Film Sealing Units with electric magnet GEHO TM-series

Film Sealing Units with electric magnet GEHO TM-series

Film Sealing Units with electric magnet GEHO TM-series

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Film</strong> <strong>Sealing</strong> <strong>Units</strong> <strong>with</strong><br />

<strong>electric</strong> <strong>magnet</strong> <strong>GEHO</strong> <strong>TM</strong>-<strong>series</strong><br />

New <strong>with</strong> DTS<br />

makes the sealing faster and prevents heating<br />

wires and PTFE-isolation from early wear and<br />

tear.<br />

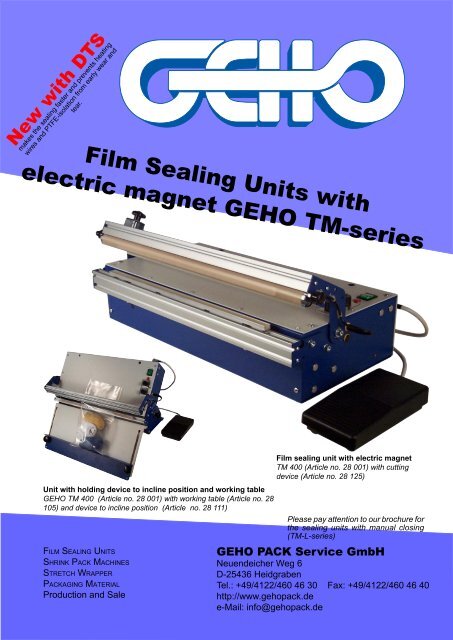

Unit <strong>with</strong> holding device to incline position and working table<br />

<strong>GEHO</strong> <strong>TM</strong> 400 (Article no. 28 001) <strong>with</strong> working table (Article no. 28<br />

105) and device to incline position (Article no. 28 111)<br />

<strong>Film</strong> <strong>Sealing</strong> UnitS<br />

Shrink Pack machineS<br />

Stretch WraPPer<br />

Packaging material<br />

Production and Sale<br />

<strong>Film</strong> sealing unit <strong>with</strong> <strong>electric</strong> <strong>magnet</strong><br />

<strong>TM</strong> 400 (Article no. 28 001) <strong>with</strong> cutting<br />

device (Article no. 28 125)<br />

Please pay attention to our brochure for<br />

the sealing units <strong>with</strong> manual closing<br />

(<strong>TM</strong>-L-<strong>series</strong>)<br />

<strong>GEHO</strong> PACK Service GmbH<br />

Neuendeicher Weg 6<br />

D-25436 Heidgraben<br />

Tel.: +49/4122/460 46 30 Fax: +49/4122/460 46 40<br />

http://www.gehopack.de<br />

e-Mail: info@gehopack.de

<strong>Film</strong> sealing units <strong>with</strong> <strong>electric</strong><br />

<strong>magnet</strong> <strong>GEHO</strong> <strong>TM</strong>-Series<br />

The units of the <strong>GEHO</strong> <strong>TM</strong> <strong>series</strong> are efficient film sealing units. They can be used <strong>with</strong>out a<br />

preheating period and are capable of being used for industrial purposes. The units equipped<br />

<strong>with</strong> <strong>electric</strong> <strong>magnet</strong> are very easy to use: The sealing frame closes automatically when<br />

the foot pedal is slightly pushed, sealing and cooling time run off and the sealing frame<br />

opens again.<br />

Accessories:<br />

Short and brief:<br />

With a cutting device the film can be cut a few millimeters<br />

UElektro<strong>magnet</strong>ic sealing pressure, so that little<br />

strength is required from operating people<br />

behind the seam. The knife of the cutting device is sunk in for<br />

injury protection.<br />

UHeat impulse sealing system<br />

UBoth hands can be used to hold the goods that are<br />

to be packed<br />

UPTFE supply reel which can be forwarded when<br />

old part is worn down<br />

UThe full pressure of the <strong>magnet</strong> is only reached<br />

when the sealing bars are closed all the way, for<br />

injury prevention<br />

The holding device provides the possibility to incline the unit<br />

into various different positions, which improves the handling of<br />

the bags. This way also difficult goods can be easily packed<br />

(such as liquids).<br />

The goods to be packed can be layed on the working table.<br />

It is height adjustable, so that bags of different lengths can be<br />

sealed easily. The shifting square is adjustable too and makes it<br />

easy to produce bags of the same size and makes the working<br />

sequence faster for the positioning of the bag is easier. With<br />

U Seam to seam-sealing is possible<br />

the lengthening for the working table also larger bags can<br />

UThe endings of the heating wires are coppered for<br />

be sealed.<br />

a long lifetime<br />

The electronic counting device has a zero position and counts<br />

UWith heating wire tension spring<br />

up to 99.999 sealings.<br />

UElectronic sealing and cooling time regulation<br />

UDynamic temperature regulation (DTS): after a<br />

short period of heating up the temperature stays<br />

constant, which shortens the sealing time and<br />

reduces the wear and tear of the heating wire and<br />

teflon isolation<br />

A funnel holder is used to alter the unit into a smalll part packer<br />

(for further information refer to the extra catalogue).<br />

The sealing unit is screwed to an undercarriage, so that no<br />

table is needed.The basic version has a working height of<br />

approximately 800 mm. The other version is height adjustable<br />

and movable.<br />

ULarge opening between the two sealing bars<br />

UVarious accessories<br />

The rolling off device for one film roll is positioned behind the<br />

unit and provides the possibility to work <strong>with</strong> a tubular films. By<br />

this means bags of different sizes can be produced <strong>with</strong> the<br />

cutting device.<br />

Optional equipment:<br />

Executions<br />

<strong>GEHO</strong> <strong>TM</strong> 400, <strong>TM</strong> 600 und <strong>TM</strong> 800<br />

<strong>Film</strong> sealing units equipped <strong>with</strong> <strong>electric</strong> <strong>magnet</strong>, used<br />

<strong>with</strong> very little strength, sealing and cooling time run off<br />

automatically, impulse is released through a foot pedal<br />

<strong>GEHO</strong> <strong>TM</strong> 400 D, <strong>TM</strong> 600 D und <strong>TM</strong> 800 D<br />

Same version as above, but double sided heated.<br />

<strong>GEHO</strong> <strong>TM</strong> 400 T und <strong>TM</strong> 600 T<br />

<strong>Units</strong> <strong>with</strong> hotwire sealing; the film is sealed <strong>with</strong> a PTFE<br />

sealing wire, which also separares the film. The seam is<br />

not as robust as the 3 mm standard seam, but the sealing<br />

time is shorter than the one of the 3 mm seam.<br />

Technical Data <strong>TM</strong> 400<br />

<strong>TM</strong> 400 D<br />

<strong>TM</strong> 400 T<br />

The Piezo pulse emitter signalizes you the sealing time acousticly.<br />

Range of operation:<br />

� <strong>Sealing</strong> of thermoplastic films, such as Polyethylen (PE),<br />

Polypropylen (PP), aluminium covered films and different<br />

laminated films.<br />

� Covered cardboard header (for example <strong>with</strong> suspensionhole)<br />

together <strong>with</strong> PE-filmbags (double heated versions<br />

-D)<br />

� Closing of bags<br />

� Manufacturing of bags (combined <strong>with</strong> the cutting device)<br />

<strong>TM</strong> 600<br />

<strong>TM</strong> 600 D<br />

<strong>TM</strong> 600 T<br />

Stop angle adjustable from 0 - 290 mm (<strong>with</strong> lengthening 0 - 450 mm)<br />

Weights and dimenstions are approxiamtely only. Technical changes <strong>with</strong>out notice.<br />

<strong>TM</strong> 800<br />

<strong>TM</strong> 800 D<br />

<strong>Sealing</strong> length 420 mm 620 mm 820 mm<br />

<strong>Sealing</strong> width 3 mm (0,7 mm <strong>with</strong> hotwire equipment T)<br />

Cutting length 420 mm 620 mm 820 mm<br />

Possible film passage 420 mm 620 mm 820 mm<br />

Opening of the sealing arm 45 mm (30 mm <strong>with</strong> cutting device)<br />

Sealable film thickness (PE-film) 2 x 0,2 mm (2 x 0,3 mm <strong>with</strong> double heating D, 2 x 0,1 mm <strong>with</strong> hotwire equipment T)<br />

Power supply 230 V/50 Hz AC<br />

Output 600 W 950 W 1275 W<br />

Dimensions (WxLxH) 295 x 600 x 175 mm 295 x 800 x 175 mm 295 x 1000 x 175 mm<br />

Weight ca. 22 kg ca. 28 kg ca. 36 kg<br />

Dimensions of table (WxL) 250 x 560 mm 250 x 760 mm 250 x 960 mm<br />

11/2010