Equipment Literature - American Augers, Inc.

Equipment Literature - American Augers, Inc.

Equipment Literature - American Augers, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

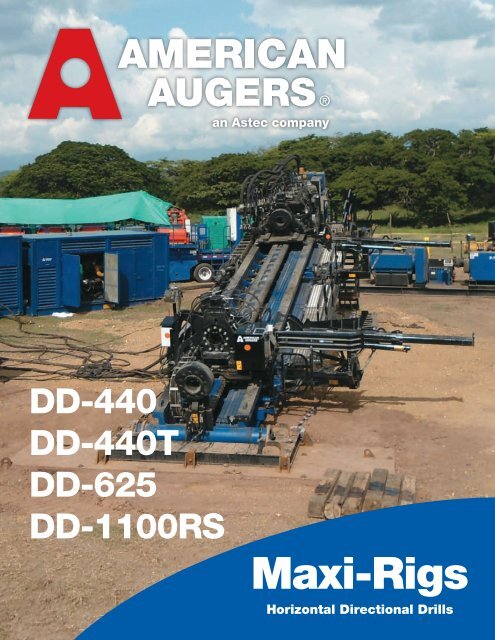

an Astec company<br />

DD-440<br />

DD-440T<br />

DD-625<br />

DD-1100RS<br />

Maxi-Rigs<br />

Horizontal Directional Drills

DD-440<br />

Horizontal Directional Drill<br />

an Astec company<br />

• PINION AND GEAR Rotary Drive<br />

• ADJUSTABLE TORQUE LIMITER for<br />

Rotary and Makeup Force<br />

• ADJUSTABLE FORCE LIMITER for<br />

Thrust and Pullback<br />

• INDEPENDENT CONTROLS AND<br />

HYDRAULIC CIRCUITS for Thrust/<br />

Pullback/Torque and Auxillary Operation<br />

• WIRELINE COMMUTATOR for Speedy<br />

Hookup of the Wireline Guidance<br />

<strong>Equipment</strong><br />

• VARIABLE Entry Angle<br />

• HYDRAULICALLY OPERATED Pipe<br />

Supports<br />

• DEDICATED Pumps for Rotary and Thrust<br />

• WRENCH TRAVELS Full Length of the<br />

Thrust Frame<br />

• ACCOMODATES Range II Drill Pipe<br />

• WIGGLE STEER <br />

• RUN-ON-ONE-TECHNOLOGY-SYSTEM<br />

(ROOTS) capable<br />

• TRI-AXLE Trailer<br />

(2) Caterpiller ® C-11<br />

Tier III Diesel<br />

Engines, 375 HP<br />

(292.2 kW) each,<br />

750 HP (584.4 kW)<br />

total<br />

Microprocessor<br />

o<br />

ce or<br />

Controlled<br />

o<br />

l • 440,000 lbs. (200<br />

tonnes) Maximum<br />

Thrust/Pullback<br />

• 60,000 ft. lbs.<br />

(81,350 Nm)<br />

Maximum Rotary<br />

Torque<br />

www.<strong>American</strong><strong>Augers</strong>.com<br />

Trailer Mounted<br />

for easy mobility

DD-440T<br />

Horizontal Directional Drill<br />

an Astec company<br />

The only Track Mounted Directional<br />

Drill that offers the highest range of<br />

field-proven thrust/pullback power<br />

The same power, torque and benefits of a<br />

DD-440 in a highly mobile track-mounted<br />

format. It’s your preference!<br />

• 440,000 lbs. (200<br />

tonnes) Maximum<br />

Thrust/Pullback<br />

• 60,000 ft. lbs.<br />

(81,350 Nm)<br />

Maximum Rotary<br />

Torque<br />

• PINION AND GEAR Rotary Drive<br />

• ADJUSTABLE TORQUE LIMITER for<br />

Rotary and Makeup Force<br />

• ADJUSTABLE FORCE LIMITER for<br />

Thrust and Pullback<br />

• INDEPENDENT CONTROLS AND<br />

HYDRAULIC CIRCUITS for Thrust/<br />

Pullback/Torque and Auxillary Operation<br />

• WIRELINE COMMUTATOR for Speedy<br />

Hookup of the Wireline Guidance<br />

<strong>Equipment</strong><br />

• VARIABLE Entry Angle<br />

• HYDRAULICALLY OPERATED Pipe<br />

Supports<br />

• DEDICATED Pumps for Rotary and Thrust<br />

• WRENCH TRAVELS Full Length of<br />

the Thrust Frame<br />

• ACCOMODATES Range II Drill Pipe<br />

• WIGGLE STEER <br />

• RUN-ON-ONE-TECHNOLOGY-SYSTEM<br />

(ROOTS) capable<br />

www.<strong>American</strong><strong>Augers</strong>.com<br />

Track Mounted for<br />

optimum jobsite<br />

mobility<br />

Cummins Tier III<br />

Diesel Engine, 600<br />

HP (441.3 kW)

DD-625<br />

Horizontal Directional Drill<br />

an Astec company<br />

Great for large diameter and long<br />

reach pipeline crossings or utility<br />

construction projects<br />

• PINION AND GEAR Rotary Drive<br />

• ADJUSTABLE TORQUE LIMITER for<br />

Rotary and Makeup Force<br />

• ADJUSTABLE FORCE LIMITER for<br />

Thrust and Pullback<br />

• INDEPENDENT CONTROLS AND<br />

HYDRAULIC CIRCUITS for Thrust/<br />

Pullback/Torque and Auxillary Operation<br />

• WIRELINE COMMUTATOR for Speedy<br />

Hookup of the Wireline Guidance<br />

<strong>Equipment</strong><br />

• VARIABLE Entry Angle<br />

• HYDRAULICALLY OPERATED Pipe<br />

Supports<br />

• DEDICATED Pumps for Rotary and Thrust<br />

• WRENCH TRAVELS Full Length of<br />

the Thrust Frame<br />

• ACCOMODATES Range II Drill Pipe<br />

• WIGGLE STEER <br />

• RUN-ON-ONE-TECHNOLOGY-SYSTEM<br />

(ROOTS) capable<br />

• 625,000 lbs. (283<br />

tonnes) Maximum<br />

Thrust/Pullback<br />

• 80,000 ft. lbs.<br />

(108,500 Nm)<br />

Maximum m Rotary<br />

Torque<br />

Cummins Tier III<br />

Diesel Engine, 600<br />

HP (441.3 kW)<br />

Tri-Axle Suspension-<br />

Mounted Thrust Frame<br />

www.<strong>American</strong><strong>Augers</strong>.com

DD-1100RS<br />

Horizontal Directional Drill with Rapid Setup<br />

Most Advanced<br />

Maxi-Rig in Its Class<br />

an Astec company<br />

Back-In Instead of Pull-In<br />

The <strong>American</strong> <strong>Augers</strong> Rapid Setup<br />

procedure consists of a few simple steps!<br />

1) Position the front and rear foot<br />

2) Position the rig at the jobsite<br />

3) Lower the arms to the rear foot<br />

4) Move the dolly<br />

5) Disconnect the tractor<br />

6) Raise the rig<br />

7) Insert locking pins at different angles to<br />

complete the Rapid Setup<br />

• Rapid set up without a crane<br />

• Back the rig into place<br />

• Optional pipe handling<br />

• Noise deadening power packs<br />

Versatile • Cost-Saving •<br />

Maximum Power<br />

This brand new, time -saving drill<br />

allows contractors ease of<br />

mobility and versatility with<br />

maximum power of a 1,100,000 lb.<br />

rig!<br />

www.<strong>American</strong><strong>Augers</strong>.com<br />

• 1,100,000 1 0 , 0 0 0 lbs. (500<br />

0<br />

tonnes) Maximum<br />

Thrust/Pullback<br />

• 100,000 ft. lbs.<br />

(136,000 Nm)<br />

Maximum<br />

Rotary Torque<br />

• Caterpiller ® C-18<br />

Tier III Diesel<br />

engines, 765 HP/unit<br />

• Microprocessor Controlled<br />

Fuel Savings<br />

• Improved Hydraulic Hose<br />

Routing: Less Manifolds<br />

• Best Hydraulic Filtering in<br />

the Industry!<br />

Self-Erecting Rapid Setup<br />

positions large equipment<br />

quickly and easily!

MAXI-RIG HORIZONTAL<br />

DIRECTIONAL DRILLS<br />

PERFORMANCE SPECIFICATIONS<br />

* Note: All product performance specifications, components,<br />

weights, dimensions and other related information is subject<br />

to change without notice from the manufacturer.<br />

DD-440<br />

DD-440T<br />

DD-625<br />

DD-1100RS<br />

Power Train<br />

Engine: (2) Caterpillar C-11 Tier III Diesel<br />

Rating: 375 HP (292.2 kW) each<br />

750 HP (584.4 kW) total<br />

Fuel Capacity: 300 US gal. (1136 L)<br />

Hydraulic Capacity: 275 US gal. (1041 L)<br />

Hydraulic Filter: High Pressure Filtration Return to 6 Micron<br />

ABS<br />

Battery: (2) Deka 908 DMF 12 V, 1450 CCA<br />

Engine: Cummins Tier III Diesel<br />

Rating: 600 HP (441.3 kW)<br />

Fuel Capacity: 160 US gal. (605 L)<br />

Hydraulic Capacity: 200 US gal. (757 L)<br />

Hydraulic Filter: High Pressure Filtration Return to 6 Micron<br />

ABS<br />

Battery: (2) Deka 908 DMF 12 V, 1450 CCA<br />

Engine: Cummins Tier III Diesel<br />

Rating: 600 HP (441.3 kW)<br />

Fuel Capacity: 650 US gal. (2,460 L)<br />

Hydraulic Capacity: 107 US gal. (405 L)<br />

Hydraulic Filter: High Pressure Filtration Return to 6 Micron<br />

ABS<br />

Battery: (2) Deka 908 DMF 12 V, 1450 CCA<br />

One Power Pack<br />

Engine: Caterpillar C-18 Tier III Diesel<br />

Rating: 765 HP (570 kW)<br />

Fuel Capacity: 650 US gal. (2,460 L)<br />

Hydraulic Capacity: 220 US gal. (833 L)<br />

Hydraulic Filter: High Pressure Filtration Return to 6 Micron<br />

ABS<br />

Battery: (2) Deka 908 DMF 24 V, 1450 CCA<br />

Carriage<br />

System<br />

Carriage System: Rack & Pinion (2) Pinion Drive, Adj. Force<br />

Limiter<br />

Max. Thrust/Pullback: 440,000 lbs. (200 Tonnes)<br />

Max. Carriage Speed: 95 ft. (29 m) / per minute<br />

Carriage Motors: (2) Hyd. 160 cc, Radial Piston / Dual<br />

Displacement<br />

Carriage Brakes: (2) Spring Applied / Hydraulic Release<br />

Planetary Gearbox: (2)<br />

Carriage System: Rack & Pinion (2) Pinion Drive, Adj. Force<br />

Limiter<br />

Max. Thrust/Pullback: 440,000 lbs. (200 Tonnes)<br />

Max. Carriage Speed: 95 ft. (29 m) / per minute<br />

Carriage Motors: (2) Hyd. 160 cc, Radial Piston / Dual<br />

Displacement<br />

Carriage Brakes: (2) Spring Applied / Hydraulic Release<br />

Planetary Gearbox: (2)<br />

Carriage System: Rack & Pinion (4) Pinion Drive, Adj. Force<br />

Limiter<br />

Max. Thrust/Pullback: 625,000 lbs. (283 Tonnes)<br />

Max. Carriage Speed: 120 ft. (36 m) / per minute<br />

Carriage Motors: (4) Radial Piston / Dual Displacement<br />

Carriage Brakes: (2) Spring Applied / Hydraulic Release<br />

Planetary Gearbox: (4)<br />

Carriage System: Rack & Pinion (6) Pinion Drive, Adj. Force<br />

Limiter<br />

Max. Thrust/Pullback: 1,100,000 lbs. (500 Tonnes)<br />

Max. Carriage Speed: 101 ft. (30.7 m) / per minute<br />

Carriage Motors: (6) Radial Piston / Dual Displacement<br />

Carriage Brakes: (6) Spring Applied / Hydraulic Release<br />

Planetary Gearbox: (6)<br />

Rotary Drive<br />

Rotary System: (3) Pinion & Gear Drive with Infinitely Variable<br />

Torque<br />

Max. Rotary Torque: 60,000 ft. lbs. (80,000 Nm) @ 0-43 RPM<br />

Min. Rotary Torque: 25,500 ft. lbs. (34,700 Nm) @ 0-95 RPM<br />

Max. Rotary Speed: 95 RPM<br />

Rotary Motor: (3) 160 cc, Axial Piston, Variable Displacement<br />

Rotary Brakes: (2) Spring Applied / Hydraulic Release<br />

Fluid Course: 4" (102 mm)<br />

Mud Flow Rate: Permits up to 1,000 US gal. (3,785 L) / per<br />

minute<br />

Max. Mud Pressure: 1,500 psi (103 bar)<br />

Mud Swivel: Rear Mounted, 5 ½ IFLH Pin<br />

Slip Spindle: 6 " API-FH Pin<br />

Other Features: Digital Tach., Adj. Torque Limiter,<br />

Wiggle Steer ®<br />

Rotary System: (3) Pinion & Gear Drive with Infinitely Variable<br />

Torque<br />

Max. Rotary Torque: 60,000 ft. lbs. (80,000 Nm) @ 0-43 RPM<br />

Min. Rotary Torque: 40,635 ft. lbs. (56,198 Nm) @ 0-95 RPM<br />

Max. Rotary Speed: 95 RPM<br />

Rotary Motor: (3) 160 cc, Axial Piston, Variable Displacement<br />

Rotary Brakes: (2) Spring Applied / Hydraulic Release<br />

Fluid Course: 3" (76 mm)<br />

Mud Flow Rate: Permits up to 650 US gal. (2,460 L) / per<br />

minute<br />

Max. Mud Pressure: 1,500 psi (103 bar)<br />

Mud Swivel: Rear Mounted, 5 ½ IFLH Pin<br />

Other Features: Digital Tach., Adj. Torque Limiter,<br />

Wiggle Steer ®<br />

Rotary System: (4) Pinion & Gear Drive with Infinitely Variable<br />

Torque<br />

Max. Rotary Torque: 80,000 ft. lbs. (108,800 Nm) @ 0-33 RPM<br />

Min. Rotary Torque: 23,500 ft. lbs. (31,800 Nm) @ 0-90 RPM<br />

Max. Rotary Speed: 90 RPM<br />

Rotary Motor: (4) 160 cc, Axial Piston, Variable Displacement<br />

Rotary Brakes: (2) Spring Applied / Hydraulic Release<br />

Fluid Course: 3" (76 mm)<br />

Mud Flow Rate: Permits up to 650 US gal. (2,460 L) / per<br />

minute<br />

Max. Mud Pressure: 1,500 psi (103 bar)<br />

Mud Swivel: Rear Mounted, 5 ½ IFLH Down Hole x 6<br />

Other Features: Digital Tach., Adj. Torque Limiter,<br />

Wiggle Steer ®<br />

Rotary System: (4) Pinion & Gear Drive with Infinitely Variable<br />

Torque<br />

Max. Rotary Torque: 100,000 ft. lbs. (136,000 Nm) @ 0-37<br />

RPM<br />

Min. Rotary Torque: 40,000 ft. lbs. (54,000 Nm) @ 0-85 RPM<br />

Max. Rotary Speed: 85 RPM<br />

Rotary Motor: (4) 160 cc, Axial Piston, Variable Displacement<br />

Rotary Brakes: (4) Spring Applied / Hydraulic Release<br />

Fluid Course: 4" (102 mm) for increased down hole hydraulic<br />

power<br />

Mud Flow Rate: Permits up to 1,000 US gal. (3,785 L) / per<br />

minute<br />

Max. Mud Pressure: 1,500 psi (103 bar)<br />

Hydraulic Pump: (2) Piston Pump, Closed Loop<br />

Slip Spindle: 8 " Pin<br />

Other Features: Digital Tach., Adj. Torque Limiter,<br />

Wiggle Steer ®<br />

Drill Rig &<br />

Wrench<br />

Wrench/Clamp System: Triple Jaw Wrenches with 12"<br />

(305 mm) Sep.<br />

Wrench Travel: Wrench has full length thrust frame travel<br />

Max. Breakout Torque: 154,000 ft. lbs. (209,400 Nm)<br />

Max. Makeup Torque: 101,700 ft. lbs. (138,312 Nm)<br />

Clamp/Grip Range: 2 ¾" - 10 ¾" (70-273 mm) OD<br />

Wrench Assembly Motor: (2) Hydraulic LSHT, 12 CIR<br />

Wrench Assembly Brake: (1) Spring Applied / Hydraulic Release<br />

Planetary Gearbox: (2) SGL<br />

Hydraulic Wrench Cylinder: (6) 8" Bore x 3" Stroke<br />

Drill Angle: 10°-18°<br />

Drill Pipe: Range II—34 ft. (10.4 m)<br />

Mounting: Thrust Frame Mounted to Tri-Axle Trailer with<br />

Air-Ride Suspension and 5 th Wheel Hitch<br />

Wrench/Clamp System: Triple Jaw Wrenches with 12"<br />

(305 mm) Sep.<br />

Wrench Travel: Wrench has full length thrust frame travel<br />

Max. Breakout Torque: 154,000 ft. lbs. (209,400 Nm)<br />

Max. Makeup Torque: 101,700 ft. lbs. (138,312<br />

Nm)<br />

Clamp/Grip Range: 2 ¾" - 10 ¾" (70-273 mm) OD<br />

Wrench Assembly Motor: (2) Hydraulic LSHT,<br />

12 CIR<br />

Wrench Assembly Brake: (1) Spring Applied / Hydraulic<br />

Release<br />

Planetary Gearbox: (2) SGL<br />

Hydraulic Wrench Cylinder: (6) 8" Bore x 3" Stroke<br />

Drill Angle: 10°-18°<br />

Drill Pipe: Range II—34 ft. (10.4 m)<br />

Travel System: Track Mounted under Carriage C<br />

Assembly<br />

Crawler<br />

Wrench/Clamp System: Triple Jaw Wrenches with 12"<br />

(305 mm) Sep.<br />

Wrench Travel: Wrench has full length thrust frame travel<br />

Max. Breakout Torque: 212,000 ft. lbs. (288,000 Nm)<br />

Max. Makeup Torque: 140,000 ft. lbs. (190,000 Nm)<br />

Clamp/Grip Range: 3 ½" - 10 ½" (89-267 mm) OD<br />

Wrench Assembly Motor: (1) Hydraulic LSHT, 12.5 CIR<br />

Wrench Assembly Brake: (1) Spring Applied / Hydraulic<br />

Release<br />

Hydraulic Wrench Cylinder: (6) 8" Bore x 3" Stroke<br />

Drill Angle: 10°-18°<br />

Drill Pipe: Range II—34 ft. (10.4 m)<br />

Mounting: Thrust Frame mounted to Tri-Axle Suspension Base<br />

Wrench/Clamp System: Triple Jaw Wrenches with 12"<br />

(305 mm) Sep.<br />

Wrench Travel: Wrench has full length thrust frame travel<br />

Max. Breakout Torque: 230,000 ft. lbs. (312,000 Nm)<br />

Max. Makeup Torque: 100,183 ft. lbs. (138,252 Nm)<br />

Clamp/Grip Range: 3 ½" - 10 ½" (89-267 mm) OD<br />

Wrench Assembly Motor: (2) Hydraulic LSHT, 12.5 CIR<br />

Wrench Assembly Brake: (1) Spring Applied / Hydraulic<br />

Release<br />

Clamp Cylinder: 8" Bore x 3" Stroke for 226,000 lbs. of<br />

Clamping Force<br />

Hydraulic Breakout / Makeup Cylinder: 6" Bore x 16" Stroke<br />

Wrench Separation Cylinder: 4" Bore x 12" Stroke<br />

Pivoting Hook Pads: Ability to remove the wrench w/o tools or<br />

bolts<br />

Drill Angle: 10°-18°<br />

Drill Pipe: Range II—34 ft. (10.4 m)<br />

Mounting: Thrust Frame mounted to Tri-Axle Suspension Base

MAXI-RIG HORIZONTAL<br />

DIRECTIONAL DRILLS<br />

TRANSPORT INFORMATION & EXTRAS<br />

DD-440<br />

DD-440T<br />

DD-625<br />

DD-1100RS<br />

Dimensions<br />

Length: 51 ft. 5 in. (15.7 m)<br />

Width: 8 ft. 2 in. (2.5 m)<br />

Height: 13 ft. 6 in. (4.1 m)<br />

Length: 49 ft. (14.93 m)<br />

Width: 8 ft. 2 in. (2.5 m)<br />

Height: 11 ft. 8 in. (3.6 m)<br />

Length: 55 ft. (16.8 m)<br />

Width: 8 ft. 6 in. (2.59 m)<br />

Height:<br />

Working: 17 ft. (5.18 m)<br />

Transport: 11 ft. 6 in. (3.35 m)<br />

Transport Length: 64 ft. 10 in. (19.5 m)<br />

Transport Width: 8 ft. 2 in. (2.5 m)<br />

Height:<br />

Working: 19 ft. (5.79m)<br />

Transport: 11 ft. 10 in. (3.04 m)<br />

Single Power Pack Length: 19 ft. 8 in. (6.03 m)<br />

Single Power Pack Width: 8 ft. (2.43 m)<br />

Single Power Pack Height: 9 ft. 5 in. (2.9 m)<br />

Weights<br />

Total Weight: 93,000 lbs. (42,185 kg)<br />

Total Weight w/o Wrenches: 86,000 lbs. (39,009 kg)<br />

Wrenches are removable for lighter transport<br />

Total Weight: 95,400 lbs. (43,273 kg)<br />

Total Weight w/o Wrenches: 87,600 lbs. (39,785 kg)<br />

Wrenches are removable for lighter transport<br />

Total Weight: 93,800 lbs. (42,547 kg)<br />

Total Weight w/o Wrenches: 86,000 lbs. (39,009 kg)<br />

Wrenches are removable for lighter transport<br />

Single Power Pack Weight: 33,000 lbs. (14,969 kg)<br />

Estimated Transport Total Weight: 113,000 lbs. (51,256 kg)<br />

Estimated Transport Total Weight w/o Wrenches: 105,300 lbs. (47,763 kg)<br />

Wrenches are removable for lighter transport<br />

Single Power Pack Weight: 35,500 lbs. (16,103 kg)<br />

<strong>Inc</strong>luded with<br />

Base Unit<br />

Run-On-One Technology System Free Standing Operator’s Console with Pressure Gauges<br />

Es!Lok Entry / Exit Side Lockout, 1 mile (1.6 km) range Safety System package with ZapAlert<br />

Wiggle Steer ® Operator’s Manual and other Unit Support Materials<br />

Free Standing Operator’s Console with Pressure Gauges Es!Lok Entry / Exit Side Lockout, 1 mile (1.6 km) range<br />

Safety System package with ZapAlert Wiggle Steer ® Operator’s Manual and other Unit Support Materials<br />

* Note: All product performance specifications, components,<br />

weights, dimensions and other related information is subject<br />

to change without notice from the manufacturer.

MAXI-RIG HORIZONTAL<br />

DIRECTIONAL DRILLS<br />

PREMIUM OPTIONS<br />

ISO-Style Driller’s Cabin<br />

for Rugged, Construction-Grade Reliability! This new design with ISO<br />

corners is the world standard conguration for ofoading during export.<br />

12-gauge corrugated siding with thermo pane windows. The cabin<br />

interior boasts an ergonomically congured design for optimum visibility<br />

and new 6-way adjustable tension chair with seat and side<br />

pod controls.<br />

Climate controlled environment, dual joysticks and abundant work<br />

surface. Can be ordered with 50 Hz option. 8' x 12' or 8' x 20' sizes<br />

available.<br />

DD-440 DD-440T DD-625 DD-1100RS<br />

ISO-Style Trailer (51' x 96" for both Power Packs)<br />

Sound deadening enclosure for your power units. Made up of<br />

removable panels that contain 2" of acoustical absorbing material<br />

keeping dBs to 80. There are three lockable double doors for easy<br />

access.<br />

Secondary Power Pack includes ROOTS - Run on One Technology System<br />

Drill can operate on one or both units. Allows you to do maintenance on one unit without experiencing<br />

any down time.<br />

Certied Pullback Test a guarantee of exactly what YOUR machine can pull.<br />

Pipe Loader improves safety with less crew around the rig. Features include:<br />

stages 4 rods,<br />

connected to the thrust frame with pins for easy attachment and removal, can handle different sizes<br />

of drill pipe and has processor controlled extension cylinders for accurate and<br />

adjustable rod<br />

positioning.

The <strong>American</strong> <strong>Augers</strong> line of underground construction equipment is second-to-none.<br />

• Auger Boring Machines<br />

• Maxi-Rig & Mid-Size Directional Drills<br />

• Oil & Gas Drilling Rigs<br />

• Mud Pump & Cleaning Systems<br />

• Product Tooling & Accessories<br />

<strong>American</strong> <strong>Augers</strong> products are manufactured at the company’s 241,000 square-foot<br />

facility in West Salem, Ohio, in the heart of Amish country between Columbus and<br />

Cleveland.<br />

Since the founding of <strong>American</strong> <strong>Augers</strong> in 1970, there has never been a change in<br />

the company’s core value: having products developed by a can-do work force<br />

that focuses on mechanical, technological and customer-based design<br />

improvements. Our goal is to always exceed customer expectations by<br />

providing products that are not a cost of doing business, but an<br />

Investment in Success.<br />

Did You Know? <strong>American</strong> <strong>Augers</strong> was the first HDD manufacturer to eliminate chain<br />

and utilize a rack and pinion carriage design which is now the industry standard. Our<br />

rack and pinion drive provides smoother carriage movement, more precise operating<br />

control, long system life and no complicated parts.<br />

<strong>American</strong> <strong>Augers</strong> machines are supported through a dedicated parts and technical service<br />

department. We are here to help whenever you need us 24 hours a day,<br />

7 days a week, emergency or not.<br />

* Note: All product performance specifications, components,<br />

weights, dimensions and other related information is subject<br />

to change without notice from the manufacturer.<br />

www.<strong>American</strong><strong>Augers</strong>.com<br />

Environmental Commitment<br />

<strong>American</strong> <strong>Augers</strong> is committed to manufacturing equipment that helps<br />

to preserve the sanctity of the global environment, and has done so by<br />

reducing noise and/or emissions outputs, and emphasizing the fact that<br />

our trenchless technology equipment requires little or no open cutting,<br />

which has very minimal impacts on natural surfaces, features, or<br />

habitats.<br />

0512