Example: The beer game

Example: The beer game

Example: The beer game

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

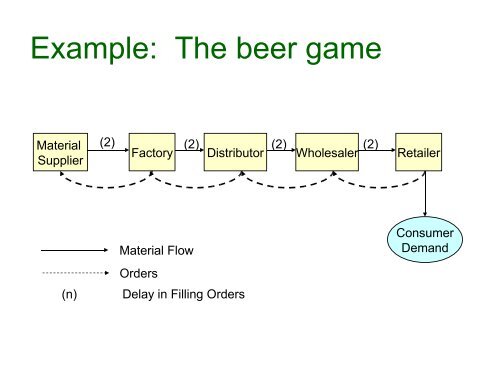

<strong>Example</strong>: <strong>The</strong> <strong>beer</strong> <strong>game</strong><br />

Material<br />

Supplier<br />

(2) (2) (2) (2)<br />

Factory Distributor Wholesaler Retailer<br />

(n)<br />

Material Flow<br />

Orders<br />

Delay in Filling Orders<br />

Consumer<br />

Demand

For each period<br />

• Fill the orders in the backlog file<br />

• Receive material from supplier<br />

• Place order with supplier<br />

• Receive order -- adjust the backlog

Operating cost penalties<br />

• <strong>The</strong>re are two operating costs:<br />

• 0.50 per unit inventory per period<br />

(this is the carrying cost)<br />

• 1.00 per unit unsatisfied demand<br />

(this is to ensure good service)

Variability<br />

Higher variability in orders placed by retailer than actual sales

Bullwhip effect<br />

Supplier<br />

Manufacturer<br />

Distributer/<br />

Wholesaler<br />

Retailer<br />

Consumer<br />

Sales<br />

Sales<br />

Sales<br />

Sales<br />

Sales<br />

Time<br />

Time<br />

Time<br />

Time<br />

Time<br />

Increase in variability as we move up in the supply chain.

What are the reasons?

Reasons<br />

• Demand Forecast Updating - each<br />

company in a supply chain forecasts<br />

demand myopically (i.e. based on past<br />

demand from their own direct<br />

customers)<br />

• Order Batching - companies placing<br />

orders on upstream suppliers usually do<br />

so periodically to save on<br />

transportation/ transaction costs.

Reasons continued<br />

• Price Fluctuation - frequent price changes<br />

(both up and down) lead buyers to purchase<br />

large quantities when prices are low and<br />

avoid buying when prices are high.<br />

• Rationing and Shortage Gaming - cyclical<br />

industries face alternating periods of<br />

oversupply and undersupply. When buyers<br />

know that a shortage is imminent and<br />

rationing will occur, they often increase the<br />

size of their orders (and vice-versa).

Multi-stage supply chains<br />

Consider a multi-stage supply chain:<br />

• Stage i places order q k to stage k+1.<br />

• L k<br />

is lead time between stage k and k+1.<br />

• Demand has mean D and standard deviation σ<br />

q o =D q 1 q 2<br />

Retailer<br />

Stage 1<br />

Manufacturer<br />

Stage 2<br />

L 1 L 2<br />

Supplier<br />

Stage 3

Variability as a function of stages<br />

Var(q k )/σ 2 σ 2<br />

30<br />

25<br />

k=5<br />

20<br />

15<br />

10<br />

5<br />

0<br />

k=3<br />

0 5 10 15 20 25

Impact of batch ordering<br />

• Why batch ordering?

Impact of batch ordering<br />

• Why batch ordering?<br />

• Fixed ordering costs<br />

• P&G estimates that the cost of placing an order with manual<br />

interventions is $35-$75<br />

• Transportation costs<br />

• Ordering FTL vs. LTL<br />

• Sales quotas or incentives<br />

• “push” ordering or “forward” buying<br />

• If the retailer uses batch ordering, the wholesaler will see<br />

spikes in orders in certain periods followed with no orders for<br />

several periods<br />

• A distorted and highly variable pattern of orders at the<br />

upstream channel

Variable pricing<br />

• Price fluctuations cause forward buying<br />

• Price/quantity discounts, Rebates, Trade deals<br />

• Customers buy in quantities that do not reflect their immediate needs<br />

• Variation of the buying quantities is larger than the variation of the<br />

consumption rate<br />

• Possible remedy: Everyday low pricing<br />

Order Quantity<br />

800<br />

600<br />

400<br />

200<br />

Bullwhip Effect due to Seasonal Sales of<br />

Soup<br />

Shipments from<br />

Manufacturer to<br />

Distributors<br />

Retailers’ Sales<br />

0<br />

1 Weeks<br />

52

Inflated orders (rationing <strong>game</strong>)<br />

• During shortage periods manufacturers allocate products to<br />

customers proportional to order size<br />

• e.g., if total supply is 50% of total orders, all customers receive<br />

50% of what they order<br />

• Inflated or duplicate orders during shortage periods<br />

• Returns and cancellations later<br />

• Customer orders give little info to the supplier<br />

• <strong>Example</strong>: Motorola cell phones<br />

• Shortage during Christmas season<br />

• Excess ordering in the following year, record 4th quarter earnings<br />

• Channels swamped with inventory, stock tumbled almost 10%<br />

• Possible remedy: allocation based on past sales

Information sharing<br />

• Demand (sales data, forecasts)<br />

• New stores<br />

• Promotions<br />

• Inventory levels, product quantities<br />

available for purchase<br />

• e.g., Sears, Okuma Corporation<br />

• Production and distribution schedules<br />

• more accurate lead times<br />

• Order status/tracking

Bypassing channels (common<br />

access to demand information)<br />

Traditional<br />

retailer<br />

Farm Importer Wholesaler Florist Customer<br />

8-12 days<br />

PUSH<br />

PULL<br />

Direct<br />

from farms<br />

Farm<br />

Proflowers.com<br />

Customer<br />

1-2 days<br />

PUSH<br />

PULL

Access to demand information<br />

in supply chains<br />

• Bypassing a downstream site in the supply chain<br />

• e.g., Dell Computers, Proflowers.com<br />

• Information sharing<br />

• <strong>The</strong> partners are given access to a system that has<br />

the shared information in it<br />

• e.g., Wal-Mart RetailLink system<br />

• One partner transmits shared information to the other<br />

partner<br />

• Shared information is stored in an “information hub”

Collaborative forecasting<br />

• Include multiple factors about future demand<br />

• past sales, pricing, promotions, new products<br />

• Who controls or has information about these<br />

factors?<br />

• E.g., retailer may control pricing, promotions,<br />

products from other competitors<br />

• Collaborative forecasting<br />

• an iterative forecasting process in which all<br />

participants in the supply chain collaborate to arrive at<br />

an agreed upon forecast<br />

• e.g., Wal-Mart and Warner-Lambert (CPFR)<br />

• eliminate 2 weeks of inventory; cut cycle times in half

Vendor Managed Inventory<br />

• Both parties must understand and agree<br />

the stocking plan the manufacturer will be<br />

using.<br />

• Frequency of replenishment (daily?<br />

once/twice per week?), replenishment<br />

quantity, etc.<br />

• <strong>The</strong> Distributor sends the manufacturer<br />

• POS history file, usually 1-2 years.<br />

• Information on the status and stock level of<br />

every item they have

Incentive Alignment<br />

• Incentive problems occur due to:<br />

• Hidden actions by partner firms<br />

• Informational asymmetries<br />

• Poorly designed incentive schemes

Hidden action example<br />

• Sears sells both Whirlpool and Kenmore<br />

(their private-label brand) washing<br />

machines<br />

• Whirlpool is relying of Sear’s salespeople<br />

• Whirlpool can’t easily track effort of<br />

salespeople pushing their brand compared<br />

to Kenmore<br />

• This hidden action makes it difficult for<br />

Whirlpool to determine proper incentives

Information asymmetries<br />

• Many partners are reluctant to share their<br />

data<br />

• Vendor for a manufacturer may be reluctant to<br />

share cost data<br />

• Company may be fearful to share certain<br />

design data with contract manufacturer<br />

• When there is hidden data in a supply<br />

chain, it can hurt efficiency

Poorly designed schemes<br />

• <strong>Example</strong>: Grocery store has a vendor<br />

managed inventory relationship with a<br />

dairy farm for milk<br />

• Store allocates shelf space for milk provider<br />

• Store pays provider at delivery<br />

• Provider has responsibility for stocking<br />

• Q: What will be the impact of this policy?<br />

• Q: What might eliminate this problem?

How to tackle incentive problem?<br />

• Acknowledge when this is a problem<br />

• Common with new initiatives since this can<br />

modify incentives of key stakeholders<br />

• Find the cause<br />

• Hidden action, hidden information, badly<br />

designed incentive<br />

• Redesign incentives<br />

• Contracting, revealing information,<br />

independent party (intermediaries)

1. Contracting<br />

• Most straight forward approach<br />

• Contracts can “unhide” actions<br />

• Blockbuster example<br />

• Q: What could be done with the Whirlpool/<br />

Sears case?<br />

• Difficulty – impossible to contract against<br />

all conditions

<strong>Example</strong> – Tweeter and Bryn Mawr<br />

• Bryn Mawr (acquired by Tweeter in 1996) seller<br />

of electronics<br />

• Bryn Mawr deducted full value of stolen goods<br />

from manager’s pay<br />

• Result – kept impulse-based purchases locked up<br />

(e.g., batteries, audiotapes, etc.)<br />

• Sacrificed sales for shrink reduction<br />

• Tweeter changed contract – paid managers<br />

based on % of profits, and profits increased<br />

significantly

2. Revealing hidden information<br />

• Tracking and monitoring<br />

• Use of agents to collect data (third party,<br />

spy) such as a “mystery shopper”

3. Intermediary<br />

• Has become more prevalent with<br />

outsourcing since contracts can be hard to<br />

enforce in certain countries<br />

• Fear of contractors engaging in behavior such<br />

as bribery, child labor, etc.<br />

• Intermediary can help align incentives<br />

between parties

Li & Fung example<br />

• Created a network of factories in Asia<br />

• Enforce a code of ethics for participation<br />

• Wage, hygienic work conditions, etc.<br />

• Monitors suppliers through use of chief<br />

compliance officer<br />

• Cuts companies off if make unreasonable<br />

demands of suppliers or don’t take delivery<br />

• <strong>The</strong>ir size helps them to do this and that they<br />

account for about half of volume for their<br />

suppliers

Conclusions<br />

• Incentives are key to supply chain<br />

performance<br />

• Although issues are challenging to<br />

address, companies should spend time<br />

studying this problem in their supply<br />

chains