7. Istruzioni per una saldatura di tasca corretta

7. Istruzioni per una saldatura di tasca corretta

7. Istruzioni per una saldatura di tasca corretta

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>7.</strong>2 Fusion<br />

<strong>7.</strong>2.1 Mark the pipe<br />

Mark the pipe for depth of penetration into<br />

the heater bush and fitting (see table).<br />

The mark must remain visible under heating<br />

and joining.<br />

<strong>7.</strong>2.3 Joint pipe & fitting<br />

Joint the pipe & the fitting and push the pipe<br />

until it reaches the mark (that has to stay<br />

outside).<br />

During the jointing time the welded part of<br />

pipe and fitting must remain fix, without any<br />

rotation.<br />

During the cooling time, the welded part of<br />

pipe and fitting can be adjusted until cold.<br />

<strong>7.</strong>2.2 Heat pipe & fitting<br />

Push the pipe and the fitting into the heating<br />

tools. Once pipe and fitting are hot (after the<br />

correct time), pull out pipe and fitting very<br />

slowly.<br />

<strong>7.</strong>2.4 Fusion inspection<br />

Fusion inspection.<br />

The outer fusion seam must be inspected.<br />

The seam must be present all around the<br />

pipe.<br />

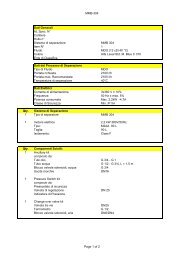

Summary Value table<br />

pipe minimum wall insert heating jointing cooling<br />

<strong>di</strong>ameter thickness depth time time time<br />

(mm) (mm) (mm) (sec.) (sec.) (min.)<br />

20 3,4 14 6 4 2<br />

25 4,2 16 7 4 3<br />

32 5,4 18 8 6 4<br />

40 6,7 20 12 6 4<br />

50 8,4 23 18 6 5<br />

63 10,5 26 25 8 6<br />

75 12,5 28 30 8 8<br />

90 15,0 31 40 10 8<br />

110 18,4 33 50 10 8<br />

22