Pulse Firing - Hauck Manufacturing

Pulse Firing - Hauck Manufacturing

Pulse Firing - Hauck Manufacturing

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

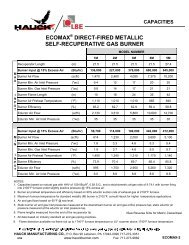

2 · <strong>Pulse</strong> <strong>Firing</strong> · Edition 05.10<br />

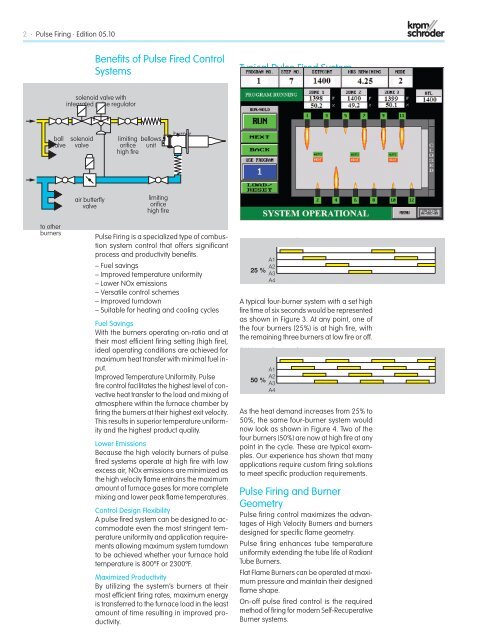

Benefits of <strong>Pulse</strong> Fired Control<br />

Systems<br />

Typical <strong>Pulse</strong> Fired System<br />

solenoid valve with<br />

integrated pulse regulator<br />

ball<br />

valve<br />

solenoid<br />

valve<br />

limiting<br />

orifice<br />

high fire<br />

bellows<br />

unit<br />

burner<br />

air butterfly<br />

valve<br />

limiting<br />

orifice<br />

high fire<br />

to other<br />

burners<br />

<strong>Pulse</strong> <strong>Firing</strong> is a specialized type of combustion<br />

system control that offers significant<br />

process and productivity benefits.<br />

– Fuel savings<br />

– Improved temperature uniformity<br />

– Lower NOx emissions<br />

– Versatile control schemes<br />

– Improved turndown<br />

– Suitable for heating and cooling cycles<br />

Fuel Savings<br />

With the burners operating on-ratio and at<br />

their most efficient firing setting (high fire),<br />

ideal operating conditions are achieved for<br />

maximum heat transfer with minimal fuel input.<br />

Improved Temperature Uniformity. <strong>Pulse</strong><br />

fire control facilitates the highest level of convective<br />

heat transfer to the load and mixing of<br />

atmosphere within the furnace chamber by<br />

firing the burners at their highest exit velocity.<br />

This results in superior temperature uniformity<br />

and the highest product quality.<br />

Lower Emissions<br />

Because the high velocity burners of pulse<br />

fired systems operate at high fire with low<br />

excess air, NOx emissions are minimized as<br />

the high velocity flame entrains the maximum<br />

amount of furnace gases for more complete<br />

mixing and lower peak flame temperatures.<br />

Control Design Flexibility<br />

A pulse fired system can be designed to accommodate<br />

even the most stringent temperature<br />

uniformity and application requirements<br />

allowing maximum system turndown<br />

to be achieved whether your furnace hold<br />

temperature is 800ºF or 2300ºF.<br />

Maximized Productivity<br />

By utilizing the system’s burners at their<br />

most efficient firing rates, maximum energy<br />

is transferred to the furnace load in the least<br />

amount of time resulting in improved productivity.<br />

25% Heat Demand<br />

A1<br />

A2<br />

25 %<br />

A3<br />

A4<br />

A typical four-burner system with a set high<br />

fire time of six seconds would be represented<br />

as shown in Figure 3. At any point, one of<br />

the four burners (25%) is at high fire, with<br />

the remaining three burners at low fire or off.<br />

50% Heat Demand<br />

A1<br />

A2<br />

50 %<br />

A3<br />

A4<br />

As the heat demand increases from 25% to<br />

50%, the same four-burner system would<br />

now look as shown in Figure 4. Two of the<br />

four burners (50%) are now at high fire at any<br />

point in the cycle. These are typical examples.<br />

Our experience has shown that many<br />

applications require custom firing solutions<br />

to meet specific production requirements.<br />

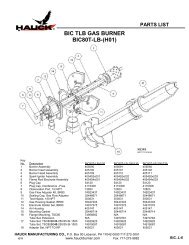

<strong>Pulse</strong> <strong>Firing</strong> and Burner<br />

Geometry<br />

<strong>Pulse</strong> firing control maximizes the advantages<br />

of High Velocity Burners and burners<br />

designed for specific flame geometry.<br />

<strong>Pulse</strong> firing enhances tube temperature<br />

uniformity extending the tube life of Radiant<br />

Tube Burners.<br />

Flat Flame Burners can be operated at maximum<br />

pressure and maintain their designed<br />

flame shape.<br />

On-off pulse fired control is the required<br />

method of firing for modern Self-Recuperative<br />

Burner systems.