Jonathan W. Bender - Physics

Jonathan W. Bender - Physics

Jonathan W. Bender - Physics

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

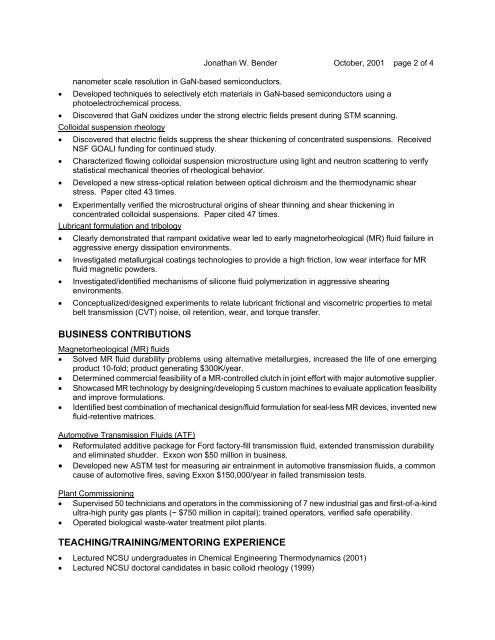

<strong>Jonathan</strong> W. <strong>Bender</strong> October, 2001 page 2 of 4<br />

nanometer scale resolution in GaN-based semiconductors.<br />

• Developed techniques to selectively etch materials in GaN-based semiconductors using a<br />

photoelectrochemical process.<br />

• Discovered that GaN oxidizes under the strong electric fields present during STM scanning.<br />

Colloidal suspension rheology<br />

• Discovered that electric fields suppress the shear thickening of concentrated suspensions. Received<br />

NSF GOALI funding for continued study.<br />

• Characterized flowing colloidal suspension microstructure using light and neutron scattering to verify<br />

statistical mechanical theories of rheological behavior.<br />

• Developed a new stress-optical relation between optical dichroism and the thermodynamic shear<br />

stress. Paper cited 43 times.<br />

• Experimentally verified the microstructural origins of shear thinning and shear thickening in<br />

concentrated colloidal suspensions. Paper cited 47 times.<br />

Lubricant formulation and tribology<br />

• Clearly demonstrated that rampant oxidative wear led to early magnetorheological (MR) fluid failure in<br />

aggressive energy dissipation environments.<br />

• Investigated metallurgical coatings technologies to provide a high friction, low wear interface for MR<br />

fluid magnetic powders.<br />

• Investigated/identified mechanisms of silicone fluid polymerization in aggressive shearing<br />

environments.<br />

• Conceptualized/designed experiments to relate lubricant frictional and viscometric properties to metal<br />

belt transmission (CVT) noise, oil retention, wear, and torque transfer.<br />

BUSINESS CONTRIBUTIONS<br />

Magnetorheological (MR) fluids<br />

• Solved MR fluid durability problems using alternative metallurgies, increased the life of one emerging<br />

product 10-fold; product generating $300K/year.<br />

• Determined commercial feasibility of a MR-controlled clutch in joint effort with major automotive supplier.<br />

• Showcased MR technology by designing/developing 5 custom machines to evaluate application feasibility<br />

and improve formulations.<br />

• Identified best combination of mechanical design/fluid formulation for seal-less MR devices, invented new<br />

fluid-retentive matrices.<br />

Automotive Transmission Fluids (ATF)<br />

• Reformulated additive package for Ford factory-fill transmission fluid, extended transmission durability<br />

and eliminated shudder. Exxon won $50 million in business.<br />

• Developed new ASTM test for measuring air entrainment in automotive transmission fluids, a common<br />

cause of automotive fires, saving Exxon $150,000/year in failed transmission tests.<br />

Plant Commissioning<br />

• Supervised 50 technicians and operators in the commissioning of 7 new industrial gas and first-of-a-kind<br />

ultra-high purity gas plants (~ $750 million in capital); trained operators, verified safe operability.<br />

• Operated biological waste-water treatment pilot plants.<br />

TEACHING/TRAINING/MENTORING EXPERIENCE<br />

• Lectured NCSU undergraduates in Chemical Engineering Thermodynamics (2001)<br />

• Lectured NCSU doctoral candidates in basic colloid rheology (1999)