Servo-Pusher Type 2157 - Heye International

Servo-Pusher Type 2157 - Heye International

Servo-Pusher Type 2157 - Heye International

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

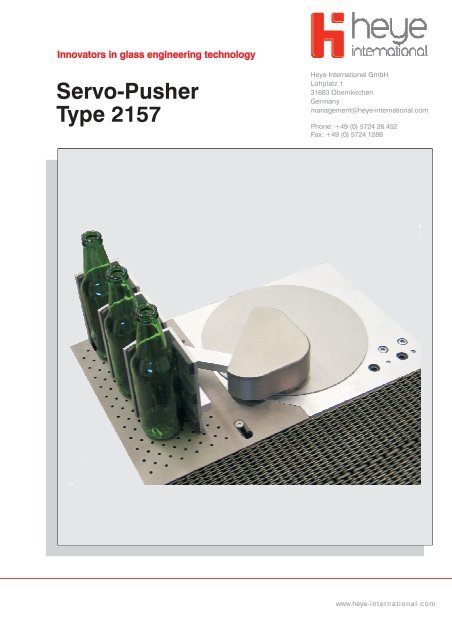

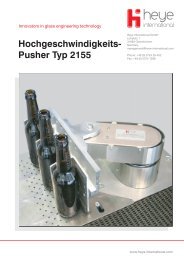

Innovators in glass engineering technology<br />

<strong>Servo</strong>-<strong>Pusher</strong><br />

<strong>Type</strong> <strong>2157</strong><br />

<strong>Heye</strong> <strong>International</strong> GmbH<br />

Lohplatz 1<br />

31683 Obernkirchen<br />

Germany<br />

management@heye-international.com<br />

Phone: +49 (0) 5724 26 452<br />

Fax: +49 (0) 5724 1288<br />

www.heye-international.com

The <strong>Servo</strong> <strong>Pusher</strong> <strong>Type</strong> <strong>2157</strong> is part of the <strong>Heye</strong> Modular <strong>Servo</strong> Technology.<br />

This <strong>Pusher</strong> is used at IS-Machines with up to 24 sections - preferably in double gob operation.<br />

The design principle fulfills highest operational safety. There is no risk of squeeze and cut.<br />

The <strong>Pusher</strong> has a very low weight as it only consists of few components. Hence, mounting and<br />

demounting is simple and safe.<br />

As the <strong>Pusher</strong> is operated without any pneumatic means to increase the speed there is no risk of<br />

article deformation by compressed air or vacuum.<br />

By the modular design both right-hand and left-hand operation of the <strong>Pusher</strong> is possible.<br />

This minimizes the spare parts stocking.<br />

Instead of the air cylinder used so far the <strong>Pusher</strong> is now driven by two independently operating<br />

servo motors. The directly driven axes only need few operating elements. This reduces the<br />

servicing considerably and simplifies repairs.

Motion Profile of the <strong>Pusher</strong><br />

Compared with air cylinders the advantage is that the push-out and retract motion of the pusher<br />

fingers is carried out controlled and absolutely reproducible.<br />

Advantages of the system<br />

- Compact and flexible.<br />

- Service reduced operation, minimum wear, long lifetime.<br />

- Simple operation. Parameter setting via dialogue even during run.<br />

- Motion and speed profiles can be adapted to the article geometry and transport speed even<br />

during run.<br />

- To support the bottle transport compressed air and vacuum is not needed. Accordingly the<br />

articles will not be deformed.<br />

- Minimization of danger spots as all driving parts are arranged below the machine conveyor<br />

level.<br />

- Exchangeability of components in a section without stopping the entire system.<br />

- Quick and simple exchange of the entire finger arm.<br />

- Robust and solid pusher fingers made of stainless steel (”soft touch” plating on request).<br />

- No active electronics in the machine area.<br />

- In case of failures the pusher always returns to its home position. This avoids that the pusher<br />

stops in the article stream. Thus, no blockages on the machine conveyor.<br />

- Automatic restart of the <strong>Pusher</strong> after a blockage.<br />

- Switching output available to switch the gob off or to stop the section if the <strong>Pusher</strong> completely<br />

failed.<br />

- Coupling with any IS E-Timing possible.<br />

- Also available for TG applications.<br />

Technical Data<br />

Machine conveyor speed : up to 70 m/min<br />

Weight of the unit : approx. 30 kg<br />

Dimensions of the<br />

unit (width x height x depth) : 294 x 400 x 270 mm<br />

Ambient temperature for the<br />

control cabinet : max. 35°C<br />

Dimensions of the<br />

control cabinet (width x height x depth) : 800 x 2200 x 600 mm

<strong>Heye</strong> Modular <strong>Servo</strong> Technology (HMST)<br />

The HMST is a trend-setting drive concept to control servo drives in the IS-Machine and their periphery.<br />

The modular system design allows a system-specific solution including the option to be upgraded.<br />

The standard system consists of :<br />

- an infeed cabinet and a module cabinet,<br />

- a PC with process visualisation and the option to link all <strong>Heye</strong> Hot End Drives.<br />

HMST Main Menu<br />

You can reach the menu level of a section or of a peripheral device by clicking on the relevant display in the<br />

main menu.<br />

Menu of a Machine Section<br />

The menus of the individual servo mechanisms can be opened by clicking on the corresponding display.<br />

Advantages of the process visualization<br />

- High availability by an independently operating visualization and real time control.<br />

- Easy access on all parameters.<br />

- Article administration for all process parameters allows short job change times.<br />

- Error report for all systems connected.<br />

- Option to link all <strong>Heye</strong> Hot End Equipments via CAN-Bus / Ethernet makes the entire system<br />

easy-to-follow.<br />

- Use of Windows XP / Windows 2000 as operating system on a standard PC<br />

Beh/1008