Hawkes Bay Winegrowers Booklet

Hawkes Bay Winegrowers Booklet

Hawkes Bay Winegrowers Booklet

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Minimising spray applications<br />

The average number of spray passes applied at Gimblett<br />

Road across all varieties in 2008/09 was just 6.5 applications.<br />

Some blocks, including Sauvignon Blanc, Cabernet Franc<br />

and Cabernet Sauvignon received just 5 applications. The<br />

maximum number of spray passes was 8, for one block of<br />

Merlot and Syrah.<br />

While this may not be typical of every season, every spray<br />

application uses over 100 litres of fuel, so fewer passes<br />

means less fuel consumption and lower costs, in addition to<br />

the savings from using less spray products. The table below<br />

calculates the savings at Gimblett Road in 2008/09 as a result<br />

of using just 6.5 applications.<br />

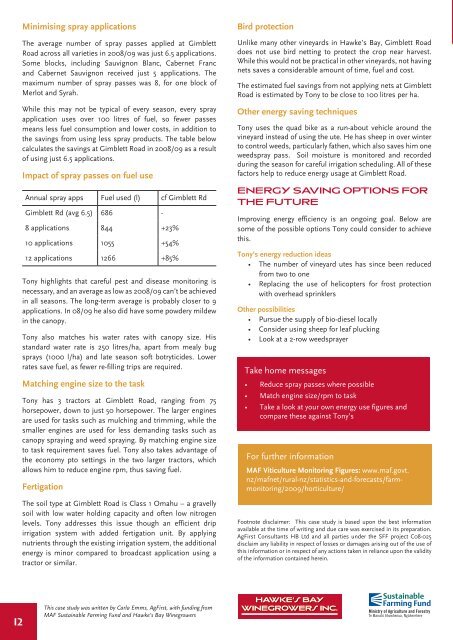

Impact of spray passes on fuel use<br />

Annual spray apps Fuel used (l) cf Gimblett Rd<br />

Gimblett Rd (avg 6.5) 686 -<br />

8 applications 844 +23%<br />

10 applications 1055 +54%<br />

12 applications 1266 +85%<br />

Tony highlights that careful pest and disease monitoring is<br />

necessary, and an average as low as 2008/09 can’t be achieved<br />

in all seasons. The long-term average is probably closer to 9<br />

applications. In 08/09 he also did have some powdery mildew<br />

in the canopy.<br />

Tony also matches his water rates with canopy size. His<br />

standard water rate is 250 litres/ha, apart from mealy bug<br />

sprays (1000 l/ha) and late season soft botryticides. Lower<br />

rates save fuel, as fewer re-filling trips are required.<br />

Matching engine size to the task<br />

Tony has 3 tractors at Gimblett Road, ranging from 75<br />

horsepower, down to just 50 horsepower. The larger engines<br />

are used for tasks such as mulching and trimming, while the<br />

smaller engines are used for less demanding tasks such as<br />

canopy spraying and weed spraying. By matching engine size<br />

to task requirement saves fuel. Tony also takes advantage of<br />

the economy pto settings in the two larger tractors, which<br />

allows him to reduce engine rpm, thus saving fuel.<br />

Fertigation<br />

The soil type at Gimblett Road is Class 1 Omahu – a gravelly<br />

soil with low water holding capacity and often low nitrogen<br />

levels. Tony addresses this issue though an efficient drip<br />

irrigation system with added fertigation unit. By applying<br />

nutrients through the existing irrigation system, the additional<br />

energy is minor compared to broadcast application using a<br />

tractor or similar.<br />

Bird protection<br />

Unlike many other vineyards in Hawke’s <strong>Bay</strong>, Gimblett Road<br />

does not use bird netting to protect the crop near harvest.<br />

While this would not be practical in other vineyards, not having<br />

nets saves a considerable amount of time, fuel and cost.<br />

The estimated fuel savings from not applying nets at Gimblett<br />

Road is estimated by Tony to be close to 100 litres per ha.<br />

Other energy saving techniques<br />

Tony uses the quad bike as a run-about vehicle around the<br />

vineyard instead of using the ute. He has sheep in over winter<br />

to control weeds, particularly fathen, which also saves him one<br />

weedspray pass. Soil moisture is monitored and recorded<br />

during the season for careful irrigation scheduling. All of these<br />

factors help to reduce energy usage at Gimblett Road.<br />

ENERGY SAVING OPTIONS FOR<br />

THE FUTURE<br />

Improving energy efficiency is an ongoing goal. Below are<br />

some of the possible options Tony could consider to achieve<br />

this.<br />

Tony’s energy reduction ideas<br />

• The number of vineyard utes has since been reduced<br />

from two to one<br />

• Replacing the use of helicopters for frost protection<br />

with overhead sprinklers<br />

Other possibilities<br />

• Pursue the supply of bio-diesel locally<br />

• Consider using sheep for leaf plucking<br />

• Look at a 2-row weedsprayer<br />

Take home messages<br />

• Reduce spray passes where possible<br />

• Match engine size/rpm to task<br />

• Take a look at your own energy use figures and<br />

compare these against Tony’s<br />

For further information<br />

MAF Viticulture Monitoring Figures: www.maf.govt.<br />

nz/mafnet/rural-nz/statistics-and-forecasts/farmmonitoring/2009/horticulture/<br />

Footnote disclaimer: This case study is based upon the best information<br />

available at the time of writing and due care was exercised in its preparation.<br />

AgFirst Consultants HB Ltd and all parties under the SFF project C08-025<br />

disclaim any liability in respect of losses or damages arising out of the use of<br />

this information or in respect of any actions taken in reliance upon the validity<br />

of the information contained herein.<br />

16 12<br />

This case study was written by Carla Emms, AgFirst, with funding from<br />

MAF Sustainable Farming Fund and Hawke’s <strong>Bay</strong> <strong>Winegrowers</strong><br />

HAWKE’S BAY<br />

WINEGROWERS INC.