DEFECTS IN METALS AND SIMULATION OF MECHANICAL ...

DEFECTS IN METALS AND SIMULATION OF MECHANICAL ...

DEFECTS IN METALS AND SIMULATION OF MECHANICAL ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

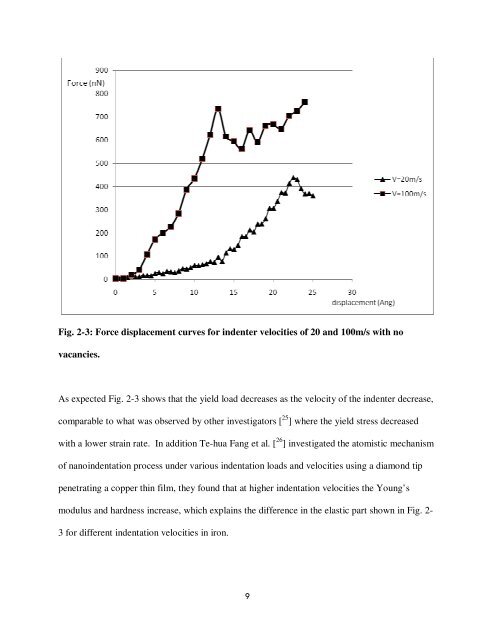

Fig. 2-3: Force displacement curves for indenter velocities of 20 and 100m/s with no<br />

vacancies.<br />

As expected Fig. 2-3 shows that the yield load decreases as the velocity of the indenter decrease,<br />

comparable to what was observed by other investigators [ 25 ] where the yield stress decreased<br />

with a lower strain rate. In addition Te-hua Fang et al. [ 26 ] investigated the atomistic mechanism<br />

of nanoindentation process under various indentation loads and velocities using a diamond tip<br />

penetrating a copper thin film, they found that at higher indentation velocities the Young’s<br />

modulus and hardness increase, which explains the difference in the elastic part shown in Fig. 2-<br />

3 for different indentation velocities in iron.<br />

9