authority.<br />

A lrepairs and modifications wi lbe inspected for conformity to accepted<br />

or approved data and certified by qualified personnelprior to release of the<br />

aircraft for return to service.<br />

Specialised work sha lonly be performed and certified by an Approved<br />

Maintenance Organisation appropriately certified for the work being<br />

accomplished.<br />

4.3.1 Company policy –(internal/external–sources of repair approval)<br />

4.3.2 Company approval–scope of work –limitations and conditions<br />

4.3.3 Controlsystems for repair for parts manufacture, processing and inspection<br />

4.3.4 Modification control–(requirements and approval)<br />

SECTION 4.4 – USE OF MAINTENANCE DOCUMENTATION<br />

Details of the method used to record and maintain records of work performed<br />

(Refer to Operators’ MCM + additional as req.)<br />

4.4.1 Worksheets for non-routine tasks<br />

4.4.2 Assembly of work packages for issue to maintenance activity<br />

4.4.3 Worksheet/work card completion work package for certification<br />

4.4.4 Recording of test results and dimensions<br />

4.4.5 Verification of completeness prior to aircraft release [Production audit]<br />

4.4.6 Log entry procedures (i.e.: print capitalletters with black ink)<br />

4.4.7 Log entry correction procedures (single line through errors, initialcorrection)<br />

4.4.8 Log audits<br />

4.4.9 Records handling, and routing to storage [Refer to Section 7]<br />

4.4.10 Record retention periods (2 years after permanently removed from service for<br />

logbooks)<br />

Revision: 12 Page 18<br />

08/09/02August 21, 2002<br />

<strong>FSAW</strong> <strong>0301</strong>

GENERIC AVIATION SERVICES LIMITED<br />

Maintenance Procedures Manual<br />

SECTION 4.5 - AIRWORTH INESS CERTIFICATION AND AUTH ORISATION<br />

Note 1:<br />

Note 2:<br />

Note 3:<br />

Maintenance certification sha lconform to the requirements of the <strong>Civil</strong><strong>Aviation</strong><br />

Regulations and a lpersonnelcertifying aircraft or aitrcraft components must be<br />

appropriately licensed by the JCAA.<br />

The Quality Assurance Section sha l maintain a list of a l individuals having<br />

certifying authority. This list must include the names, AME license numbers and<br />

ratings when applicable, the scope of certification authority each person holds, and<br />

their training records.<br />

The procedures specified below MUST refer [when applicable] to the requirement<br />

to conform with the approved procedures of customers.<br />

4.5.1 Company procedures – (CRS statement)<br />

4.5.2 Issue of CRS after Scheduled Maintenance<br />

4.5.3 Issue CRS after Line Maintenance<br />

4.5.4 Issue of CRS after Defects Rectification – Base – Line. (inc. Mechanic self-certifying,<br />

if applicable)<br />

4.5.5 Duplicate Inspections<br />

Note: A duplicate inspection is required in accordance with the <strong>Civil</strong> <strong>Aviation</strong><br />

Regulations and Personnel Licensing H andbook, after any change or<br />

adjustment to a control system by which the propulsive force or flight<br />

attitude<br />

4.5.6 Issue of Authorised Release Certificate [for aircraft components]<br />

4.5.7 Certification – identity – qualified staff e.g. signature + (lic# or Comp ID or App. #<br />

etc.)<br />

4.5.8 Cross-reference to workpacks<br />

4.5.9 Re-lease of components removed serviceable from aircraft (if permitted) of an aircraft<br />

is changed.<br />

4.5.10 ConditionalRelease [Refer to QA]<br />

Aircraft may be released for test flight purposes in<br />

accordance with the provisions of the JCAR's [and any<br />

foreign country of registry as is applicable]. Systems subject<br />

to the test flight are to be clearly indicated in the release<br />

statement. Certification of satisfactory performance to the<br />

standard for the type is to be entered by the pilot on<br />

completion of the test flight fo lowed by re-certification by<br />

the AMO.<br />

Revision: 12 Page 19<br />

08/09/02August 21, 2002<br />

<strong>FSAW</strong> <strong>0301</strong>

GENERIC AVIATION SERVICES LIMITED<br />

Maintenance Procedures Manual<br />

SECTION 4.6 - RECTIFICATION OF DEFECTS ARISING DURING SCHEDULED<br />

MAINTENANCE<br />

Note : The procedures specified below MUST refer [when applicable] to the requirement<br />

to conform with the approved procedures of customers.<br />

4.6.1 Use of AMO Work Order Number or similar to identify work packages<br />

4.6.2 Recording and sign-off scheduled maintenance defects<br />

4.6.3 Carrying forward defects to future maintenance inputs – (control and accountability)<br />

4.6.4 Analysis of defects and rectification – human factors – maintenance programme<br />

implications – reliability<br />

SECTION 4.7 - Human Factors<br />

4.7.1 Duty Periods [Ref. PLSH Volume 2 Part IV Section 4.0]<br />

AMO to formulate training programmes to educate staff on identifying human factors that can lead<br />

to errors and initating safety nets to prevent accidents or incidents from occurring.<br />

[OTHER AREAS TO BE DEVELOPED….<br />

…. amenities, individualtoolcontrol, experience, coaching etc.???]<br />

NOTE: MORE DEFINITIVE GUIDANCE TO BE PROVIDED AS<br />

TOTALREQUIREMENTS FOR HUMAN FACTORS IS FORMALLY ESTABLISHED<br />

Revision: 12 Page 20<br />

08/09/02August 21, 2002<br />

<strong>FSAW</strong> <strong>0301</strong>

GENERIC AVIATION SERVICES LIMITED<br />

Maintenance Procedures Manual<br />

SECTION 5 - PRODUCTS AND MATERIALS CONTROL<br />

Describe the system that will be used to ensure only parts purchased from approved sources with<br />

proper certification shall be used in the maintenance of aircraft. Include procedures for stores staff<br />

training (identification of unapproved/bogus parts), receiving inspections, traceability, shelf life<br />

control, quarantine stores, repairable item control, issue of parts, tagging, batch control,<br />

unserviceable parts disposition,), petroleum product storage, etc.<br />

Note:<br />

(1) Parts Tags - Green coloured tags will be used for serviceable parts<br />

- Red coloured tags will be used for unserviceable parts<br />

(2) Parts Disposal - Describe a system that will be used to ensure that are<br />

unserviceable, un-repairable and or time-lifed parts are<br />

disposed of to prevent re-installation in a serviceable aircraft.<br />

(i.e.: cut O-rings, drill holes, etc.)<br />

SECTION 5.1 - SUPPLIER EVALUATION PROCEDURE<br />

5.1.1 Company Policy – (sources of supplies)<br />

5.1.2 Approved Suppliers<br />

5.1.3 Monitoring of Supplies<br />

5.1.4 System for placing orders<br />

SECTION 5.2 - ACCEPTANCE/INSPECTION OF AIRCRAFT COMPONENTS AND<br />

MATERIALS [FROM CUSTOMERS, INTERNAL SOURCES OR<br />

CONTRACTED AGENCIES.]<br />

5.2.1 Component/Materialacceptance procedures (sources, conformity with company<br />

requirements, records)<br />

5.2.2 Incoming inspection (required documentation, compliance with order, condition,<br />

and “Quarantine”procedure)<br />

5.2.3 Acceptance of components from internal sources.<br />

5.2.4 Components removed serviceable from aircraft [ i.e. re-certification procedure].<br />

5.2.5 Components received from customers for Repair and/or Overhaul etc.<br />

Revision: 12 Page 21<br />

08/09/02August 21, 2002<br />

<strong>FSAW</strong> <strong>0301</strong>

GENERIC AVIATION SERVICES LIMITED<br />

Maintenance Procedures Manual<br />

SECTION 5.3 - STORAGE, TAGGING AND RELEASE OF AIRCRAFT PARTS<br />

[COMPONENTS AND MATERIAL TO AIRCRAFT/COMPONENT MAINTENANCE]<br />

5.3.1 Procedures for maintaining satisfactory storage conditions (rotables, perishables,<br />

flammable, fluids, engine, bulky assemblies, specialstorage requirements)<br />

5.3.2 System for control of shelf life and modification standard<br />

5.3.3 Tagging/Labelling system (serviceable, unserviceable, robbery, scrap etc.)<br />

5.3.4 Issue of components to the maintenance process. Free-issue dispensing of standard parts<br />

(control, identification, and segregation)<br />

SECTION 5.4 - ACCEPTANCE OF TOOLS AND EQUIPMENT<br />

5.4.1 Process for acceptance –(identification, certification, control, calibration)<br />

5.4.2 Procedure for use of non-manufacturer recommended (i.e. alternative) tools and equipment<br />

SECTION 5.5 - CALIBRATION OF TOOLS AND EQUIPMENT<br />

Generalidentification of the types of tools to be calibrated, time between calibrations and<br />

record keeping system. The company sha lhave a lthe necessary precision tools required<br />

for the performance of maintenance on aircraft. The Accountable Manager sha lensure<br />

that such tools are tested and calibrated as required, at specific intervals to a standard<br />

traceable to the manufacturer, nationalor internationalstandard. He sha lalso maintain<br />

a record of the tests and calibrations.<br />

5.5.1 Inspection, servicing and calibration programme/equipment register<br />

5.5.2 Establishment of inspection, servicing and calibration time periods and frequencies<br />

5.5.3 Identification of servicing/calibration due dates<br />

SECTION 5.6 - USE OF TOOLING AND EQUIPMENT<br />

5.6.1 Issue of tools –(record of user and location)<br />

5.6.2 Determining toolserviceability prior to issue<br />

5.6.3 Training and controlof personnelin the use of tools and equipment<br />

(including records of training)<br />

5.6.4 Personal(own) instrument/toolcontrol[if applicable]<br />

5.6.5 Loan toolcontroland audit<br />

Revision: 12 Page 22<br />

08/09/02August 21, 2002<br />

<strong>FSAW</strong> <strong>0301</strong>

GENERIC AVIATION SERVICES LIMITED<br />

Maintenance Procedures Manual<br />

SECTION 5.7 - RETURN OF DEFECTIVE [AIRCRAFT] COMPONENTS TO STORE<br />

5.7.1 Labe ling and identification (required information)<br />

5.7.2 Handling and movement of components<br />

5.7.3 Storage of defective components<br />

5.7.4 Components “on hold”(Quarantine/UREC pending determination of serviceability<br />

status)<br />

SECTION 5.8 - RETURN OF DEFECTIVE COMPONENTS TO [EXTERNAL]<br />

CONTRACTORS<br />

5.8.1 Dispatch of components for repair/overhaul/calibration<br />

5.8.2 Control of dispatch, location and return<br />

5.8.3 Identification of required work<br />

5.8.4 Return of unserviceable loan parts<br />

SECTION 5.9 – AIRCRAFT PARTS SCRAP PROGRAMME<br />

5.9.1 Policy for determination of parts to be mutilated<br />

5.9.2 Procedure for permanent removalfrom parts inventory [incl. Ext. notification as reqd.]<br />

5.9.3 Mutilation methods/procedure [e.g. AWN 96 etc]<br />

5.9.4 Verification of Mutilation and disposalof mutilated parts<br />

SECTION 5.10 - RETURN OF COMPONENTS TO CUSTOMERS -owners<br />

5.10.1 Return of serviceable parts.<br />

5.10.2 Return of unserviceable parts<br />

Revision: 12 Page 23<br />

08/09/02August 21, 2002<br />

<strong>FSAW</strong> <strong>0301</strong>

GENERIC AVIATION SERVICES LIMITED<br />

Maintenance Procedures Manual<br />

SECTION 6 - QUALITY ASSURANCE<br />

Describe how the company wi l inspect and evaluate its programs and systems on a<br />

continual basis to ensure compliance with the Regulations and procedures are being<br />

maintained. This program wi linclude an annualaudit plan and a copy of the check<br />

sheets that wi lbe used (include copy in Appendix).<br />

SECTION 6.1- POLICY<br />

6.1.1 Company Audit Policy<br />

6.1.2 Definition of the Quality System – independence<br />

6.1.3 Composition and functions of management quality group<br />

6.1.4 Access to Accountable Manager.<br />

SECTION 6.2- AUDITING<br />

6.2.1 Quality Audit Of Organisational Procedures<br />

6.2.1.1 Annual Review of Maintenance Procedures<br />

6.2.1.2 Audit programme Adequate and satisfactory facilities<br />

Compliance with approved procedures<br />

Dates and timescales<br />

6.2.2 Quality Audit Of Aircraft (and/or Equipment)<br />

System description and initiation of corrective action (see 6.3)<br />

6.2.2.1 Audit programme – Auditing of standards<br />

Product samples (aircraft and/or components)<br />

Dates and timescales<br />

6.2.2.2 Auditing methods –Sampling –“Trail”audits<br />

6.2.3 Quality Audit Remedial Action Procedure<br />

6.2.1.1 Quality audit report feedback system<br />

6.2.1.2 Corrective action and timescale – remedial action<br />

disciplinary action<br />

6.2.1.3 Management responsibilities for corrective action and follow-up<br />

Revision: 12 Page 24<br />

08/09/02August 21, 2002<br />

<strong>FSAW</strong> <strong>0301</strong>

SECTION 6.3 - TRAINING<br />

GENERIC AVIATION SERVICES LIMITED<br />

Maintenance Procedures Manual<br />

Describe the training program including the fo lowing:<br />

6.3.1 Qualifying Mechanics/Technicians<br />

6.3.1.1 Experience [duration and technical]<br />

6.3.1.2 Training and competence requirements<br />

6.3.1.3 Assessment procedures –examination and test<br />

6.3.1.4 Continuation/recurrent training –programme and procedures<br />

6.3.1.5 Certification training<br />

6.3.1.6 Delegation of certification authority<br />

6.3.2 Qualifying Inspectors<br />

6.3.2.1 Experience [duration and technical]<br />

6.3.2.2 Training and competence requirements<br />

6.3.2.3 Assessment procedures –examination and test<br />

6.3.2.4 Continuation/recurrent training –programme and procedures<br />

6.3.2.5 CMR certification<br />

6.3.3 Training for other areas as applicable<br />

e.g. Engineering, Planning, Stores, Washing/Cleaning,<br />

6.3.4 Orientation for new employees<br />

6.3.4.1 Legalframework of aviation<br />

6.3.4.2 Accountability & Responsibilities<br />

6.3.4.3 Safety<br />

6.3.5 Qualification Procedure for Specialised Activities<br />

e.g. NDT, Welding, Ground Run, Taxi, Towing, Use of specialised Support equipment etc.<br />

6.3.5.1 Experience, training and examination<br />

6.3.5.2 Continuation/recurrent training and testing<br />

6.3.5.3 Auditing of staff and system<br />

6.3.5.4 Procedure for amendment of Capability Listing<br />

Revision: 12 Page 25<br />

08/09/02August 21, 2002<br />

<strong>FSAW</strong> <strong>0301</strong>

GENERIC AVIATION SERVICES LIMITED<br />

Maintenance Procedures Manual<br />

SECTION 6.4 –RECORDS OF CERTIFYING STAFF<br />

6.4.1 Maintaining records of certifying personnel<br />

6.4.2 Minimum information of staff particulars<br />

6.4.3 Control of certifying staff records<br />

6.4.4 Access to staff records – authorised persons [CAA/FAA personnel, authorised manager etc]<br />

6.4.4 Retention of records<br />

SECTION 6.5 - EXTENSION OF QUALITY SYSTEM<br />

6.5.1 Extension Of Quality System to Manufacturer’s Working Teams<br />

6.5.1.1 Source of work – authorisation of personnel<br />

6.5.1.2 System for control of materials, working instructions and procedures<br />

6.5.1.3 Control of documentation – drawings – modification – repair instructions<br />

6.5.1.4 Certification – repair – replacement – modification – overhaul – inspection<br />

6.5.1.5 Environmental conditions<br />

6.5.1.6 Final certification by the company<br />

6.5.2 Extension of Quality System to Subcontractors<br />

6.5.2.1 Assessing the competence of the subcontractor<br />

6.5.2.2 Documentation and procedures<br />

6.5.2.3 Quality monitoring - expertise<br />

records of monitoring<br />

feedback and remedial action<br />

6.5.2.4 Certification of subcontractor’s work<br />

Revision: 12 Page 26<br />

08/09/02August 21, 2002<br />

<strong>FSAW</strong> <strong>0301</strong>

GENERIC AVIATION SERVICES LIMITED<br />

Maintenance Procedures Manual<br />

SECTION 6.6 –DEVIATION FROM PROCEDURES<br />

6.6.1 Procedure for Seeking Exemptions From The JCAA<br />

6.6.1.1 Persons authorised to request exemptions/concessions<br />

6.6.1.2 Minimum notification interval to be applied to exemption/concession requests<br />

6.6.1.3 Request Procedure<br />

6.6.1.4 System for control and processing with CAA<br />

6.6.2 Concession ControlFor Deviation From The Organisation’s Procedures<br />

6.6.2.1 System for approval and control of concession<br />

6.6.2.2 Concession criteria<br />

6.6.2.3 Request procedure<br />

6.6.2.4 Evaluation; response and approval<br />

SECTION 6.7 –REPORTING TO THE JCAA/OPERATOR/MANUFACTURER<br />

6.7.1 Reports To The JCAA<br />

6.7.1.1 Reports to be supplied to the JCAA [including Mandatory Occurrence Reports as<br />

required by the <strong>Civil</strong><strong>Aviation</strong> Regulations on JCAA Form #AW12.]<br />

6.7.1.2 Persons responsible for Reporting<br />

6.7.1.3 Permitted Reporting Periods and Retention of Data<br />

6.7.1.4 Reportable Defects Investigation procedure and follow-up system<br />

6.7.2 Reports To Operators or Manufacturers<br />

6.7.2.1 Items to be reported<br />

6.7.2.2 Persons responsible for Reporting<br />

6.7.2.3 Permitted Reporting Periods and Retention of Data<br />

Revision: 12 Page 27<br />

08/09/02August 21, 2002<br />

<strong>FSAW</strong> <strong>0301</strong>

GENERIC AVIATION SERVICES LIMITED<br />

Maintenance Procedures Manual<br />

SECTION 7 –TECH NICAL RECORDS CONTROL AND<br />

STORAGE<br />

SECTION 7.1 - PRIMARY MAINTENANCE RECORDS<br />

7.1.1 System for control, storage, and retrieval(paper or computer based)<br />

7.1.2 Controlof access to records –(paper and/or computer based records)<br />

7.1.3 Record-keeping systems –(essentialrecords)<br />

7.1.4 Turbine engines –module records<br />

7.1.5 Disposalof records –transfer of aircraft<br />

7.1.6 Lost or destroyed records (reconstruction and JCAA acceptance)<br />

7.1.7 Provision of records (CRS) to operator<br />

7.1.8 Responsibility of AMO to retain records of work accomplished on contracted<br />

operators.<br />

7.1.9 Retention of records (periods –methods and security)<br />

SECTION 7.2 - COMPUTER BASED MAINTENANCE RECORDING SYSTEM<br />

[AS APPLICABLE]<br />

7.2.1 Information retrieval<br />

7.2.2 Back-up systems and second site storage<br />

7.2.3 Security and safeguards to unauthorised access<br />

SECTION 7.3 - THIRD PARTY RECORDS MAINTENANCE<br />

7.3.1 Contracted record keeping – specific operators<br />

7.3.2 Keeping the Operator’s technical records<br />

7.3.3 Retention of records on behalf of operators<br />

Revision: 12 Page 28<br />

08/09/02August 21, 2002<br />

<strong>FSAW</strong> <strong>0301</strong>

GENERIC AVIATION SERVICES LIMITED<br />

Maintenance Procedures Manual<br />

SECTION 8 - MAINTENANCE AGREEMENTS<br />

Maintenance agreements with other Approved Maintenance Organisations within <strong>Jamaica</strong> may be<br />

entered into for the purpose of providing additional maintenance services. Copies of such<br />

agreements sha lbe provided to the JCAA for their records. Use of foreign repair stations or<br />

maintenance facilities wi lrequire prior approvalfrom the JCAA.<br />

Revision: 12 Page 29<br />

08/09/02August 21, 2002<br />

<strong>FSAW</strong> <strong>0301</strong>

GENERIC AVIATION SERVICES LIMITED<br />

Maintenance Procedures Manual<br />

AMENDMENT CONTROL SHEET<br />

Form # ________<br />

Appendix A<br />

Company Forms<br />

REMOVE PAGES ANNOTATED<br />

INSERT PAGES ANNOTATED<br />

Prepared by: ____________________ Accepted by (JCAA): _______________________<br />

Amendment inserted by: _________________________<br />

**(submit per MCM section 1.2)**<br />

Date______________________<br />

Revision: 12 Page 30<br />

08/09/02August 21, 2002<br />

<strong>FSAW</strong> <strong>0301</strong>

GENERIC AVIATION SERVICES LIMITED<br />

Maintenance Procedures Manual<br />

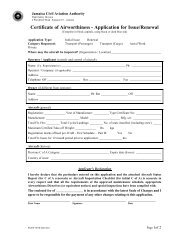

APPENDIX “A”<br />

CERTIFICATE OF RELEASE TO SERVICE<br />

I hereby certify that the work recorded above has been carried out in accordance with the<br />

requirements of the <strong>Civil</strong><strong>Aviation</strong> Regulations currently in force and that this aircraft is<br />

therefore considered fit for return to service.<br />

Signature:___________________Lic./App.Nbr._______________Date_______________<br />

Figure 1<br />

CERTIFICATE OF MAINTENANCE REVIEW<br />

I hereby certify that a Maintenance Review of this aircraft and its records has been completed<br />

in accordance with the requirements of the <strong>Civil</strong> <strong>Aviation</strong> Regulations currently in force and<br />

the aircraft is considered fit to continue in service. The next review shall be accomplished no<br />

later than:________________<br />

Operator________________________Aircraft Registration_______________________<br />

Signature_______________________Lic./App.No._________________Date________<br />

Figure 2<br />

DUPLICATE INSPECTION<br />

We hereby certify that the control system identified below has been inspected for condition,<br />

correct installation, security and functioning in accordance with the <strong>Civil</strong> <strong>Aviation</strong> Regulations<br />

currently in force and found to be serviceable. In that respect, the aircraft is considered fit for<br />

release to service.<br />

System_________________Defect/Work No.__________Date:_________Stn:_______<br />

Signature(#1)________________________Lic./App.No:_____________Time:_______<br />

Signature(#2)________________________Lic./App. No:_____________Time:_______<br />

Figure 3<br />

Revision: 12 Page 31<br />

08/09/02August 21, 2002<br />

<strong>FSAW</strong> <strong>0301</strong>

GENERIC AVIATION SERVICES LIMITED<br />

Maintenance Procedures Manual<br />

APPENDIX B<br />

Contract Agreements with External Parties Including Other Approved Maintenance<br />

Organisations<br />

Revision: 12 Page 32<br />

08/09/02August 21, 2002<br />

<strong>FSAW</strong> <strong>0301</strong>

GENERIC AVIATION SERVICES LIMITED<br />

Maintenance Procedures Manual<br />

APPENDIX C<br />

AMO Capability ListingApprovalSchedule<br />

(Tasks for which AMO is authorised to accomplish----Copy of AMO ApprovalSchedule to be inserted.)<br />

Revision: 12 Page 33<br />

08/09/02August 21, 2002<br />

<strong>FSAW</strong> <strong>0301</strong>

GENERIC AVIATION SERVICES LIMITED<br />

Maintenance Procedures Manual<br />

ADDITIONAL TOPICS FOR MCM<br />

LINE MAINTENANCE CONTROL OF AIRCRAFT COMPONENTS, TOOLS,<br />

EQUIPMENT, ETC.<br />

Component/Materialacceptance –(required documentation, condition, “Quarantine”procedure)<br />

Components removed serviceable from aircraft<br />

Procedures for maintaining satisfactory storage conditions – (rotables, perishables, flammable fluids,<br />

engines, bulky assemblies, special storage requirements)<br />

System for control of shelf life and modification standard<br />

Tagging/Labelling system (serviceable, robbery, scrap etc)<br />

Issue of components to the maintenance process<br />

Free-issue dispensing of standards parts (control, identification, and segregation)<br />

Tools and Test Equipment, servicing and calibration programme/equipment register<br />

Identification of servicing/calibration due dates<br />

LINE MAINTENANCE PROCEDURES RELATED TO SERVICING/FUELLING/DE-<br />

ICING etc.<br />

Maintenance documentation –(controland amendment)<br />

Airworthiness data – (control and amendment)<br />

Fuel supply quality monitoring – bulk storage<br />

aircraft re-fuelling<br />

Ground de-icing - procedures<br />

monitoring of sub-contractors<br />

Maintenance carried out in the open –(limitations)<br />

Maintenance of ground support equipment<br />

Monitoring of sub-contracted ground handling and servicing<br />

Care and maintenance of ULD and cargo loading systems/retention equipment<br />

LINE MAINTENANCE CONTROL OF DEFECTS AND REPETITIVE DEFECTS<br />

Worksheets for non-routine tasks<br />

Reportable defects – PIPERS – Engineering entries – Cabin<br />

Deferred defect classification system<br />

Rules for deferring (periods – review – permitted personnel – conformity with MEL provisions)<br />

Certification of defects rectification – Transfer of defects to worksheets/cards<br />

Awareness of deferred defects carried by aircraft – monitoring of repetitive defects<br />

Revision: 12 Page 34<br />

08/09/02August 21, 2002<br />

<strong>FSAW</strong> <strong>0301</strong>

GENERIC AVIATION SERVICES LIMITED<br />

Maintenance Procedures Manual<br />

Communication with main base<br />

LINE PROCEDURE FOR COMPLETION OF TECHNICAL LOG<br />

Explanation of TechnicalLog system –completion of Sector Record Page –Distribution of copies<br />

Certification/Sign-off – Maintenance, Pre-flight/Transit, ETOPS – Duplicate Inspections<br />

Maintenance control systems – Special Inspection, Out-of-Phase maintenance<br />

Retention of records<br />

Maintenance Statements<br />

LINE PROCEDURE FOR POOLED PARTS AND LOAN PARTS<br />

Verification of approved sources of parts –Modification Standard and AD compliance<br />

Compliance with loan and contract requirements – Tracking and control<br />

Required documentation<br />

Processing removed loan parts for return to source – service record<br />

Robbery system – control procedures, authority<br />

LINE PROCEDURE FOR RETURN OF DEFECTIVE PARTS REMOVED FROM<br />

AIRCRAFT<br />

Required documentation – service record<br />

Processing advice of removal and dispatch to Technical Records<br />

Dispatch to rectification<br />

CONTRACT AGREEMENTS WITH APPROVED MAINTENANCE ORGANISATIONS<br />

Revision: 12 Page 35<br />

08/09/02August 21, 2002<br />

<strong>FSAW</strong> <strong>0301</strong>