Reflectix ® - Reflective Insulation - Protective Packaging from ...

Reflectix ® - Reflective Insulation - Protective Packaging from ...

Reflectix ® - Reflective Insulation - Protective Packaging from ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

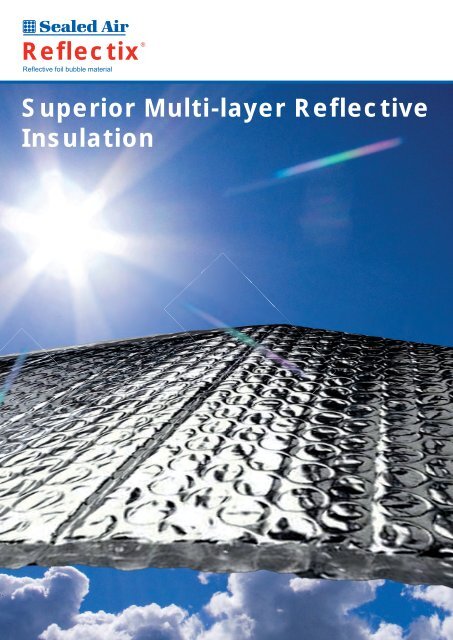

<strong>Reflectix</strong> ®<br />

<strong>Reflective</strong> foil bubble material<br />

Superior Multi-layer <strong>Reflective</strong><br />

<strong>Insulation</strong>

<strong>Reflectix</strong> ® – <strong>Reflective</strong> <strong>Insulation</strong><br />

<strong>Reflectix</strong> ® technology was initially created by<br />

NASA, used as protective insulation material for<br />

astronaut suits. It was soon recognised as an<br />

excellent heat insulation product, widely used in<br />

construction.<br />

What is <strong>Reflectix</strong> ® ?<br />

<strong>Reflectix</strong> ® is a multi-layer reflective insulation consisting of<br />

two external, high purity layers of aluminium foil covering<br />

layers of AirCap ® bubble and Cell-Aire ® polyethylene foam.<br />

How is heat transferred?<br />

There are three ways heat moves <strong>from</strong> warm to cool regions:<br />

● Radiation – electromagnetic transfer of energy through<br />

space.<br />

● Convection – heat flow transferred by the movement of air.<br />

● Conduction – heat flow through a fluid or solid material.<br />

Convection<br />

Conduction<br />

Radiation<br />

Radiation<br />

1<br />

2<br />

3<br />

4<br />

Anti-corrosion layer<br />

High purity aluminium foil<br />

AirCap ® bubble<br />

Cell-Aire ® Polyethylene Foam

The story behind the technology<br />

How does <strong>Reflectix</strong> ® work?<br />

While the aluminium reflects up to 95-97% of heat<br />

transferred via radiation, AirCap ® and Cell-Aire ® provide the<br />

necessary mechanical strength to the final product.<br />

They also give additional thermal resistance to heat<br />

transferred via conduction.<br />

With <strong>Reflectix</strong> ® Without <strong>Reflectix</strong> ®<br />

According to U.S. <strong>Reflective</strong> <strong>Insulation</strong> Manufacturers<br />

Association (R.I.M.A.), heat transmitted via radiation represents<br />

at least 50% of all heat transferred in nature.<br />

Traditional thermal insulation like foam or fibres are resistant to<br />

heat transferred via conduction, but are unable to reflect more<br />

than 30% of the heat transmitted via radiation.<br />

The benefits of aluminium?<br />

Compared with other surface materials, aluminium foil has<br />

superior reflectivity:<br />

Surface material Reflectivity (%)<br />

Aluminium foil 95% - 97%<br />

Asphalt 2% - 10%<br />

Brick 7%<br />

Concrete 5% - 15%<br />

Glass 5%<br />

Limestone 10% - 84%<br />

Marble 7%<br />

Paper 8%<br />

Plaster 9%<br />

Steel 88%<br />

There are three heat transfer directions<br />

Radiation<br />

Convection<br />

Conduction<br />

According to an analysis performed at Penn State University, approximately 75% of total heat transfer in<br />

structures occurs through radiation. The foil in <strong>Reflectix</strong> ® reflects 95 - 97% of the radiant energy striking it.<br />

An example of down heat flow is through the floor in the winter or through the attic in the summer. Up<br />

heat flow is through the ceiling in the winter. Side heat flow refers to heat loss through the walls.<br />

Down Heat Flow %<br />

Up Heat Flow %<br />

Side Heat Flow %<br />

10<br />

5 to 7%<br />

100<br />

10 20 30 40 50 60 70 80 90 100<br />

20<br />

90<br />

30<br />

40<br />

80<br />

70<br />

50% to<br />

50% to<br />

75%<br />

75%<br />

85% 65% to to<br />

80% 80%<br />

50<br />

60<br />

60<br />

70<br />

50<br />

40<br />

Up to<br />

Up to<br />

45%<br />

45%<br />

15% to to<br />

28% 28%<br />

80<br />

90<br />

Up to<br />

93%<br />

30<br />

20<br />

5%<br />

to<br />

7%<br />

100<br />

10<br />

5 to 7%

Why choose <strong>Reflectix</strong> ® ?<br />

Compare the values<br />

R values<br />

R values rate how much heat loss the material resists <strong>from</strong><br />

passing through.<br />

U-values<br />

U-values rate how much heat the component allows to pass<br />

through it.<br />

R values rate one single material while U values measure entire<br />

components. For example R values measure how much heat<br />

loss passes through fibreglass insulation while U values rate how<br />

much heat can pass through a window component (glass, air,<br />

vinyl sash).<br />

Material<br />

Gauge<br />

(in mm)<br />

R-Value<br />

U-Value<br />

<strong>Reflectix</strong> ® DB 10mm 0.90 1.110<br />

Mineral Fibre 25mm 0.750 1.33<br />

Tile 20mm 0.044 22.73<br />

Coating 2mm 0.027 37.04<br />

Brick 120mm 0.267 3.75<br />

Concrete 200mm 0.114 8.77<br />

Extruded Polystyrene 30mm 1.071 0.93<br />

Extruded Polystyrene 50mm 1.613 0.62<br />

Polyurethane 25mm 0.836 1.20<br />

Fibreglass 30mm 1.000 1.00<br />

Fibreglass 50mm 1.666 0.60<br />

Source: <strong>Reflective</strong> <strong>Insulation</strong> Manufacturers Association (R.I.M.A.)<br />

R = m 2 K/W U = W/m 2 K<br />

Converting a U value to a R value is as simple as:<br />

R = 1/U. So a U value of 1.110 would equal a R value of<br />

0.90<br />

Features & benefits of<br />

<strong>Reflectix</strong> ®<br />

Being an energy and cost effective insulation product,<br />

<strong>Reflectix</strong> ® is one of the most versatile building materials on the<br />

market today. Ideal for new construction or retrofit installation<br />

in commercial or domestic structures <strong>Reflectix</strong> ® delivers<br />

unsurpassed benefits:<br />

Lowers heating and cooling costs<br />

● Reflects 95 - 97% of radiant energy<br />

● Controls condensation<br />

Lowers insulation cost<br />

● Easy to install<br />

● Permanent and maintenance free<br />

● Durable and lightweight<br />

● Does not compress, collapse or disintegrate<br />

● Does not promote nesting or rodents<br />

● Not affected by moisture or humidity<br />

Lowers recycling cost<br />

● Environmentally safe<br />

● Non-toxic/non-carcinogenic<br />

● Fibre-free

The versatility of <strong>Reflectix</strong> ®<br />

The versatility of <strong>Reflectix</strong> ® means that it is the ideal solution for a number of applications <strong>from</strong> domestic attics to<br />

insulating cartons for shipping. The possibilities are endless.<br />

ATTIC AND ROOF<br />

EXTERIOR WALLS<br />

INTERIOR WALLS<br />

RADIATOR<br />

CRAWL SPACE<br />

BASEMENT<br />

PIPES AND DUCTS<br />

UNDERFLOOR<br />

HEATING<br />

Being easy to install <strong>Reflectix</strong> ® is suited for use by both the competent DIY-ers and the Professional Contractors:<br />

ATTIC AND ROOF<br />

PIPES AND DUCTS<br />

CRAWL SPACE<br />

BASEMENT<br />

INTERIOR WALLS<br />

EXTERIOR WALLS<br />

UNDERFLOOR HEATING<br />

RADIATOR

The versatility of <strong>Reflectix</strong> ®<br />

Metal buildings applications<br />

For roof and wall insulation, <strong>Reflectix</strong> ® is a quick and easy, high performance<br />

and cost effective solution for agricultural and commercial buildings.<br />

Non construction applications<br />

Shipping<br />

One area where temperature can be an issue is during the shipping of your product. You can use<br />

<strong>Reflectix</strong> ® not only to cover the walls of your truck but you can also use sheets of our material to<br />

cover your boxes. It is ideal for shipping anything <strong>from</strong> fish to pharmaceuticals.<br />

Hobby<br />

Ever thought of insulating your caravan or mobile home? <strong>Reflectix</strong> ® can make your trip even more<br />

comfortable during hot summers or cold winters.<br />

Apply our <strong>Reflectix</strong> ® SB to the walls or the top and either save energy in winter or keep cool in<br />

summer.<br />

More Proven Applications<br />

For extended protection of extremely perishable products, dry ice and or other refrigerants can be placed in a package without<br />

damage to the liner.<br />

Perishable Foods<br />

● Seafood, Meat and Poultry<br />

● Beverages i.e. wine, juices<br />

● Gourmet Foods<br />

● Baked Goods<br />

● Dairy i.e. ice cream, milk,<br />

cheese<br />

● Confectionary i.e sweets and chocolates<br />

Medical<br />

● Pharmaceutical<br />

● Healthcare<br />

● Biotechnology<br />

Scientific/Industrial<br />

● Chemicals<br />

● Adhesives<br />

● Bio Chemicals<br />

● Solders<br />

● Ink Manufacturers<br />

Animal Health<br />

● Animal Fluids<br />

● Animal Labs<br />

● Veterinarian Products and<br />

Supplies<br />

● Dead Animal Removal<br />

● Blood Transport<br />

● Clinical Labs<br />

● Cryogenic Research<br />

● Organ Transporting<br />

● Medical Supplies (implants)<br />

● Prescription Labs<br />

● Genetics, DNA<br />

Other<br />

● Flowers<br />

● Cosmetics/Perfumes<br />

● Tropical Fish<br />

● Freight Companies<br />

● Banquet Facilities

REPORT NO.: 26315-2.a. Page 1 of 7<br />

Technical data and certification<br />

Product Type<br />

<strong>Reflectix</strong> ® SB<br />

(single bubble)<br />

<strong>Reflectix</strong> ® DB<br />

(double bubble)<br />

<strong>Reflectix</strong> ® DB+<br />

(double bubble Plus)<br />

Top layer: Alu Foil<br />

Foil+AirCap ® +Cell-Aire ® 1,5mm<br />

+AirCap ® + Foil<br />

Foil+AirCap ® + Cell-Aire ®<br />

5,0mm+AirCap ® +Foil<br />

Description<br />

Middle Layer: AirCap ® bubble<br />

Bottom layer: Alu Foil<br />

Nominal Thickness 4,0mm (±10%) 9,5mm (±10%) 13,0mm (±10%)<br />

Aluminium Foil Thickness 8MY + 25MY PE 8MY + 25MY PE 8MY + 25MY PE<br />

Aluminium Foil Purity 99,9% 99,9% 99,9%<br />

Aluminium Foil Reflectivity 95-97% 95-97% 95-97%<br />

Foil Anti-corrosion coating NC lacquer NC lacquer NC lacquer<br />

AirCap ® bubble density 90 gr/m 2 (±5%) 90 gr/m 2 (±5%) 90 gr/m 2 (±5%)<br />

Total Product Density 200 gr/m 2 (±5%) 310 gr/m 2 (±5%) 360 gr/m 2 (±5%)<br />

Rolls Size 1,20m x 50m = 60m 2 1,20m x 25m = 30m 2 1,20m x 20m = 24m 2<br />

U Value 1,30 W/m 2 K 1,11 W/m 2 K 1,15 W/m 2 K<br />

Test Method UNE-EN ISO 8990:1997 UNE-EN ISO 8990:1997 UNE-EN ISO 8990:1997<br />

Institution tested Cidemco/Spain Cidemco/Spain Cidemco/Spain<br />

Flame Resistance B2 B2 B2<br />

Test Method DIN 4102 DIN 4102 DIN 4102<br />

Institution tested Firelabs/Germany Firelabs/Germany Firelabs/Germany<br />

Certification<br />

CIDEMCO-Tecnalia<br />

Área Anardi, nº 5<br />

Apartado 134 P.O. Box<br />

E-20730 Azpeitia (Guipúzcoa) / Spain<br />

Tel.: +34 943 81 68 00<br />

Fax: +34 943 81 60 74<br />

Nº INFORME: 26315-2. Hoja 1 de 7<br />

www.cidemco.es<br />

cidemco@cidemco.es<br />

CLIENTE:<br />

SOLICITANTE:<br />

DIRECCIÓN:<br />

INFORME DE ENSAYO<br />

SEALED AIR PACKAGING, S.L.<br />

MANEL PEÑARROYA<br />

HOSTAL DEL PI, 16 POL. IND. BARCELONÉS<br />

08630 ABRERA (SPAIN)<br />

CIDEMCO-Tecnalia<br />

Área Anardi, nº 5<br />

Apartado 134 P.O. Box<br />

E-20730 Azpeitia (Guipúzcoa) / Spain<br />

Tel.: +34 943 81 68 00<br />

Fax: +34 943 81 60 74<br />

www.cidemco.es<br />

cidemco@cidemco.es<br />

CLIENT:<br />

TEST REPORT<br />

SEALED AIR PACKAGING, S.L.<br />

Razón Social: Fundación Cidemco • Nº F-231 Registro de Fundaciones Vasco • CIF: G20971214<br />

MATERIAL ENSAYADO: AISLANTE REFLEXIVO<br />

APPLICANT: MANEL PEÑARROYA<br />

REF. «REFLECTIX®DB+ (DOUBLE BUBBLE<br />

PLUS)»<br />

ADDRESS: HOSTAL DEL PI, 16 POL. IND. BARCELONÉS<br />

08630 ABRERA (SPAIN)<br />

OBJETO DE LA PETICIÓN: ENSAYO DE RESISTENCIA TÉRMICA<br />

(UNE-EN ISO 8990:1997)<br />

MATERIAL TESTED:<br />

REFLECTIVE INSULATION<br />

FECHA DE RECEPCIÓN:<br />

30.09.2010<br />

REF. "REFLECTIX®DB+ (DOUBLE BUBBLE<br />

FECHA DE INICIO DEL ENSAYO:<br />

27.10.2010<br />

PLUS)"<br />

FECHA DE FINALIZACIÓN DEL ENSAYO: 27.10.2010<br />

FECHA DE EMISIÓN DEL INFORME: 03.11.2010<br />

PURPOSE OF THE REQUEST: THERMAL RESISTANCE TEST<br />

(UNE-EN ISO 8990:1997)<br />

Los resultados recogidos en este informe solo se refieren al material recibido y sometido a<br />

ensayo en este Centro de Investigación en las fechas indicadas.<br />

DATE OF RECEIPT:<br />

30.09.2010<br />

Este Informe consta de siete (7) páginas y no podrá ser reproducido sin la autorización<br />

DATE OF TEST COMMENCEMENT: 27.10.2010<br />

expresa de CIDEMCO, excepto cuando lo sea de forma íntegra.<br />

DATE OF TEST COMPLETION:<br />

27.10.2010<br />

DATE OF ISSUE OF REPORT:<br />

03.11.2010<br />

The results compiled in this report refer only to the material received and submitted to<br />

testing at this Research Centre on the dates indicated.<br />

Company Name: Fundación Cidemco • Nº F-231 Registro de Fundaciones Vasco • CIF: G20971214<br />

This report consists of seven (7) pages and may not be reproduced without the express<br />

Nerea Berra<br />

Sergio Saiz<br />

authorisation of CIDEMCO, unless when done so in full.<br />

Eficiencia Energética en la Edificación<br />

Resp. Eficiencia Energética en la Edificación<br />

Arquitectura y Tecnologías para la Construcción<br />

Arquitectura y Tecnologías para la Construcción<br />

Nerea Berra<br />

Energy Efficiency in Building Manager<br />

Architecture and Construction Technology<br />

Sergio Saiz<br />

Energy Efficiency in Building Manager<br />

Architecture and Construction Technology

Creating World Class <strong>Packaging</strong> Solutions<br />

AirCap ®<br />

Barrier-sealed bubble packaging<br />

Pack Tiger ®<br />

Paper packaging system<br />

Cell-Aire ®<br />

Polyethylene Foam<br />

Instapak ®<br />

Foam-in-place<br />

Fill-Air ®<br />

Inflatable <strong>Packaging</strong> system<br />

Korrvu ®<br />

Suspension packaging<br />

NewAir I.B. ®<br />

On-site air cushioning system<br />

PriorityPak ®<br />

Automated packaging system<br />

Instapak ® Quick<br />

Quick foam-in-place<br />

Sealed Air has identified the opportunity whilst improving our business to make a<br />

positive difference in the world by increasing our commitment to sustainable packaging.<br />

Sustainable packaging, which makes efficient use of natural resources and minimises<br />

the impact on the environment, can include many forms of packaging. Improving<br />

the sustainability of our offering can come by reducing packaging via thinner, lighter<br />

products, removing packaging via new package designs, recycling packaging to reduce<br />

waste going to landfills and redesigning packaging using materials <strong>from</strong> bio-based<br />

sources. Sealed Air is working closely with key customers in target applications to<br />

advance environmentally friendly, innovative packaging solutions.<br />

Distributed by:<br />

RFX-GB-02-11<br />

Our <strong>Protective</strong> Products <strong>Packaging</strong><br />

Protect Your Products ®<br />

Telford Way, Kettering NN16 8UN<br />

United Kingdom<br />

+44 1536 315700 Fax: +44 1536 410576<br />

Email: PPDeuromktg@sealedair.com<br />

www.sealedair-emea.com<br />

Our Products Protect Your Products ®<br />

Corporate office: Sealed Air Corporation,<br />

200 Riverfront Boulevard, Elmwood Park, NJ 07407, USA<br />

www.sealedair.com<br />

Sealed Air has companies throughout the world.<br />

© Sealed Air Corporation 2011. All rights reserved.<br />

Printed on recycled and<br />

recyclable paper.