DA 516 Submittal F315 - Flow Design Inc.

DA 516 Submittal F315 - Flow Design Inc.

DA 516 Submittal F315 - Flow Design Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

F L O W D E S I G N I N C<br />

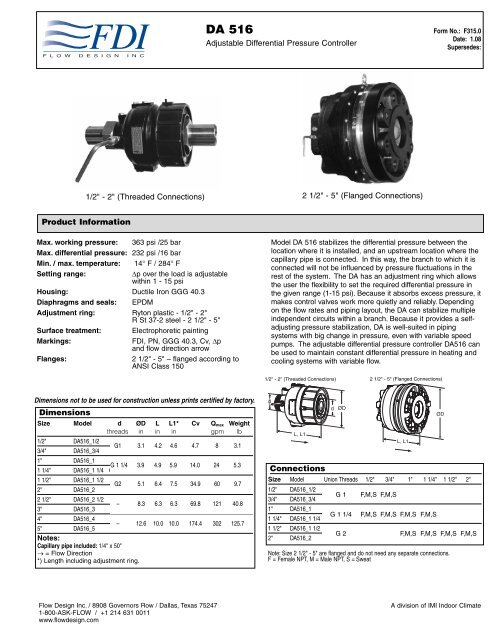

<strong>DA</strong> <strong>516</strong><br />

Adjustable Differential Pressure Controller<br />

Form No.: <strong>F315</strong>.0<br />

Date: 1.08<br />

Supersedes:<br />

1/2" - 2" (Threaded Connections) 2 1/2" - 5" (Flanged Connections)<br />

Product Information<br />

Max. working pressure: 363 psi /25 bar<br />

Max. differential pressure: 232 psi /16 bar<br />

Min. / max. temperature: 14° F / 284° F<br />

Setting range:<br />

∆p over the load is adjustable<br />

within 1 - 15 psi<br />

Housing: Ductile Iron GGG 40.3<br />

Diaphragms and seals: EPDM<br />

Adjustment ring: Ryton plastic - 1/2" - 2"<br />

R St 37-2 steel - 2 1/2" - 5"<br />

Surface treatment: Electrophoretic painting<br />

Markings:<br />

FDI, PN, GGG 40.3, Cv, ∆p<br />

and flow direction arrow<br />

Flanges:<br />

2 1/2" - 5" – flanged according to<br />

ANSI Class 150<br />

Model <strong>DA</strong> <strong>516</strong> stabilizes the differential pressure between the<br />

location where it is installed, and an upstream location where the<br />

capillary pipe is connected. In this way, the branch to which it is<br />

connected will not be influenced by pressure fluctuations in the<br />

rest of the system. The <strong>DA</strong> has an adjustment ring which allows<br />

the user the flexibility to set the required differential pressure in<br />

the given range (1-15 psi). Because it absorbs excess pressure, it<br />

makes control valves work more quietly and reliably. Depending<br />

on the flow rates and piping layout, the <strong>DA</strong> can stabilize multiple<br />

independent circuits within a branch. Because it provides a selfadjusting<br />

pressure stabilization, <strong>DA</strong> is well-suited in piping<br />

systems with big change in pressure, even with variable speed<br />

pumps. The adjustable differential pressure controller <strong>DA</strong><strong>516</strong> can<br />

be used to maintain constant differential pressure in heating and<br />

cooling systems with variable flow.<br />

1/2” - 2” Threaded<br />

1/2" - 2" (Threaded Connections) 2 1/2" 2 1/2” - 5" -(Flanged 5” Flanged Connections)<br />

Dimensions not to be used for construction unless prints certified by factory.<br />

Dimensions<br />

Size Model d ØD L L1* Cv Q max Weight<br />

threads in in in gpm lb<br />

1/2" <strong>DA</strong><strong>516</strong>_1/2<br />

G1 3.1 4.2 4.6 4.7 8 3.1<br />

3/4" <strong>DA</strong><strong>516</strong>_3/4 G1 3.1 4.2 4.6 4.7 8 3.1<br />

1" <strong>DA</strong><strong>516</strong>_1<br />

G 1 1/4 3.9 4.9 5.9 14.0 24 5.3<br />

1 1/4" <strong>DA</strong><strong>516</strong>_1 1/4 G 1 1/4 3.9 4.9 5.9 14.0 24 5.3<br />

1 1/2" <strong>DA</strong><strong>516</strong>_1 1/2<br />

G2 5.1 6.4 7.5 34.9 60 9.7<br />

2" <strong>DA</strong><strong>516</strong>_2 G2 5.1 6.4 7.5 34.9 60 9.7<br />

2 1/2" <strong>DA</strong><strong>516</strong>_2 1/2<br />

3" <strong>DA</strong><strong>516</strong>_3<br />

– 8.3 6.3 6.3 69.8 121 40.8<br />

Notes:<br />

4" <strong>DA</strong><strong>516</strong>_4<br />

5" <strong>DA</strong><strong>516</strong>_5<br />

– 12.6 10.0 10.0 174.4 302 125.7<br />

Capillary pipe included: 1/4" x 50"<br />

→ = <strong>Flow</strong> Direction<br />

*) Length including adjustment ring.<br />

d<br />

L, L1<br />

Connections<br />

Size Model Union Threads 1/2" 3/4" 1" 1 1/4" 1 1/2" 2"<br />

1/2" <strong>DA</strong><strong>516</strong>_1/2<br />

G 1 F,M,S F,M,S<br />

3/4" <strong>DA</strong><strong>516</strong>_3/4<br />

1" <strong>DA</strong><strong>516</strong>_1<br />

1 1/4" <strong>DA</strong><strong>516</strong>_1 1/4<br />

1 1/2" <strong>DA</strong><strong>516</strong>_1 1/2<br />

2" <strong>DA</strong><strong>516</strong>_2<br />

d<br />

ØD<br />

G 1 1/4<br />

G 2<br />

L, L1<br />

F,M,S F,M,S F,M,S F,M,S<br />

ØD<br />

F,M,S F,M,S F,M,S F,M,S<br />

Note: Size 2 1/2" - 5" are flanged and do not need any separate connections.<br />

F = Female NPT, M = Male NPT, S = Sweat<br />

<strong>Flow</strong> <strong>Design</strong> <strong>Inc</strong>. / 8908 Governors Row / Dallas, Texas 75247<br />

1-800-ASK-FLOW / +1 214 631 0011<br />

www.flowdesign.com<br />

A division of IMI Indoor Climate

F L O W D E S I G N I N C<br />

Operating Function<br />

Operating Function<br />

The pressure before the load (object across which you want to stabilize pressure) acts<br />

through an external capillary pipe (∆p+) on the plus side of the diaphragm (1) and<br />

attempts to close the valve.<br />

The pressure after the load acts via an internal capillary pipe in the valve body and<br />

attempts, together with the spring (3) force, to open the valve. In this way, the<br />

differential pressure over the load is kept constant on the set value.<br />

The spring force can be adjusted by turning the adjustment ring (5). Adjustment can be<br />

fixed by tightening the fixing screw (4).<br />

(1) Diaphragm (2) Venting Screws (3) Spring<br />

(4) Fixing Screw (5) Adjustment Ring<br />

∆p+<br />

1 2 3 4 5<br />

∆p-<br />

R1/4<br />

Installation<br />

Note! <strong>DA</strong> <strong>516</strong> valve closes at increasing<br />

differential pressure. Therefore, it is not<br />

recommended to install the <strong>DA</strong> <strong>516</strong> valves in the<br />

bypass line of constant flow systems. It is not<br />

allowed to disassemble the valve body. By<br />

incorrect handling, the controller may not<br />

∆p+<br />

work properly and safety problems may<br />

occur.<br />

Turn the adjustment ring (5) clock-wise until<br />

stop and the nut (7) on the outlet side will<br />

be accessible.<br />

The <strong>DA</strong> <strong>516</strong> must be installed downstream of<br />

the load for which the pressure is being<br />

controlled. <strong>Flow</strong> direction is shown by arrow (11)<br />

on the valve's identification plate (10). The best<br />

position is horizontal with the venting screws (2)<br />

pointing upwards. Installation of a strainer (<strong>Flow</strong><br />

<strong>Design</strong> model YC) is recommended upstream of the<br />

valve. Connect capillary pipe (∆p+), to the pipeline<br />

upstream of the load. In case of a horizontal pipeline<br />

connect the capillary pipe laterally to prevent air and<br />

dirt from entering. When filling, vent the body by using<br />

the venting screws (2). When soldering the valve must<br />

be protected from too high temperature. This typically<br />

means that soldering should be carried out by<br />

slipping union nut and tail piece onto the pipe<br />

separate from the valve, soldering the tailpiece in<br />

place, and installing the valve with its gaskets<br />

between the tailpieces after they have cooled.<br />

Capillary pipe<br />

Before taking into operation, the capillary pipe must<br />

be installed. One end of the capillary pipe goes into<br />

the <strong>DA</strong> <strong>516</strong> and the other end of the capillary pipe is<br />

connected to the strainer YC (through the provided<br />

1/4" NPT fitting connection).<br />

11<br />

10<br />

Figure 3 b: Two Water 7<br />

9 8 Loops with TBV-Cs, <strong>DA</strong> <strong>516</strong> and YC<br />

YC<br />

<strong>DA</strong> <strong>516</strong><br />

2<br />

Figure 3<br />

UB<br />

∆p+<br />

∆p+<br />

5<br />

<strong>DA</strong> <strong>516</strong><br />

<strong>DA</strong> <strong>516</strong><br />

YC<br />

M<br />

M<br />

UP<br />

Figure 1<br />

Figure 2<br />

TBV-C

<strong>DA</strong> <strong>516</strong><br />

Adjustable Differential Presssure Controller<br />

Setting<br />

The differential pressure can be adjusted by turning the adjustment ring. For 2" and smaller valves, the adjustment ring has a marking<br />

for ∆p for each turn. The preset value can be secured by attaching a wire through the holes.<br />

Pressure Adjustment<br />

Differential pressure adjustment for <strong>DA</strong> <strong>516</strong>, ½” to 2”<br />

1. Unscrew the fixing screw (4) with a 2mm Allen key on the setting wheel (1).<br />

2. Turn the setting wheel clockwise to increase the differential pressure and<br />

vice versa.<br />

3. On the setting wheel, there is a mark which shows how the ∆p changes at one<br />

turn of the setting wheel.<br />

4. The pressure can also be measured through pressure gauges on the pipeline<br />

and adjusted through the setting wheel.<br />

5. After the required differential pressure ∆p is reached, tighten the fixing screw<br />

on the setting wheel.<br />

6. It is also possible to secure the setting with the leaden seal by using the holes<br />

on the body and the setting wheel (1).<br />

1<br />

4<br />

∆p<br />

∆p<br />

Differential pressure adjustment for <strong>DA</strong> <strong>516</strong>, 2 ½” and above<br />

1. The principle of adjustment for the <strong>DA</strong> <strong>516</strong>, size 2 1/2” and above is the same<br />

as size 2“ and below, except there is no mark which shows how the ∆p<br />

changes at one turn of the setting wheel. Also there is no fixing screw and no<br />

leaden seal.<br />

∆p =min<br />

2. The setting wheel (10) moves indirectly by the middle nut (11), which can be<br />

turned by the tool provided with the <strong>DA</strong> <strong>516</strong> in the package.<br />

∆p<br />

3. The pressure can be set by reading the pressure gauges on the pipeline and<br />

adjusting the middle nut according to the requirements.<br />

11 10

<strong>DA</strong> <strong>516</strong><br />

Adjustable Differential Presssure Controller<br />

F L O W D E S I G N I N C<br />

Sizing<br />

1. Select the smallest size for the designed flow according to the diagram.<br />

2. Check that the available ∆p is bigger than the pressure drop of the <strong>DA</strong> <strong>516</strong> at the designed flow.<br />

The pressure drop can be found in the diagram or calculated by the formula:<br />

Differential Pressure (psi)<br />

3<br />

2<br />

Size Size Size Size Size<br />

1/2” / 3/4” 1” / 1 1/4” 1 1/2” / 2” 2 1/2” / 3” 4” / 5”<br />

1<br />

0.5<br />

0.25<br />

0.2<br />

1.5 2<br />

4 8 16 32 64 128 256 350<br />

Q (gpm)<br />

8908 Governors Row / Dallas, Texas 75247<br />

1-800-ASK-FLOW / +1 214 631 0011<br />

www.flowdesign.com