You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

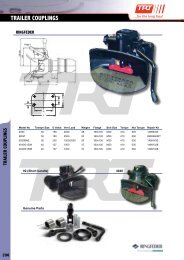

<strong>SLACK</strong> <strong>ADJUSTERS</strong><br />

<strong>MANUAL</strong> <strong>SLACK</strong> <strong>ADJUSTERS</strong><br />

Application Std Part No. ¾ Adj Nut Arm Lengths - A B C D Spline Teeth<br />

Universal Straight Std Trailer KN47001 BR120019 5” 6” 7” 1-½” - 10 Spl<br />

Universal Straight Std ( 4 Hole ) 18048 5” 6” 7” 8” 1-½” - 10 Spl<br />

Universal Truck Drive Straight KN47011 BR120020 5-½” 6-½” 1-½” - 10 Spl<br />

Cranked Low Loader 1296 6” 1-½” - 10 Spl<br />

Left Hand Offset 5/8” KN50060 4” 5” 6” 1-½” - 10 Spl<br />

Right Hand Offset 5/8” KN50070 4” 5” 6” 1-½” - 10 Spl<br />

BPW H, R, KH, KR 4 HOLE 0517452610 150, 180, 220, 250mm 1-½” - 10 Spl<br />

Universal Truck Drive KN44061 BR220219 5-½” 6-½” 1-½” 28 Spl<br />

Universal Straight Std Trailer KN44051 BR210219 5 “ 6” 1-½” 28 Spl<br />

Propar Trailer KN44041 6” 1-⅝” 37 Spl<br />

Left Offset<br />

Right Offset<br />

ARM LENGTH<br />

C<br />

B<br />

A<br />

C<br />

½” DIA ½” DIA<br />

B<br />

Proper Viewing<br />

Angle to<br />

Determine left<br />

or right offset<br />

ARM LENGTH<br />

A<br />

BRAKE<br />

SPLINE<br />

& TEETH<br />

OFFSET<br />

<strong>SLACK</strong><br />

SPLINE<br />

& TEETH<br />

STRAIGHT<br />

<strong>SLACK</strong><br />

TIP<br />

Offset<br />

If your Slack Adjuster is not shown above, measure it as per the key dimensions<br />

shown above. We will also need the application details.<br />

BPW ROR Low Loader Jap<br />

128

<strong>SLACK</strong> <strong>ADJUSTERS</strong><br />

AUTO <strong>SLACK</strong> <strong>ADJUSTERS</strong><br />

Auto Slack Adjusters operate exactly the same as Manual Slack Adjusters, without the<br />

need for constant manual adjustment for wear.<br />

There are two styles of actuation-external bracket, and link rod. Through normal brake<br />

operation, the fixed control point moves a rack in the slack adjuster body. As the<br />

clutches are engaged, on regular release, the worm screw is turned by the clutch and<br />

rack. The worm screw then turns the worm wheel adjusting the foundation brakes.<br />

This will continue until lining and drum contact is achieved.<br />

At the time of contact, the clutch to worm shaft is disengaged stopping worm wheel<br />

rotation. (See diagram below)<br />

An Automatic Slack Adjuster should never be adjusted manually while in service. Apart<br />

from the necessary adjustments on installation or at reline, manual adjustment will shorten<br />

clutch life. Check control arms and brackets for damage, these are the most vulnerable<br />

areas of an Auto Slack, and if damaged can cause improper actuation and failure.<br />

External Bracket Actuation<br />

Link Rod Activation<br />

BRAKE<br />

TIP<br />

Not sure what Auto slack you have? The numbers stamped and cast into the body<br />

will help us ID it for you.<br />

129