DEFECTS IN METALS AND SIMULATION OF MECHANICAL ...

DEFECTS IN METALS AND SIMULATION OF MECHANICAL ...

DEFECTS IN METALS AND SIMULATION OF MECHANICAL ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

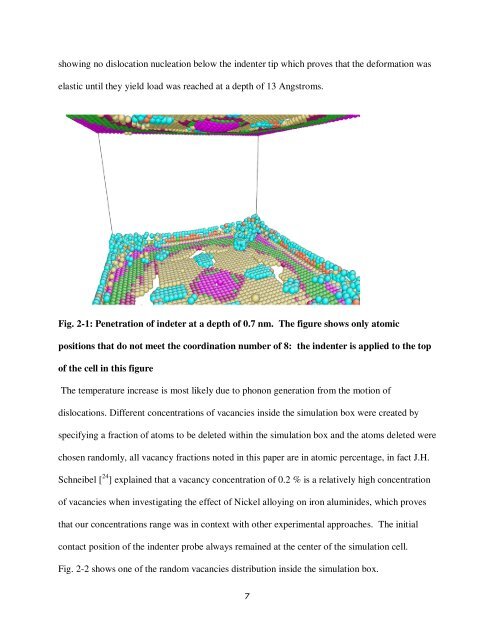

showing no dislocation nucleation below the indenter tip which proves that the deformation was<br />

elastic until they yield load was reached at a depth of 13 Angstroms.<br />

Fig. 2-1: Penetration of indeter at a depth of 0.7 nm. The figure shows only atomic<br />

positions that do not meet the coordination number of 8: the indenter is applied to the top<br />

of the cell in this figure<br />

The temperature increase is most likely due to phonon generation from the motion of<br />

dislocations. Different concentrations of vacancies inside the simulation box were created by<br />

specifying a fraction of atoms to be deleted within the simulation box and the atoms deleted were<br />

chosen randomly, all vacancy fractions noted in this paper are in atomic percentage, in fact J.H.<br />

Schneibel [ 24 ] explained that a vacancy concentration of 0.2 % is a relatively high concentration<br />

of vacancies when investigating the effect of Nickel alloying on iron aluminides, which proves<br />

that our concentrations range was in context with other experimental approaches. The initial<br />

contact position of the indenter probe always remained at the center of the simulation cell.<br />

Fig. 2-2 shows one of the random vacancies distribution inside the simulation box.<br />

7