Technical Data Sheet - Den Braven

Technical Data Sheet - Den Braven

Technical Data Sheet - Den Braven

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

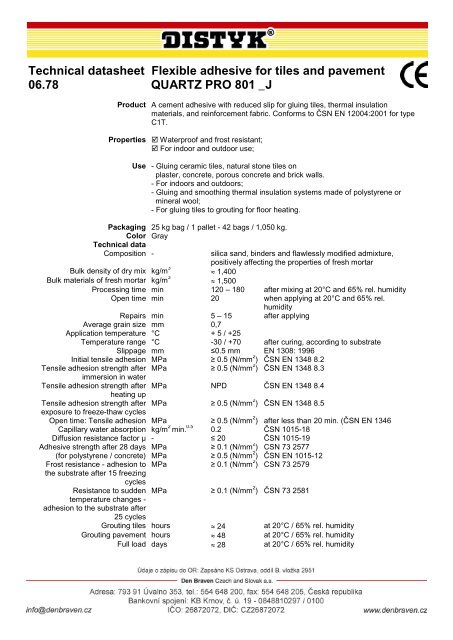

<strong>Technical</strong> datasheet Flexible adhesive for tiles and pavement<br />

06.78 QUARTZ PRO 801 _J<br />

Product A cement adhesive with reduced slip for gluing tiles, thermal insulation<br />

materials, and reinforcement fabric. Conforms to ČSN EN 12004:2001 for type<br />

C1T.<br />

Properties Waterproof and frost resistant;<br />

For indoor and outdoor use;<br />

Use - Gluing ceramic tiles, natural stone tiles on<br />

plaster, concrete, porous concrete and brick walls.<br />

- For indoors and outdoors;<br />

- Gluing and smoothing thermal insulation systems made of polystyrene or<br />

mineral wool;<br />

- For gluing tiles to grouting for floor heating.<br />

Packaging 25 kg bag / 1 pallet - 42 bags / 1,050 kg.<br />

Color Gray<br />

<strong>Technical</strong> data<br />

Composition -<br />

silica sand, binders and flawlessly modified admixture,<br />

positively affecting the properties of fresh mortar<br />

Bulk density of dry mix kg/m 3 ≈ 1,400<br />

Bulk materials of fresh mortar kg/m 3 ≈ 1,500<br />

Processing time min 120 – 180 after mixing at 20°C and 65% rel. humidity<br />

Open time min 20 when applying at 20°C and 65% rel.<br />

humidity<br />

Repairs min 5 – 15 after applying<br />

Average grain size mm 0,7<br />

Application temperature °C + 5 / +25<br />

Temperature range °C -30 / +70 after curing, according to substrate<br />

Slippage mm ≤0.5 mm EN 1308: 1996<br />

Initial tensile adhesion MPa ≥ 0.5 (N/mm 2 ) ČSN EN 1348 8.2<br />

Tensile adhesion strength after MPa ≥ 0.5 (N/mm 2 ) ČSN EN 1348 8.3<br />

immersion in water<br />

Tensile adhesion strength after MPa NPD ČSN EN 1348 8.4<br />

heating up<br />

Tensile adhesion strength after MPa ≥ 0.5 (N/mm 2 ) ČSN EN 1348 8.5<br />

exposure to freeze-thaw cycles<br />

Open time: Tensile adhesion MPa ≥ 0.5 (N/mm 2 ) after less than 20 min. (ČSN EN 1346<br />

Capillary water absorption kg/m 2 min. 0.5 0.2 ČSN 1015-18<br />

Diffusion resistance factor μ - ≤ 20 ČSN 1015-19<br />

Adhesive strength after 28 days<br />

(for polystyrene / concrete)<br />

Frost resistance - adhesion to<br />

the substrate after 15 freezing<br />

cycles<br />

Resistance to sudden<br />

temperature changes -<br />

adhesion to the substrate after<br />

25 cycles<br />

MPa<br />

MPa<br />

≥ 0.1 (N/mm 2 )<br />

≥ 0.5 (N/mm 2 )<br />

CSN 73 2577<br />

ČSN EN 1015-12<br />

MPa ≥ 0.1 (N/mm 2 ) CSN 73 2579<br />

MPa ≥ 0.1 (N/mm 2 ) ČSN 73 2581<br />

Grouting tiles hours ≈ 24 at 20°C / 65% rel. humidity<br />

Grouting pavement hours ≈ 48 at 20°C / 65% rel. humidity<br />

Full load days ≈ 28 at 20°C / 65% rel. humidity

<strong>Technical</strong> datasheet Flexible adhesive for tiles and pavement<br />

06.78 QUARTZ PRO 801 _J<br />

Consumption of water liters ≈ 6.0 – 7.0 25 kg of adhesive<br />

Consumption of adhesive kg/m 2 1.6 – 2.4 gluing a mosaic<br />

kg/m 2 2.4 – 3.4 tile adhesive<br />

kg/m 2 3.6 – 4.5 gluing coarse ceramic<br />

kg/m 2 ≈ 3.0 gluing 3 mm thick insulation material.<br />

kg/m 2 ≈ 4.0 smoothing reinforcing grid<br />

Limitations Do not use when temperatures are below +5°C (air and surface) and frost is<br />

expected. It is not suitable for gluing in direct sunlight – protect from rapid<br />

drying. Not suitable for metal, plastic materials and wood-based materials. Not<br />

suitable for sticking tiles to heated floors with rapid increases in temperature<br />

(electric matting). Do not use on lime plaster, paint coatings, wood and old<br />

tiles.<br />

It cannot be used for gluing tiles made of high-absorbent materials like slate<br />

and marble, etc.<br />

Surface preparation: The substrate must be solid and loadbearing, mature enough, free of any<br />

efflorescence, dirt, dust, oil, grease, wax, paint residues and other materials<br />

that can reduce adhesion and the adhesion of the mix to the substrate. The<br />

substrate must be uniformly porous and must not be frozen. If the surface is<br />

very absorbent, we recommend using primer S2802A or S-T70; otherwise it<br />

will significantly reduce the open time of the applied adhesive and reduce the<br />

adhesive bonding. Not suitable for use on surfaces made out of wood, metal<br />

and plastic!<br />

Mixing the adhesive mortar: Use potable water or water complying with ČSN EN 1008 for preparation.<br />

Thoroughly mix the dry matter with water in a quantity of 6.0 to 7.5 liters to 25<br />

kg of the mix until a smooth, homogeneous mixture is reached and let stand<br />

for 5 minutes. Do not allow the formation of lumps. Then mix thoroughly again.<br />

For mixing, it is recommended using a drill with an adapter (stirrer) at low<br />

speed (500 rpm). The prepared material can be used for 2-3 hours.<br />

Using the adhesive mortar: Apply a thin layer across the entire surface of the substrate using the smooth<br />

side of the trowel. Then using the notched side, apply a “combed” coating by<br />

contacting the surface with the teeth of the trowel. The contact area between<br />

the component and the substrate indoors must be more than 65% and<br />

outdoors more than 90%. The tiles or pavement are then placed onto the<br />

prepared substrate and pressed at the same time. The maximum thickness of<br />

the applied layer is 5 mm. ATTENTION, do not pre-moisten the tiles or<br />

pavement!<br />

The period during which the tiles or pavement can be placed (open time) is<br />

about 20 minutes. This time is usually shortened during conditions of extreme<br />

heat. It is best to try the gluing mortar with your fingertips to see if it does not<br />

create a non-sticking crust. If the mortar is defective, the entire non-sticking<br />

layer needs to be scraped away and a new adhesive layer reapplied to the<br />

cleaned surface. Wait at least 24 hours before grouting wall tile; other tiles can<br />

be grouted after two days at the earliest and can come under load after seven<br />

days. When gluing tiles outdoors (frost-resistant, sintered, or designated<br />

otherwise), we recommend applying a thin layer of glue to the paving tile<br />

using the smooth side of the trowel. Then apply a thicker layer of adhesive<br />

mortar on the substrate using the smooth side of the trowel and then comb it<br />

with the notched side with the teeth a minimum of 6x6 mm.

<strong>Technical</strong> datasheet Flexible adhesive for tiles and pavement<br />

06.78 QUARTZ PRO 801 _J<br />

Note: Tiles with highly compact shards and a maximum absorption rate of<br />

0.5% are considered frost-resistant. Their surface can be smooth, polished,<br />

satinato, embossed, imitative natural stone tiles, etc. These types are suitable<br />

not only for indoors, but mainly outdoors.<br />

Gluing thermal insulation<br />

materials:<br />

Styrofoam plates and mats made of mineral wool are placed in unison without<br />

filling in the gaps. For surfaces with an unevenness of greater than ±4 mm,<br />

the sealing compound should be applied to the insulation material in a<br />

thickness of up to 2 cm around the edges and in 2-3 places on the inside in<br />

the same thickness. At least 40% of the plate must represent the contact<br />

surface after sticking. For surfaces with an unevenness of less than ±4 mm,<br />

the sealing compound is applied to the insulation material with a notched<br />

trowel with tooth size up to 10 mm.<br />

Wait at least 24 hours before anchoring the glued plates. The façade can be<br />

smoothed after 1-2 days.<br />

Gritting insulating materials: You can then proceed to strengthening and reinforcing the insulation material<br />

with an embedded fiberglass mesh (gauze). This procedure should be<br />

performed in two steps: applying the glue and pressing the reinforcing fabric<br />

into the fresh layer. Place the gauze with an overlap of at least 10 cm. Add an<br />

extra reinforcement layer in corners and around jambs and set corner slats in<br />

place. Level and smooth the surface. The final thickness of the reinforcing<br />

material is about 4-5 mm. The reinforcement layer hardens in approximately<br />

48 – 72 hours, after which it can be sanded and a leveling layer applied.<br />

Note: It is necessary to sand façade plates made of EPS again if the<br />

reinforcing layer is laid more than 14 days after gluing the insulation material.<br />

Precautions Adding additional aggregates, binders and additives to the ready mix or sifting<br />

it is not permitted.<br />

Immediately clean any possible contamination of aluminum and anodized<br />

finishing edges, otherwise a permanent stain may occur. If gluing tiles without<br />

surface treatment (enamel), such as natural stone like slate, sandstone and<br />

other material with surfaces that are difficult to clean, take the added<br />

precaution of not staining them during placement. It is very difficult to remove<br />

cement glue from the surface, and then only by machine.<br />

The manufacturer is not liable for damages caused by the misuse of the<br />

product.<br />

Cleaning Material: water immediately<br />

Hands: water and soap, hand cream regeneration.<br />

Safety See «Safety <strong>Data</strong> <strong>Sheet</strong>».<br />

Updates Updated: January 23, 2011 Prepared: March 12, 2010<br />

The product is in conformity with the warranty specifications. This information is based on objective testing and<br />

our experience. Under no circumstances are we liable beyond the framework of this information, which is the<br />

result of our testing and experience. These are, however, general properties with no guarantee. Each user is<br />

required to check the suitability with his own testing.