Main catalogue - Athena Building

Main catalogue - Athena Building

Main catalogue - Athena Building

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

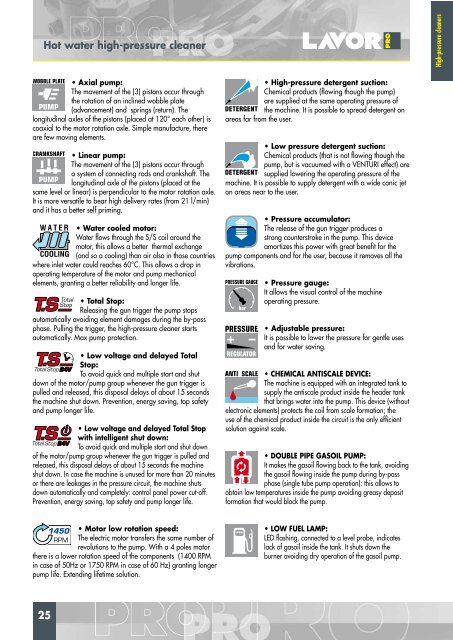

Hot water high-pressure cleaner<br />

High-pressure cleaners<br />

<br />

<br />

the rotation of an inclined wobble plate<br />

(advancement) and springs (return). The<br />

<br />

coaxial to the motor rotation axle. Simple manufacture, there<br />

are few moving elements.<br />

<br />

<br />

a system of connecting rods and crankshaft. The<br />

longitudinal axle of the pistons (placed at the<br />

same level or linear) is perpendicular to the motor rotation axle.<br />

<br />

and it has a better self priming.<br />

<br />

<br />

motor, this allows a better thermal exchange<br />

(and so a cooling) than air also in those countries<br />

<br />

operating temperature of the motor and pump mechanical<br />

elements, granting a better reliability and longer life.<br />

<br />

Releasing the gun trigger the pump stops<br />

automatically avoiding element damages during the by-pass<br />

phase. Pulling the trigger, the high-pressure cleaner starts<br />

<br />

<br />

Stop:<br />

To avoid quick and multiple start and shut<br />

<br />

<br />

the machine shut down. Prevention, energy saving, top safety<br />

and pump longer life.<br />

<br />

with intelligent shut down:<br />

To avoid quick and multiple start and shut down<br />

<br />

<br />

<br />

or there are leakages in the pressure circuit, the machine shuts<br />

down automatically and completely: control panel power cut-off.<br />

Prevention, energy saving, top safety and pump longer life.<br />

<br />

Chemical products (flowing though the pump)<br />

are supplied at the same operating pressure of<br />

the machine. It is possible to spread detergent on<br />

areas far from the user.<br />

<br />

Chemical products (that is not flowing though the<br />

pump, but is vacuumed with a VENTURI effect) are<br />

supplied lowering the operating pressure of the<br />

machine. It is possible to supply detergent with a wide conic jet<br />

on areas near to the user.<br />

<br />

The release of the gun trigger produces a<br />

strong counterstroke in the pump. This device<br />

amortizes this power with great benefit for the<br />

pump components and for the user, because it removes all the<br />

vibrations.<br />

<br />

It allows the visual control of the machine<br />

operating pressure.<br />

<br />

It is possible to lower the pressure for gentle uses<br />

and for water saving.<br />

<br />

The machine is equipped with an integrated tank to<br />

supply the antiscale product inside the header tank<br />

that brings water into the pump. This device (without<br />

electronic elements) protects the coil from scale formation; the<br />

use of the chemical product inside the circuit is the only efficient<br />

solution against scale.<br />

<br />

It makes the gasoil flowing back to the tank, avoiding<br />

the gasoil flowing inside the pump during by-pass<br />

phase (single tube pump operation): this allows to<br />

obtain low temperatures inside the pump avoiding greasy deposit<br />

formation that would block the pump.<br />

<br />

The electric motor transfers the same number of<br />

revolutions to the pump. With a 4 poles motor<br />

<br />

<br />

pump life. Extending lifetime solution.<br />

<br />

LED flashing, connected to a level probe, indicates<br />

lack of gasoil inside the tank. It shuts down the<br />

burner avoiding dry operation of the gasoil pump.<br />

25