G - Parting and grooving.FH11 - Canela Tools

G - Parting and grooving.FH11 - Canela Tools

G - Parting and grooving.FH11 - Canela Tools

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

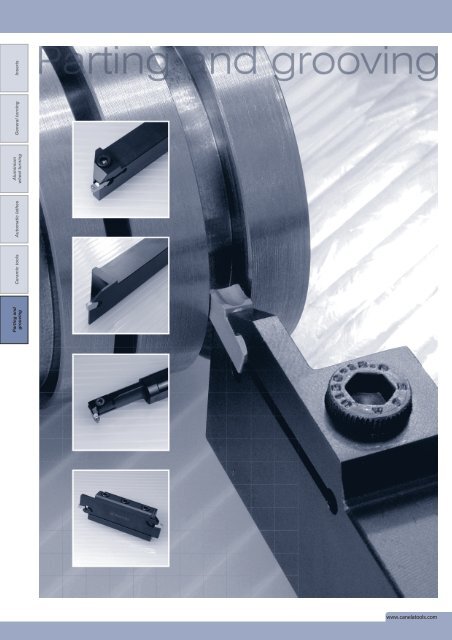

<strong>Parting</strong> <strong>and</strong><br />

<strong>grooving</strong><br />

Ceramic tools<br />

Automatic lathes<br />

Aluminium<br />

wheel turning<br />

General turning<br />

Inserts<br />

www.canelatools.com

Tooling<br />

Brazed tools Cartridges Drills<br />

Threading<br />

<strong>Parting</strong> <strong>and</strong><br />

<strong>grooving</strong><br />

<strong>Parting</strong> <strong>and</strong> <strong>grooving</strong><br />

Inserts<br />

Applications<br />

Toolholders<br />

Boring bars<br />

Tool blocks<br />

Blades<br />

Notch tools<br />

Cutting data<br />

G.02<br />

G.07<br />

G.08<br />

G.14<br />

G.16<br />

G.17<br />

G.20<br />

G.24<br />

CANELA<br />

G.01

<strong>Parting</strong> <strong>and</strong> <strong>grooving</strong><br />

For more information see page:<br />

Inserts:G.02<br />

Applications: G.07<br />

Cutting data: G.24<br />

Toolholders: G.08<br />

Boring bars: G.14<br />

Tool blocks: G.16<br />

Blades: G.17<br />

Notch tools: G.20<br />

Contents<br />

Inserts<br />

MRCN<br />

MRCR/L<br />

MTE<br />

MTC<br />

MTCJ<br />

MTR<br />

MTRJ<br />

General turning<br />

Single-ended.<br />

Page G.<br />

03<br />

PTNT<br />

Single-ended.<br />

Page G.<br />

03<br />

PTR/LT<br />

Single-ended.<br />

Page G.<br />

03<br />

Double-ended.<br />

Page G.03<br />

Double-ended.<br />

Page G.03<br />

Double-ended.<br />

Page G.04<br />

Double-ended.<br />

Page G04<br />

Aluminium<br />

wheel turning<br />

Single ended.<br />

Page G.04<br />

Single-ended.<br />

Page G. 04<br />

Automatic lathes<br />

NG<br />

NR<br />

NT<br />

Ceramic tools<br />

Double-ended<br />

For <strong>Parting</strong><br />

Double-ended<br />

For <strong>Parting</strong> (radius)<br />

Double-ended<br />

For Threading<br />

Page G.05 Page G.<br />

05<br />

Page G.06<br />

<strong>Parting</strong> <strong>and</strong><br />

<strong>grooving</strong><br />

ER/L LG<br />

Triangular<br />

negative<br />

Page G. 06<br />

G.02<br />

www.canelatools.com

Inserts<br />

<strong>Parting</strong> <strong>and</strong> <strong>grooving</strong><br />

Normally available for immediate delivery<br />

s<br />

r<br />

MRCR<br />

MRCL<br />

6°<br />

6°<br />

MRCN<br />

MRCN 1.6<br />

MRCN 2.2<br />

MRCN 3.0<br />

MRCN 4.0<br />

MRCN 5.0<br />

MRCN 6.0<br />

MRCR/L<br />

MRCR 3.0<br />

MRCR 4.0<br />

MRCL 3.0<br />

MRCL 4.0<br />

MTE<br />

s<br />

1,6<br />

2,2<br />

3,0<br />

4,0<br />

5,0<br />

6,0<br />

s<br />

3,0<br />

4,0<br />

3,0<br />

4,0<br />

s<br />

r<br />

0,15<br />

0,20<br />

0,20<br />

0,20<br />

0,30<br />

0,40<br />

r<br />

0,20<br />

0,20<br />

0,20<br />

0,20<br />

r<br />

KM15<br />

KM15<br />

KM15<br />

Only available in a limited quantity<br />

PM25<br />

PM40<br />

TIN16<br />

TIN17<br />

TIN22<br />

TIN32<br />

ZR10<br />

Normally available for immediate delivery<br />

Only available in a limited quantity<br />

PM25<br />

PM40<br />

TIN16<br />

TIN17<br />

TIN22<br />

TIN32<br />

ZR10<br />

Normally available for immediate delivery<br />

Only available in a limited quantity<br />

PM25<br />

PM40<br />

TIN16<br />

TIN17<br />

TIN22<br />

TIN32<br />

ZR10<br />

TL40 TL40<br />

TL40<br />

MTE 3.0<br />

MTE 4.0<br />

3,0<br />

4,0<br />

0,20<br />

0,20<br />

<strong>Parting</strong> <strong>and</strong><br />

<strong>grooving</strong><br />

s<br />

s<br />

r<br />

r<br />

MTC<br />

MTC 3.0<br />

MTC 4.0<br />

MTCJ<br />

MTCJ 3.0<br />

MTCJ 4.0<br />

s<br />

3,0<br />

4,0<br />

s<br />

3,0<br />

4,0<br />

r<br />

0,15<br />

0,20<br />

r<br />

0,15<br />

0,20<br />

KM15<br />

KM15<br />

Normally available for immediate delivery<br />

Only available in a limited quantity<br />

PM25<br />

PM40<br />

TIN16<br />

TIN17<br />

TIN22<br />

TIN32<br />

ZR10<br />

Normally available for immediate delivery<br />

Only available in a limited quantity<br />

PM25<br />

PM40<br />

TIN16<br />

TIN17<br />

TIN22<br />

TIN32<br />

ZR10<br />

Brazed tools Cartridges Drills<br />

Threading<br />

s<br />

r<br />

Tooling<br />

CANELA<br />

G.03

<strong>Parting</strong> <strong>and</strong> <strong>grooving</strong><br />

For more information see page:<br />

Inserts:G.02<br />

Applications index: G.07<br />

Cutting data: G.24<br />

Toolholders: G.08<br />

Boring bars: G.14<br />

Tool blocks: G.16<br />

Blades: G.17<br />

Notch tools: G.20<br />

Inserts<br />

Normally available for immediate delivery<br />

Inserts<br />

MTR<br />

s<br />

r<br />

KM15<br />

PM25<br />

Only available in a limited quantity<br />

PM40<br />

TIN16<br />

TIN17<br />

TIN22<br />

TIN32<br />

ZR10<br />

MTR 3.0<br />

MTR 3.8<br />

3,0<br />

3,8<br />

1,50<br />

1,90<br />

General turning<br />

s<br />

r<br />

Aluminium<br />

wheel turning<br />

MTRJ<br />

s<br />

r<br />

KM15<br />

Normally available for immediate delivery<br />

Only available in a limited quantity<br />

PM25<br />

PM40<br />

TIN16<br />

TIN17<br />

TIN22<br />

TIN32<br />

ZR10<br />

Automatic lathes<br />

s<br />

r<br />

MTRJ 3.0<br />

MTRJ 3.8<br />

3,0<br />

3,8<br />

1,50<br />

1,90<br />

Ceramic tools<br />

PTNT<br />

s<br />

KM15<br />

Normally available for immediate delivery<br />

Only available in a limited quantity<br />

PM25<br />

PM40<br />

TIN16<br />

TIN17<br />

TIN22<br />

TIN32<br />

ZR10<br />

<strong>Parting</strong> <strong>and</strong><br />

<strong>grooving</strong><br />

s<br />

PTNT 02<br />

PTNT 03<br />

PTNT 04<br />

PTNT 05<br />

PTNT 06<br />

PTNT 08<br />

PTNT 09<br />

2,10<br />

3,10<br />

4,10<br />

5,10<br />

6,10<br />

8,10<br />

9,10<br />

Normally available for immediate delivery<br />

PTR/LT<br />

s<br />

KM15<br />

PM25<br />

Only available in a limited quantity<br />

PM40<br />

TIN16<br />

TIN17<br />

TIN22<br />

TIN32<br />

ZR10<br />

PTRT<br />

8°<br />

PTRT 03 R8<br />

PTRT 04 R8<br />

3,0<br />

4,0<br />

PTLT 03 R8<br />

PTLT 04 R8<br />

3,0<br />

4,0<br />

PTLT<br />

8°<br />

G.04<br />

www.canelatools.com

G.05<br />

CANELA<br />

Drills<br />

Brazed tools Cartridges Threading<br />

<strong>Parting</strong> <strong>and</strong><br />

<strong>grooving</strong><br />

Tooling<br />

NG-2031R/L<br />

NG-210R/L<br />

NG2041R/L<br />

NG2047R/L<br />

NG2058R/L<br />

NG2062R/L<br />

NG220R/L<br />

NG2094R/L<br />

NG230R/L<br />

NG2125R/L<br />

NG3031R/L<br />

NG310R/L<br />

NG3047R/L<br />

NG3062R/L<br />

NG3072R/L<br />

NG3078R/L<br />

NG320R/L<br />

NG3088R/L<br />

NG3094R/L<br />

NG3105R/L<br />

NG3110R/L<br />

NG330R/L<br />

NG3122R/L<br />

NG3125R/L<br />

NG3142R/L<br />

NG3156R/L<br />

NG340R/L<br />

NG3178R/L<br />

NG3185R/L<br />

NG3189R/L<br />

NG4125R/L<br />

NG4189R/L<br />

NG450R/L<br />

NG4213R/L<br />

NG4219R/L<br />

NG4250R/L<br />

NG4312R/L<br />

NG6281R/L<br />

NG6312R/L<br />

NG6375R/L<br />

4,76<br />

4,76<br />

4,76<br />

4,76<br />

4,76<br />

4,76<br />

4,76<br />

4,76<br />

4,76<br />

4,76<br />

9,53<br />

9,53<br />

9,53<br />

9,53<br />

9,53<br />

9,53<br />

9,53<br />

9,53<br />

9,53<br />

9,53<br />

9,53<br />

9,53<br />

9,53<br />

9,53<br />

9,53<br />

9,53<br />

9,53<br />

9,53<br />

9,53<br />

9,53<br />

9,53<br />

9,53<br />

9,53<br />

9,53<br />

9,53<br />

9,53<br />

9,53<br />

9,53<br />

9,53<br />

9,53<br />

3,81<br />

3,81<br />

3,81<br />

3,81<br />

3,81<br />

3,81<br />

3,81<br />

3,81<br />

3,81<br />

3,81<br />

4,95<br />

4,95<br />

4,95<br />

4,95<br />

4,95<br />

4,95<br />

4,95<br />

4,95<br />

4,95<br />

4,95<br />

4,95<br />

4,95<br />

4,95<br />

4,95<br />

4,95<br />

4,95<br />

4,95<br />

4,95<br />

4,95<br />

4,95<br />

6,48<br />

6,48<br />

6,48<br />

6,48<br />

6,48<br />

6,48<br />

6,48<br />

9,73<br />

9,73<br />

9,73<br />

NG<br />

Normally available for immediate delivery<br />

Only available in a limited quantity<br />

A<br />

s<br />

KM15<br />

PM25<br />

PM40<br />

TIN17<br />

TIN22<br />

ZR10<br />

TIN16<br />

TIN32<br />

5,56<br />

5,56<br />

5,56<br />

5,56<br />

5,56<br />

5,56<br />

5,56<br />

5,56<br />

5,56<br />

5,56<br />

8,74<br />

8,74<br />

8,74<br />

8,74<br />

8,74<br />

8,74<br />

8,74<br />

8,74<br />

8,74<br />

8,74<br />

8,74<br />

8,74<br />

8,74<br />

8,74<br />

8,74<br />

8,74<br />

8,74<br />

8,74<br />

8,74<br />

8,74<br />

11,51<br />

11,51<br />

11,51<br />

11,51<br />

11,51<br />

11,51<br />

11,51<br />

11,51<br />

11,51<br />

11,51<br />

B<br />

6,86<br />

6,86<br />

6,86<br />

6,86<br />

6,86<br />

6,86<br />

6,86<br />

6,86<br />

6,86<br />

6,86<br />

10,29<br />

10,29<br />

10,29<br />

10,29<br />

10,29<br />

10,29<br />

10,29<br />

10,29<br />

10,29<br />

10,29<br />

10,29<br />

10,29<br />

10,29<br />

10,29<br />

10,29<br />

10,29<br />

10,29<br />

10,29<br />

10,29<br />

10,29<br />

16,15<br />

16,15<br />

16,15<br />

16,15<br />

16,15<br />

16,15<br />

16,15<br />

16,15<br />

16,15<br />

16,15<br />

E<br />

1,27<br />

1,27<br />

1,27<br />

1,27<br />

1,27<br />

2,79<br />

2,79<br />

2,79<br />

2,79<br />

2,79<br />

1,27<br />

1,27<br />

1,91<br />

3,05<br />

3,05<br />

3,05<br />

3,05<br />

3,05<br />

4,57<br />

4,57<br />

4,57<br />

4,57<br />

4,57<br />

4,57<br />

4,57<br />

4,57<br />

4,57<br />

4,57<br />

4,57<br />

4,57<br />

6,35<br />

6,35<br />

6,35<br />

6,35<br />

6,35<br />

6,35<br />

6,35<br />

6,35<br />

6,35<br />

6,35<br />

r<br />

0,79<br />

0,99<br />

1,04<br />

1,19<br />

1,47<br />

1,57<br />

2,01<br />

2,39<br />

3,00<br />

3,18<br />

0,79<br />

0,99<br />

1,19<br />

1,57<br />

1,83<br />

1,98<br />

2,01<br />

2,24<br />

2,39<br />

2,67<br />

2,79<br />

3,00<br />

3,10<br />

3,18<br />

3,61<br />

3,96<br />

4,01<br />

4,52<br />

4,70<br />

4,80<br />

3,18<br />

4,80<br />

5,00<br />

5,41<br />

5,56<br />

6,35<br />

7,92<br />

7,14<br />

7,92<br />

9,53<br />

W<br />

NR2031R/L<br />

NR2047R/L<br />

NR2062R/L<br />

NR3031R/L<br />

NR3047R/L<br />

NR3062R/L<br />

NR3078R/L<br />

NR3094R/L<br />

NR4062R/L<br />

NR4094R/L<br />

NR4125R/L<br />

4,76<br />

4,76<br />

4,76<br />

9,53<br />

9,53<br />

9,53<br />

9,53<br />

9,53<br />

9,53<br />

9,53<br />

9,53<br />

3,81<br />

3,81<br />

3,81<br />

4,95<br />

4,95<br />

4,95<br />

4,95<br />

4,95<br />

6,48<br />

6,48<br />

6,48<br />

NR<br />

Normally available for immediate delivery<br />

Only available in a limited quantity<br />

d<br />

s<br />

KM15<br />

PM25<br />

PM40<br />

TIN17<br />

TIN22<br />

ZR10<br />

TIN16<br />

TIN32<br />

5,56<br />

5,56<br />

5,56<br />

8,74<br />

8,74<br />

8,74<br />

8,74<br />

8,74<br />

11,51<br />

11,51<br />

11,51<br />

B<br />

6,81<br />

6,79<br />

6,77<br />

10,24<br />

10,22<br />

10,20<br />

10,18<br />

10,16<br />

16,07<br />

10,03<br />

15,98<br />

E<br />

0,79<br />

1,19<br />

1,57<br />

0,79<br />

1,19<br />

1,57<br />

1,98<br />

2,39<br />

1,57<br />

2,39<br />

3,18<br />

r<br />

1,57<br />

2,39<br />

3,18<br />

1,57<br />

2,39<br />

3,18<br />

3,96<br />

4,78<br />

3,18<br />

4,78<br />

6,35<br />

W<br />

d<br />

0,05<br />

0,05<br />

0,05<br />

0,05<br />

0,05<br />

0,05<br />

0,05<br />

0,05<br />

0,05<br />

0,05<br />

0,05<br />

0,05<br />

0,05<br />

0,13<br />

0,13<br />

0,13<br />

0,13<br />

0,13<br />

0,13<br />

0,13<br />

0,13<br />

0,13<br />

0,13<br />

0,13<br />

0,13<br />

0,13<br />

0,13<br />

0,13<br />

0,51<br />

0,51<br />

0,13<br />

0,51<br />

0,25<br />

0,13<br />

0,51<br />

0,51<br />

0,76<br />

0,76<br />

0,76<br />

0,76<br />

A<br />

2,79<br />

2,79<br />

2,79<br />

3,81<br />

3,81<br />

3,81<br />

3,81<br />

3,81<br />

6,35<br />

6,35<br />

6,35<br />

W<br />

55º<br />

r<br />

E<br />

B<br />

s<br />

A<br />

d<br />

55º<br />

r<br />

s<br />

A<br />

d<br />

B<br />

E<br />

W<br />

Inserts<br />

<strong>Parting</strong> <strong>and</strong> <strong>grooving</strong>

<strong>Parting</strong> <strong>and</strong> <strong>grooving</strong><br />

For more information see page:<br />

Inserts:G.02<br />

Applications: G.07<br />

Cutting data: G.24<br />

Toolholders: G.08<br />

Boring bars: G.14<br />

Tool blocks: G.16<br />

Blades: G.17<br />

Notch tools: G.20<br />

Inserts<br />

Normally available for immediate delivery<br />

Inserts<br />

NT<br />

d<br />

A<br />

B<br />

E<br />

r<br />

s<br />

KM15<br />

PM25<br />

Only available in a limited quantity<br />

PM40<br />

TIN16<br />

TIN17<br />

TIN22<br />

TIN32<br />

ZR10<br />

General turning<br />

55º<br />

E<br />

60º<br />

r<br />

B<br />

d<br />

A<br />

s<br />

NT2R/L<br />

NT3R/L<br />

NT4R/L<br />

4,76<br />

9,53<br />

9,53<br />

5,56<br />

8,74<br />

11,51<br />

6,76<br />

10,16<br />

15,98<br />

1,91<br />

2,49<br />

3,25<br />

0,08<br />

0,13<br />

0,13<br />

3,81<br />

4,95<br />

6,48<br />

Aluminium<br />

wheel turning<br />

Grooving - External inserts<br />

Lock ring groove inserts type LG<br />

Normally available for immediate delivery<br />

Only available in a limited quantity<br />

ER-LG<br />

l d<br />

W KM15 PM25 TIN25 TL20<br />

Automatic lathes<br />

ER-LG<br />

16ER-100LG<br />

16ER-120LG<br />

16ER-150LG<br />

16ER-175LG<br />

16ER-200LG<br />

16,00<br />

16,00<br />

16,00<br />

16,00<br />

16,00<br />

9,52<br />

9,52<br />

9,52<br />

9,52<br />

9,52<br />

1,15<br />

1,35<br />

1,65<br />

1,90<br />

2,15<br />

Ceramic tools<br />

<strong>Parting</strong> <strong>and</strong><br />

<strong>grooving</strong><br />

d<br />

W<br />

l<br />

ER<br />

EL-LG<br />

l<br />

d<br />

W KM15 PM25 TIN25 TL20<br />

16EL-100LG<br />

16EL-120LG<br />

16EL-150LG<br />

16EL-175LG<br />

16EL-200LG<br />

16,00<br />

16,00<br />

16,00<br />

16,00<br />

16,00<br />

9,52<br />

9,52<br />

9,52<br />

9,52<br />

9,52<br />

1,15<br />

1,35<br />

1,65<br />

1,90<br />

2,15<br />

d<br />

W<br />

l<br />

EL<br />

G.06<br />

www.canelatools.com

Applications<br />

<strong>Parting</strong> <strong>and</strong> <strong>grooving</strong><br />

Toolholders<br />

CZGB<br />

CZFB<br />

CZCB<br />

CZCF<br />

CZCP<br />

XLCF<br />

Page G.08<br />

MTE 03/04<br />

MRCN 03/04 Page G.08<br />

MTE 03/04<br />

MRCN 03/04<br />

Page G10<br />

MRCN 1,6<br />

...<br />

MRCN 6,0<br />

MTC 3,0<br />

MTC 4,0<br />

Page G.11<br />

MTR 3,0<br />

MTR 3,8 Page G.12<br />

MTC 3,0<br />

MTC 4,0<br />

MTR 3,0<br />

MTR 3,8<br />

Page G.13<br />

PTNT 02<br />

PTNT 03<br />

PTNT 04<br />

Boring bars<br />

CZGF<br />

CZGB<br />

Page G.14<br />

MTCJ 3,0<br />

MTCJ 4,0<br />

MTRJ 3,0<br />

MTRJ 3,8<br />

Page G.15<br />

MTCJ 3,0<br />

MTCJ 4,0<br />

MTRJ 3,0<br />

MTRJ 3,8<br />

Tool blocks<br />

CPTS<br />

DPTS<br />

Page G.16<br />

Page G.16<br />

Blades<br />

CRCFN<br />

XLCFN<br />

XLCTN<br />

<strong>Parting</strong> <strong>and</strong><br />

<strong>grooving</strong><br />

MRCN 2,2<br />

Page G.17<br />

...<br />

MRCN 6,0<br />

Page G.18<br />

Top Notch <strong>Tools</strong><br />

PTNT 02<br />

...<br />

PTNT 09<br />

Page G.19<br />

PTNT 02<br />

...<br />

PTNT 06<br />

NE 93° NR 45° NS 93°<br />

NNTO 93°<br />

N.. 2<br />

N.. 2<br />

Page G.20 N.. 3<br />

N.. 3<br />

N.. 4 Page G.21 N.. 3 Page G.22 N.. 4 Page G.23<br />

N.. 2<br />

N.. 3<br />

N.. 4<br />

Tooling<br />

Brazed tools Cartridges Drills<br />

Threading<br />

CANELA<br />

G.07

<strong>Parting</strong> <strong>and</strong> <strong>grooving</strong><br />

For more information see page:<br />

Inserts:G.02<br />

Applications: G.07<br />

Cutting data: G.24<br />

Toolholders: G.08<br />

Boring bars: G.14<br />

Tool blocks: G.16<br />

Blades: G.17<br />

Notch tools: G.20<br />

Toolholders<br />

Inserts<br />

Characteristics:<br />

Modular system for inserts with thickness from 3 to 4 mm.<br />

The "V" positioning system of the pocket <strong>and</strong> the clamp integrated to the tool ensure maximum security <strong>and</strong><br />

repetitivity on the dimensions when the insert is changed.<br />

Applications:<br />

<strong>Parting</strong>, <strong>grooving</strong> <strong>and</strong> face <strong>grooving</strong> toolholder that works well on steels, alloyed steels, stainless steels <strong>and</strong><br />

refractories.<br />

L2<br />

General turning<br />

h1<br />

B<br />

T<br />

L1<br />

h<br />

b<br />

Aluminium<br />

wheel turning<br />

CZGB<br />

h<br />

Kg<br />

b L1<br />

L2 h1<br />

B T<br />

Automatic lathes<br />

Ref.<br />

CZGB R/L 2020 M34<br />

CZGB R/L 2525 M34<br />

CZGB R/L 3232 P34<br />

20<br />

25<br />

32<br />

20<br />

25<br />

32<br />

150<br />

150<br />

170<br />

53<br />

53<br />

53<br />

20<br />

25<br />

32<br />

3-4<br />

3-4<br />

3-4<br />

25-30<br />

25-30<br />

25-30<br />

0,600<br />

0,750<br />

1,300<br />

Ceramic tools<br />

Ref.<br />

CZGB R/L 2020 M34<br />

CZGB R/L 2525 M34<br />

CZGB R/L 3232 P34<br />

1096<br />

1096<br />

1096<br />

1240<br />

1240<br />

1240<br />

5005<br />

5005<br />

5005<br />

5515<br />

5515<br />

5515<br />

<strong>Parting</strong> <strong>and</strong><br />

<strong>grooving</strong><br />

Characteristics:<br />

Modular system for inserts with thickness from 3 to 4 mm.<br />

The "V" positioning system of the pocket <strong>and</strong> the clamp integrated to the tool ensure maximum security <strong>and</strong><br />

repetitivity on the dimensions when the insert is changed.<br />

Applications:<br />

<strong>Parting</strong>, <strong>grooving</strong> <strong>and</strong> face <strong>grooving</strong> toolholder that works well on steels, alloyed steels, stainless steels <strong>and</strong><br />

refractories.<br />

h1<br />

h<br />

b<br />

T<br />

B<br />

L2<br />

L1<br />

CZFB<br />

h<br />

Kg<br />

b L1<br />

L2 h1<br />

B T<br />

Ref.<br />

CZFB R/L 2525 M34<br />

CZFB R/L 3232 P34<br />

25<br />

32<br />

25<br />

32<br />

150<br />

170<br />

25<br />

25<br />

25<br />

32<br />

3-4<br />

3-4<br />

25-30<br />

25-30<br />

0,750<br />

1,300<br />

Ref.<br />

CZFB R/L 2525 M34<br />

CZFB R/L 3232 P34<br />

1096<br />

1096<br />

1240<br />

1240<br />

5005<br />

5005<br />

5515<br />

5515<br />

G.08<br />

www.canelatools.com

Toolholders<br />

<strong>Parting</strong> <strong>and</strong> <strong>grooving</strong><br />

CZXB 00<br />

L<br />

L2<br />

B<br />

Insert size<br />

L<br />

Ref.<br />

CZXB R/L 00X03<br />

CZXB R/L 00X04<br />

53<br />

53<br />

25<br />

25<br />

3<br />

4<br />

MRCN 03<br />

MRCN 04<br />

B<br />

L2<br />

CZXB 40-50<br />

L<br />

L2<br />

B<br />

Ø Range<br />

Insert size<br />

L<br />

Ref.<br />

CZXB R/L 4050X03<br />

CZXB R/L 4050X04<br />

53<br />

53<br />

20<br />

20<br />

3<br />

4<br />

40 - 50<br />

40 - 50<br />

MTE 03<br />

MTE 04<br />

B<br />

L2<br />

CZXB 50-65<br />

L<br />

L2<br />

B<br />

Ø Range<br />

Insert size<br />

L<br />

Ref. CZXB R/L 5065X03 53 20<br />

CZXB R/L 5065X04 53 20<br />

3<br />

4<br />

50 - 65<br />

50 - 65<br />

MTE 03<br />

MTE 04<br />

B<br />

L2<br />

CZXB 65-92<br />

L<br />

L2<br />

B<br />

Ø Range<br />

Insert size<br />

L<br />

Ref.<br />

CZXB R/L 6592X03<br />

CZXB R/L 6592X04<br />

53<br />

53<br />

20<br />

20<br />

3<br />

4<br />

65 - 92<br />

65 - 92<br />

MTE 03<br />

MTE 04<br />

B<br />

L2<br />

CZXB 90-122<br />

Ref. CZXB R/L 90122X03 53 25<br />

CZXB R/L 90122X04 53 25<br />

L<br />

L2<br />

B<br />

3<br />

4<br />

Ø Range<br />

90 - 122<br />

90 - 122<br />

Insert size<br />

MTE 03<br />

MTE 04<br />

L<br />

<strong>Parting</strong> <strong>and</strong><br />

<strong>grooving</strong><br />

B<br />

L2<br />

CZXB 120-160<br />

Ref. CZXB R/L 120160X03 53 25<br />

CZXB R/L 120160X04 53 25<br />

CZXB 150-500<br />

L<br />

L2<br />

Ref. CZXB R/L 150500X03 53 25<br />

CZXB R/L 150500X04 53 25<br />

MRCN / MTE<br />

Ref. MRCN 03 / MTE 03 3,0<br />

MRCN 04 / MTE 04<br />

4,0<br />

s<br />

L<br />

L2<br />

B<br />

3<br />

4<br />

B<br />

3<br />

4<br />

r<br />

0,20<br />

0,20<br />

Ø Range<br />

120 - 160<br />

120 - 160<br />

Ø Range<br />

150 - 500<br />

150 - 500<br />

Insert size<br />

MTE 03<br />

MTE 04<br />

Insert size<br />

MTE 03<br />

MTE 04<br />

B<br />

B<br />

L2<br />

L2<br />

Single-ended insert for parting <strong>and</strong> <strong>grooving</strong><br />

L<br />

L<br />

Brazed tools Cartridges Drills<br />

Threading<br />

s<br />

r<br />

MRCN<br />

MTE<br />

For more information see page: G.03<br />

Tooling<br />

CANELA<br />

G.09

<strong>Parting</strong> <strong>and</strong> <strong>grooving</strong><br />

For more information see page:<br />

Inserts:G.02<br />

Applications: G.07<br />

Cutting data: G.24<br />

Toolholders: G.08<br />

Boring bars: G.14<br />

Tool blocks: G.16<br />

Blades: G.17<br />

Notch tools: G.20<br />

Toolholders<br />

Inserts<br />

Characteristics:<br />

One sided inserts with thickness from 1,6 to 6 mm.<br />

The "V" positioning system of the pocket <strong>and</strong> the clamp integrated to the tool ensure maximum security <strong>and</strong><br />

repetitivity on the dimensions when the insert is changed.<br />

Applications:<br />

<strong>Parting</strong>, <strong>grooving</strong> <strong>and</strong> side turning toolholder that works well on steels, alloyed steels, stainless steels <strong>and</strong><br />

refractories.<br />

General turning<br />

a<br />

B<br />

h<br />

h1<br />

b<br />

L2<br />

L1<br />

Aluminium<br />

wheel turning<br />

CZCB<br />

h b L1 L2 h1 B a Insert size<br />

Kg<br />

Automatic lathes<br />

Ref.<br />

CZCB R/L 1010 J01<br />

CZCB R/L 1010 J02<br />

CZCB R/L 1212 J01<br />

CZCB R/L 1212 J02<br />

CZCB R/L 1612 J02<br />

CZCB R/L 1612 J03<br />

10<br />

10<br />

12<br />

12<br />

16<br />

16<br />

10<br />

10<br />

12<br />

12<br />

12<br />

12<br />

110<br />

110<br />

110<br />

110<br />

110<br />

110<br />

25<br />

25<br />

25<br />

25<br />

29<br />

29<br />

21<br />

21<br />

21<br />

21<br />

21<br />

21<br />

1,6<br />

2,2<br />

1,6<br />

2,2<br />

2,2<br />

3,0<br />

22<br />

22<br />

22<br />

22<br />

32<br />

32<br />

MRCN 1,6<br />

MRCN 2,2<br />

MRCN 1,6<br />

MRCN 2,2<br />

MRCN 2,2<br />

MRCN 3,0<br />

0,080<br />

0,080<br />

0,100<br />

0,100<br />

0,150<br />

0,150<br />

Ceramic tools<br />

<strong>Parting</strong> <strong>and</strong><br />

<strong>grooving</strong><br />

CZCB R/L 2016 K03<br />

CZCB R/L 2016 K04<br />

CZCB R/L 2016 K05<br />

CZCB R/L 2016 K06<br />

CZCB R/L 2520 M03<br />

CZCB R/L 2520 M04<br />

CZCB R/L 2520 M05<br />

CZCB R/L 2520 M06<br />

20<br />

20<br />

20<br />

20<br />

25<br />

25<br />

25<br />

25<br />

16<br />

16<br />

16<br />

16<br />

20<br />

20<br />

20<br />

20<br />

125<br />

125<br />

125<br />

125<br />

150<br />

150<br />

150<br />

150<br />

35<br />

35<br />

35<br />

35<br />

50<br />

50<br />

50<br />

50<br />

30<br />

30<br />

30<br />

30<br />

30<br />

30<br />

30<br />

30<br />

3,0<br />

4,0<br />

5,0<br />

6,0<br />

3,0<br />

4,0<br />

5,0<br />

6,0<br />

42<br />

42<br />

42<br />

42<br />

80<br />

80<br />

80<br />

80<br />

MRCN 3,0<br />

MRCN 4,0<br />

MRCN 5,0<br />

MRCN 6,0<br />

MRCN 3,0<br />

MRCN 4,0<br />

MRCN 5,0<br />

MRCN 6,0<br />

0,350<br />

0,350<br />

0,350<br />

0,350<br />

0,550<br />

0,550<br />

0,550<br />

0,550<br />

Ref.<br />

CZCB R/L 1010 J01<br />

CZCB R/L 1010 J02<br />

1905<br />

1905<br />

5004<br />

5004<br />

CZCB R/L 1212 J01<br />

CZCB R/L 1212 J02<br />

1905<br />

1905<br />

5004<br />

5004<br />

CZCB R/L 1612 J02<br />

CZCB R/L 1612 J03<br />

1916<br />

1916<br />

5005<br />

5005<br />

CZCB R/L 2016 K03<br />

CZCB R/L 2016 K04<br />

CZCB R/L 2016 K05<br />

CZCB R/L 2016 K06<br />

1906<br />

1906<br />

1906<br />

1906<br />

5005<br />

5005<br />

5005<br />

5005<br />

CZCB R/L 2520 M03<br />

CZCB R/L 2520 M04<br />

CZCB R/L 2520 M05<br />

CZCB R/L 2520 M06<br />

1906<br />

1906<br />

1906<br />

1906<br />

5005<br />

5005<br />

5005<br />

5005<br />

MRCN<br />

s<br />

r<br />

Single-ended insert for parting <strong>and</strong> <strong>grooving</strong><br />

s<br />

r<br />

Ref. MRCN 1,6<br />

MRCN 2,2<br />

MRCN 3,0<br />

MRCN 4,0<br />

MRCN 5,0<br />

MRCN 6,0<br />

MRCN<br />

1,6<br />

2,2<br />

3,0<br />

4,0<br />

5,0<br />

6,0<br />

0,15<br />

0,20<br />

0,20<br />

0,20<br />

0,30<br />

0,40<br />

For more information see page: G.03<br />

G.10<br />

www.canelatools.com

<strong>Parting</strong> <strong>and</strong><br />

<strong>grooving</strong><br />

Toolholders<br />

<strong>Parting</strong> <strong>and</strong> <strong>grooving</strong><br />

Characteristics:<br />

Double sided inserts with thickness from 3 to 4 mm.<br />

The "V" positioning system of the pocket <strong>and</strong> the clamp integrated to the tool ensure maximum security <strong>and</strong><br />

repetitivity on the dimensions when the insert is changed.<br />

Applications:<br />

Face <strong>grooving</strong> <strong>and</strong> side turning toolholder that works well on steels, alloyed steels, stainless steels <strong>and</strong><br />

refractories.<br />

h<br />

h1<br />

B<br />

a<br />

b<br />

L2<br />

L1<br />

CZCF<br />

h=h1<br />

b L1<br />

L2 B<br />

a<br />

Insert size<br />

Kg<br />

Ref.<br />

CZCF R/L 1616 H34<br />

CZCF R/L 2020 K34<br />

CZCF R/L 2525 M34<br />

16<br />

20<br />

25<br />

16<br />

20<br />

25<br />

100<br />

125<br />

150<br />

24<br />

24<br />

24<br />

3-4<br />

3-4<br />

3-4<br />

4,5<br />

4,5<br />

4,5<br />

MT.. 3,0-4,0<br />

MT.. 3,0-4,0<br />

MT.. 3,0-4,0<br />

0,200<br />

0,300<br />

0,450<br />

Ref.<br />

s<br />

CZCF R/L 1616 H34<br />

CZCF R/L 2020 K34<br />

CZCF R/L 2525 M34<br />

MTC<br />

r<br />

MT..<br />

Ref. MTC 3,0<br />

MTC 4,0<br />

MTR 3,0<br />

MTR 3,8<br />

1916<br />

1906<br />

1906<br />

s<br />

3,0<br />

4,0<br />

3,0<br />

3,8<br />

r<br />

0,15<br />

0,20<br />

1,50<br />

1,90<br />

5005<br />

5005<br />

5005<br />

Double-ended insert for turning <strong>and</strong> <strong>grooving</strong>.<br />

Brazed tools Cartridges Drills<br />

Threading<br />

For more information see page: G.03<br />

s<br />

MTR<br />

r<br />

MTC<br />

MTR<br />

Tooling<br />

CANELA<br />

G.11

<strong>Parting</strong> <strong>and</strong> <strong>grooving</strong><br />

For more information see page:<br />

Inserts:G.02<br />

Applications: G.07<br />

Cutting data: G.24<br />

Toolholders: G.08<br />

Boring bars: G.14<br />

Tool blocks: G.16<br />

Blades: G.17<br />

Notch tools: G.20<br />

Toolholders<br />

Inserts<br />

Characteristics:<br />

Double sided inserts with thickness from 3 to 3,8 mm.<br />

The "V" positioning system of the pocket <strong>and</strong> the clamp integrated to the tool ensure maximum security <strong>and</strong><br />

repetitivity on the dimensions when the insert is changed.<br />

Applications:<br />

<strong>Parting</strong>, <strong>grooving</strong> <strong>and</strong> side turning toolholder that works well on steels, alloyed steels, stainless steels <strong>and</strong><br />

refractories.<br />

General turning<br />

B<br />

a<br />

h<br />

h1<br />

b<br />

L2<br />

L1<br />

Aluminium<br />

wheel turning<br />

CZCP<br />

h=h1<br />

b L1<br />

L2 B<br />

a<br />

Insert size<br />

Kg<br />

Automatic lathes<br />

Ref.<br />

CZCP R/L 1616 H34<br />

CZCP R/L 2020 K34<br />

CZCP R/L 2525 M34<br />

16<br />

20<br />

25<br />

16<br />

20<br />

25<br />

100<br />

125<br />

150<br />

30<br />

30<br />

30<br />

3-4<br />

3-4<br />

3-4<br />

12<br />

12<br />

12<br />

MT.. 3,0-4,0<br />

MT.. 3,0-4,0<br />

MT.. 3,0-4,0<br />

0,200<br />

0,300<br />

0,450<br />

<strong>Parting</strong> <strong>and</strong><br />

<strong>grooving</strong><br />

Ceramic tools<br />

Ref.<br />

CZCP R/L 1616 H34<br />

CZCP R/L 2020 K34<br />

CZCP R/L 2525 M34<br />

1916<br />

1906<br />

1906<br />

5005<br />

5005<br />

5005<br />

MT..<br />

s<br />

r<br />

Double-ended insert for turning <strong>and</strong> <strong>grooving</strong>.<br />

s<br />

MTC<br />

r<br />

Ref. MTC 3,0<br />

MTC 4,0<br />

MTR 3,0<br />

MTR 3,8<br />

3,0<br />

4,0<br />

3,0<br />

3,8<br />

0,15<br />

0,20<br />

1,50<br />

1,90<br />

MTC<br />

MTR<br />

For more information see page: G.03<br />

s<br />

MTR<br />

r<br />

G.12<br />

www.canelatools.com

<strong>Parting</strong> <strong>and</strong><br />

<strong>grooving</strong><br />

Toolholders<br />

<strong>Parting</strong> <strong>and</strong> <strong>grooving</strong><br />

Characteristics:<br />

One sided inserts with thickness from 2 to 4 mm.<br />

The "V" positioning system of the pocket <strong>and</strong> the clamp integrated to the tool ensure maximum security <strong>and</strong><br />

repetitivity on the dimensions when the insert is changed.<br />

Applications:<br />

<strong>Parting</strong> <strong>and</strong> <strong>grooving</strong> toolholder that works well on steels, alloyed steels, stainless steels <strong>and</strong> refractories.<br />

h<br />

h1<br />

B<br />

b<br />

L2<br />

L1<br />

XLCF<br />

h=h1<br />

Kg<br />

b L1<br />

L2<br />

B<br />

Insert size<br />

Ref.<br />

XLCF R/L 1010 J02<br />

10<br />

10<br />

110<br />

18<br />

2<br />

PTNT 02 0,080<br />

XLCF R/L 1210 J02 12 10<br />

110 18<br />

2 PTNT 02 0,100<br />

XLCF R/L 1212 J02<br />

12<br />

12<br />

110<br />

18<br />

2<br />

PTNT 02 0,100<br />

XLCF R/L 1612 J03<br />

XLCF R/L 1612 J04<br />

16<br />

16<br />

12<br />

12<br />

110<br />

110<br />

20<br />

20<br />

3<br />

4<br />

PTNT 03<br />

PTNT 04<br />

0,150<br />

0,150<br />

XLCF R/L 2012 K03<br />

XLCF R/L 2012 K04<br />

20<br />

20<br />

12<br />

12<br />

125<br />

125<br />

20<br />

20<br />

3<br />

4<br />

PTNT 03<br />

PTNT 04<br />

0,200<br />

0,200<br />

XLCF R/L 2020 K03<br />

XLCF R/L 2020 K04<br />

20<br />

20<br />

20<br />

20<br />

125<br />

125<br />

20<br />

20<br />

3<br />

4<br />

PTNT 03<br />

PTNT 04<br />

0,350<br />

0,350<br />

XLCF R/L 2525 M03<br />

XLCF R/L 2525 M04<br />

25<br />

25<br />

25<br />

25<br />

150<br />

150<br />

20<br />

20<br />

3<br />

4<br />

PTNT 03<br />

PTNT 04<br />

0,650<br />

0,650<br />

Ref.<br />

XLCF R/L 1010 J02<br />

5732<br />

XLCF R/L 1210 J02 5732<br />

XLCF R/L 1212 J02<br />

5732<br />

XLCF R/L 1612 J03<br />

XLCF R/L 1612 J04<br />

XLCF R/L 2012 K03<br />

XLCF R/L 2012 K04<br />

XLCF R/L 2020 K03<br />

XLCF R/L 2020 K04<br />

XLCF R/L 2525 M03<br />

XLCF R/L 2525 M04<br />

PTNT<br />

Ref. PTNT 02<br />

PTNT 03<br />

PTNT 04<br />

s<br />

2,10<br />

3,10<br />

4,10<br />

5732<br />

5732<br />

5732<br />

5732<br />

5732<br />

5732<br />

5732<br />

5732<br />

Single-ended insert for parting <strong>and</strong> <strong>grooving</strong>.<br />

Brazed tools Cartridges Drills<br />

Threading<br />

s<br />

PTNT<br />

For more information see page: G.04<br />

Tooling<br />

CANELA<br />

G.13

<strong>Parting</strong> <strong>and</strong> <strong>grooving</strong><br />

For more information see page:<br />

Inserts:G.02<br />

Applications: G.07<br />

Cutting data: G.24<br />

Toolholders: G.08<br />

Boring bars: G.14<br />

Tool blocks: G.16<br />

Blades: G.17<br />

Notch tools: G.20<br />

Boring bars<br />

Inserts<br />

Characteristics:<br />

Double sided inserts with thickness from 3 to 4 mm.<br />

The "V" positioning system of the pocket <strong>and</strong> the clamp integrated to the tool ensure maximum security <strong>and</strong><br />

repetitivity on the dimensions when the insert is changed.<br />

Applications:<br />

Grooving <strong>and</strong> internal turning toolholder that works well on steels, alloyed steels, stainless steels <strong>and</strong> refractories.<br />

General turning<br />

a<br />

h<br />

D<br />

A<br />

B<br />

L2<br />

L1<br />

Aluminium<br />

wheel turning<br />

CZGF<br />

D<br />

A h L1 L2 B<br />

a<br />

Insert size<br />

Kg<br />

Automatic lathes<br />

Ref.<br />

S20R CZGF R/L 34<br />

S25R CZGF R/L 34<br />

S32S CZGF R/L 34<br />

20<br />

25<br />

32<br />

16,5<br />

25,0<br />

30,0<br />

18<br />

23<br />

30<br />

200<br />

200<br />

250<br />

40<br />

50<br />

60<br />

3-4<br />

3-4<br />

3-4<br />

5<br />

5<br />

5<br />

MT.. 3,0-4,0<br />

MT.. 3,0-4,0<br />

MT.. 3,0-4,0<br />

0,400<br />

0,650<br />

1,400<br />

<strong>Parting</strong> <strong>and</strong><br />

<strong>grooving</strong><br />

Ceramic tools<br />

Ref. S20R CZGF R/L 34<br />

S25R CZGF R/L 34<br />

S32S CZGF R/L 34<br />

1250<br />

-<br />

-<br />

5520<br />

-<br />

-<br />

-<br />

1006<br />

1006<br />

-<br />

5004<br />

5004<br />

MT..J<br />

s<br />

r<br />

Double-ended insert for turning <strong>and</strong> <strong>grooving</strong>.<br />

s<br />

MTCJ<br />

r<br />

Ref. MTCJ 3,0<br />

MTCJ 4,0<br />

MTRJ 3,0<br />

MTRJ 3,8<br />

3,0<br />

4,0<br />

3,0<br />

3,8<br />

0,15<br />

0,20<br />

1,50<br />

1,90<br />

MTCJ<br />

MTRJ<br />

For more information see page: G.03<br />

s<br />

MTRJ<br />

r<br />

G.14<br />

www.canelatools.com

<strong>Parting</strong> <strong>and</strong><br />

<strong>grooving</strong><br />

Boring bars<br />

<strong>Parting</strong> <strong>and</strong> <strong>grooving</strong><br />

Characteristics:<br />

Single sided inserts with thickness from 3 to 4 mm.<br />

The "V" positioning system of the pocket <strong>and</strong> the clamp integrated to the tool ensure maximum security <strong>and</strong><br />

repetitivity on the dimensions when the insert is changed.<br />

Applications:<br />

Grooving toolholder that works well on steels, alloyed steels, stainless steels <strong>and</strong> refractories.<br />

D<br />

h<br />

A<br />

a<br />

B<br />

L2<br />

L1<br />

CZGB<br />

D<br />

A<br />

h L1 L2 B<br />

a<br />

Insert size<br />

Kg<br />

Ref.<br />

S16M CZGB R/L 03<br />

S20R CZGB R/L 03<br />

S25S CZGB R/L 03<br />

16<br />

20<br />

25<br />

16<br />

20<br />

25<br />

15<br />

18<br />

23<br />

150<br />

200<br />

250<br />

30<br />

40<br />

50<br />

3<br />

3<br />

3<br />

4<br />

6<br />

8<br />

MCRN 3,0<br />

MCRN 3,0<br />

MCRN 3,0<br />

0,180<br />

0,400<br />

0,650<br />

S20R CZGB R/L 04<br />

S25S CZGB R/L 04<br />

20<br />

25<br />

20<br />

25<br />

18<br />

23<br />

200<br />

250<br />

40<br />

50<br />

4<br />

4<br />

6<br />

8<br />

MCRN 4,0<br />

MCRN 4,0<br />

0,400<br />

0,650<br />

Ref. S16M CZGB R/L 03<br />

S20R CZGB R/L 03<br />

S25S CZGB R/L 03<br />

S20R CZGB R/L 04<br />

S25S CZGB R/L 04<br />

MRCN<br />

Ref. MRCN 3,0<br />

MRCN 4,0<br />

1250<br />

1250<br />

-<br />

-<br />

-<br />

s<br />

3,0<br />

4,0<br />

5520<br />

5520<br />

-<br />

-<br />

-<br />

r<br />

0,20<br />

0,20<br />

-<br />

-<br />

1006<br />

1006<br />

1006<br />

Single-ended insert for parting <strong>and</strong> <strong>grooving</strong><br />

-<br />

-<br />

5004<br />

5004<br />

5004<br />

Brazed tools Cartridges Drills<br />

Threading<br />

s<br />

r<br />

MRCN<br />

For more information see page: G.03<br />

Tooling<br />

CANELA<br />

G.15

<strong>Parting</strong> <strong>and</strong> <strong>grooving</strong><br />

For more information see page:<br />

Inserts:G.02<br />

Applications: G.07<br />

Cutting data: G.24<br />

Toolholders: G.08<br />

Boring bars: G.14<br />

Tool blocks: G.16<br />

Blades: G.17<br />

Notch tools: G.20<br />

Tool blocks<br />

Inserts<br />

Characteristics:<br />

Tool blocks manufactured with two slot-guide which allows to mantain the blade always guided.<br />

The fixing system by flexion ensures good rigidity <strong>and</strong> security.<br />

Applications:<br />

Tool block for manual <strong>and</strong> C.N.C. lathes.<br />

General turning<br />

h<br />

h1<br />

L<br />

b<br />

Aluminium<br />

wheel turning<br />

CPTS<br />

h1<br />

L<br />

h<br />

b<br />

Kg<br />

Ref.<br />

CPTS 1916<br />

19<br />

76<br />

16<br />

16<br />

0,300<br />

1075<br />

5004<br />

Automatic lathes<br />

Ceramic tools<br />

CPTS 2616<br />

CPTS 2620<br />

CPTS 2625<br />

CPTS 3220<br />

CPTS 3225<br />

CPTS 3232<br />

CPTS 5250<br />

26<br />

26<br />

26<br />

32<br />

32<br />

32<br />

52<br />

87<br />

87<br />

87<br />

100<br />

110<br />

120<br />

135<br />

16<br />

20<br />

25<br />

20<br />

25<br />

32<br />

50<br />

16<br />

20<br />

25<br />

20<br />

25<br />

32<br />

50<br />

0,450<br />

0,500<br />

0,650<br />

0,700<br />

0,950<br />

1,400<br />

3,400<br />

1076<br />

1076<br />

1076<br />

1076<br />

1076<br />

1076<br />

1078<br />

5005<br />

5005<br />

5005<br />

5005<br />

5005<br />

5005<br />

5006<br />

<strong>Parting</strong> <strong>and</strong><br />

<strong>grooving</strong><br />

Characteristics:<br />

Tool blocks manufactured with two slot-guide which allows to mantain the blade always guided.<br />

Fixing system in two parts for machines with difficult access.<br />

Applications:<br />

Tool block for manual <strong>and</strong> C.N.C. lathes.<br />

h<br />

h1<br />

L<br />

b<br />

DPTS<br />

h1<br />

L<br />

h<br />

b<br />

Kg<br />

Ref.<br />

DPTS 1916<br />

19<br />

76<br />

16<br />

16<br />

0,250<br />

1075<br />

5004<br />

DPTS 2620<br />

DPTS 2625<br />

26<br />

26<br />

87<br />

87<br />

20<br />

25<br />

20<br />

25<br />

0,550<br />

0,700<br />

1076<br />

1076<br />

5005<br />

5005<br />

DPTS 3220<br />

DPTS 3225<br />

DPTS 3232<br />

32<br />

32<br />

32<br />

100<br />

110<br />

120<br />

20<br />

25<br />

32<br />

20<br />

25<br />

32<br />

0,750<br />

1,000<br />

1,450<br />

1076<br />

1076<br />

1076<br />

5005<br />

5005<br />

5005<br />

DPTS 5250<br />

52<br />

135<br />

50<br />

50<br />

3,450<br />

1078<br />

5006<br />

G.16<br />

www.canelatools.com

<strong>Parting</strong> <strong>and</strong><br />

<strong>grooving</strong><br />

Blades<br />

<strong>Parting</strong> <strong>and</strong> <strong>grooving</strong><br />

Characteristics:<br />

One sided inserts with thickness from 2,2 to 6 mm.<br />

The double "V" pocket ensures a reliable <strong>and</strong> repetitive insert positioning <strong>and</strong> centering.<br />

Available in 4 sizes (19, 26 <strong>and</strong> 32).<br />

Applications:<br />

<strong>Parting</strong> <strong>and</strong> <strong>grooving</strong> blade that works well on steels, alloyed steels, stainless steels <strong>and</strong> refractories.<br />

B<br />

h1<br />

h<br />

L<br />

CRCFN<br />

Kg<br />

h L<br />

h1<br />

B<br />

Insert size<br />

Ref.<br />

CRCF N 1901 X02<br />

19<br />

86<br />

15,4<br />

2,2<br />

MRCN 2,2<br />

0,040<br />

CRCF N 2601 J02<br />

CRCF N 2602 J03<br />

CRCF N 2603 J04<br />

CRCF N 2604 J05<br />

CRCF N 2605 J06<br />

26<br />

26<br />

26<br />

26<br />

26<br />

110<br />

110<br />

110<br />

110<br />

110<br />

21,4<br />

21,4<br />

21,4<br />

21,4<br />

21,4<br />

2,2<br />

3,0<br />

4,0<br />

5,0<br />

6,0<br />

MRCN 2,2<br />

MRCN 3,0<br />

MRCN 4,0<br />

MRCN 5,0<br />

MRCN 6,0<br />

0,060<br />

0,070<br />

0,090<br />

0,100<br />

0,100<br />

CRCF N 3202 M03<br />

CRCF N 3203 M04<br />

CRCF N 3204 M05<br />

CRCF N 3205 M06<br />

32<br />

32<br />

32<br />

32<br />

150<br />

150<br />

150<br />

150<br />

25,0<br />

25,0<br />

25,0<br />

25,0<br />

3,0<br />

4,0<br />

5,0<br />

6,0<br />

MRCN 3,0<br />

MRCN 4,0<br />

MRCN 5,0<br />

MRCN 6,0<br />

0,100<br />

0,125<br />

0,150<br />

0,170<br />

Ref.<br />

s<br />

CRCF N 1901 X02<br />

CRCF N 2601 J02<br />

CRCF N 2602 J03<br />

CRCF N 2603 J04<br />

CRCF N 2604 J05<br />

CRCF N 2605 J06<br />

CRCF N 3202 M03<br />

CRCF N 3203 M04<br />

CRCF N 3204 M05<br />

CRCF N 3205 M06<br />

r<br />

MRCN<br />

Ref. MRCN 2,2<br />

MRCN 3,0<br />

MRCN 4,0<br />

MRCN 5,0<br />

MRCN 6,0<br />

MRCN<br />

s<br />

2,2<br />

3,0<br />

4,0<br />

5,0<br />

6,0<br />

r<br />

0,20<br />

0,20<br />

0,20<br />

0,30<br />

0,40<br />

5733<br />

5733<br />

5733<br />

5733<br />

5733<br />

5733<br />

5733<br />

5733<br />

5733<br />

5733<br />

Single-ended insert for parting <strong>and</strong> <strong>grooving</strong><br />

For more information see page: G.03<br />

Brazed tools Cartridges Drills<br />

Threading<br />

Tooling<br />

CANELA<br />

G.17

<strong>Parting</strong> <strong>and</strong> <strong>grooving</strong><br />

For more information see page:<br />

Inserts:G.02<br />

Applications: G.07<br />

Cutting data: G.24<br />

Toolholders: G.08<br />

Boring bars: G.14<br />

Tool blocks: G.16<br />

Blades: G.17<br />

Notch tools: G.20<br />

Blades<br />

Inserts<br />

Characteristics:<br />

One sided inserts with thickness from 2 to 9 mm.<br />

The double "V" pocket ensures a reliable <strong>and</strong> repetitive insert positioning <strong>and</strong> centering.<br />

Available in 4 sizes (19, 26, 32 <strong>and</strong> 53).<br />

Applications:<br />

<strong>Parting</strong>, <strong>grooving</strong> blade that works well on steels, alloyed steels, stainless steels <strong>and</strong> refractories.<br />

General turning<br />

B<br />

h<br />

L<br />

Aluminium<br />

wheel turning<br />

XLCFN<br />

h<br />

L<br />

B<br />

Insert size<br />

Kg<br />

Ref.<br />

XLCF N 1901 X02<br />

19<br />

86<br />

2,1<br />

PTNT 02<br />

0,040<br />

5732<br />

Automatic lathes<br />

XLCF N 2601 J02<br />

XLCF N 2602 J03<br />

XLCF N 2603 J04<br />

XLCF N 2604 J05<br />

XLCF N 2605 J06<br />

26<br />

26<br />

26<br />

26<br />

26<br />

110<br />

110<br />

110<br />

110<br />

110<br />

2,1<br />

3,1<br />

4,1<br />

5,1<br />

6,1<br />

PTNT 02<br />

PTNT 03<br />

PTNT 04<br />

PTNT 05<br />

PTNT 06<br />

0,050<br />

0,050<br />

0,085<br />

0,095<br />

0,120<br />

5732<br />

5732<br />

5732<br />

5732<br />

5732<br />

Ceramic tools<br />

XLCF N 3201 M02<br />

XLCF N 3202 M03<br />

XLCF N 3203 M04<br />

XLCF N 3204 M05<br />

XLCF N 3205 M06<br />

XLCF N 3207 M08<br />

XLCF N 3208 M09<br />

32<br />

32<br />

32<br />

32<br />

32<br />

32<br />

32<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

2,1<br />

3,1<br />

4,1<br />

5,1<br />

6,1<br />

8,1<br />

9,1<br />

PTNT 02<br />

PTNT 03<br />

PTNT 04<br />

PTNT 05<br />

PTNT 06<br />

PTNT 08<br />

PTNT 09<br />

0,075<br />

0,100<br />

0,130<br />

0,160<br />

0,190<br />

0,230<br />

0,270<br />

5732<br />

5732<br />

5732<br />

5732<br />

5732<br />

5732<br />

5732<br />

<strong>Parting</strong> <strong>and</strong><br />

<strong>grooving</strong><br />

XLCF N 5207 X08<br />

XLCF N 5208 X09<br />

XLCF N 5307 X08<br />

XLCF N 5308 X09<br />

53<br />

53<br />

53<br />

53<br />

190<br />

190<br />

260<br />

260<br />

8,1<br />

9,1<br />

8,1<br />

9,1<br />

PTNT 08<br />

PTNT 09<br />

PTNT 08<br />

PTNT 09<br />

0,500<br />

0,600<br />

0,700<br />

0,800<br />

5732<br />

5732<br />

5732<br />

5732<br />

PTNT<br />

s<br />

Single-ended insert for parting <strong>and</strong> <strong>grooving</strong>.<br />

s<br />

Ref. PTNT 02<br />

PTNT 03<br />

PTNT 04<br />

PTNT 05<br />

PTNT 06<br />

PTNT 08<br />

PTNT 09<br />

PTNT<br />

2,10<br />

3,10<br />

4,10<br />

5,10<br />

6,10<br />

8,10<br />

9,10<br />

For more information see page: G.04<br />

G.18<br />

www.canelatools.com

<strong>Parting</strong> <strong>and</strong><br />

<strong>grooving</strong><br />

Blades<br />

<strong>Parting</strong> <strong>and</strong> <strong>grooving</strong><br />

Characteristics:<br />

Positive stop blade for inserts with thickness from 2 to 6 mm.<br />

The double "V" pocket ensures a reliable <strong>and</strong> repetitive insert positioning <strong>and</strong> centering.<br />

Available in 4 sizes (19, 26, <strong>and</strong> 32).<br />

Applications:<br />

<strong>Parting</strong>, <strong>grooving</strong> blade that works well on steels, alloyed steels, stainless steels <strong>and</strong> refractories.<br />

B<br />

h<br />

L<br />

XLCTN<br />

h<br />

L<br />

B<br />

Insert size<br />

Kg<br />

Ref.<br />

XLCT N 1901 X02<br />

19<br />

86<br />

2,1<br />

PTNT 02<br />

0,040<br />

XLCT N 2601 J02<br />

XLCT N 2602 J03<br />

XLCT N 2603 J04<br />

XLCT N 2604 J05<br />

XLCT N 2605 J06<br />

26<br />

26<br />

26<br />

26<br />

26<br />

110<br />

110<br />

110<br />

110<br />

110<br />

2,1<br />

3,1<br />

4,1<br />

5,1<br />

6,1<br />

PTNT 02<br />

PTNT 03<br />

PTNT 04<br />

PTNT 05<br />

PTNT 06<br />

0,050<br />

0,050<br />

0,085<br />

0,095<br />

0,120<br />

XLCT N 3201 M02<br />

XLCT N 3202 M03<br />

XLCT N 3203 M04<br />

XLCT N 3204 M05<br />

XLCT N 3205 M06<br />

32<br />

32<br />

32<br />

32<br />

32<br />

150<br />

150<br />

150<br />

150<br />

150<br />

2,1<br />

3,1<br />

4,1<br />

5,1<br />

6,1<br />

PTNT 02<br />

PTNT 03<br />

PTNT 04<br />

PTNT 05<br />

PTNT 06<br />

0,075<br />

0,100<br />

0,130<br />

0,160<br />

0,190<br />

Ref.<br />

XLCT N 1901 X02<br />

XLCT N 2601 J02<br />

XLCT N 2602 J03<br />

XLCT N 2603 J04<br />

XLCT N 2604 J05<br />

XLCT N 2605 J06<br />

XLCT N 3201 M02<br />

XLCT N 3202 M03<br />

XLCT N 3203 M04<br />

XLCT N 3204 M05<br />

XLCT N 3205 M06<br />

PTNT<br />

Ref. PTNT 02<br />

PTNT 03<br />

PTNT 04<br />

PTNT 05<br />

PTNT 06<br />

s<br />

2,10<br />

3,10<br />

4,10<br />

5,10<br />

6,10<br />

5732<br />

5732<br />

5732<br />

5732<br />

5732<br />

5732<br />

5732<br />

5732<br />

5732<br />

5732<br />

5732<br />

Single-ended insert for parting <strong>and</strong> <strong>grooving</strong>.<br />

Brazed tools Cartridges Drills<br />

Threading<br />

s<br />

PTNT<br />

For more information see page: G.04<br />

Tooling<br />

CANELA<br />

G.19

<strong>Parting</strong> <strong>and</strong> <strong>grooving</strong><br />

For more information see page:<br />

Inserts:G.02<br />

Applications index: G.07<br />

Cutting data: G.24<br />

Toolholders: G.08<br />

Boring bars: G.14<br />

Tool blocks: G.16<br />

Blades: G.17<br />

Notch tools: G.20<br />

Notch tools<br />

Inserts<br />

Characteristics:<br />

Multipurpose <strong>grooving</strong> <strong>and</strong> threading top clamp toolholder.<br />

Right tools require left inserts <strong>and</strong> vice versa.<br />

Maximum <strong>grooving</strong> depth depending on insert.<br />

Applications:<br />

External/internal <strong>grooving</strong> toolholder.<br />

General turning<br />

3º<br />

f<br />

B4<br />

h<br />

h1<br />

b<br />

L2<br />

CD<br />

L1<br />

Aluminium<br />

wheel turning<br />

NE 93°<br />

Kg<br />

h=h1 b<br />

L1 L2<br />

f Insert size<br />

Automatic lathes<br />

Ref.<br />

NE R/L 1616 H02<br />

NE R/L 2020 K02<br />

NE R/L 2525 M02<br />

NE R/L 2525 M03<br />

NE R/L 3225 P03<br />

16<br />

20<br />

25<br />

25<br />

32<br />

16<br />

20<br />

25<br />

25<br />

25<br />

100<br />

125<br />

150<br />

150<br />

170<br />

25,40<br />

25,40<br />

25,40<br />

50,80<br />

50,80<br />

20<br />

25<br />

32<br />

32<br />

32<br />

N..2<br />

N..2<br />

N..2<br />

N..3<br />

N..3<br />

0,200<br />

0,400<br />

0,700<br />

0,700<br />

1,000<br />

Ceramic tools<br />

NE R/L 2525 M04<br />

NE R/L 3225 P04<br />

NE R/L 3232 P04<br />

25<br />

32<br />

32<br />

25<br />

25<br />

32<br />

150<br />

170<br />

170<br />

50,80<br />

50,80<br />

50,80<br />

35<br />

35<br />

40<br />

N..4<br />

N..4<br />

N..4<br />

0,700<br />

1,000<br />

1,250<br />

<strong>Parting</strong> <strong>and</strong><br />

<strong>grooving</strong><br />

R<br />

L<br />

Ref.<br />

NE R/L 1616 H02<br />

NE R/L 2020 K02<br />

NE R/L 2525 M02<br />

TF-75<br />

TF-75<br />

TF-75<br />

TF-74<br />

TF-74<br />

TF-74<br />

1494<br />

1494<br />

1494<br />

NE R/L 2525 M03<br />

NE R/L 3225 P03<br />

TF-73<br />

TF-73<br />

TF-72<br />

TF-72<br />

1495<br />

1495<br />

NE R/L 2525 M04<br />

NE R/L 3225 P04<br />

NE R/L 3232 P04<br />

TF-73<br />

TF-73<br />

TF-73<br />

TF-72<br />

TF-72<br />

TF-72<br />

1495<br />

1495<br />

1495<br />

NG<br />

s<br />

Ref.<br />

N..<br />

N.. 2<br />

N.. 3<br />

N.. 4<br />

D<br />

4,76<br />

9,53<br />

9,53<br />

A T NG: Insert for parting<br />

5,56<br />

8,74<br />

11,51<br />

3,81<br />

4,95<br />

6,48<br />

NR: Insert for parting with radius<br />

NT: Insert for threading<br />

NR<br />

s<br />

For more information see page: G.05<br />

NG NR NT<br />

NT<br />

s<br />

G.20<br />

www.canelatools.com

<strong>Parting</strong> <strong>and</strong><br />

<strong>grooving</strong><br />

Notch tools<br />

<strong>Parting</strong> <strong>and</strong> <strong>grooving</strong><br />

Characteristics:<br />

Specific application <strong>grooving</strong> toolholder.<br />

Right tools require left inserts <strong>and</strong> vice versa.<br />

Maximum <strong>grooving</strong> depth depending on insert.<br />

Applications:<br />

External <strong>grooving</strong> toolholder.<br />

h<br />

h1<br />

45º<br />

f<br />

b<br />

L2<br />

L1<br />

NR 45°<br />

h=h1 b<br />

L1 L2<br />

f Insert size<br />

Kg<br />

Ref.<br />

NR R/L 2020 K03<br />

NR R/L 2525 M03<br />

NR R/L 3225 P03<br />

20<br />

25<br />

32<br />

20<br />

25<br />

25<br />

125<br />

150<br />

170<br />

32<br />

32<br />

32<br />

25<br />

32<br />

32<br />

N..3<br />

N..3<br />

N..3<br />

0,400<br />

0,700<br />

1,000<br />

R<br />

L<br />

Ref.<br />

NG<br />

NR R/L 2020 K03<br />

NR R/L 2525 M03<br />

NR R/L 3225 P03<br />

s<br />

Ref.<br />

N..<br />

N.. 3<br />

TF-73<br />

TF-73<br />

TF-73<br />

D<br />

A<br />

9,53 8,74 4,95<br />

T<br />

TF-72<br />

TF-72<br />

TF-72<br />

NG: Insert for parting<br />

NR: Insert for parting with radius<br />

NT: Insert for threading<br />

1495<br />

1495<br />

1495<br />

Brazed tools Cartridges Drills<br />

Threading<br />

NR<br />

s<br />

For more information see page: G.05<br />

NT<br />

s<br />

NG NR NT<br />

Tooling<br />

CANELA<br />

G.21

<strong>Parting</strong> <strong>and</strong> <strong>grooving</strong><br />

For more information see page:<br />

Inserts:G.02<br />

Applications: G.07<br />

Cutting data: G.24<br />

Toolholders: G.08<br />

Boring bars: G.14<br />

Tool blocks: G.16<br />

Blades: G.17<br />

Notch tools: G.20<br />

Notch tools<br />

Inserts<br />

Characteristics:<br />

Multipurpose <strong>grooving</strong> <strong>and</strong> threading top clamp toolholder.<br />

Maximum <strong>grooving</strong> depth depending on insert.<br />

Applications:<br />

External <strong>grooving</strong> toolholder.<br />

General turning<br />

f<br />

t<br />

93º<br />

h<br />

h1<br />

b<br />

L2<br />

L1<br />

Aluminium<br />

wheel turning<br />

NS 93°<br />

Kg<br />

h=h1 b<br />

L1 L2<br />

f Insert size<br />

Automatic lathes<br />

Ceramic tools<br />

Ref.<br />

NS R/L 1010 E02<br />

NS R/L 1212 F02<br />

NS R/L 1616 H02<br />

NS R/L 2020 K02<br />

NS R/L 2525 M02<br />

NS R/L 2020 K03<br />

NS R/L 2525 M03<br />

NS R/L 3225 P03<br />

NS R/L 3232 P03<br />

NS R/L 2525 M04<br />

NS R/L 3225 P04<br />

NS R/L 3232 P04<br />

10<br />

12<br />

16<br />

20<br />

25<br />

20<br />

25<br />

32<br />

32<br />

25<br />

32<br />

32<br />

10<br />

12<br />

16<br />

20<br />

25<br />

20<br />

25<br />

25<br />

32<br />

25<br />

25<br />

32<br />

70<br />

80<br />

100<br />

125<br />

150<br />

125<br />

150<br />

170<br />

170<br />

150<br />

170<br />

170<br />

6,35<br />

6,35<br />

6,35<br />

6,35<br />

6,35<br />

9,65<br />

9,65<br />

9,65<br />

9,65<br />

9,65<br />

9,65<br />

9,65<br />

14<br />

16<br />

20<br />

25<br />

32<br />

25<br />

32<br />

32<br />

40<br />

32<br />

32<br />

40<br />

N..2<br />

N..2<br />

N..2<br />

N..2<br />

N..2<br />

N..3<br />

N..3<br />

N..3<br />

N..3<br />

N..4<br />

N..4<br />

N..4<br />

0,070<br />

0,100<br />

0,200<br />

0,400<br />

0,700<br />

0,400<br />

0,700<br />

0,900<br />

1,250<br />

0,700<br />

0,900<br />

1,250<br />

<strong>Parting</strong> <strong>and</strong><br />

<strong>grooving</strong><br />

R<br />

L<br />

Ref.<br />

NS R/L 1010 E02<br />

NS R/L 1212 F02<br />

NS R/L 1616 H02<br />

NS R/L 2020 K02<br />

NS R/L 2525 M02<br />

TF-74<br />

TF-74<br />

TF-74<br />

TF-74<br />

TF-74<br />

TF-75<br />

TF-75<br />

TF-75<br />

TF-75<br />

TF-75<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

1494<br />

1494<br />

1494<br />

1494<br />

1494<br />

NS R/L 2020 K03<br />

NS R/L 2525 M03<br />

NS R/L 3225 P03<br />

NS R/L 3232 P03<br />

TF-72<br />

TF-72<br />

TF-72<br />

TF-72<br />

TF-73<br />

TF-73<br />

TF-73<br />

TF-73<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

1495<br />

1495<br />

1495<br />

1495<br />

NS R/L 2525 M04<br />

NS R/L 3225 P04<br />

NS R/L 3232 P04<br />

TF-72<br />

TF-72<br />

TF-72<br />

TF-73<br />

TF-73<br />

TF-73<br />

3521<br />

3521<br />

3521<br />

1625<br />

1625<br />

1625<br />

1495<br />

1495<br />

1495<br />

NG<br />

s<br />

Ref.<br />

N..<br />

N.. 2<br />

N.. 3<br />

N.. 4<br />

D<br />

4,76<br />

9,53<br />

9,53<br />

A<br />

5,56<br />

8,74<br />

11,51<br />

T<br />

3,81<br />

4,95<br />

6,48<br />

NG: Insert for parting<br />

NR: Insert for parting with radius<br />

NT: Insert for threading<br />

NR<br />

s<br />

For more information see page: G.05<br />

NG NR NT<br />

NT<br />

s<br />

G.22<br />

www.canelatools.com

<strong>Parting</strong> <strong>and</strong><br />

<strong>grooving</strong><br />

Notch tools<br />

<strong>Parting</strong> <strong>and</strong> <strong>grooving</strong><br />

Characteristics:<br />

Multipurpose <strong>grooving</strong> <strong>and</strong> threading top clamp boring bar.<br />

Right tools require left inserts <strong>and</strong> vice versa.<br />

Maximum <strong>grooving</strong> depth depending on insert.<br />

Applications:<br />

Internal <strong>grooving</strong> toolholder.<br />

D<br />

h1<br />

h<br />

A<br />

f<br />

93º<br />

L1<br />

NNTO 93°<br />

D h<br />

h1<br />

L1 f<br />

A Insert size<br />

Kg<br />

Ref.<br />

A12M-NNTO R/L 02<br />

A16M-NNTO R/L 02<br />

A20Q-NNTO R/L 02<br />

A25R-NNTO R/L 02<br />

12<br />

16<br />

20<br />

25<br />

11<br />

15<br />

18<br />

23<br />

5,5<br />

7,5<br />

9,0<br />

11,5<br />

150<br />

150<br />

180<br />

200<br />

11<br />

11<br />

13<br />

17<br />

18,5<br />

22,0<br />

26,0<br />

34,0<br />

N..2<br />

N..2<br />

N..2<br />

N..2<br />

0,150<br />

0,200<br />

0,400<br />

0,700<br />

A25R-NNTO R/L 03<br />

A32S-NNTO R/L 03<br />

A40T-NNTO R/L 03<br />

25<br />

32<br />

40<br />

23<br />

30<br />

37<br />

11,5<br />

15,0<br />

18,5<br />

200<br />

250<br />

300<br />

17<br />

22<br />

27<br />

34,0<br />

44,0<br />

54,0<br />

N..3<br />

N..3<br />

N..3<br />

0,700<br />

1,400<br />

2,650<br />

A40T-NNTO R/L 04<br />

A50U-NNTO R/L 04<br />

40<br />

50<br />

37<br />

47<br />

18,5<br />

23,5<br />

300<br />

350<br />

27<br />

35<br />

54,0<br />

70,0<br />

N..4<br />

N..4<br />

2,650<br />

5,400<br />

R<br />

L<br />

Ref.<br />

NG<br />

NR<br />

A12M-NNTO R/L 02<br />

A16M-NNTO R/L 02<br />

A20Q-NNTO R/L 02<br />

A25R-NNTO R/L 02<br />

A25R-NNTO R/L 03<br />

A32S-NNTO R/L 03<br />

A40T-NNTO R/L 03<br />

A40T-NNTO R/L 04<br />

A50U-NNTO R/L 04<br />

s<br />

s<br />

Ref.<br />

N..<br />

N.. 2<br />

N.. 3<br />

N.. 4<br />

TF-147<br />

TF-75<br />

TF-75<br />

TF-75<br />

TF-73<br />

TF-73<br />

TF-73<br />

TF-73<br />

TF-73<br />

D<br />

4,76<br />

9,53<br />

9,53<br />

A<br />

5,56<br />

8,74<br />

11,51<br />

T<br />

3,81<br />

4,95<br />

6,48<br />

TF-146<br />

TF-74<br />

TF-74<br />

TF-74<br />

TF-72<br />

TF-72<br />

TF-72<br />

TF-72<br />

TF-72<br />

NG: Insert for parting<br />

NR: Insert for parting with radius<br />

NT: Insert for threading<br />

1494<br />

1494<br />

1494<br />

1494<br />

1495<br />

1495<br />

1495<br />

1495<br />

1495<br />

For more information see page: G.05<br />

Brazed tools Cartridges Drills<br />

Threading<br />

NT<br />

s<br />

NG NR NT<br />

Tooling<br />

CANELA<br />

G.23

<strong>Parting</strong> <strong>and</strong> <strong>grooving</strong><br />

For more information see page:<br />

Inserts:G.02<br />

Applications: G.07<br />

Cutting data: G.24<br />

Toolholders: G.08<br />

Boring bars: G.14<br />

Tool blocks: G.16<br />

Blades: G.17<br />

Notch tools: G.20<br />

Cutting data<br />

Inserts<br />

General turning<br />

Nominal cutting speed for parting<br />

Material HB Condition<br />

Unalloyed steel<br />

Low alloyed steel<br />

P<br />

125<br />

150<br />

200<br />

180<br />

275<br />

300<br />

350<br />

C=0.15%<br />

C=0.35%<br />

C=0.60%<br />

Annealed<br />

Hardened<br />

Hardened<br />

Hardened<br />

Basic qualities<br />

TIN32 PM25 KM15<br />

Cutting speed m/min.<br />

200-150<br />

190-140<br />

170-120<br />

180-130<br />

160-110<br />

150-100<br />

140-90<br />

160-120<br />

150-110<br />

130-90<br />

140-100<br />

120-80<br />

110-70<br />

90-60<br />

Specific<br />

cutting<br />

force<br />

N/mm 2<br />

1900<br />

2100<br />

2250<br />

2100<br />

2600<br />

2700<br />

2850<br />

Aluminium<br />

wheel turning<br />

High alloyed steel<br />

Stainless steel<br />

200<br />

325<br />

200<br />

Annealed<br />

Hardened<br />

Martensitic/Ferritic<br />

110-90<br />

70-50<br />

170-120<br />

70-60<br />

45-30<br />

130-90<br />

2600<br />

3900<br />

2300<br />

Automatic lathes<br />

Ceramic tools<br />

Steel<br />

180<br />

200<br />

225<br />

M<br />

Stainless steel annealed<br />

180<br />

Heat resistant alloys<br />

Titanium alloys<br />

200<br />

280<br />