GRUNFOS FIRE SYSYTEMS O & M MANUALS - Xact

GRUNFOS FIRE SYSYTEMS O & M MANUALS - Xact

GRUNFOS FIRE SYSYTEMS O & M MANUALS - Xact

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

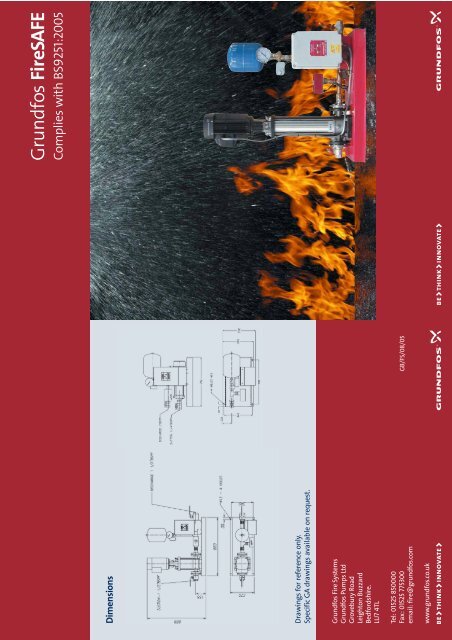

Dimensions<br />

Drawings for reference only.<br />

Specific GA drawings available on request.<br />

Grundfos Fire Systems<br />

Grundfos Pumps Ltd<br />

Grovebury Road<br />

Leighton Buzzard<br />

Bedfordshire.<br />

LU7 4TL<br />

Tel: 01525 850000<br />

Fax: 01525 775300<br />

email: fire@grundfos.com<br />

www.grundfos.co.uk<br />

GB/FS/08/05<br />

Grundfos FireSAFE<br />

Complies with BS9251:2005

Outline<br />

In Britain each year there are over 60,000<br />

domestic & residential fires which are responsible<br />

for at least 600 deaths and 10, 000 serious injuries.<br />

As a result, there has been a growing awareness<br />

in the UK market of the virtues of a correctly<br />

designed and installed sprinkler system to detect<br />

and control a fire at an early stage, thus providing<br />

a cost effective safeguard against loss of life and<br />

property in such dwellings.<br />

The Grundfos FireSAFE (Safe Active Fire Equipment)<br />

range of pump packages is designed to comply with<br />

the recommendations of draft British Standard,<br />

BS9251:2005.<br />

In some situations, and with the permission of the<br />

Water Utility, it may be possible to connect the<br />

Grundfos FireSAFE set directly to the town water<br />

mains. A dedicated suction pipe will be required, the<br />

diameter of which should match the pump suction as<br />

an absolute minimum.<br />

In situations where the town mains supply cannot be<br />

utilised directly it will be necessary to install a water<br />

storage (break) tank between the mains and the<br />

Grundfos FireSAFE set. Grundfos can offer a suitable<br />

break tank.<br />

The Grundfos FireSAFE supplies water via a riser<br />

system within the building to a series of sprinkler<br />

heads. When the air temperature around a sprinkler<br />

head reaches a predetermined level, the glass bulb<br />

bursts, leading to a loss of system pressure and/or a<br />

water flow. This is detected by a pressure switch or a<br />

flow switch integral to the Grundfos Fire SAFE set,<br />

so activating the pump. Only sprinkler heads affected<br />

directly by the heat source will operate.<br />

Specification Details<br />

Pump Type - Grundfos Horizontal or Vertical<br />

Multistage - sized according to individual<br />

system flow / pressure requirements.<br />

Electrical Supply - 240/1/50 or 400/3/50<br />

The pump unit is supplied on a powder-coated<br />

base, pre-wired and tested with all equipment<br />

needed for automatic operation and also<br />

includes the components normally found in<br />

a proprietary riser assembly.<br />

Key Features<br />

8 Litre Accumulator<br />

Maintains system pressure against minor leakage and allows for<br />

thermal expansion caused by ambient temperature variations.<br />

A pressure relief valve, which is sometimes fitted on riser assemblies,<br />

is therefore not considered necessary.<br />

Dual Pressure Switches for pump control<br />

This assembly allows the pump unit to operate both as a Jockey<br />

pump, and a duty pump. Therefore, if the first pressure switch is<br />

activated, and a flow detected, a volt free contact is activated<br />

connected to a central monitoring / alarm panel.<br />

When the system pressure is restored AND a no flow condition is<br />

detected, the pump will stop and this signal will cease. Should the<br />

second pressure switch be activated, indicative of sprinkler activation,<br />

the set will run until stopped manually.<br />

Flow Switch for integration into the Alarm system<br />

Used in conjunction with pressure switches in order to activate<br />

pump unit via control panel.<br />

Pressure gauge<br />

Fitted next to accumulator to provide visual indication of<br />

system pressure.<br />

Test/Drain point<br />

Drainage point located on main manifold that allows the sprinkler<br />

system to be drained. Also allows for testing of flow meter (and<br />

alarm signal).<br />

Control panel with all functions needed for Automatic operation<br />

The control panel has been specifically designed by Grundfos to<br />

conform with BS9251: 2005. The panel will initiate the pump<br />

upon receipt of a signal from the pressure switch. It will also run<br />

the pump once a month for a few seconds at a time in order to<br />

lubricate the shaft seal and top up the hydraulic accumulator,<br />

thus making the system maintenance-free. There is a manual<br />

TEST button that allows pump rotation at any time without<br />

activating the alarm VFC.<br />

The control panel is fail-safe, so any loss in power will result<br />

in an alarm signal being sent to the alarm panel.<br />

Manual shut off switch for use after full activation<br />

This switch is located on the control panel and will<br />

shut down the pump as required by BS9251: 2005.