ARV2000 - New Hydraulics - FFG Flensburg

ARV2000 - New Hydraulics - FFG Flensburg

ARV2000 - New Hydraulics - FFG Flensburg

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

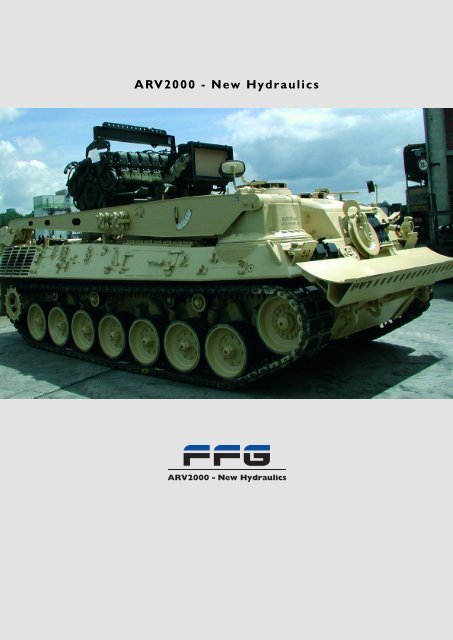

<strong>ARV2000</strong> - <strong>New</strong> <strong>Hydraulics</strong><br />

<strong>ARV2000</strong> - <strong>New</strong> <strong>Hydraulics</strong>

Optimised high-tech system<br />

The Armoured Recovery Vehicle (Leopard 1) has<br />

proved itself on numerous missions. But even with the<br />

best there is room for improvement! The engineers at<br />

<strong>Flensburg</strong>er Fahrzeugbau Gesellschaft (<strong>FFG</strong>) know the<br />

potential, but also the problems, of this tank. After all,<br />

<strong>FFG</strong> is one of the few companies to have been repairing<br />

these vehicles for many years.<br />

<strong>FFG</strong> rated the safety of the crane system and its operation<br />

as no longer up to date and has therefore developed<br />

a new hydraulic concept.This high-tech hydraulic<br />

system offers several advantages at a stroke. It will work<br />

absolutely perfectly and reliably in even the toughest<br />

conditions, so it satisfies stringent military standards in<br />

every particular. <strong>FFG</strong> uses industrial components that<br />

have proved themselves thousands upon thousands of<br />

Deployment<br />

20 <strong>ARV2000</strong> recovery tanks, Belgium<br />

6 AEV2000 engineer tanks, Belgium<br />

7 <strong>ARV2000</strong> recovery tanks, Chile<br />

times. Every single part has been tested in the field. And<br />

the system’s simple operation has been adapted to the<br />

operating structure of the “Buffelo” recovery tank.<br />

In early 2001 <strong>FFG</strong> made the <strong>ARV2000</strong> recovery tank<br />

with the new hydraulic system available to the<br />

Bundeswehr Technical Centre for Engineer and General<br />

Field Equipment (WTD 51) in Koblenz, where it was<br />

thoroughly tested, trialled and evaluated over an<br />

extended period.The vehicle passed all the necessary<br />

tests, including cross-country, EMC, vibration, climate,<br />

cold and endurance, without exception.<br />

Once more the optimised hydraulics of the <strong>ARV2000</strong><br />

recovery tank reflect the innovation and long experience<br />

of <strong>FFG</strong>.

The new hydraulic concept<br />

<strong>ARV2000</strong> with new <strong>FFG</strong> hydraulics<br />

Operator panel with 2 joysticks Winch<br />

and optional load indicators<br />

Control box for error Hydraulic motor<br />

read-out, system check<br />

and parameter adjustment<br />

on microcontroller<br />

Swivel driving<br />

mechanism<br />

Hydraulic motor<br />

Optimum operation<br />

of recovery equipment<br />

from outside<br />

High-pressure<br />

mobile control block<br />

Cable tensioner<br />

The main components<br />

Crane system cylinder<br />

Emergency hydraulics<br />

All components of the existing hydraulic system have<br />

been replaced apart from the hydraulic cylinders.The<br />

vane-cell motors have been replaced with state-of-theart<br />

inclined-axis motors. <strong>New</strong> variable displacement<br />

pumps ensure the necessary pressure. A load-sensing<br />

control block that is widely used in mobile hydraulics<br />

● Microcontroller with high computing capacity<br />

thanks to 16-bit processors<br />

● Error detection at inputs and outputs for safety<br />

monitoring<br />

● CAN bus interfaces<br />

● Sturdy, sealed, aluminium housing<br />

● Variable displacement pumps<br />

● Axial-piston inclined-axis motors<br />

● Safety concept<br />

● “Genuine” emergency stop, non-positive<br />

isolation of pumps and diesel engine<br />

● Constant monitoring by intelligent software<br />

● Overload shutdown with state-of-the-art sensor<br />

technology<br />

● Error log<br />

● Stainless steel hydraulic oil tank with oil filter, 24 V<br />

auxiliary hydraulic pump, oil monitoring<br />

Main winch<br />

Dozer blade cylinder<br />

Central switchgear assembly<br />

Hydraulic oil tank<br />

Hydraulic motor<br />

Hydraulic circuit for<br />

• Main winch gear<br />

• Pump drive<br />

Tail support cylinder<br />

Variable displacement<br />

pump for open circuit<br />

Pump drive<br />

Variable displacement pump unit<br />

Tail support cylinder controller<br />

green= existing hydraulics<br />

blue = new <strong>FFG</strong> hydraulics<br />

supplies the hydraulic cylinders with oil.The winch drives<br />

and the swivel drive for the crane arm operate in “closed”<br />

hydraulic circuits.This means that the hydraulic system<br />

can get by with fewer components.This development<br />

also offers the enormous advantage of highly sensitive,<br />

load-independent manoeuvrability.<br />

● Auxiliary winch (180 m, pull 15 kN, equivalent to<br />

1500 kg)<br />

Further options are available, depending on the user’s<br />

requirements.

Operation<br />

● Operator panel<br />

with 2 joysticks<br />

● 3D operation<br />

of crane system<br />

● Emergency stop<br />

● Indicators<br />

Logistics<br />

We offer our customers a broad spectrum of logistical<br />

services:<br />

● Development<br />

● Engineering<br />

● Manufacture<br />

● Repair<br />

● Technical documentation<br />

Every customer is different. Every customer has particular<br />

requirements.That is why we produce an individual<br />

service package in close consultation with our<br />

Display and<br />

operator unit<br />

● Text display<br />

● Clearing<br />

● Salvaging<br />

● Craning<br />

● Emergency stop<br />

● Hours-run meter<br />

● Mode selector switch<br />

● Lamp test<br />

● Training<br />

● Logistical all-round service<br />

● Fleet management<br />

● On-site service<br />

<strong>ARV2000</strong> - <strong>New</strong> <strong>Hydraulics</strong><br />

customers. In this way we ensure that all our customers<br />

receive the right service to suit their own specific<br />

requirements.<br />

<strong>Flensburg</strong>er Fahrzeugbau Gesellschaft mbH · Werftstraße 24 · 24939 <strong>Flensburg</strong> · Germany<br />

Tel. +49 (4 61) 48 12-0 · Fax +49 (4 61) 48 12-100 · www.ffg-flensburg.de · info@ffg-flensburg.de