Flowcoat 944 HB Sanitile® 944 HB Sanitile® 944 HB - Carboline

Flowcoat 944 HB Sanitile® 944 HB Sanitile® 944 HB - Carboline

Flowcoat 944 HB Sanitile® 944 HB Sanitile® 944 HB - Carboline

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

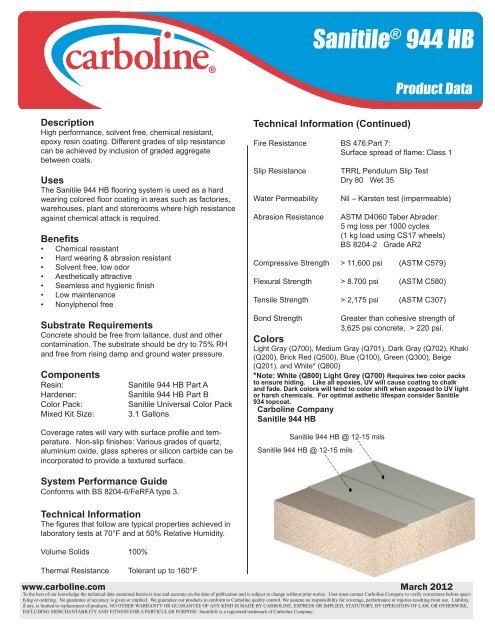

<strong>Flowcoat</strong> Sanitile ® <strong>944</strong> <strong>HB</strong><br />

Product Data<br />

Description<br />

High performance, solvent free, chemical resistant,<br />

epoxy resin coating. Different grades of slip resistance<br />

can be achieved by inclusion of graded aggregate<br />

between coats.<br />

Uses<br />

The Sanitile <strong>944</strong> <strong>HB</strong> flooring system is used as a hard<br />

wearing colored floor coating in areas such as factories,<br />

warehouses, plant and storerooms where high resistance<br />

against chemical attack is required.<br />

Benefits<br />

• Chemical resistant<br />

• Hard wearing & abrasion resistant<br />

• Solvent free, low odor<br />

• Aesthetically attractive<br />

• Seamless and hygienic finish<br />

• Low maintenance<br />

• Nonylphenol free<br />

Substrate Requirements<br />

Concrete should be free from laitance, dust and other<br />

contamination. The substrate should be dry to 75% RH<br />

and free from rising damp and ground water pressure.<br />

Components<br />

Resin:<br />

Hardener:<br />

Color Pack:<br />

Mixed Kit Size:<br />

Sanitile <strong>944</strong> <strong>HB</strong> Part A<br />

Sanitile <strong>944</strong> <strong>HB</strong> Part B<br />

Sanitile Universal Color Pack<br />

3.1 Gallons<br />

Coverage rates will vary with surface profile and temperature.<br />

Non-slip finishes: Various grades of quartz,<br />

aluminium oxide, glass spheres or silicon carbide can be<br />

incorporated to provide a textured surface.<br />

Technical Information (Continued)<br />

Fire Resistance BS 476:Part 7:<br />

Surface spread of flame: Class 1<br />

Slip Resistance<br />

Water Permeability<br />

Abrasion Resistance<br />

TRRL Pendulum Slip Test<br />

Dry 80 Wet 35<br />

Nil – Karsten test (impermeable)<br />

ASTM D4060 Taber Abrader:<br />

5 mg loss per 1000 cycles<br />

(1 kg load using CS17 wheels)<br />

BS 8204-2 Grade AR2<br />

Compressive Strength > 11,600 psi (ASTM C579)<br />

Flexural Strength > 8.700 psi (ASTM C580)<br />

Tensile Strength > 2,175 psi (ASTM C307)<br />

Bond Strength Greater than cohesive strength of<br />

3,625 psi concrete, > 220 psi.<br />

Colors<br />

Light Gray (Q700), Medium Gray (Q701), Dark Gray (Q702), Khaki<br />

(Q200), Brick Red (Q500), Blue (Q100), Green (Q300), Beige<br />

(Q201), and White* (Q800)<br />

*Note: White (Q800) Light Grey (Q700) Requires two color packs<br />

to ensure hiding. Like all epoxies, UV will cause coating to chalk<br />

and fade. Dark colors will tend to color shift when exposed to UV light<br />

or harsh chemicals. For optimal asthetic lifespan consider Sanitile<br />

934 topcoat.<br />

<strong>Carboline</strong> Company<br />

Sanitile <strong>944</strong> <strong>HB</strong><br />

Sanitile <strong>944</strong> <strong>HB</strong> @ 12-15 mils<br />

Sanitile <strong>944</strong> <strong>HB</strong> @ 12-15 mils<br />

System Performance Guide<br />

Conforms with BS 8204-6/FeRFA type 3.<br />

Technical Information<br />

The figures that follow are typical properties achieved in<br />

laboratory tests at 70°F and at 50% Relative Humidity.<br />

Volume Solids 100%<br />

Thermal Resistance Tolerant up to 160°F<br />

www.carboline.com March 2012<br />

To the best of our knowledge the technical data contained herein is true and accurate on the date of publication and is subject to change without prior notice. User must contact <strong>Carboline</strong> Company to verify correctness before specifying<br />

or ordering. No guarantee of accuracy is given or implied. We guarantee our products to conform to <strong>Carboline</strong> quality control. We assume no responsibility for coverage, performance or injuries resulting from use. Liability,<br />

if any, is limited to replacement of products. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY CARBOLINE, EXPRESS OR IMPLIED, STATUTORY, BY OPERATION OF LAW, OR OTHERWISE,<br />

INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. <strong>Sanitile®</strong> is a registered trademark of <strong>Carboline</strong> Company.

<strong>Carboline</strong> Company<br />

Speed of Cure 50°F 70°F 85°F<br />

Light traffic<br />

48 hrs 16 hrs 12 hrs<br />

Full traffic<br />

72 hrs 48 hrs 40 hrs<br />

Full chemical cure<br />

12 days 7 days 7 days<br />

Recoat Times<br />

Minimum recoat time<br />

Maximum recoat time<br />

60-80°F<br />

6 hours<br />

24 hours<br />

Aftercare - Cleaning and Maintenance<br />

Clean regularly using a single or double headed rotary<br />

scrubber drier in conjunction with a mildly alkaline detergent.<br />

Application Instructions<br />

Preparation/Substrate<br />

Surfaces to be coated should be sound and provide<br />

adequate strength for the proposed end use (minimum<br />

3500 psi compressive strength). The surface profile and<br />

levels should be appropriate for the system to be applied.<br />

The concrete substrate moisture emission should<br />

not exceed 3 pounds per 1000ft over 24 hours when<br />

tested prior to application, and be free from excessive<br />

rising moisture. A light shot blasting should be employed<br />

to remove laitance. Irregularities, damage and<br />

cracks are filled with epoxy filler. All residues must be<br />

removed to provide a dry, dust free open textured surface.<br />

Contact us for advice if there are impurities, such<br />

as oils etc., in the concrete. Check the relative humidity<br />

of floors at ground level. Follow our instructions for connections<br />

to grid drains, cesspools, pipes and pipe inlets.<br />

Outline Specification<br />

Apply Sanitile <strong>944</strong> <strong>HB</strong> at approximately 120 square feet<br />

per gallon.<br />

Priming<br />

Priming is not necessary, unless the substrate is very<br />

porous, in which case a single application of Sanitile<br />

900 (at 200 square feet per gallon) is applied.<br />

Application Conditions<br />

Sanitile ® <strong>944</strong> <strong>HB</strong><br />

Condition Material Surface Ambient Humidity<br />

Recommended<br />

Minimum<br />

Recommended<br />

Maximum<br />

60°F<br />

(16°C)<br />

80°F<br />

(27°C)<br />

50°F<br />

(10°C)<br />

80°F<br />

(27°C)<br />

60°F<br />

(16°C)<br />

80°F<br />

(27°C)<br />

0%<br />

90%<br />

Anti-slip texture<br />

If an anti-slip finish is required, scatter silica sand into the first<br />

coat of Sanitile <strong>944</strong> <strong>HB</strong>. Once this coat is tack free, remove<br />

the excess sand and apply the second coat. Degree of<br />

texture and coverage of Sanitile <strong>944</strong> <strong>HB</strong> is dependant on the<br />

grade of sand used.<br />

Note that:<br />

<strong>Carboline</strong> products are often multiple-component systems. Poor<br />

mixing, or incorrect mixing procedures, can result in irregular and<br />

incomplete hardening, which in turn can result in an inferior final<br />

result.<br />

Packaging, Handling, & Storage<br />

Packaging<br />

Shipping Wieght (Approx.)<br />

Flash Point (Setaflash)<br />

Storage Temperture<br />

Part A:<br />

Part B:<br />

Universal Color Pack:<br />

Shelf Llife (Part A):<br />

Shelf Life (Part B):<br />

Shelf Life (Color Pack):<br />

3.1 and 12.6 gallon kits<br />

9.4 lb/gal. (4.3 kg/gal.)<br />

Part A: >200°F (92°C)<br />

Part B: >200°F (92°C)<br />

40 to 100°F (4-38°C)<br />

Resin (2 or 4 Gallons)<br />

Hardner (1 or 4 Gallons)<br />

Color Pack (.14 Gallons)<br />

12 Months<br />

12 Months<br />

12 Months<br />

* Shelf Life: (actual stated shelf life) when kept at recommended storage<br />

conditions and in original unopened containers.<br />

Mixing<br />

Sanitile <strong>944</strong> <strong>HB</strong> in 3 gallon units, consisting of the Resin<br />

(Part A - 2 gallons), Hardener (Part B - 1 gallon), and a<br />

Universal Color Pack (.1 gallon).<br />

Add the color pack to Base A and mix thoroughly, then<br />

add Hardener B with mixing and mix for 2 minutes.<br />

Application<br />

Sanitile <strong>944</strong> <strong>HB</strong> is spread with rubber squeegee and<br />

finished with a roller. The second coat is applied when<br />

the first coat is dry. Subsequent coats should be applied<br />

no later than 24 hours after previous coats.<br />

2150 Schuetz Rd., St. Louis, MO 63146<br />

PH: 314-644-1000 Toll-Free: 800-848-4645<br />

www.carboline.com<br />

www.carboline.com<br />

To the best of our knowledge the technical data contained herein is true and accurate on the date of publication and is subject to change without prior notice. User must contact <strong>Carboline</strong> Company to verify correctness before specifying<br />

or ordering. No guarantee of accuracy is given or implied. We guarantee our products to conform to <strong>Carboline</strong> quality control. We assume no responsibility for coverage, performance or injuries resulting from use. Liability,<br />

if any, is limited to replacement of products. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY CARBOLINE, EXPRESS OR IMPLIED, STATUTORY, BY OPERATION OF LAW, OR OTHERWISE,<br />

INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. <strong>Sanitile®</strong> is a registered trademark of <strong>Carboline</strong> Company.<br />

An<br />

Company