Single package roof-top heat pump unit for high effluence Range 45 ...

Single package roof-top heat pump unit for high effluence Range 45 ...

Single package roof-top heat pump unit for high effluence Range 45 ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

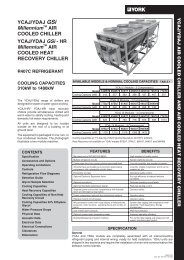

<strong>Single</strong> <strong>package</strong> <strong>roof</strong>-<strong>top</strong> <strong>heat</strong> <strong>pump</strong> <strong>unit</strong> <strong>for</strong> <strong>high</strong> <strong>effluence</strong><br />

<strong>Range</strong> <strong>45</strong>-246 kW<br />

• SCROLL compressors<br />

• Sandwich panel structure<br />

• Air section: air quality CO 2 probe<br />

• Air section: static recuperator<br />

• RS 485 connectivity<br />

• User friendly<br />

• R410A refrigerant

N∞1-GR<br />

8 0x8 0<br />

3 0 mc/h<br />

N∞1-GR<br />

8 0x8 0<br />

3 0 mc/h<br />

N∞2- DM<br />

DN 4 0<br />

1 0 mc/h<br />

N∞4- DM<br />

DN 4 0<br />

1 0 mc/h<br />

1200 mc/h<br />

SPLIT<br />

2,5KW<br />

400 mc/h<br />

3x2,5KW<br />

21 0 mc/h<br />

AR1<br />

SPLIT<br />

2,5KW<br />

400 mc/h<br />

HALL-MX:<br />

OUTSTANDING AIR QUALITY. ALWAYS.<br />

In multi-screen cinemas, where the various rooms can be<br />

crowded to a lesser or greater extent, air quality is a fundamental<br />

requirement of spectators.<br />

This quality greatly depends on the capacity of the airconditioning<br />

system to optimise temperature and humidity levels<br />

whilst ensuring silent running.<br />

With this in mind, Climaveneta has developed a simple<br />

and reliable system <strong>for</strong> delivering constantly clean and healthy<br />

air at optimal levels of energy efficiency. Thanks to a built-in <strong>heat</strong><br />

recovery system, the new HALL-MX independent conditioning<br />

<strong>unit</strong>s ensure low installation and running costs whilst providing<br />

the required environmental conditions.<br />

Designed <strong>for</strong> cinemas, shopping centres, restaurants, conference<br />

halls, open-space offices, gyms, sports centres and discos,<br />

the new Climaveneta HALL-MX range, featuring special attention<br />

to design and accurate selection of materials, provides constantly<br />

clean and healthy air whilst offering energy savings of up to 20%<br />

compared with other systems.<br />

Sala 1<br />

Sala 2 Sala 3 Sala 4 Sala 5<br />

TORRINO T2<br />

MOTOCONDENSANTE<br />

CASSE SX<br />

TORRINO ESTR.<br />

CASSE SX<br />

TRIAL SPLIT<br />

Sala 6 Sala 7 Sala 8 Sala 9 Sala 10 Sala 11<br />

MOTOCONDENSANTE<br />

CASSE DX<br />

TORRINO ESTR.<br />

CASSE DX<br />

FWS<br />

SUPERVISION<br />

SYSTEM.<br />

The FWS supervision<br />

system allows the system<br />

to be monitored without<br />

having to install any<br />

additional software onto the<br />

dedicated supervision PC's<br />

as standard applications<br />

(Internet Explorer,<br />

Netscape,...) that are<br />

normally already installed<br />

on PC's are used.<br />

Tremestieri Shopping Centre and Multi-screen Cinema<br />

(Messina).<br />

Above: plan of the 11 cinemas on the 2 nd floor of the building.<br />

The cinemas are incorporated in a shopping centre containing<br />

approximately 50 shops.<br />

Right: cross-section of two of the 11 cinemas.<br />

2

MAIN ADVANTAGES.<br />

Structure<br />

The structure comprises a base made from<br />

hot-galvanised, epoxy powder-painted sheet steel<br />

profiles.<br />

The frame and outer panelling are made<br />

from aluminium alloy which offers total protection<br />

from atmospheric agents.<br />

The panels are easy to remove and allow easy<br />

access to internal components.<br />

The area in contact with the treated air is made<br />

from double-wall (42 mm) sandwich panelling in<br />

galvanised sheet metal <strong>for</strong> the delivery fans and<br />

expansion coil, in galvanised sheet metal (internal)<br />

and aluminium (external) <strong>for</strong> the other components,<br />

separated by an insulation layer of hot-injected<br />

polyurethane with an average density of <strong>45</strong> kg/m 3 .<br />

Cross-section of Sandwich panel<br />

Outstanding air quality.<br />

The incoming air filter sections (EU4),<br />

the banks of bag filters (up to EU7) and the CO 2<br />

probe provide excellent treated air quality even<br />

<strong>for</strong> <strong>high</strong>ly crowded areas containing <strong>high</strong> levels<br />

of contaminants.<br />

CO 2 probe<br />

All the surfaces in contact with the treated<br />

air are made from perfectly cleanable metal,<br />

hence guaranteeing hygiene, internal air quality<br />

(IAQ) and compliance with Legislative Decree<br />

626/94 regulating occupational health and safety.<br />

Static <strong>heat</strong> recovery<br />

<strong>unit</strong><br />

Energy saving.<br />

As the system is required to condition <strong>high</strong> flows<br />

of external air, the presence of an air/air plate-type<br />

static <strong>heat</strong> recovery <strong>unit</strong> effectively reduces running<br />

costs as well as complying with DPR (Decree of the<br />

President of the Republic) n° 412: “Design rules <strong>for</strong><br />

the purposes of energy saving”.<br />

The greater the temperature difference between<br />

the external air and ambient return air flows which<br />

are combined inside the <strong>heat</strong> recovery <strong>unit</strong>,<br />

the more thermal energy can be recovered.<br />

Peak efficiency levels lie at around 75%.<br />

The ambient return air and the external air flows<br />

are hermetically separated and cannot mix, hence<br />

totally guaranteeing the quality of the treated air.<br />

3

Minimum space, minimum impact.<br />

Its particular aesthetic and structural compactness<br />

makes it possible to install HALL-MX anywhere<br />

with a minimum of environmental impact.<br />

Easy maintenance.<br />

Large access panels make maintenance particularly<br />

simple, while ad hoc construction solutions make it<br />

easy to access and remove components requiring<br />

periodic cleaning.<br />

Easy installation.<br />

After positioning the <strong>unit</strong>, it is now ready<br />

to be connected to the ducts. During this operation,<br />

the electrical connections can also be completed,<br />

thereby allowing assembly to be per<strong>for</strong>med rapidly<br />

along with ventilation testing and calibration<br />

of the air circuit.<br />

Wide range of accessories:<br />

• additional <strong>heat</strong>ing<br />

- hot water coil<br />

- <strong>heat</strong>ing element,<br />

• humidification<br />

- immersed electrode humidifier,<br />

• dirty filter detector,<br />

• gas <strong>heat</strong>ing <strong>unit</strong>.<br />

• enthalpic free cooling.<br />

Free-energy.<br />

In normal air-conditioning <strong>unit</strong>s, the rooms are cooled<br />

or <strong>heat</strong>ed by a cooling circuit which uses electricity<br />

to power the relative compressors and fans.<br />

In spring and autumn, in winter with crowded rooms<br />

or in summer during the coolest hours<br />

of the day, the external air may very well have<br />

the same temperature and humidity conditions<br />

as those required <strong>for</strong> the rooms.<br />

If these external conditions are suitably used, they<br />

can respect internal rated conditions by simply<br />

keeping the fans working. S<strong>top</strong>ping the cooling<br />

compressors makes drastic reductions in power<br />

consumption and there<strong>for</strong>e saves a large amount<br />

of money.<br />

In particular, if the external air is fresher than the<br />

internal air, the room can be cooled by directly<br />

delivering the suitably filtered external air without<br />

having to use the cooling section (Free- Cooling).<br />

Similarly, the rooms can be <strong>heat</strong>ed when external air<br />

conditions allow (Free- Heating).<br />

In both cases, the modes are automatically activated<br />

by the electronic control <strong>unit</strong> on board the <strong>unit</strong> which<br />

is programmed to keep the system as efficient as<br />

possible and minimise running costs.<br />

4

Ease of selection and choice<br />

of the most suitable <strong>unit</strong>.<br />

Units sized and tested to ensure<br />

optimal com<strong>for</strong>t, air quality,<br />

temperature, humidity and silent<br />

running <strong>for</strong> multi-screen cinemas<br />

depending on the number<br />

of seats and an external airflow<br />

of 8 l/s per person.<br />

ENERGY COEFFICIENTS<br />

PRELIMINARY DATA<br />

HALL-MX 120 150 180 200 230 280 340 380 400 440 480 520<br />

Cooling mode<br />

Cooling Power + Recovery kW <strong>45</strong>,1 54,6 67,3 75,5 89,1 110,9 128,0 152,5 169,6 201,5 219,3 246,6<br />

E.E.R. Total 3,5 2,9 3,1 3,1 3,6 3,2 3,2 3,1 2,7 3,1 3,0 2,8<br />

Heating mode<br />

Heating Capacity + Recovery kW 48,6 62,8 67,1 76,5 88,7 109,7 131,4 150,9 167,9 203,5 222,1 2<strong>45</strong>,0<br />

C.O.P. Total 5,0 4,6 4,4 4,4 5,0 4,5 4,7 4,1 3,5 4,2 4,0 3,7<br />

Cooling mode parameters: External 34°C 55% H.R. Internal 26°C 55% H.R.<br />

Heating mode parameters: External -5°C 85% H.R. Internal 20°C 40% H.R.<br />

Calculating energy coefficients:<br />

Cooling mode<br />

Heating mode<br />

E.E.R.<br />

=<br />

Total<br />

Cooling Capacity + Recovery<br />

Power Input<br />

(Compressors + Condensing sect. fans<br />

+ delivery and return fans)<br />

C.O.P. =<br />

Total<br />

Heating Capacity + Recovery<br />

Power Input<br />

(Compressors + Condensing sect. fans<br />

+ delivery and return fans)<br />

5

FWS supervision system.<br />

RS-485<br />

RS-485<br />

FWS<br />

by Climaveneta<br />

Configuration 1 Configuration 2<br />

LAN<br />

PC<br />

Conditioning<br />

Supervision System<br />

by Climaveneta<br />

HUB<br />

ROUTER<br />

Fixed Modem or GSM<br />

WWW<br />

PC on LAN<br />

Conditioning Supervision<br />

System by Climaveneta<br />

WWW<br />

SPARE PARTS SERVICE. (Climaveneta Service)<br />

Though an unoriginal spare part may seem<br />

an advantageous solution in the short-term,<br />

it can cause premature faults or damage to<br />

other vital components.<br />

Climaveneta Service offers:<br />

- elevated availability of spare parts,<br />

- competitive prices <strong>for</strong> <strong>top</strong> quality spares,<br />

- each component is guaranteed<br />

by its manufacturer,<br />

- one supplier <strong>for</strong> all spare parts,<br />

- original spare parts = safety,<br />

- 24h delivery.<br />

Climaveneta Service<br />

controls the price of each<br />

component in order to offer<br />

<strong>high</strong>ly competitive prices<br />

<strong>for</strong> the thousands of spare<br />

parts that it always keeps<br />

in stock. Check these prices<br />

against the <strong>high</strong> quality of our<br />

spares.<br />

6

FWS SUPERVISION. (optional)<br />

The FWS supervision system allows the system<br />

to be monitored without having to install any<br />

additional software onto the dedicated supervision<br />

PC's as standard applications (Internet Explorer,<br />

Netscape,...) that are normally already installed<br />

on PC's are used.<br />

The FWS module is generally installed near the<br />

PC.The <strong>unit</strong>s communicate with the module along<br />

an RS 485 local network <strong>for</strong> a maximum distance<br />

of 1,000 metres, while the module and the PC<br />

either communicate directly or along an Ethernet<br />

network (LAN).<br />

The supervision PC shows the following in<strong>for</strong>mation<br />

<strong>for</strong> each <strong>unit</strong>:<br />

- <strong>unit</strong> status and alarms<br />

- main temperature settings<br />

- set-points and operating mode<br />

- compressor status and operating hours<br />

The following can be set and modified:<br />

- operating mode<br />

- room washing override<br />

-rapid start-up up override<br />

- weekly/daily programming with five time bands.<br />

If the supervisor is disabled, each <strong>unit</strong> can work<br />

normally using the on-board thermoregulation<br />

device.<br />

Access to the supervision programme is reserved to<br />

users with Login and Password.<br />

A customided access profile may also be defined <strong>for</strong><br />

each user to allow them to operate in pre-selected<br />

and well-defined areas.<br />

The user interface has been organised like<br />

a website with dynamic pages that can be accessed<br />

through links. The in<strong>for</strong>mation on each page<br />

is organised in the <strong>for</strong>m of a table.<br />

On request, the pages can be customised with<br />

photos, diagrams and descriptive texts, or links<br />

to screens showing details of the <strong>unit</strong>s.<br />

If the FWS <strong>unit</strong> is connected to the Internet,<br />

the supervision software can be updated<br />

or modified from a remote PC.<br />

For equipment not supplied by Climaveneta (e.g.<br />

exhaust fans, split,...), the FWS supervision system<br />

allows commands to be made through volt-free<br />

contacts and temperatures to be read through NTC<br />

probes.<br />

It is also possible to configure FWS to report any<br />

alarms directly to “Climaveneta Service” by e-mail<br />

and/or SMS.<br />

Connectivity:<br />

Communication protocols: BacNet, Echelon,<br />

ModBus, Climaveneta. Through: Fixed modem,<br />

GSM or RS 485 serial.<br />

Spare parts supplied by Climaveneta Service<br />

Electrical circuit components<br />

Microprocessor-controlled systems<br />

Temperature and pressure probes<br />

Bag filters<br />

Cooling circuit components<br />

Heat exchangers<br />

Compressors<br />

7

OPERATING METHOD.<br />

Standard operation.<br />

It may be necessary to cool or <strong>heat</strong> a room according<br />

to temperatures and crowding levels. Depending on<br />

requirements, the <strong>unit</strong> will automatically operate in<br />

the cooling, dehumidification or <strong>heat</strong> <strong>pump</strong> mode.<br />

Considering that using external air alone<br />

is extremely expensive, a varying blend of external<br />

air and ambient return air is used.<br />

To guarantee the quality of the air in the room, some<br />

of the inlet air is constantly discharged externally.<br />

Flow is adjusted according to the level of crowding<br />

and, consequently, the number of people in the<br />

room. This value is measured by a CO 2 probe and<br />

processed by the control <strong>unit</strong>.<br />

The external air used in the blend is pre-<strong>heat</strong>ed or<br />

pre-cooled using a static <strong>heat</strong> recovery <strong>unit</strong> which<br />

makes it possible to significantly reduce energy costs<br />

connected with the treatment of external air.<br />

The recovery <strong>unit</strong> transfers <strong>heat</strong> between the<br />

ambient return air and the external air without it<br />

being possible <strong>for</strong> the two floes to contaminate one<br />

another and totally free of charge as no power is<br />

required. The external air leaving the <strong>heat</strong> recovery<br />

<strong>unit</strong> and the ambient return air make up the flow<br />

that will be sent to the room after final treatment is<br />

per<strong>for</strong>med by the cooling circuit treatment bank.<br />

For special requirements, it may be necessary to<br />

adjust the humidity level in the room separately from<br />

the temperature.<br />

To satisfy these needs, the dehumidified and<br />

there<strong>for</strong>e thoroughly cooled air goes through a post<strong>heat</strong>ing<br />

coil where part of the condensation gas from<br />

the refrigerating system circulates, and then it is<br />

released into the room. As a result, the dehumidified<br />

air is <strong>heat</strong>ed free of charge, thus providing an<br />

elevated level of com<strong>for</strong>t at low power costs.<br />

The static <strong>heat</strong> recovery <strong>unit</strong> is an extremely safe<br />

and reliable <strong>heat</strong> exchanger with no moving parts.<br />

Standard <strong>heat</strong>ing mode<br />

Plan<br />

exhausted air<br />

static <strong>heat</strong> recovery <strong>unit</strong><br />

working<br />

external air<br />

ambient<br />

return air<br />

Section<br />

ambient<br />

return air<br />

ambient return air<br />

8

The <strong>unit</strong> can be fitted with a direct steam humidifier<br />

in order to maintain constant control of the internal<br />

humidity conditions also during winter.<br />

The quantity of vapour is constantly adjusted<br />

according to the real requirements of the system.<br />

Start-up. Used ambient air only.<br />

This <strong>heat</strong>s the room rapidly by circulating<br />

the same air. This function is used after the room<br />

washing function when the room is empty and offers<br />

considerable energy saving.<br />

Room washing.<br />

This rapidly refreshes the ambient air.<br />

External air is introduced into the room<br />

<strong>for</strong> a pre-set time while the used ambient<br />

air is totally expelled.<br />

<strong>heat</strong> recovery <strong>unit</strong><br />

external air<br />

cooling circuit<br />

in <strong>heat</strong> <strong>pump</strong><br />

ambient return<br />

air<br />

mixture<br />

exhausted air<br />

Standard cooling mode<br />

ambient return air<br />

Plan<br />

exhausted air<br />

static <strong>heat</strong><br />

recovery <strong>unit</strong> working<br />

external air<br />

ambient<br />

return air<br />

Section<br />

ambient<br />

return air<br />

ambient return air<br />

9

PRELIMINARY DATA<br />

HALL-MX 120 150 180 200 230 280<br />

Cooling (1)<br />

Cooling Capacity + Recovery kW <strong>45</strong>,1 54,6 67,3 75,5 89,1 110,9<br />

Sensible Cooling Capacity + Recovery kW 32,4 38,1 46,5 54,7 63,2 78,1<br />

Heat Recovery Capacity kW 8,0 9,0 10,5 12,8 14,8 16,4<br />

Compressors Total Power Input kW 8,3 12,7 14,0 14,7 17,3 23,1<br />

Total Power Input kW 12,8 18,3 21,2 23,6 24,4 33,8<br />

Heating Mode (2)<br />

Heating Capacity + Recovery kW 48,6 62,8 67,1 76,5 88,7 109,7<br />

Heat Recovery Capacity kW 25,0 30,0 32,0 38,0 41,0 49,0<br />

Compressors Power Input kW 5,1 7,9 8,0 8,3 10,6 13,3<br />

Total Power Input kW 9,6 13,5 15,1 17,2 17,7 24,0<br />

Treatment area (Delivery)<br />

Type<br />

Centrifugal<br />

Number of fans n° 1 1 1 1 2 2<br />

Delivery air flow m 3 /h 6.500 7.800 8.600 10.500 13.000 15.500<br />

Treated external air flow m 3 /h 4.875 5.850 6.<strong>45</strong>0 7.875 9.750 11.625<br />

Treatment area (Return)<br />

Type<br />

Centrifugal<br />

Number of fans n° 2 2 2 2 2 2<br />

Return/Exhaust Airflow rate m 3 /h<br />

6.500/ 7.800/ 8.600/ 10.500/ 13.000/ 15.500/<br />

4.875 5.850 6.<strong>45</strong>0 7.875 9.750 11.650<br />

External section fans<br />

Type<br />

Axial<br />

Number of fans n° 4 4 4 4 4 4<br />

Compressors<br />

Number of compressors n° 2 2 2 2 2 2<br />

Number of circuits n° 2 2 2 2 2 2<br />

Capacity steps n° 2 2 2 2 2 2<br />

Operating weight (std <strong>unit</strong>) Kg 1.500 1.540 1.610 1.650 2.190 2.270<br />

Voltage<br />

400/3/50+N<br />

Sound power (3) dB(A) 63 63 63 63 68 68<br />

H<br />

Dimensions 120 150 180 200 230<br />

Width (A) mm 1.780 1.780 1.780 1.780 2.330<br />

Length (B) mm 5.250 5.250 5.250 5.250 6.<strong>45</strong>0<br />

B<br />

Height (H) mm 1.640 1.640 1.640 1.640 1.790<br />

A<br />

10

PRELIMINARY DATA<br />

HALL-MX 340 380 400 440 480 520<br />

Cooling (1)<br />

Cooling Capacity + Recovery kW 128,0 152,5 169,6 201,5 219,3 246,6<br />

Sensible Cooling Capacity + Recovery kW 89,6 107,1 118,7 139,4 149,8 169,6<br />

Heat Recovery Capacity kW 19,8 22,8 24,9 29,5 31,2 33,0<br />

Compressors Total Power Input kW 26,6 27,9 35,5 39,8 <strong>45</strong>,0 53,1<br />

Total Power Input kW 38,9 47,8 61,4 63,8 72,0 87,1<br />

Heating Mode (2)<br />

Heating Capacity + Recovery kW 131,4 150,9 167,9 203,5 222,1 2<strong>45</strong>,0<br />

Heat Recovery Capacity kW 64,0 71,0 76,0 92,5 97,5 105,5<br />

Compressors Power Input kW 15,6 16,7 20,9 24,3 28,1 31,4<br />

Total Power Input kW 27,9 36,6 46,8 48,3 55,1 65,4<br />

Treatment area (Delivery)<br />

Type<br />

Centrifugal<br />

Number of fans n° 2 2 2 2 2 2<br />

Delivery air flow m 3 /h 17.500 21.000 23.500 27.000 29.000 32.000<br />

Treated external air flow m 3 /h 13.125 15.750 17.625 20.250 21.750 24.000<br />

Treatment area (Return)<br />

Type<br />

Centrifugal<br />

Number of fans n° 2 2 2 2 2 2<br />

Return/Exhaust Airflow rate m 3 /h<br />

17.500/ 21.000/ 23.500/ 27.000/ 29.000/ 32.000/<br />

13.125 15.750 17.625 20.250 21.750 24.000<br />

External section fans<br />

Type<br />

Axial<br />

Number of fans n° 4 4 4 4 4 4<br />

Compressors<br />

Number of compressors n° 2 4 4 4 4 4<br />

Number of circuits n° 2 2 2 2 2 2<br />

Capacity steps n° 2 4 4 4 4 4<br />

Operating weight (std <strong>unit</strong>) Kg 2.330 2.550 2.640 3.240 3.350 3.490<br />

Voltage<br />

400/3/50+N<br />

Sound power (3) dB(A) 68 71 71 76 76 76<br />

(1) Cooling mode parameters: External 34°C 55% R.H. - Internal 26°C 55% R.H.<br />

(2) Heating mode parameters: External -5°C 85% R.H. - Internal 20°C 40% R.H.<br />

(3) Sound pressure In free field on reflecting surface. Average value on the coil side at a distance of 1m from the surface of the <strong>unit</strong> and a<br />

height of 1m from its base.<br />

280 340 380 400 440 480 520<br />

2.330 2.330 2.330 2.330 2.340 2.340 2.340<br />

6.<strong>45</strong>0 6.<strong>45</strong>0 6.950 6.950 6.950 6.950 6.950<br />

1.790 1.790 1.820 1.820 2.380 2.380 2.380<br />

11