Using Sonic Drilling Technology in Challenging ... - Sonic Drilling Ltd.

Using Sonic Drilling Technology in Challenging ... - Sonic Drilling Ltd.

Using Sonic Drilling Technology in Challenging ... - Sonic Drilling Ltd.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Us<strong>in</strong>g</strong> <strong>Sonic</strong> <strong>Drill<strong>in</strong>g</strong><br />

<strong>Technology</strong> <strong>in</strong><br />

Challeng<strong>in</strong>g<br />

Conditions<br />

www.sonic-drill.com<br />

www.sonicdrill<strong>in</strong>g.com

A Brief History of <strong>Sonic</strong> <strong>Drill<strong>in</strong>g</strong><br />

First wave<br />

transmission rock<br />

drill (1913)<br />

The concept of sonic drill<strong>in</strong>g technology was born nearly 100 years ago when<br />

Romanian civil eng<strong>in</strong>eer George Constant<strong>in</strong>esco wrote a treatise for the British<br />

Admiralty called the Theory of <strong>Sonic</strong>s.<br />

www.sonic-drill.com<br />

www.sonicdrill<strong>in</strong>g.com

A Brief History of <strong>Sonic</strong> <strong>Drill<strong>in</strong>g</strong><br />

In May 1918, the<br />

British Admiralty<br />

decided to back<br />

sonic research by<br />

establish<strong>in</strong>g a<br />

new research<br />

facility, built <strong>in</strong><br />

England, to meet<br />

Constant<strong>in</strong>esco’s<br />

specifications.<br />

<strong>Sonic</strong> Works facility at West Drayton, England.<br />

www.sonic-drill.com<br />

www.sonicdrill<strong>in</strong>g.com

A Brief History of <strong>Sonic</strong> <strong>Drill<strong>in</strong>g</strong><br />

<strong>Sonic</strong> fuel <strong>in</strong>jection for diesel eng<strong>in</strong>es.<br />

Silent sonic gun us<strong>in</strong>g compressed liquid and<br />

an explosive charge.<br />

Dur<strong>in</strong>g the next few years, a number of research projects were developed for wartime<br />

use. Unfortunately, when WW I ended, so did sonic research and the facility was<br />

dismantled.<br />

www.sonic-drill.com<br />

www.sonicdrill<strong>in</strong>g.com

A Brief History of <strong>Sonic</strong> <strong>Drill<strong>in</strong>g</strong><br />

In 1930, another<br />

Romanian eng<strong>in</strong>eer,<br />

Dr. Ion Basgan applied<br />

sonic vibrations to the<br />

drill pipe str<strong>in</strong>g of a<br />

conventional drill<strong>in</strong>g<br />

rig.<br />

Amaz<strong>in</strong>gly, the result<br />

was <strong>in</strong>creased drill<br />

depth and speed.<br />

Basgan’s sonic drill was used <strong>in</strong> the Moreni oil fields <strong>in</strong> 1938.<br />

www.sonic-drill.com<br />

www.sonicdrill<strong>in</strong>g.com

A Brief History of <strong>Sonic</strong> <strong>Drill<strong>in</strong>g</strong><br />

The United States took up the torch of<br />

sonic research dur<strong>in</strong>g the 1940’s through<br />

the efforts of the <strong>Drill<strong>in</strong>g</strong> Research<br />

Institute (DRI) which <strong>in</strong>cluded American<br />

<strong>in</strong>ventor Albert Bod<strong>in</strong>e, supported by the<br />

Shell Oil company.<br />

Eventually, Bod<strong>in</strong>e sold his sonic<br />

equipment <strong>in</strong> the early 1970’s to the<br />

British aerospace company, Hawker-<br />

Siddeley, who assigned the next<br />

generation of research to one of its<br />

Canadian offices.<br />

Albert Bod<strong>in</strong>e’s sonic earth<br />

bor<strong>in</strong>g drill (1964)<br />

www.sonic-drill.com<br />

www.sonicdrill<strong>in</strong>g.com

A Brief History of <strong>Sonic</strong> <strong>Drill<strong>in</strong>g</strong><br />

One of the first persons hired for the<br />

Hawker Siddeley design team was a<br />

young mechanical eng<strong>in</strong>eer named Ray<br />

Roussy.<br />

In 1980, when the sonic project was<br />

abandoned dur<strong>in</strong>g a recession, Ray<br />

Roussy left Hawker Siddeley to cont<strong>in</strong>ue<br />

development work on the sonic drill<br />

head.<br />

In a recent photo, Ray Roussy stands with<br />

his v<strong>in</strong>tage Navion aircraft.<br />

www.sonic-drill.com<br />

www.sonicdrill<strong>in</strong>g.com

A Brief History of <strong>Sonic</strong> <strong>Drill<strong>in</strong>g</strong><br />

After years of research and<br />

field-test<strong>in</strong>g, Roussy’s<br />

persistence resulted <strong>in</strong> a<br />

number of patents and <strong>in</strong> the<br />

successful commercialization of<br />

a revolutionary new drill<strong>in</strong>g<br />

technology.<br />

Roussy’s first commercial sonic drill rig (seen above) is still<br />

<strong>in</strong> active use today despite be<strong>in</strong>g more than 26 years old.<br />

Recently, Roussy’s sonic drill<strong>in</strong>g<br />

system won a prestigious award<br />

for “best new drill<strong>in</strong>g<br />

technology” from the Canadian<br />

federal government and the<br />

Canadian GeoExchange<br />

Coalition.<br />

www.sonic-drill.com<br />

www.sonicdrill<strong>in</strong>g.com

How <strong>Sonic</strong> <strong>Drill<strong>in</strong>g</strong> Works<br />

• The drill pipe physically vibrates up and<br />

down, <strong>in</strong> addition to be<strong>in</strong>g pushed down<br />

and rotated.<br />

• The energy produced by the drill head<br />

liquefies overburden and bedrock and<br />

pushes the material up and away.<br />

• Water or compressed air is used to flush<br />

the “cutt<strong>in</strong>gs” up to the surface. If water is<br />

used, it is then screened for particles,<br />

recycled then re-used as drill<strong>in</strong>g progresses.<br />

• Depend<strong>in</strong>g on the soil conditions<br />

encountered, the drill rig operator is able to<br />

adjust the sonic frequency to suit the<br />

terra<strong>in</strong>, allow<strong>in</strong>g penetration rates 3-5<br />

times greater than conventional drill<strong>in</strong>g.<br />

www.sonic-drill.com<br />

www.sonicdrill<strong>in</strong>g.com

How <strong>Sonic</strong> <strong>Drill<strong>in</strong>g</strong> Works<br />

Today, this patented technology is only<br />

available on drill<strong>in</strong>g rigs built by the<br />

<strong>Sonic</strong> Drill Corporation.<br />

<strong>Sonic</strong> rigs:<br />

• Drill 3-5X faster than other rigs<br />

• Drill us<strong>in</strong>g only water or air.<br />

• Don’t require drill<strong>in</strong>g mud.<br />

• Produce 70% less mess on-site.<br />

• Reduce on-site clean up costs.<br />

• Drill to 300 ft. and beyond.<br />

• Produce cont<strong>in</strong>uous core samples.<br />

www.sonic-drill.com<br />

www.sonicdrill<strong>in</strong>g.com

<strong>Drill<strong>in</strong>g</strong> Green With <strong>Sonic</strong>: Environmental Benefits<br />

Compar<strong>in</strong>g a sonic rig, you'll also notice a big<br />

difference that makes this technology both "green"<br />

and cost-effective.<br />

• <strong>Sonic</strong> rigs, built by the <strong>Sonic</strong> Drill Corporation,<br />

use 50% less horsepower while still drill<strong>in</strong>g faster.<br />

This means that fuel consumption, on a hole to<br />

hole basis, is considerably less.<br />

• <strong>Sonic</strong> rig eng<strong>in</strong>es are physically smaller and<br />

lighter, further reduc<strong>in</strong>g fuel consumption when<br />

mov<strong>in</strong>g the rig around.<br />

• <strong>Sonic</strong> rig eng<strong>in</strong>es never exceed 1850 rpm, keep<strong>in</strong>g<br />

noise relatively low and the eng<strong>in</strong>e runn<strong>in</strong>g <strong>in</strong> an<br />

efficient rpm range.<br />

• <strong>Sonic</strong> rigs can use “green” hydraulic oil that will<br />

not harm the environment.<br />

www.sonic-drill.com<br />

www.sonicdrill<strong>in</strong>g.com

<strong>Drill<strong>in</strong>g</strong> Green With <strong>Sonic</strong>: Environmental Reclamation<br />

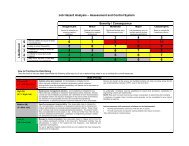

In an <strong>in</strong>dependent review, the United States Los Alamos National Laboratory’s Energy<br />

and Environmental Analysis Group conducted a study of sonic drill<strong>in</strong>g compared to cable<br />

and mud rotary drill<strong>in</strong>g. The review evaluated the cost of all three types of drill<strong>in</strong>g on a<br />

clean site, hazardous site and mixed waste site.<br />

Graph produced by Los Alamos National Laboratory’s Energy and Environmental Analysis Group.<br />

www.sonic-drill.com<br />

www.sonicdrill<strong>in</strong>g.com

<strong>Drill<strong>in</strong>g</strong> <strong>in</strong> Challeng<strong>in</strong>g<br />

Conditions<br />

• <strong>Sonic</strong> technology allows the operator to vary the<br />

frequency to suit specific soil conditions.<br />

• This allows the drill to cont<strong>in</strong>ue through mixed<br />

soils, where other drills would get stuck.<br />

• In holes with layers of sand, silt, clay, gravel and<br />

boulders, the sonic is able to buzz through without<br />

jamm<strong>in</strong>g.<br />

• The sonic drill rig can also be operated as a<br />

conventional drill rig, if desired.<br />

A recent geothermal drill<strong>in</strong>g project produced<br />

this boulder which the sonic drill easily<br />

“buzzed” through.<br />

• <strong>Sonic</strong> rigs are often called <strong>in</strong> as “rescue rigs” or<br />

specified <strong>in</strong> contracts for sensitive government<br />

projects.<br />

www.sonic-drill.com<br />

www.sonicdrill<strong>in</strong>g.com

<strong>Drill<strong>in</strong>g</strong> <strong>in</strong> Challeng<strong>in</strong>g Conditions<br />

• Another benefit of the technology is that<br />

vibrations from the drill bit are not transmitted<br />

very far beyond the drill.<br />

• This allows penetrations <strong>in</strong>to very sensitive areas<br />

such as critical eco-systems, unstable terra<strong>in</strong> or<br />

vulnerable situations where traditional drill<strong>in</strong>g<br />

would cause more harm or be impossible to<br />

complete.<br />

• <strong>Sonic</strong> rigs have been used (and specified <strong>in</strong><br />

government contracts) for sensitive projects such<br />

as dam remediation, nuclear site <strong>in</strong>vestigations and<br />

hazardous waste site reclamation.<br />

www.sonic-drill.com<br />

www.sonicdrill<strong>in</strong>g.com

Applications of <strong>Sonic</strong> <strong>Drill<strong>in</strong>g</strong> <strong>Technology</strong><br />

While there are unlimited<br />

applications, the top three uses for<br />

a sonic drill rig are:<br />

• Geothermal <strong>in</strong>stallations: The<br />

sonic can drill, case, loop and grout<br />

<strong>in</strong> one operation.<br />

• Environmental <strong>in</strong>vestigations: The<br />

speed at which a sonic drill operates<br />

allows any project to proceed<br />

quickly and profitably due to lower<br />

drill<strong>in</strong>g costs and reduced site cleanup<br />

costs.<br />

• M<strong>in</strong>eral explorations: The sonic can<br />

provide cont<strong>in</strong>uous core samples to<br />

300 ft.<br />

www.sonic-drill.com<br />

www.sonicdrill<strong>in</strong>g.com

A Battle Between Old and New <strong>Technology</strong> - Case #1<br />

Langara Community College<br />

A geothermal <strong>in</strong>stallation at Langara community college <strong>in</strong> Vancouver, Canada,<br />

became the sett<strong>in</strong>g for a duel between old and new technology.<br />

After encounter<strong>in</strong>g difficult soil conditions, the sonic was brought <strong>in</strong> as the<br />

“rescue rig” for the project. The numbers below expla<strong>in</strong> why.<br />

Conventional rig:<br />

• Three rigs on site<br />

• Two months drill<strong>in</strong>g<br />

• 18 holes <strong>in</strong>stalled<br />

<strong>Sonic</strong> rig:<br />

• One rig on site<br />

• Two weeks drill<strong>in</strong>g<br />

• 23 holes <strong>in</strong>stalled<br />

www.sonic-drill.com<br />

www.sonicdrill<strong>in</strong>g.com

A Battle Between Old and New <strong>Technology</strong> - Case #2<br />

University of British Columbia<br />

A conventional drill failed at drill<strong>in</strong>g a test hole for a geothermal feasibility study<br />

at the University of British Columbia. A sonic rig was brought <strong>in</strong> and completed<br />

the hole <strong>in</strong> two hours and 13 m<strong>in</strong>utes, despite drill<strong>in</strong>g through tough overburden.<br />

Conventional rig:<br />

• Failed on site.<br />

<strong>Sonic</strong> rig:<br />

• One rig on site<br />

• 300 ft. hole drilled<br />

through tough overburden<br />

<strong>in</strong> two hrs. and 13 m<strong>in</strong>utes.<br />

www.sonic-drill.com<br />

www.sonicdrill<strong>in</strong>g.com

A Battle Between Old and New <strong>Technology</strong> - Case #3<br />

Woodward Hill Elementary School<br />

Conventional rigs work<strong>in</strong>g on an extensive geothermal field, under a new<br />

elementary school soccer field, failed due to delays <strong>in</strong> drill<strong>in</strong>g through<br />

overburden. Two sonic rigs completed the project which called for 120 holes to a<br />

depth of 180 ft. each. The client reported that the sonic rigs drilled six times<br />

faster.<br />

Conventional rig:<br />

• Failed on site.<br />

<strong>Sonic</strong> rig:<br />

• Two sonic rigs used.<br />

• Made deadl<strong>in</strong>e by drill<strong>in</strong>g<br />

holes six times faster.<br />

www.sonic-drill.com<br />

www.sonicdrill<strong>in</strong>g.com

What Others Are Say<strong>in</strong>g<br />

“Basically, a sonic rig is capable of gett<strong>in</strong>g through th<strong>in</strong>gs that would take several<br />

other conventional methods to get through.”<br />

— Shane Hughes, Miller <strong>Drill<strong>in</strong>g</strong> Co. Inc., Tennessee, USA<br />

On one m<strong>in</strong>e expansion site, where we brought our sonic drill <strong>in</strong>, seven other<br />

companies had already tried and failed to produce the needed results.”<br />

— Daryl Karasch, Traut Wells Inc., M<strong>in</strong>nesota, USA<br />

“I have witnessed rapid drill<strong>in</strong>g through materials (dense sand and silts, with<br />

cobbles, boulders, and sandstone bedrock) that other more common methods<br />

would be hard-pressed to match.”<br />

— Ruben Arellano, P. Eng., LEED AP, HEMMERA Energy, Vancouver, BC,<br />

Canada<br />

www.sonic-drill.com<br />

www.sonicdrill<strong>in</strong>g.com

What Others Are Say<strong>in</strong>g<br />

“In my experience, <strong>Sonic</strong> has made geothermal drill<strong>in</strong>g and ground loop <strong>in</strong>sertion<br />

quick and easy. The speed of the drill<strong>in</strong>g is <strong>in</strong> my op<strong>in</strong>ion unchallenged.<br />

I watched <strong>Sonic</strong> drill 200 ft. <strong>in</strong> twenty-seven m<strong>in</strong>utes on a site <strong>in</strong> Burnaby.”<br />

— Chris Patterson, Paradigm Ground Loop Services <strong>Ltd</strong>., Vancouver, BC,<br />

Canada<br />

“The drill<strong>in</strong>g performance exceeds our expectations. We’ve drilled through 500<br />

gpm aquifers, dense till with 2 ft. diameter granite boulders and limestone/shale<br />

(at 4 ft. per m<strong>in</strong>ute).”<br />

— Brian Beatty, GeoEnergy Solutions Inc., Bolton, Ontario, Canada<br />

“I th<strong>in</strong>k what it comes down to is that the sonic drill really has a market all its<br />

own that no other rig can touch.”<br />

— Gary Whitesell, Crater Lake <strong>Drill<strong>in</strong>g</strong> <strong>Ltd</strong>., Red Deer, Alberta, Canada<br />

www.sonic-drill.com<br />

www.sonicdrill<strong>in</strong>g.com

What Others Are Say<strong>in</strong>g<br />

“The sonic drill is noth<strong>in</strong>g short of amaz<strong>in</strong>g <strong>in</strong> what it can do. My newest driller<br />

came from work<strong>in</strong>g on rotary drill<strong>in</strong>g rigs and was simply amazed at the<br />

capabilities of the sonic drill – its versatility and speed are second to none.”<br />

— Paul Catton, Virsare, Thornbury, Ontario, Canada<br />

“Geothermal is boom<strong>in</strong>g here and the sonic rig allows us to drill much faster and<br />

cheaper which keeps the per-foot costs of drill<strong>in</strong>g down. And, if we hit mixed<br />

soils, we don’t have to pull a conventional rig off and try to put someth<strong>in</strong>g else<br />

<strong>in</strong> there.”<br />

It’s a super mach<strong>in</strong>e and, for those people who have never seen one, they are<br />

very impressed.”<br />

— Rene Kroonen, Conex, Belgium<br />

www.sonic-drill.com<br />

www.sonicdrill<strong>in</strong>g.com

A Hundred Years <strong>in</strong> the Mak<strong>in</strong>g<br />

Despite tak<strong>in</strong>g nearly 100 years to perfect, sonic drill<strong>in</strong>g technology is now <strong>in</strong> use<br />

<strong>in</strong> countries all around the world <strong>in</strong>clud<strong>in</strong>g Japan, Africa, South America, Europe<br />

and, of course, North America.<br />

Today, sonic drill<strong>in</strong>g technology is robust,<br />

reliable and profitable.<br />

Across the planet, it is quickly becom<strong>in</strong>g the<br />

drill<strong>in</strong>g method of choice.<br />

Thank you for your <strong>in</strong>terest.<br />

May we answer any questions?<br />

In 2009, the <strong>Sonic</strong> Drill Corp. unveiled a new<br />

m<strong>in</strong>i-sonic drill rig, able to fit <strong>in</strong>side a 20’<br />

shipp<strong>in</strong>g conta<strong>in</strong>er.<br />

www.sonic-drill.com<br />

www.sonicdrill<strong>in</strong>g.com