Technical Report on Resources Cerro Colorado ... - Goldgroup Mining

Technical Report on Resources Cerro Colorado ... - Goldgroup Mining

Technical Report on Resources Cerro Colorado ... - Goldgroup Mining

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<str<strong>on</strong>g>Technical</str<strong>on</strong>g> <str<strong>on</strong>g>Report</str<strong>on</strong>g> <strong>on</strong> <strong>Resources</strong><br />

<strong>Cerro</strong> <strong>Colorado</strong> Gold Mine<br />

S<strong>on</strong>ora, Mexico<br />

<strong>Goldgroup</strong> <strong>Mining</strong> Inc.<br />

1055 Dunsmuir Street<br />

Suite 2184<br />

Vancouver BC Canada<br />

V7X 1L3<br />

Date: May 14, 2012<br />

Effective date: February 29, 2012<br />

Prepared by:<br />

Marc Simps<strong>on</strong> P.Geo.<br />

2184-1055 Dunsmuir Street,<br />

Vancouver BC<br />

And<br />

Gary Giroux, MASc., P.Eng.<br />

Giroux C<strong>on</strong>sultants Ltd.<br />

1215 – 675 West Hastings Street<br />

Vancouver, B.C. CANADA<br />

And<br />

Fernando Rodrigues BSc, MBA, MAusIMM, MMSAQP<br />

SRK C<strong>on</strong>sulting (U.S.) Ltd.<br />

Suite 3000<br />

7175 West Jeffers<strong>on</strong> Avenue<br />

Lakewood, <strong>Colorado</strong>, USA

Table of C<strong>on</strong>tents<br />

1. Summary ......................................................................................................... 6<br />

2. Introducti<strong>on</strong> ..................................................................................................... 8<br />

i) Scope of Work and Terms of Reference ......................................................... 8<br />

ii) Terminology and Unit C<strong>on</strong>versi<strong>on</strong> .................................................................. 8<br />

3. Reliance <strong>on</strong> Other Experts ............................................................................. 10<br />

4. Property Descripti<strong>on</strong> and Locati<strong>on</strong> ................................................................ 11<br />

5. Accessibility, Climate, Local <strong>Resources</strong>, Infrastructure and Physiography . 16<br />

i) Access ............................................................................................................ 16<br />

ii) Climate .......................................................................................................... 16<br />

iii) Local <strong>Resources</strong> and Infrastructure ............................................................... 16<br />

iv) Physiography ................................................................................................. 18<br />

6. History ........................................................................................................... 19<br />

i) Explorati<strong>on</strong> History ....................................................................................... 19<br />

a. C<strong>on</strong>tratista Tormex ........................................................................................ 19<br />

b. Papant<strong>on</strong> Minas S.A. de C.V. – BP Minerals ................................................ 19<br />

c. Compañía Fresnillo S.A. ............................................................................... 19<br />

d. Minera Secotec S.A. de C.V. ......................................................................... 20<br />

e. Sierra Minerals .............................................................................................. 23<br />

f. <strong>Goldgroup</strong> <strong>Mining</strong> Inc. .................................................................................. 24<br />

7. Geological Setting and Mineralizati<strong>on</strong> .......................................................... 25<br />

i) Regi<strong>on</strong>al Geology .......................................................................................... 25<br />

ii) Local and Property Geology .......................................................................... 26<br />

iii) Structural Geology ........................................................................................ 30<br />

iv) Mineralizati<strong>on</strong> ............................................................................................... 32<br />

a. Breccia Central .............................................................................................. 32<br />

b. Obra X ........................................................................................................... 32<br />

c. Harris - Sorpresa - Abejas Areas ................................................................... 33<br />

d. Abejas ............................................................................................................ 34<br />

e. Harris Breccia ................................................................................................ 34<br />

f. La Sorpresa .................................................................................................... 37<br />

8. Deposit Types ................................................................................................ 39<br />

9. Explorati<strong>on</strong> .................................................................................................... 40<br />

10. Drilling .......................................................................................................... 41<br />

11. Sample Preparati<strong>on</strong>, Analyses and Security .................................................. 46<br />

i) Sample Preparati<strong>on</strong> Procedure at the On Site Laboratory ............................. 46<br />

12. Data Verificati<strong>on</strong> ........................................................................................... 48<br />

i) Site Visit, November 2011 ............................................................................ 48<br />

13. Mineral Processing and Metallurgical Testing .............................................. 49<br />

i) Historic .......................................................................................................... 49<br />

ii) Present Processing and Metallurgical Testing ............................................... 49<br />

a. Processing and Metallurgical Informati<strong>on</strong> .................................................... 49<br />

b. Ore Processing ............................................................................................... 50<br />

c. Plant Performance ......................................................................................... 50<br />

1 | P age

d. Plant flow sheet descripti<strong>on</strong> .......................................................................... 51<br />

e. Heap Pads (pad design) ................................................................................. 53<br />

f. M<strong>on</strong>itoring daily c<strong>on</strong>trol ............................................................................... 55<br />

g. Gold Analysis ................................................................................................ 55<br />

14. MINERAL RESOURCE ESTIMATION ..................................................... 57<br />

i) Data Analysis ................................................................................................ 57<br />

ii) Composites .................................................................................................... 61<br />

iii) Variography ................................................................................................... 62<br />

iv) Block Model .................................................................................................. 62<br />

v) Bulk Density .................................................................................................. 63<br />

vi) Grade Interpolati<strong>on</strong> ........................................................................................ 64<br />

vii) Classificati<strong>on</strong> ................................................................................................. 65<br />

viii) Block Model Verificati<strong>on</strong> .............................................................................. 68<br />

ix) Pit Optimizati<strong>on</strong> Study .................................................................................. 75<br />

a. Mineral Resource Statement Procedure ........................................................ 75<br />

x) Block Model Resource Within the Resource Whittle Shell .......................... 89<br />

15. Mineral Reserve Estimates ............................................................................ 90<br />

16. <strong>Mining</strong> Methods ............................................................................................ 91<br />

17. Recovery Methods ......................................................................................... 97<br />

i) Forecast Producti<strong>on</strong> ....................................................................................... 98<br />

ii) Gold Recovery ............................................................................................... 99<br />

18. Project Infrastructure ................................................................................... 100<br />

19. Market Studies and C<strong>on</strong>tracts ...................................................................... 101<br />

20. Envir<strong>on</strong>mental Studies, Permitting and Social or Community Impact ....... 102<br />

21. Capital and Operating Costs ........................................................................ 103<br />

22. Ec<strong>on</strong>omic Analysis ...................................................................................... 104<br />

23. Adjacent Properties ..................................................................................... 105<br />

24. Other Relevant Data and Informati<strong>on</strong> ......................................................... 106<br />

25. Interpretati<strong>on</strong> and C<strong>on</strong>clusi<strong>on</strong>s .................................................................... 107<br />

26. Recommendati<strong>on</strong>s ....................................................................................... 109<br />

27. Date and Signature Page .............................................................................. 111<br />

28. References ................................................................................................... 113<br />

29. Appendix 1 - Certificates ............................................................................ 114<br />

30. Appendix 2 – LISTING OF DRILL HOLES .............................................. 118<br />

Those that intersect the mineralized solids are highlighted ............................................ 118<br />

31. Appendix 3– SEMIVARIOGRAMS ........................................................... 139<br />

2 | P age

Table of Tables<br />

Table 1: <strong>Cerro</strong> <strong>Colorado</strong> C<strong>on</strong>cessi<strong>on</strong>s, April 2012 ........................................................... 14<br />

Table 2: Significant 2010 drill program results ................................................................ 41<br />

Table 3: Significant 2010-2011 drill program results ....................................................... 41<br />

Table 4: Gold assay statistics for samples within the mineralized solids ......................... 60<br />

Table 5: Gold populati<strong>on</strong>s present within mineralized solids ........................................... 60<br />

Table 6: Capped Gold assay statistics for samples within the mineralized solids ............ 60<br />

Table 7: Gold statistics for 5 m Composites inside and outside the mineralized solids ... 61<br />

Table 8: Semivariogram parameters for gold ................................................................... 62<br />

Table 9: Specific gravities used in the 2009 resource model (St<strong>on</strong>e, 2011) ..................... 64<br />

Table 10: Kriging search parameters for gold .................................................................. 65<br />

Table 11: Measured Resource in Mineralized Porti<strong>on</strong> of Blocks ..................................... 67<br />

Table 12: Indicated Resource in Mineralized Porti<strong>on</strong> of Blocks ...................................... 67<br />

Table 13: Measured plus Indicated Resource in Mineralized Porti<strong>on</strong> of Blocks ............. 67<br />

Table 14: Inferred Resource in Mineralized Porti<strong>on</strong> of Blocks ........................................ 67<br />

Table 15: Measured Resource in Total Blocks ................................................................. 68<br />

Table 16: Indicated Resource in Total Blocks .................................................................. 68<br />

Table 17: Measured plus Indicated Resource in Total Blocks ......................................... 68<br />

Table 18: Inferred Resource in Total Blocks .................................................................... 68<br />

Table 19: Measured Resource in Mineralized Porti<strong>on</strong> of Blocks within SRK Pit ............ 89<br />

Table 20: Indicated Resource in Mineralized Porti<strong>on</strong> of Blocks within SRK Pit Outline 89<br />

Table 21: Measured and Indicated Resource in Mineralized Porti<strong>on</strong> of Blocks within<br />

SRK Pit Outline ................................................................................................................ 89<br />

Table 22: Inferred Resource in Mineralized Porti<strong>on</strong> of Blocks within SRK Pit Outline . 89<br />

Table 23: Gold Recovery 2011 (source: <strong>Goldgroup</strong> AIF) ................................................ 99<br />

Table 24: 2010 and 2011 Operating costs per ounce of gold ......................................... 103<br />

Table 25: Proposed Budget, <strong>Cerro</strong> <strong>Colorado</strong> .................................................................. 110<br />

3 | P age

Table of Figures<br />

Figure 1: <strong>Cerro</strong> <strong>Colorado</strong> Mine Site C<strong>on</strong>cessi<strong>on</strong>s ............................................................ 12<br />

Figure 2: Overall <strong>Cerro</strong> <strong>Colorado</strong> C<strong>on</strong>cessi<strong>on</strong>s, March 2012........................................... 13<br />

Figure 3: Ownership Structure .......................................................................................... 15<br />

Figure 4: <strong>Cerro</strong> <strong>Colorado</strong> Infrastructure, November 2011 ............................................... 17<br />

Figure 5: General Physiography of <strong>Cerro</strong> <strong>Colorado</strong>, November 2011 ............................. 18<br />

Figure 6: Map showing the explorati<strong>on</strong> targets defined by Secotec based <strong>on</strong> the results of<br />

soil sampling (modified from Kappes, Cassiday & Associates (2005)). .......................... 23<br />

Figure 7: Regi<strong>on</strong>al Geological Map, <strong>Cerro</strong> <strong>Colorado</strong> ....................................................... 28<br />

Figure 8: Local geological map of the area around the <strong>Cerro</strong> <strong>Colorado</strong> Gold Mine ........ 29<br />

Figure 9: Mineralizati<strong>on</strong> model for <strong>Cerro</strong> <strong>Colorado</strong> from St<strong>on</strong>e (2011) .......................... 35<br />

Figure 10: L<strong>on</strong>g secti<strong>on</strong> through the Breccia Central area looking north. from St<strong>on</strong>e<br />

(2011) ................................................................................................................................ 36<br />

Figure 11: Drill Hole Locati<strong>on</strong> Map, <strong>Cerro</strong> <strong>Colorado</strong> ...................................................... 45<br />

Figure 12: Process diagram for gold producti<strong>on</strong> at <strong>Cerro</strong> <strong>Colorado</strong>. From St<strong>on</strong>e (2011) 53<br />

Figure 13: Isometric view looking north showing Feb. Topography and mineralized<br />

solids ................................................................................................................................. 57<br />

Figure 14: Plan and fr<strong>on</strong>t secti<strong>on</strong> showing blast holes in blue and drill hole assays in red<br />

........................................................................................................................................... 58<br />

Figure 15: Lognormal Cumulative Frequency Plot for All Samples ................................ 59<br />

Figure 16: Lognormal Cumulative Frequency Plot for All Samples within Mineralized<br />

Solids................................................................................................................................. 59<br />

Figure 17: Lognormal Cumulative Frequency Plot for Au within Mineralized Solids .... 61<br />

Figure 18: Isometric view looking NE showing blocks below current topography in white<br />

and mineralized solids in red ............................................................................................ 63<br />

Figure 19: Plan view showing various sample areas (St<strong>on</strong>e, 2011) ................................. 64<br />

Figure 20: Level plan showing 560 level with gold grades and classificati<strong>on</strong> shown ...... 70<br />

Figure 21: Level plan showing 570 Level with gold grades and classificati<strong>on</strong> shown .... 71<br />

Figure 22:Level plan showing 580 Level with gold grades and classificati<strong>on</strong> shown ..... 72<br />

Figure 23: Level plan showing 590 Level with gold grades and classificati<strong>on</strong> shown .... 73<br />

Figure 24: : Level plan showing 600 Level with gold grades and classificati<strong>on</strong> shown .. 74<br />

Figure 25: Resource Whittle shell at Gold price $1500 per t.oz – Plan view .................. 76<br />

Figure 26: Resource Whittle shell at Gold price $1500 per t.oz – Plan view showing<br />

current topography and shell ............................................................................................. 78<br />

Figure 27: Resource Whittle shell at Gold price $1500 per t.oz – Vertical Cross Secti<strong>on</strong><br />

View showing current topography and shell (West-East at 3,343,900 North, looking<br />

North ................................................................................................................................. 80<br />

Figure 28: Resource Whittle shell at Gold price $1500 per t.oz – Vertical Cross Secti<strong>on</strong><br />

View showing current topography and shell (West-East @ 3,344,100 North, looking<br />

North ) ............................................................................................................................... 82<br />

Figure 29: Resource Whittle shell at Gold price $1500 per t.oz – Vertical Cross Secti<strong>on</strong><br />

View showing current topography and shell (West-East secti<strong>on</strong> @ 3,344,200 North,<br />

looking North ) .................................................................................................................. 84<br />

Figure 30: Resource Whittle shell at Gold price $1500 per t.oz – Vertical Cross Secti<strong>on</strong><br />

View showing current topography and shell (West-East at 3,344,300 North ) ................ 86<br />

4 | P age

Figure 31: Resource Whittle shell at Gold price $1500 per t.oz – Vertical Cross Secti<strong>on</strong><br />

View showing current topography and a shell (SW – NE Secti<strong>on</strong> @ N45E, looking northwest<br />

) ................................................................................................................................. 88<br />

Figure 32: Blast hole drill ................................................................................................. 92<br />

Figure 33: Bench blast hole pattern November 2011 ....................................................... 92<br />

Figure 34: Ore haulage, Breccia Central Pit, November 2011 ......................................... 93<br />

Figure 35: loading ore into primary crusher, photo courtesy <strong>Goldgroup</strong> ......................... 93<br />

Figure 36: primary and sec<strong>on</strong>dary crushers, photo courtesy <strong>Goldgroup</strong> .......................... 94<br />

Figure 37: crushed mineralized material stockpile for placement <strong>on</strong> heap leach pad, photo<br />

courtesy <strong>Goldgroup</strong> ........................................................................................................... 94<br />

Figure 38: <strong>Cerro</strong> <strong>Colorado</strong> Heap Leach Pads, November 2011 ....................................... 95<br />

Figure 39: Heap leach pad lift/level with cyanide distributi<strong>on</strong> piping and sprinklers,<br />

November 2011 ................................................................................................................. 96<br />

Figure 40: Sprinklers for broadcasting cyanide soluti<strong>on</strong> <strong>on</strong> heap leach pad, November<br />

2011................................................................................................................................... 96<br />

Figure 41: Carb<strong>on</strong> flow circuit, <strong>Cerro</strong> <strong>Colorado</strong> November 2011 .................................... 98<br />

5 | P age

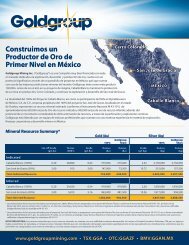

1. Summary<br />

This technical report was prepared for <strong>Goldgroup</strong> <strong>Mining</strong> Inc. (“<strong>Goldgroup</strong>”) to document an<br />

updated mineral resource estimate and complete a technical report (the “<str<strong>on</strong>g>Report</str<strong>on</strong>g>”) compliant with<br />

Nati<strong>on</strong>al Instrument 43-101 (“NI 43-101”), compani<strong>on</strong> policy NI 43-101CP and Form 43-101F1<br />

for the <strong>Cerro</strong> <strong>Colorado</strong> Property and mine in S<strong>on</strong>ora, Mexico. This <str<strong>on</strong>g>Report</str<strong>on</strong>g> provides a brief<br />

overview of the work programs completed by <strong>Goldgroup</strong> during 2010 and 2011 and the results<br />

of the resource estimate and pit optimizati<strong>on</strong> study.<br />

The <strong>Cerro</strong> <strong>Colorado</strong> Gold Mine is located in northern S<strong>on</strong>ora, Mexico approximately 35<br />

kilometres southwest of the town of Trincheras. The Property c<strong>on</strong>sists of six c<strong>on</strong>cessi<strong>on</strong>s<br />

covering the area of the mine and 48 c<strong>on</strong>cessi<strong>on</strong>s in the immediate vicinity of the mine covering<br />

a total of approximately 24,100 hectares. <strong>Cerro</strong> <strong>Colorado</strong> is owned by <strong>Goldgroup</strong> through its<br />

Mexican operating company Granmin S.A. de C.V. (“Granmin Mexico”). Cyanide leaching at<br />

<strong>Cerro</strong> <strong>Colorado</strong> commenced in 2003 and has produced approximately 128,611 ounces of gold<br />

between the 3 rd quarter of 2006 and the 1 st quarter of 2012.<br />

Property geology is composed of three major units, Proterozoic amphibolite to orthogneiss,<br />

Paleozoic layered dolomite/limest<strong>on</strong>e (marble) with minor siltst<strong>on</strong>e/arenite. Both of these<br />

lithologies are intruded by a central mid Cretaceous age rhyolite dome. The rhyolite is generally<br />

massive although locally it is flow banded or occurs as rhyolite auto-breccia. Gold mineralizati<strong>on</strong><br />

is mostly hosted by the rhyolite although some gold is found locally within dolomite layers <strong>on</strong><br />

the west side of the dome.<br />

<strong>Goldgroup</strong>’s explorati<strong>on</strong> model for <strong>Cerro</strong> <strong>Colorado</strong> is the Kidst<strong>on</strong> gold-silver deposit,<br />

Queensland, Australia (e.g., Baker and Andrew, 1991). The Kidst<strong>on</strong> was a significant gold<br />

deposit and c<strong>on</strong>tained high grade resources. Mineralizati<strong>on</strong> was hosted within a trapezoid-shaped<br />

breccia pipe with surface dimensi<strong>on</strong>s of approximately 900 metres by 1,100 metres 900 metres.<br />

Rhyolite dikes are associated both spatially and temporally with the mineralizati<strong>on</strong> and<br />

brecciati<strong>on</strong> of the host rocks. Furthermore, the collapse breccia does not reach the current land<br />

surface. At the Kidst<strong>on</strong> deposit, mineralizati<strong>on</strong> that was not related to the breccia (stockwork in<br />

host rhyolite) was unec<strong>on</strong>omic. The breccias at Kidst<strong>on</strong> formed a single mineralized system<br />

which coalesced at depth.<br />

The open pits have been operati<strong>on</strong>al since 2003, with full producti<strong>on</strong> starting in 2006. In 2011,<br />

the full year producti<strong>on</strong> totalled 20,361.112 ounces, with an additi<strong>on</strong>al 4,462 ounces produced in<br />

the first quarter of 2012. Two pits are currently operating; Breccia Central and Obra X. A total of<br />

85,058 metres in 821 explorati<strong>on</strong> holes have been drilled in and around the mine to the end of<br />

2011.<br />

The results of the 2010-2011 explorati<strong>on</strong> drilling were used to estimate the total t<strong>on</strong>nes and grade<br />

of mineralizati<strong>on</strong> at the <strong>Cerro</strong> <strong>Colorado</strong> Gold Mine. The mineral resource for the <strong>Cerro</strong> <strong>Colorado</strong><br />

Gold Mine area at a 0.2 g/t Au cut-off is estimated to be approximately 720,000 t<strong>on</strong>nes at 0.62<br />

g/t Au in the Measured category, 1.86 milli<strong>on</strong> t<strong>on</strong>nes at 0.51 g/t Au in the Indicated category and<br />

3.05 milli<strong>on</strong> t<strong>on</strong>nes at 0.57 g/t Au in the Inferred category. These mineral resources c<strong>on</strong>tain a<br />

6 | P age

total of 14,000 Measured ounces, 30,000 Indicated ounces and 56,000 Inferred ounces of gold.<br />

Mineral resources were calculated from explorati<strong>on</strong> drilling data in the area of the mine. Mineral<br />

resources are not mineral reserves as the ec<strong>on</strong>omic viability has not been dem<strong>on</strong>strated.<br />

SRK completed a pit optimizati<strong>on</strong> study for the <strong>Cerro</strong> <strong>Colorado</strong> Mine and created a Whittle Shell<br />

for Measured and Indicated Resource, using parameters supplied by <strong>Goldgroup</strong>. Using this<br />

Whittle Shell model, a total of 33,000 ounces of Measured and Indicated resource and 1,300<br />

ounces of Inferred resource are c<strong>on</strong>tained within the modeled Whittle Shells.<br />

Work recommended at the <strong>Cerro</strong> <strong>Colorado</strong> Mine should c<strong>on</strong>tinue to focus <strong>on</strong> outlining additi<strong>on</strong>al<br />

mineralizati<strong>on</strong> to extend the life of the mine as well as define and upgrade existing resources for<br />

the mine. A full QAQC program for all explorati<strong>on</strong> drilling completed at <strong>Cerro</strong> <strong>Colorado</strong> is<br />

recommended al<strong>on</strong>g with downhole surveys of future drilling programs. A 10,000 metre<br />

explorati<strong>on</strong> drill program is recommended to outline additi<strong>on</strong>al mineralizati<strong>on</strong> in the <strong>Cerro</strong><br />

<strong>Colorado</strong> Mine area.<br />

7 | P age

2. Introducti<strong>on</strong><br />

This technical report presents an independent review and updated estimati<strong>on</strong> of a precious<br />

metal resource at the <strong>Cerro</strong> <strong>Colorado</strong> Mine in S<strong>on</strong>ora State, Mexico. The report has been<br />

prepared by Marc Simps<strong>on</strong>, P. Geo. (Qualified Pers<strong>on</strong>), Gary Giroux, P. Eng. (Qualified<br />

Pers<strong>on</strong>) of Giroux C<strong>on</strong>sultants Ltd., and Fernando Rodrigues BSc, MBA, MAusIMM,<br />

MMSAQP (Qualified Pers<strong>on</strong>) of SRK C<strong>on</strong>sulting at the request of Mr. Keith Piggott,<br />

President and CEO of <strong>Goldgroup</strong> <strong>Mining</strong> Inc. <strong>Goldgroup</strong> is a public company with head<br />

offices in Vancouver, B.C. Canada and a main field office in Hermosillo, Mexico.<br />

Summaries and c<strong>on</strong>clusi<strong>on</strong>s c<strong>on</strong>tained in this report are c<strong>on</strong>sidered compliant with Nati<strong>on</strong>al<br />

Instrument 43-101 and the December 11, 2005 Canadian Institute of <strong>Mining</strong>, Metallurgy<br />

and Petroleum (CIM) standards and definiti<strong>on</strong>s. This report may be used by the company to<br />

support and maintain future public financings.<br />

i) Scope of Work and Terms of Reference<br />

One field visit to the <strong>Cerro</strong> <strong>Colorado</strong> Mine was completed by Marc Simps<strong>on</strong> <strong>on</strong> November 29 th ,<br />

2011. He was accompanied by Vice President of Explorati<strong>on</strong> Kevin Sullivan and Senior<br />

Geologist Omar Felix, both with <strong>Goldgroup</strong>. During the field visit Simps<strong>on</strong> was able to verify<br />

drill hole collar locati<strong>on</strong>s, visit the <strong>on</strong>-site laboratory, sample storage facilities, explorati<strong>on</strong>/mine<br />

offices and the processing plant. However no explorati<strong>on</strong> drilling activity was being carried out<br />

during the site visit. The author has relied <strong>on</strong> informati<strong>on</strong> from <strong>Goldgroup</strong> regarding the<br />

procedures used for the explorati<strong>on</strong> drilling programs at the <strong>Cerro</strong> <strong>Colorado</strong> mine.<br />

Data compilati<strong>on</strong> for this technical report <strong>on</strong> <strong>Cerro</strong> <strong>Colorado</strong> is based <strong>on</strong> research from<br />

internal reports, opini<strong>on</strong>s and general impressi<strong>on</strong>s and ideas gathered from <strong>Goldgroup</strong><br />

pers<strong>on</strong>nel. Electr<strong>on</strong>ic data were obtained from company ‘MapInfo’ and 'Surpac' databases<br />

c<strong>on</strong>taining the bulk of the geological, geophysical and geochemical informati<strong>on</strong> generated<br />

<strong>on</strong> the project. All regi<strong>on</strong>al and local property maps, figures and diagrams in this report were<br />

generated by <strong>Goldgroup</strong> or the authors using a UTM NAD27 US (Z<strong>on</strong>e 14N) projecti<strong>on</strong> or<br />

NAD27 L<strong>on</strong>gitude / Latitude (Mexico) where the scale dictates. Current field work <strong>on</strong> the<br />

property is all being collected in UTM WGS84 (Z<strong>on</strong>e 14N). The authors have drawn their<br />

own c<strong>on</strong>clusi<strong>on</strong>s for this report and have prepared it based <strong>on</strong> informati<strong>on</strong> believed accurate<br />

at the time of completi<strong>on</strong>.<br />

ii)<br />

Terminology and Unit C<strong>on</strong>versi<strong>on</strong><br />

The Metric System is the primary system of measure used in this <str<strong>on</strong>g>Report</str<strong>on</strong>g>. Length is generally<br />

expressed in kilometres, metres and centimetres, volume is expressed as cubic metres, mass<br />

expressed as metric t<strong>on</strong>nes, and gold grades are expressed as “grams per t<strong>on</strong>ne” and abbreviated<br />

as g/t Au.<br />

8 | P age

Frequently used abbreviati<strong>on</strong>s and acr<strong>on</strong>yms include:<br />

3D = three dimensi<strong>on</strong>al<br />

% = percent<br />

°C = degrees Celsius<br />

AA = atomic absorpti<strong>on</strong><br />

ALS = ALS Minerals<br />

Ag = silver<br />

Au = gold<br />

CAT = Caterpillar<br />

CDN = Canadian<br />

CIM = Canadian Institute of <strong>Mining</strong>, Metallurgical, and Petroleum<br />

cm = centimetre(s)<br />

CN = sodium cyanide<br />

EW = Electro Winning<br />

FA = fire assay<br />

Fresnillo = Compañia Fresnillo, S.A.<br />

g = gram(s)<br />

g/t = grams per t<strong>on</strong>ne<br />

<strong>Goldgroup</strong> = <strong>Goldgroup</strong> <strong>Mining</strong> Inc.<br />

Granmin Mexico = Granmin S.A. de C.V.<br />

Ha or ha = hectares<br />

HDPE = high-density polyurethane<br />

ICP = inductively coupled plasma spectroscopy<br />

ICPMS = inductively coupled plasma mass spectroscopy<br />

IP = induced polarizati<strong>on</strong><br />

IPL = Internati<strong>on</strong>al Plasma Laboratory<br />

km = kilometres(s)<br />

m = metre(s)<br />

m 2 = metres squared<br />

m 3 = metres cubed<br />

mm = millimetre(s)<br />

MMI = Mexican <strong>Mining</strong> Investments<br />

NAD = North American Datum<br />

NI 43-101 = Nati<strong>on</strong>al Instrument 43-101<br />

NSR = net smelter return<br />

oz = ounces<br />

QAQC = quality assurance and quality c<strong>on</strong>trol<br />

RC = reverse circulati<strong>on</strong><br />

ROM = run of mine<br />

RTO = reverse take-over transacti<strong>on</strong><br />

SG = specific gravity<br />

Sierra = Sierra Minerals Inc.<br />

t = metric t<strong>on</strong>ne (1,000 kg)<br />

Tormex = C<strong>on</strong>tratista Tormex<br />

tpd = t<strong>on</strong>nes per day<br />

Treasury = Treasury Metals Inc.<br />

US$ = United States (American) dollars<br />

UTM = Universal Transverse Mercator<br />

Dollars are expressed in United States currency (US$) unless otherwise noted. Gold prices are<br />

stated in US$ per troy ounce (US$/oz). All Universal Transverse Mercator (“UTM”) coordinates<br />

in this <str<strong>on</strong>g>Report</str<strong>on</strong>g> are provided in the datum of Mexico, NAD 27 Z<strong>on</strong>e 12 unless otherwise<br />

menti<strong>on</strong>ed.<br />

9 | P age

3. Reliance <strong>on</strong> Other Experts<br />

The authors of this report have obtained informati<strong>on</strong> c<strong>on</strong>cerning the <strong>Cerro</strong> <strong>Colorado</strong> Project from<br />

several sources, including a 2011 <str<strong>on</strong>g>Technical</str<strong>on</strong>g> <str<strong>on</strong>g>Report</str<strong>on</strong>g> prepared by Michelle St<strong>on</strong>e, Mexican<br />

government reports, a site visit by Marc Simps<strong>on</strong> in 2011, as well as reports and data provided<br />

by <strong>Goldgroup</strong>.<br />

Informati<strong>on</strong> regarding land tenure, technical informati<strong>on</strong> not in the public domain and underlying<br />

agreements were provided to the authors by <strong>Goldgroup</strong>, and the authors have relied <strong>on</strong> this<br />

informati<strong>on</strong> exclusively. This informati<strong>on</strong> appears to be of good quality. The authors are not<br />

aware of any other technical data other than that which was provided by <strong>Goldgroup</strong>. The author<br />

has not completed an in depth check and review of the mineral title and ownership of the mineral<br />

titles, with all informati<strong>on</strong> related to these titles obtained from <strong>Goldgroup</strong>.<br />

Marc Simps<strong>on</strong>, P.Geo. is resp<strong>on</strong>sible for all parts of this <str<strong>on</strong>g>Technical</str<strong>on</strong>g> <str<strong>on</strong>g>Report</str<strong>on</strong>g> <strong>on</strong> <strong>Cerro</strong> <strong>Colorado</strong>,<br />

excluding Secti<strong>on</strong> 14 <strong>on</strong> “Mineral Resource Estimates” and “Block model resource within the<br />

Resource Whittle shell” (Secti<strong>on</strong>s 14 (i) to 14 (viii) and Secti<strong>on</strong> 14(x)) which was completed by<br />

Gary Giroux of Giroux C<strong>on</strong>sultants Ltd., Vancouver, B.C., Canada, and Secti<strong>on</strong> 14 (ix) <strong>on</strong> “Pit<br />

Optimizati<strong>on</strong>” which was completed by Fernando Rodrigues of SRK C<strong>on</strong>sulting, Denver,<br />

<strong>Colorado</strong>.<br />

10 | P age

4. Property Descripti<strong>on</strong> and Locati<strong>on</strong><br />

<strong>Cerro</strong> <strong>Colorado</strong> is located in northwestern Mexico in the State of S<strong>on</strong>ora, approximately 35<br />

kilometres southwest of the town of Trincheras, the largest town in the area, with a populati<strong>on</strong> of<br />

approximately 5,000 people. The town of La Cienega is roughly 10 kilometres southwest of the<br />

property.<br />

The <strong>Cerro</strong> <strong>Colorado</strong> property is made up of 53 mineral c<strong>on</strong>cessi<strong>on</strong>s (Figure 2 and Table 1). Total<br />

land area held by <strong>Goldgroup</strong> is 24,107.2892 hectares. C<strong>on</strong>cessi<strong>on</strong>s are located using the positi<strong>on</strong><br />

of a single claim m<strong>on</strong>ument, with the corners of the c<strong>on</strong>cessi<strong>on</strong> being determined based <strong>on</strong><br />

surveyed distances from this m<strong>on</strong>ument. The survey is completed by a registered Mexican<br />

Mineral C<strong>on</strong>cessi<strong>on</strong> Surveyor. The mine proper is within 6 c<strong>on</strong>cessi<strong>on</strong>s located c<strong>on</strong>tiguously<br />

(Figure 1).<br />

One c<strong>on</strong>cessi<strong>on</strong> (Palo Verde 1) is held by a n<strong>on</strong> Granmin owner (Minera Frisco). Minera Frisco<br />

holds the mineral rights to this c<strong>on</strong>cessi<strong>on</strong> via a subsidiary, Minera Cumobabi S.A. de C.V which<br />

in turn holds the property via a subsidiary, Minera Maria S.A. de C.V. Granmin was granted the<br />

surface rights to the area of the Palo Verde 1 c<strong>on</strong>cessi<strong>on</strong> as part of its Surface C<strong>on</strong>tract (C<strong>on</strong>trato<br />

de la Superficie).<br />

<strong>Cerro</strong> <strong>Colorado</strong> is wholly owned by <strong>Goldgroup</strong> via 100% ownership of Granmin Malaysia Ltd.<br />

which in turn owns 99%+1% of Granmin S.A. de C.V. (Granmin Mexico). Granmin Mexico is<br />

the Mexican operating company for <strong>Goldgroup</strong>. Refer to Figure 3 for the current ownership<br />

structure.<br />

On February 23, 2010, Sierra Minerals Inc. and <strong>Goldgroup</strong> <strong>Resources</strong> Inc., a privately held<br />

British Columbia company and a current subsidiary of <strong>Goldgroup</strong>, entered into a definitve<br />

agreement with respect to a proposed business combinati<strong>on</strong> (the “RTO”).<br />

On April 30, 2010, <strong>Goldgroup</strong> changed its name from Sierra Minerals Inc. to <strong>Goldgroup</strong> <strong>Mining</strong><br />

Inc. and c<strong>on</strong>solidated its comm<strong>on</strong> shares <strong>on</strong> the basis of <strong>on</strong>e new comm<strong>on</strong> share for 2.85 old<br />

comm<strong>on</strong> shares. Effective April 30, 2010, <strong>Goldgroup</strong> completed the RTO with Pre-RTO<br />

<strong>Goldgroup</strong> pursuant to a statutory plan of arrangement under the Business Corporati<strong>on</strong>s Act<br />

(British Columbia).<br />

In the first half of 2012 <strong>Goldgroup</strong> paid a total of US$87,500 (1,151,253 Mexican Pesos) in<br />

taxes. Payments are paid in two installments over the course of the year to maintain the mineral<br />

c<strong>on</strong>cessi<strong>on</strong>s.<br />

11 | P age

Figure 1: <strong>Cerro</strong> <strong>Colorado</strong> Mine Site C<strong>on</strong>cessi<strong>on</strong>s<br />

12 | P age

Figure 2: Overall <strong>Cerro</strong> <strong>Colorado</strong> C<strong>on</strong>cessi<strong>on</strong>s, March 2012<br />

13 | P age

Table 1: <strong>Cerro</strong> <strong>Colorado</strong> C<strong>on</strong>cessi<strong>on</strong>s, April 2012<br />

Mexican Pesos<br />

C<strong>on</strong>cessi<strong>on</strong> Owner Title Number Area (ha) Issue Date Expiry Date<br />

Taxes Paid<br />

2012<br />

1 AMPLY.JUDY GRANMIN 233463 5,135.0000 02/25/2009 02/24/2059 43,735.00<br />

2 AUSTRALIA<br />

HECTOR<br />

GRAHAM*<br />

232115 454.1997 06/20/2008 06/19/2058 8,003.00<br />

3 CERRO COLORADO GRANMIN 186367 20.8179 03/29/1990 03/28/2040 2,597.00<br />

4 EL CAJON FRACC.I GRANMIN 236889 60.1670 09/24/2010 09/23/2060 513.00<br />

5 EL CAJON FRACC.II GRANMIN 236890 102.6476 09/24/2010 09/23/2060 875.00<br />

6 EL CAJON FRACC.III GRANMIN 236891 482.1547 09/24/2010 09/23/2060 4,108.00<br />

7 EL CAJON FRACC.IV GRANMIN 236892 86.5917 09/24/2010 09/23/2060 738.00<br />

8 EL FILON<br />

HECTOR<br />

GRAHAM*<br />

213844 8.0731 3/7/2001 2/7/2051 1,008.00<br />

9 EL FILON<br />

HECTOR<br />

GRAHAM*<br />

213915 0.2558 07/13/2001 12/7/2051 32.00<br />

10 EL FILON FRACC. 1<br />

HECTOR<br />

GRAHAM*<br />

213916 0.6771 07/13/2001 12/7/2051 85.00<br />

11 EL ORERO<br />

HECTOR<br />

GRAHAM*<br />

223071 87.2571 8/10/2004 7/10/2054 3,094.00<br />

12 EL SOCORRO<br />

HECTOR<br />

GRAHAM*<br />

207572 9.0000 06/30/1998 06/29/2048 1,125.00<br />

13 ESCONDIDA<br />

HECTOR<br />

GRAHAM*<br />

218515 9.0000 5/11/2002 4/11/2052 638.00<br />

14 ESCONDIDA 2<br />

HECTOR<br />

GRAHAM*<br />

221953 127.4567 04/16/2004 04/15/2054 9,035.00<br />

15 JUDY GRANMIN 236196 2,202.0392 05/19/2010 07/17/2058 38,800.00<br />

16 LA HORCHATA MASORO 191148 40.0000 12/15/1986 12/14/2036 4,990.00<br />

17 LA PLOMOSA MASORO 193790 6.0000 12/19/1991 12/18/2041 749.00<br />

18<br />

MASORO 1<br />

FRACCION I<br />

MASORO 220537 2,192.2898 08/15/2003 08/14/2053 155,390.00<br />

19<br />

MASORO 1<br />

FRACCION II<br />

MASORO 220538 496.8429 08/15/2003 08/14/2053 35,217.00<br />

20 MASORO 2 MASORO 227120 91.2935 11/5/2006 10/5/2056 3,237.00<br />

21 MAYTO<br />

HECTOR<br />

GRAHAM*<br />

223808 14.2562 02/22/2005 02/21/2055 506.00<br />

22 MAYTO<br />

HECTOR<br />

GRAHAM*<br />

223809 72.5680 02/22/2005 02/21/2055 2,573.00<br />

23 MAYTO<br />

HECTOR<br />

GRAHAM*<br />

223810 2.5116 02/22/2005 02/21/2055 90.00<br />

24 NORMA LARA 218449 60.0255 5/11/2002 4/11/2052 4,255.00<br />

25<br />

NUEVO GRAN<br />

VALLE FRACCIÓN 1<br />

MASORO 218755 5,886.3238 01/17/2003 01/16/2053 417,223.00<br />

26<br />

NUEVO GRAN<br />

VALLE FRACCIÓN 2<br />

MASORO 218756 682.6921 01/17/2003 01/16/2053 48,390.00<br />

27<br />

NUEVO GRAN<br />

VALLE FRACCIÓN 3<br />

MASORO 218757 0.0150 01/17/2003 01/16/2053 2.00<br />

28<br />

NUEVO GRAN<br />

VALLE FRACCIÓN 4<br />

MASORO 231501 5.0000 4/3/2008 3/3/2058 159.00<br />

29 ORERO<br />

HECTOR<br />

GRAHAM*<br />

221952 63.4377 04/16/2004 04/15/2054 4,497.00<br />

30 ORERO 10<br />

HECTOR<br />

GRAHAM*<br />

224293 23.5724 04/22/2005 04/21/2055 836.00<br />

31 ORERO 11 FRACC. 1<br />

HECTOR<br />

GRAHAM*<br />

228955 11.7429 02/22/2007 02/21/2057 207.00<br />

32 ORERO 11 FRACC. 2<br />

HECTOR<br />

GRAHAM*<br />

228956 54.2564 02/22/2007 02/21/2057 956.00<br />

33 ORERO 12<br />

HECTOR<br />

GRAHAM*<br />

227168 100.2807 05/17/2006 05/16/2056 3,555.00<br />

34 ORERO 14<br />

HECTOR<br />

GRAHAM*<br />

227327 44.0376 9/6/2006 8/6/2056 1,562.00<br />

35 ORERO 14<br />

HECTOR<br />

GRAHAM*<br />

227325 37.5792 9/6/2006 8/6/2056 1,333.00<br />

36 ORERO 15<br />

HECTOR<br />

GRAHAM*<br />

227326 40.8263 9/6/2006 8/6/2056 1,448.00<br />

37 ORERO 3<br />

HECTOR<br />

GRAHAM*<br />

221856 39.9940 2/4/2004 1/4/2054 2,835.00<br />

38 ORERO 3<br />

HECTOR<br />

GRAHAM*<br />

221857 40.8701 2/4/2004 1/4/2054 2,897.00<br />

39 ORERO 3<br />

HECTOR<br />

GRAHAM*<br />

216769 200.0000 05/28/2002 05/27/2052 24,948.00<br />

40 ORERO 5<br />

HECTOR<br />

GRAHAM*<br />

220996 99.0000 08/31/200 08/30/2050 12,350.00<br />

41 ORERO 6<br />

HECTOR<br />

GRAHAM*<br />

224789 85.2144 5/11/2002 4/11/2052 6,040.00<br />

42 ORERO 7 HECTOR 218367 28.4578 5/11/2002 4/11/2052 2,018.00<br />

14 | P age

Mexican Pesos<br />

C<strong>on</strong>cessi<strong>on</strong> Owner Title Number Area (ha) Issue Date Expiry Date<br />

Taxes Paid<br />

2012<br />

GRAHAM*<br />

43 ORERO 7<br />

HECTOR<br />

GRAHAM*<br />

217947 170.9904 09/18/2002 09/17/2052 12,120.00<br />

44 ORERO 8<br />

HECTOR<br />

GRAHAM*<br />

214529 9.0000 2/10/2001 1/10/2051 1,123.00<br />

45 ORERO 9<br />

HECTOR<br />

GRAHAM*<br />

220513 30.0000 08/14/2003 08/13/2053 2,127.00<br />

46 ORERO 9<br />

HECTOR<br />

GRAHAM*<br />

220515 88.3183 08/14/2003 08/13/2053 6,260.00<br />

47 ORERO 90<br />

HECTOR<br />

GRAHAM*<br />

212866 9.0000 02/13/2001 12/2/2051 1,124.00<br />

48 PALO VERDE III CERRO DORADO 218965 186.1761 01/28/2003 01/27/2053 13,197.00<br />

49 PALO VERDE IV CERRO DORADO 218966 6.9838 01/28/2003 01/27/2053 496.00<br />

50 SAN JORGE GRANMIN 184829 39.9912 5/12/1989 4/12/2039 4,989.00<br />

51 SAN JORGE 3<br />

HECTOR<br />

GRAHAM*<br />

220514 80.0000 08/14/2003 08/13/2053 5,671.00<br />

52 SECOTEC 2 GRANMIN 220953 2,813.5456 4/11/2003 3/11/2009 199,425.00<br />

53 SECOTEC 3 GRANMIN 224723 1,468.8583 2/6/2005 1/6/2055 52,072.00<br />

24,107.2892 1,151,253.00<br />

Figure 3: Ownership Structure<br />

15 | P age

5. Accessibility, Climate, Local <strong>Resources</strong>, Infrastructure and<br />

Physiography<br />

From St<strong>on</strong>e (2011):<br />

i) Access<br />

Access to the project is via Federal Highway 2 between Altar and Santa Ana to the<br />

kilometre 42 marker, then 22 km south by paved road to Trincheras. The property is<br />

located 37 km southwest of Trincheras al<strong>on</strong>g a maintained gravel road with no<br />

drainage improvements. The mine site grader blades this road as needed. The nearest<br />

major airports are located in Hermosillo, the capital of S<strong>on</strong>ora, or in Tucs<strong>on</strong>, Ariz<strong>on</strong>a,<br />

USA. Travel time from either of these airports to the Property is approximately four<br />

hours.<br />

ii)<br />

Climate<br />

<strong>Cerro</strong> <strong>Colorado</strong> is located in the S<strong>on</strong>oran Desert west of the Sierra Madre Occidental<br />

mountain range. The climate is typified by mild winters and hot summers. A primary<br />

rainy seas<strong>on</strong> occurs from July to October, with a sec<strong>on</strong>d rainy seas<strong>on</strong> occurring<br />

during the winter m<strong>on</strong>ths. <strong>Mining</strong> at <strong>Cerro</strong> <strong>Colorado</strong> is c<strong>on</strong>tinuous throughout the<br />

year, although minor delays and/or shut downs associated with periods of<br />

intense/excessive rainfall could occur. Vegetati<strong>on</strong> is sparse and c<strong>on</strong>sists primarily of<br />

cacti and low thorny shrubs (mesquite) (Figure 5). Surface water is rare but ground<br />

water is readily available. Arroyos and washouts are comm<strong>on</strong>. Deer, javelinas,<br />

jackrabbits and quail are comm<strong>on</strong> to the area.<br />

iii)<br />

Local <strong>Resources</strong> and Infrastructure<br />

The State of S<strong>on</strong>ora is located in the northwest porti<strong>on</strong> of Mexico and is bounded by<br />

Ariz<strong>on</strong>a and New Mexico, USA in the north, Chihuahua, Mexico in the east, Sinaloa,<br />

Mexico in the south and, the Sea of Cortez and Baja California Norte in the west.<br />

The state covers approximately 185,500 km2 and c<strong>on</strong>tains a populati<strong>on</strong> of nearly<br />

2,000,000.<br />

Infrastructure in S<strong>on</strong>ora is extensive. The state has approximately 10,000 km of<br />

paved roads in a system of 25,000 km. Additi<strong>on</strong>s to the paved porti<strong>on</strong>s of the system<br />

are in progress. Rail lines totalling 1,800 km link the major cities in the state.<br />

Numerous ports are found al<strong>on</strong>g the coast. Internati<strong>on</strong>al airlines serve Hermosillo,<br />

the state capital, several times daily. Infrastructure for the movement of either plant<br />

equipment or raw products to or from the mine is excellent. S<strong>on</strong>ora has an electrical<br />

generating capacity of 1,500 MV and a reas<strong>on</strong>ably well developed power distributi<strong>on</strong><br />

system. Telecommunicati<strong>on</strong>s in the state are linked to the country's federal<br />

microwave network which runs throughout the Pacific Coast, c<strong>on</strong>necting all main<br />

cities and towns. Water for farming and city use is primarily provided by reservoirs<br />

with groundwater being used in the country side.<br />

16 | P age

All services including rail are available at Trincheras. Electricity, satellite<br />

communicati<strong>on</strong>s and water are available at the mine site. Federal Highway 2 is paved<br />

and serves as a major transportati<strong>on</strong> route in S<strong>on</strong>ora. A labour pool, familiar with<br />

modern mining practices, is present in the area.<br />

The mine site maintains several buildings <strong>on</strong> site that include various offices, the <strong>on</strong>site<br />

laboratory, plant and maintenance facility, and a small camp (Figure 4). The<br />

crushing facilities and heap leach pads, waste areas and tailings p<strong>on</strong>ds are centrally<br />

located adjacent to the pits. There is sufficient room <strong>on</strong> the Property to expand these<br />

facilities, pads, dumps and p<strong>on</strong>ds if required.<br />

Electrical power is supplied by <strong>on</strong>-site generators. Although there is power supply in<br />

the surrounding area, tapping into the system would require a large capital injecti<strong>on</strong> in<br />

excess of $500,000. Due to mine life and known reserves at start up, <strong>on</strong>-site<br />

generati<strong>on</strong> was deemed to be the best use of capital.<br />

Heap Leach Pad<br />

Plant, Lab,<br />

Offices,<br />

Maintenance,<br />

camp<br />

Waste Dump<br />

Figure 4: <strong>Cerro</strong> <strong>Colorado</strong> Infrastructure, November 2011<br />

Prior to 2010 there were 3 generators <strong>on</strong>-site for power supply. Currently a 1250 kW generator is used<br />

for camp and plant power supply, backed up by a 350 kW generator.<br />

17 | P age

From St<strong>on</strong>e (2011):<br />

<strong>Goldgroup</strong> (via predecessor Sierra) entered into a lease agreement in 2006 with Mr.<br />

Arturo Bayardo of S<strong>on</strong>ora, Mexico, the owner of a nearby water well, for exclusive<br />

rights to use water from the well in the operati<strong>on</strong>s of the <strong>Cerro</strong> <strong>Colorado</strong> mine. No<br />

rental fees are charged or payable under this agreement. The lease has an indefinite<br />

term which runs until the cessati<strong>on</strong> of mining activities at <strong>Cerro</strong> <strong>Colorado</strong>. Fees<br />

payable to the Mexican government based <strong>on</strong> water c<strong>on</strong>sumpti<strong>on</strong> are solely the<br />

resp<strong>on</strong>sibility of the Sierra during the term of the lease. Up<strong>on</strong> expiry of the lease,<br />

ownership and all rights of use relating to the well revert back to Mr. Bayardo.<br />

Water is pumped to the mine site from the well, which is located approximately 12.5<br />

km to the west of the mine. This well is capable of pumping 65 litres per sec<strong>on</strong>d and<br />

is of sufficient quantity to meet water requirements at the mine site. Wells located<br />

closer to the mine are <strong>on</strong>ly capable of supplying water for single family dwellings for<br />

the area ranchers and are not feasible alternatives for the mine site. Ten (10) wells of<br />

15 m depth are in place around the physical plant. These wells are checked m<strong>on</strong>thly.<br />

Only rarely is there any water in them for sampling. When water is found in the wells<br />

a sample is collected and analyzed by an off-site laboratory for pH, suspended solids<br />

(c<strong>on</strong>ductivity), and gold and silver c<strong>on</strong>tents. Results to date have not shown any<br />

c<strong>on</strong>taminati<strong>on</strong>.<br />

iv)<br />

Physiography<br />

The project area occurs within the S<strong>on</strong>oran Desert physiographic sub-province and in<br />

general exhibits a relatively flat topography. However, in the immediate mine area,<br />

hills reach up to approximately 170m in relief. Figure 5 shows low lying hills north of<br />

the <strong>Cerro</strong> <strong>Colorado</strong> mine.<br />

Figure 5: General Physiography of <strong>Cerro</strong> <strong>Colorado</strong>, November 2011<br />

18 | P age

6. History<br />

From St<strong>on</strong>e (2011):<br />

i) Explorati<strong>on</strong> History<br />

The principal period of mining activity at <strong>Cerro</strong> <strong>Colorado</strong> occurred during the late<br />

1800's to early 1900's. Both hard rock and dry placer operati<strong>on</strong>s were c<strong>on</strong>ducted<br />

during this period. Limited underground work is believed to have taken place during<br />

the 1920's and 1930's. Within the district small scale dry placer operati<strong>on</strong>s have<br />

c<strong>on</strong>tinued intermittently to the present. The extent of past workings indicates that<br />

approximately 100,000 t<strong>on</strong>nes of high-grade gold-bearing rock was mined (MRDS<br />

MX00297) at <strong>Cerro</strong> <strong>Colorado</strong>. This producti<strong>on</strong> from underground mining and placer<br />

workings is estimated to have recovered approximately 50,000 ounces of gold.<br />

a. C<strong>on</strong>tratista Tormex<br />

The property was explored by C<strong>on</strong>tratista Tormex (“Tormex”) during the early<br />

1970's. They calculated that there were 1,000,000 t<strong>on</strong>nes of reserves at a grade of 2.6<br />

g/t Au in the Harris breccia from extensive underground sampling. Tormex estimated<br />

an Indicated resource, which includes the above reserve, of 3.5 to 4.0 milli<strong>on</strong> t<strong>on</strong>nes<br />

at a grade of 2.6 g/t Au. These resources and reserves are historic, are not current,<br />

have not been verified by CCIC and should not be relied up<strong>on</strong>.<br />

b. Papant<strong>on</strong> Minas S.A. de C.V. – BP Minerals<br />

In 1983 and 1984, Papant<strong>on</strong> Minas S.A. de C.V. and BP Minerals explored the area in<br />

a joint venture. A total of 25 holes, eight diam<strong>on</strong>d and 15 rotary, totalling 3,984<br />

metres were drilled in a widely spaced pattern over the property.<br />

c. Compañía Fresnillo S.A.<br />

In 1989-1990 Compañía Fresnillo, S.A. (“Fresnillo”) explored the <strong>Cerro</strong> <strong>Colorado</strong><br />

Property. Fresnillo explored the entire district and developed a target of 8.1 milli<strong>on</strong><br />

t<strong>on</strong>nes at 2.0 g/t Au. The project potential of 525,000 ounces of gold was not deemed<br />

large enough for Fresnillo, an Amax-Peñoles joint venture, and the project was turned<br />

back to its underlying landowners.<br />

6.5 Laramide <strong>Resources</strong> Ltd.<br />

Laramide <strong>Resources</strong> Ltd. opti<strong>on</strong>ed the <strong>Cerro</strong> <strong>Colorado</strong> property in 1995 and carried<br />

out the first mapping and sampling program in November and December of that year.<br />

This was followed by drilling 23 holes <strong>on</strong> accessible targets in February of 1996.<br />

Results of this work were encouraging and work c<strong>on</strong>tinued through 1996 and most of<br />

1997 with geologic mapping, surface and underground chip sampling, soil sampling<br />

and two additi<strong>on</strong>al phases of reverse circulati<strong>on</strong> (“RC”) drilling.<br />

After the first phase of c<strong>on</strong>firmati<strong>on</strong> drilling, explorati<strong>on</strong> focused <strong>on</strong> proving<br />

mineable resources by drilling the obvious mineralized z<strong>on</strong>es, in additi<strong>on</strong> to whatever<br />

19 | P age

extensi<strong>on</strong>(s) derived from them. As the z<strong>on</strong>es were drilled <strong>on</strong> approximately 20 m<br />

separati<strong>on</strong>s they quickly c<strong>on</strong>sumed the full explorati<strong>on</strong> budget. No effort was made to<br />

explore targets outside the core area. In this first drill program (February 1995), 23<br />

holes totalling 2,356 m were drilled mainly from existing roads near Harris and Obra<br />

X (CC-1 to CC-23). The sec<strong>on</strong>d drill program, completed in August and September<br />

1996, included 64 holes totalling 6,276 m (CC-24 to CC-87). These drill programs<br />

completed the drilling of the Obra X z<strong>on</strong>e and first tested the mineralizati<strong>on</strong> at<br />

Breccia Central and Abejas.<br />

In the third explorati<strong>on</strong> program, 75 holes totalling 8,289 m (CC-88 to CC-162) were<br />

drilled to prove Breccia Central and add Abejas and Sorpresa to the Harris resource.<br />

This drilling was completed between February and June 1997. At the end of this third<br />

phase of explorati<strong>on</strong> drilling, a total of 14,565m had been drilled in 162 holes to<br />

define mineable z<strong>on</strong>es at Obra X and Breccia Central. Laramide believed that<br />

additi<strong>on</strong>al drilling was required at Sorpresa, Harris and Abejas to bring these z<strong>on</strong>es<br />

into mineable resource categories. Laramide estimated an overall resource of 4.2<br />

milli<strong>on</strong> t<strong>on</strong>nes at a gold grade of 1.33 g/t Au (Wendt, 1995). This resource estimate is<br />

historic, not current, has not been verified by CCIC and should not be relied up<strong>on</strong>.<br />

Bottle roll testing of 53 composite samples from 10 representative drill holes showed<br />

gold recovery ranging from 54.7% to 90.6% with an average of 77.6% (Balderama,<br />

1997).<br />

d. Minera Secotec S.A. de C.V.<br />

In April 2000 Secotec began a preliminary feasibility study to determine the<br />

ec<strong>on</strong>omic viability of the <strong>Cerro</strong> <strong>Colorado</strong> project. This work c<strong>on</strong>sisted of rock chip<br />

sampling of the old workings, exposed breccia outcrops, infill drilling <strong>on</strong> 25m x 20m<br />

centres <strong>on</strong> the Sorpresa mineralized z<strong>on</strong>e, and column leach testing of the mineralized<br />

intercepts using the Laramide drill chips and dump material left at the surface during<br />

the old mining operati<strong>on</strong>s. Secotec also completed rock chip sampling c<strong>on</strong>firming the<br />

values encountered during the Laramide and Tormex explorati<strong>on</strong> programs.<br />

In-fill drilling <strong>on</strong> the Sorpresa mineralized z<strong>on</strong>e c<strong>on</strong>sisted of 26 vertical percussi<strong>on</strong><br />

drill holes <strong>on</strong> secti<strong>on</strong> lines spaced 25m apart. Holes were spaced 20m apart <strong>on</strong> the<br />

secti<strong>on</strong> lines. Gold mineralizati<strong>on</strong> was encountered in 21 of the 26 holes drilled, in<br />

z<strong>on</strong>es of altered and hematized rhyolite, rhyolite breccia and sometimes a few metres<br />

into the underlying limest<strong>on</strong>e. Holes drilled directly into the limest<strong>on</strong>e from surface<br />

invariably showed little or no gold. Mineralized intercepts encountered in the drilling<br />

include drill hole CCS11 (5-27m) 22m @ 3.78 g/t Au, and CCS14 (32-46m) 14m @<br />

4.84 g/t Au. The drilling c<strong>on</strong>firmed and expanded the original Laramide drilling and<br />

outlined a mineralized z<strong>on</strong>e which is roughly lenticular in shape, plunging easterly<br />

into the main <strong>Cerro</strong> <strong>Colorado</strong> hill and c<strong>on</strong>taining an estimated resource of 487,000<br />

t<strong>on</strong>nes @ 1.54 g/t Au. This resource estimate is historic, not current, has not been<br />

verified by CCIC and should not be relied up<strong>on</strong>.<br />

The Sorpresa area has been drilled <strong>on</strong> 9 secti<strong>on</strong>s, spaced 25m apart with drill holes<br />

spaced at 20m centres al<strong>on</strong>g secti<strong>on</strong> lines. The mineralized area occurs above the<br />

20 | P age

hyolite/basement c<strong>on</strong>tact al<strong>on</strong>g its southern boundary and has been traced virtually<br />

into c<strong>on</strong>tact with the Harris mineralizati<strong>on</strong>. Although the most easterly secti<strong>on</strong> drilled<br />

c<strong>on</strong>tained <strong>on</strong>ly weak mineralizati<strong>on</strong>, the best intercept of which was 12m @ 0.76 g/t<br />

Au, in drill hole CCS26 from 49-61m, the z<strong>on</strong>e c<strong>on</strong>tinues and can be traced in<br />

outcrop into c<strong>on</strong>tact with the Breccia Central mineralizati<strong>on</strong>.<br />

A total of 13 column leach tests were undertaken using percussi<strong>on</strong> drill chips from the<br />

Laramide drilling and dump material left at surface from the old mine workings. The<br />

tests ranged in size from 4 kg in 100 mm diameter columns, up to 200 kg in 2m x<br />

300mm diameter columns. Gold recoveries ranged from 81% to 99% based <strong>on</strong> the<br />

leach recovery and final tails assay. Leach times were generally less than 120 days<br />

except in three cases (Tests 5, 6 and 7), where the sample material was crushed to<br />

minus 6mm and extremely slow percolati<strong>on</strong> resulted. Test 10 was also slow at 203<br />

days <strong>on</strong> lower grade coarse dump material.<br />

Based <strong>on</strong> the above drilling and column leach test results, a decisi<strong>on</strong> was made in<br />

May 2001 to start a heap leach mining operati<strong>on</strong>. Operati<strong>on</strong>s would initially focus <strong>on</strong><br />

the Sorpresa mineralized z<strong>on</strong>e, and expand into the Harris/Abejas areas and<br />

subsequently the Breccia Central and Obra X mineralized z<strong>on</strong>es. Mine c<strong>on</strong>structi<strong>on</strong><br />

began in mid 2001 and was completed by February 2003. During the first phase of<br />

mining a trial heap of 90,000 t<strong>on</strong>nes of mineralized material with an average grade of<br />

1.24 g/t Au was placed <strong>on</strong> the leach pad at a crush size of minus 90mm with the<br />

additi<strong>on</strong> of 1.5 kg of lime per t<strong>on</strong>ne of rock. Leaching commenced in March 2003<br />

using a cyanide c<strong>on</strong>centrati<strong>on</strong> in soluti<strong>on</strong> of 150 ppm at a pH of 10.5. Gold recovery<br />

from this initial trial heap was 67%.<br />

<strong>Mining</strong> recommenced in December 2003 using a sec<strong>on</strong>dary c<strong>on</strong>e crusher to reduce<br />

the crush size to minus 45mm but due to insufficient capital the sec<strong>on</strong>dary crushing<br />

circuit could not be maintained in operati<strong>on</strong>. At the same time cyanide strength was<br />

increased and additi<strong>on</strong>al side-slope heap sprinkling was commenced. Recoveries<br />

appeared to be quicker from the finer crushed material. Since this time, a further<br />

400,000 t<strong>on</strong>nes have been placed <strong>on</strong> the pad at a similar grade.<br />

Secotec also completed a soil sampling program. Soil samples were collected over a<br />

grid covering the south and west flanks of <strong>Cerro</strong> <strong>Colorado</strong> and the low ground<br />

between <strong>Cerro</strong> <strong>Colorado</strong>, Plomosa and Hematita Hills. The samples were taken at<br />

20m intervals <strong>on</strong> lines spaced 100 metres apart and run at right angles to a picketed<br />

baseline running N76°E - S76°W from an origin at drill hole CC-10. A sec<strong>on</strong>d<br />

baseline al<strong>on</strong>g line 1W was used to cover the low ground between <strong>Cerro</strong> <strong>Colorado</strong>,<br />

Plomosa and Hematita hills. An additi<strong>on</strong>al 3-line grid was sampled over the northeast<br />

end of <strong>Cerro</strong> <strong>Colorado</strong> where breccia outcrops had been located. Samples were<br />

collected from 10 to 20 cm below the surface and sieved in the field.<br />

B<strong>on</strong>dar Clegg in Vancouver, Canada analyzed the minus 80 mesh fracti<strong>on</strong> for gold<br />

plus an additi<strong>on</strong>al 34 elements including Ag, Cu, Pb, Zn, Mo, As, Sb and Mn. Gold<br />

was the <strong>on</strong>ly element used in target definiti<strong>on</strong>. Various anomalies were defined as<br />

21 | P age

described below (an extract from Kappes, Cassiday & Associates, 2005) and located<br />

<strong>on</strong> Figure 6.<br />

Values were reported as very high through the low ground between the three hills,<br />

and spreading downhill from Harris, Abejas and Obra X (detailed assays not provided<br />

in the 2005 report). An east-west anomaly south of Abejas needs to be checked in the<br />

field. The crests of the main anomalies are labelled for reference as follows:<br />

Anomalies “A”, “B” and “C” appear to run east north-easterly through the low<br />

ground north of Sorpresa Z<strong>on</strong>e with “C” located close to the wash running westward<br />

off <strong>Cerro</strong> <strong>Colorado</strong>.<br />

This area, particularly the east ends of the three anomalies, c<strong>on</strong>tains placer pits after<br />

gold draining off <strong>Cerro</strong> <strong>Colorado</strong> but the western parts of the anomalies are equally<br />

str<strong>on</strong>g and occur in areas of little disturbance several hundred metres away from that<br />

source. Although they occur in an area c<strong>on</strong>taining placer gold, their orientati<strong>on</strong> is<br />

parallel to the mineralized trends in an area where regi<strong>on</strong>al faults underlie alluvial<br />

cover giving these anomalies c<strong>on</strong>siderable explorati<strong>on</strong> potential. A grid of holes<br />

drilled through the placer to test bedrock under the anomalies could locate other<br />

mineralizati<strong>on</strong> like the Sorpresa Z<strong>on</strong>e in this area.<br />

Anomaly “E” covers an area of surface disturbance from work at the Harris Mine,<br />

and the road from Harris to the Hematita Mill. Anomaly “G” is derived from the<br />

Abejas breccia outcrops and joins through lines 1E and 0E into the Harris Z<strong>on</strong>e and<br />

westward al<strong>on</strong>g the gneiss c<strong>on</strong>tact fault. This c<strong>on</strong>tact between Harris and Abejas<br />

should be drilled during the next explorati<strong>on</strong> program. The Abejas breccia trend<br />

reappears as anomaly “H” to the east of a slope covered by talus derived from the<br />

barren rhyolite above. Anomaly “F”, which includes 6 samples of over 1,000 ppb Au,<br />

lies in a little-disturbed area of the basement rock down-slope from Abejas. A field<br />

check with fill-in sampling is needed for this area. Anomaly “I” is derived from the<br />

Obra X Z<strong>on</strong>e, with an Inferred tail extending to the east.<br />

Explorati<strong>on</strong> targets were developed from the soil survey and previously reported as<br />

(Kappes, Cassiday & Associates, 2005; Figure 6):<br />

1) Anomalies “A”, “B”, and “C”, where colluvial placer deposits may cover bedrock<br />

gold in faults near the limest<strong>on</strong>e-rhyolite c<strong>on</strong>tact, require testing by grid drilling for<br />

placer plus enough bedrock to determine potential.<br />

2) The z<strong>on</strong>e west of anomaly “G” above the gneiss c<strong>on</strong>tact requires drilling to test<br />

north dipping mineralizati<strong>on</strong> between Abejas and Harris.<br />

3) Anomaly “F” is a puzzle, and needs to be field checked.<br />

4) The anomaly at 1+00 N and 1+20 N <strong>on</strong> line 10E should be checked for nearby<br />

bedrock c<strong>on</strong>necting with the Obra X z<strong>on</strong>e.<br />

22 | P age

Figure 6: Map showing the explorati<strong>on</strong> targets defined by Secotec based <strong>on</strong> the results of soil sampling (modified from<br />

Kappes, Cassiday & Associates (2005)).<br />

e. Sierra Minerals<br />

On November 26, 2004, Sierra entered into a letter agreement to procure the sale of<br />

the <strong>Cerro</strong> <strong>Colorado</strong> Gold Mine and Property with Mexican <strong>Mining</strong> Investments<br />

(“MMI”), which owned 98% of Secotec.<br />

Sierra completed a RC drilling program of eight (8) RC holes drilled outside the area<br />

of known resources in 2006. Thirty two metres of 3.42 g/t Au and 6.0 g/t Ag were<br />

intersected 30m below the surface in hole GM-4, while hole GM-5 intersected 32m at<br />

1.72 g/t Au approximately 80m below surface.<br />

In a Phase II RC drilling program completed in 2007, Sierra drilled 195 holes<br />

totalling 14,000m; 154 holes were resource and explorati<strong>on</strong> holes while 41 holes were<br />

23 | P age

drilled to sterilize an area for the planned operati<strong>on</strong>s. Significant intercepts included<br />

90m of 1.59 g/t Au and 1.46 g/t Ag (at a depth of 28m below surface) and 44m at<br />

0.90 g/t Au and 9.61 g/t Ag (Annual Informati<strong>on</strong> Form for Fiscal Year ending<br />

December 31st, 2007).<br />

Most holes have been drilled with a dip of 60°, which is roughly perpendicular to the<br />

dip of the known mineralizati<strong>on</strong>. Mineralized true widths are therefore approximately<br />

90% of the reported widths.<br />

N<strong>on</strong>e of the drilling by Sierra has had directi<strong>on</strong>al surveys completed. This should be<br />

d<strong>on</strong>e as a standard practice and it is recommended that a procedure be established for<br />

routine m<strong>on</strong>itoring of down-hole deviati<strong>on</strong> as they can have a significant impact <strong>on</strong><br />

geological interpretati<strong>on</strong> and c<strong>on</strong>structi<strong>on</strong> of a three dimensi<strong>on</strong>al (“3D”) model.<br />

f. <strong>Goldgroup</strong> <strong>Mining</strong> Inc.<br />

On February 23, 2010, Sierra Minerals Inc. and <strong>Goldgroup</strong> <strong>Resources</strong> Inc., a privately held<br />

British Columbia company and a current subsidiary of <strong>Goldgroup</strong>, entered into a definitve<br />

agreement with respect to a proposed business combinati<strong>on</strong> (the “RTO”).<br />

On April 30, 2010, <strong>Goldgroup</strong> changed its name from Sierra Minerals Inc. to <strong>Goldgroup</strong> <strong>Mining</strong><br />

Inc. and c<strong>on</strong>solidated its comm<strong>on</strong> shares <strong>on</strong> the basis of <strong>on</strong>e new comm<strong>on</strong> share for 2.85 old<br />

comm<strong>on</strong> shares. Effective April 30, 2010, <strong>Goldgroup</strong> completed the RTO with Pre-RTO<br />

<strong>Goldgroup</strong> pursuant to a statutory plan of arrangement under the Business Corporati<strong>on</strong>s Act<br />

(British Columbia).<br />

.<br />

24 | P age

7. Geological Setting and Mineralizati<strong>on</strong><br />

From St<strong>on</strong>e (2011):<br />

i) Regi<strong>on</strong>al Geology<br />

S<strong>on</strong>ora is comprised of three main physiographic provinces. These provinces trend<br />

approximately north-south, parallel to the Sierra Madre Occidental and include the<br />

Basin and Range Province (of which the project is a part), the Transiti<strong>on</strong>al z<strong>on</strong>e and<br />

the High Plateau (Sierra Madre Occidental). In the western porti<strong>on</strong> of the state (west<br />

of Federal Highway 15) the Basin and Range Province of the western United States<br />

c<strong>on</strong>tinues into S<strong>on</strong>ora. In S<strong>on</strong>ora, the Basin and Range Province c<strong>on</strong>sists of widely<br />

spaced mountain ranges, the result of mid-to-late Tertiary high-angle listric faults or<br />

earlier low-angle (detachment) faulting. These ranges c<strong>on</strong>tain a majority of the older<br />

Precambrian and Mesozoic rocks found in the state. The majority of the gold systems<br />

in this province have a structural comp<strong>on</strong>ent involving a combinati<strong>on</strong> of high and<br />

low-angle faulting (e.g. La Choya, <strong>Cerro</strong> <strong>Colorado</strong> and Quitovac).<br />

The Transiti<strong>on</strong>al z<strong>on</strong>e is found between Highway 15 and the Rio Yaqui and c<strong>on</strong>sists<br />

of closely spaced ranges that form a topographical high. A wide range of rock types<br />

and ages are found here but Tertiary volcanic rocks and indurated gravels are the<br />

most prevalent. This z<strong>on</strong>e hosts the Cananea and La Caridad mines which produce the<br />

bulk of Mexico's copper. Gold deposits vary from the structurally-hosted Amelia<br />

Deposit, clastic sediment hosted shear z<strong>on</strong>es at Quitovac, structural/carb<strong>on</strong>ate-hosted<br />

deposits such as at Santa Gertrudis, and to the vein/stockwork hosted La Colorada<br />

Deposit.<br />

The High Plateau or Sierra Madre Occidental is found al<strong>on</strong>g S<strong>on</strong>ora's eastern border<br />

with Chihuahua and c<strong>on</strong>sists of large, nearly layer-cake volcanic flows and tuffs with<br />

deeply incised cany<strong>on</strong>s. Tertiary volcanic rocks predominate. This regi<strong>on</strong> is host to<br />