Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

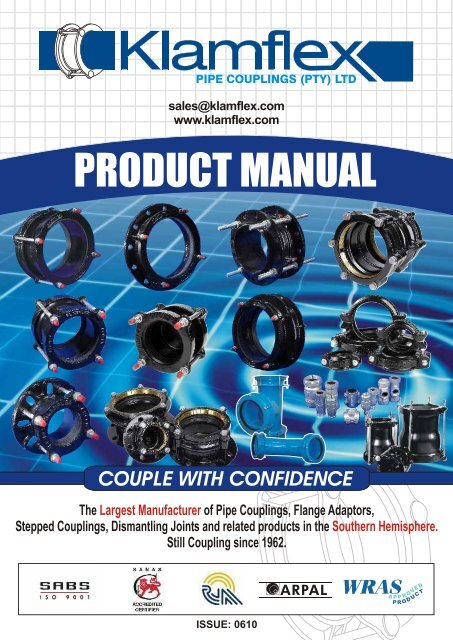

PIPE COUPLINGS (PTY) LTD<br />

sales@klamflex.com<br />

www.klamflex.com<br />

PRODUCT MANUAL<br />

COUPLE WITH CONFIDENCE<br />

The Largest Manufacturer of Pipe Couplings, Flange Adaptors,<br />

Stepped Couplings, Dismantling Joints and related products in the Southern Hemisphere.<br />

Still Coupling since 1962.<br />

ARPAL<br />

ISSUE: 0610

KEY FEATURES<br />

1<br />

HOTROLLED ASYMMETRIC STEEL T SECTION<br />

(BS EN 10025 : 2004)<br />

Free from circumferential welds providing integral strength.The offset T<br />

profile facilitates a perfect seal on the gasket and straight line bolt travel.<br />

2<br />

PROFILED ROLLED STEEL SLEEVE<br />

(SANS 1431 : 2003 / BS EN 10025 : 2004)<br />

Allows angular deflection of the pipe ends due to a thinner mid section.<br />

Rolled sleeve ends match the gasket profile exactly<br />

3<br />

EPDM GASKET with SELF CENTERING LIP<br />

(SABS 974 : 1986 / BS EN 681-1 : 1996)<br />

4<br />

D CUP AS WELL AS CUP SQUARE HEAD LOW CARBON STEEL BOLTS<br />

(SABS 1143 : 1977 / BS 970 - 1 : 1996)<br />

1<br />

3<br />

2<br />

5<br />

5<br />

NON TOXIC COATINGS AND GASKETS WITH BS 6920 CERTIFICATION<br />

4<br />

COMPANY PROFILE<br />

Established in 1962 the company is now the largest manufacturer of pipe couplings, flange adaptors,<br />

stepped couplings, dismantling joints and related products in the Southern Hemisphere. During the<br />

period to 1992 the company manufactured Viking Johnson products under a licence agreement with the<br />

Victaulic company of the U.K., the termination of which saw the emergence of <strong>Klamflex</strong> as a leading<br />

international brand name.

LISTINGS<br />

• ISO 9002 listed since 1986 Upgraded to ISO 9001 in July 2003.<br />

• RVA : Accreduted Listing by the Dutch Council for certification.<br />

• SANAS endorsed ISO 9001 listing.<br />

• ARPAL approved since August 2002.<br />

• South African Bureau of Standards Certificate of Registration.<br />

• WRAS APPROVED RUBBER - EPDM - COMPONENTS.<br />

• WRAS APPROVED COATINGS, PAINTS AND LININGS -<br />

FACTORY APPLIED - PIPE AND FITTINGS COATINGS<br />

QUALITY CONTROL<br />

• <strong>Klamflex</strong> is an ISO 9001 : 2008 listed company.<br />

• In-house production design, utilising the latest CAD systems,<br />

supported by technical staff and finite element analysis<br />

programmes.<br />

• Stringent raw material quality control and certification from<br />

international test laboratories.<br />

• Product approvals held for many countries worldwide.<br />

• In house quality inspection at all phases of production, with<br />

Hydrostatic Test Facilities<br />

• Millions of <strong>Klamflex</strong> products installed worldwide bear testament to<br />

a long history of quality production.<br />

THE MANUFACTURING PROCESS<br />

Products are manufactured in accordance with AWWA C219-01 in<br />

our 7000 sq m factory site which has recently been upgraded with<br />

the installation of a new plant and equipment including the following:<br />

• Modern shot blasting facility.<br />

• The most modern fusion bonded epoxy plant available, for spray<br />

and fluidised bed application.<br />

• A state of the art CNC controlled sleeve rolling line.<br />

• A customised follower rolling machine, CNC controlled for high<br />

precision production and quality.<br />

• The latest in plasma cutting equipment for fabricated specials.<br />

PAGE<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

17<br />

18<br />

19<br />

20<br />

21<br />

22<br />

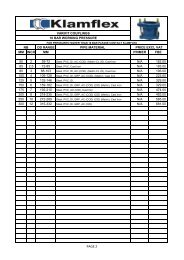

INDEX<br />

TOPIC<br />

RANGER COUPLINGS<br />

RANGER STEPPED COUPLINGS<br />

RANGER END CAPS<br />

GRIPPER COUPLINGS<br />

DEDICATED COUPLINGS<br />

STEPPED COUPLINGS<br />

RANGER FLANGE ADAPTORS<br />

DEDICATED<br />

FLANGE ADAPTORS<br />

GRIPPER FLANGE ADAPTERS<br />

DISMANTLING JOINTS<br />

SHOULDERED COUPLING<br />

JUNIOR COUPLINGS<br />

SOCKET STEEL FITTINGS<br />

PIPE OD CHART

RANGER COUPLINGS<br />

KLAMFLEX Ranger Couplings, are designed to join<br />

pipes of various outside diameters with the same or different<br />

nominal bore. The ability of KLAMFLEX Ranger<br />

Couplings to join dissimilar pipe materials is a bonus<br />

feature in both repair or permanent situations.<br />

Corrosion protection for KLAMFLEX Ranger Products<br />

is available in Fusion Bonded Epoxy, Red Oxide Primer<br />

and Galvanised finish as standard. Optional coatings to<br />

customer specifications are available on request.<br />

KLAMFLEX Ranger Couplings have application in the<br />

reticulation of potable water, waste water and sewage as<br />

well as in the marine, mining, oil, gas and general engineering<br />

sectors.<br />

Moulded, circumferentially ribbed or specially profiled<br />

gaskets, generally in EPDM or NBR materials, provide for<br />

smooth installation by minimising contact friction.<br />

KLAMFLEX Ranger Gaskets are designed to provide a<br />

leak tight seal across the O.D. range per nominal size and<br />

still allow for thermal expansion and contraction of the<br />

pipe up to 5mm per gasket, facilitated through gasket<br />

deformation.<br />

To facilitate installation and avoid possible creep under<br />

rising load, it is strongly recommended that the<br />

KLAMFLEX Ranger Rubber Sealing Gaskets are well<br />

lubricated with a suitable non toxic soap solution before<br />

the introduction of the pipe.<br />

KLAMFLEX RANGER COUPLING<br />

SUITABLE FOR JOINING PIPES OF SIMILAR OR DISSIMILAR MATERIALS WITHIN THE O.D. RANGE.<br />

USE AS A STRAIGHT COUPLING, OR IN PLACE OF A STEPPED COUPLING WITHIN THE O.D. RANGE<br />

NOM.BORE<br />

(mm/inch)<br />

50/2<br />

65/2.5<br />

80/3<br />

100/4<br />

125/5<br />

150/6<br />

175/7<br />

200/8<br />

225/9<br />

250/10<br />

250/10<br />

300/12<br />

300/12<br />

350/14<br />

400/16<br />

450/18<br />

500/20<br />

600/24<br />

PIPE O.D.<br />

RANGE(mm)<br />

APPROX<br />

MASS (kg)<br />

59-72 2.9<br />

72-85 3<br />

88-103 4.2<br />

109-128 4.6<br />

138-153 4.8<br />

159-182 7<br />

192-210 9.2<br />

218-235 10.2<br />

230-247 16.6<br />

250-267 18.2<br />

272-289 16.2<br />

315-332 23.6<br />

322-340 19.8<br />

374-391 28.2<br />

417-437 26.4<br />

480-500 33<br />

526-546 35<br />

630-650 46.8<br />

PIPE MATERIAL SUITABILITY<br />

STEEL (imperial+metric), UPVC, DI, CI, AC (imperial), ABS/DWV<br />

STEEL (imperial+metric), UPVC, DI, CI, AC (imperial), ABS/DWV<br />

STEEL (imperial+metric), UPVC, DI, CI, AC (imperial), ABS/DWV<br />

STEEL (imperial+metric), UPVC, DI, CI, AC (cod), AC (imperial)<br />

STEEL (imperial+metric), UPVC, DI, CI, AC (cod), AC (imperial)<br />

STEEL (imperial+metric), UPVC, DI, CI, AC (cod), AC (cid), AC (imperial)<br />

STEEL (imperial+metric), UPVC, CI, AC (imperial)<br />

STEEL (imperial+metric), UPVC, DI, CI, AC (cod), AC (cid), AC (imperial), GRP<br />

STEEL (imperial+metric), DI, AC (cod), AC (cid), AC (imperial)<br />

STEEL (imperial+metric), UPVC, AC (cid)<br />

STEEL (imperial+metric), UPVC, DI, CI, AC (cod), AC (cid), AC (imperial), GRP<br />

STEEL (imperial+metric), UPVC, DI, GRP<br />

STEEL (imperial+metric), DI, AC Class 12<br />

DI, GRP, AC Class 6<br />

DI, AC Class 6 and 12<br />

DI, AC Class 6 and 12, UPVC<br />

DI, AC Class 6 and 12<br />

DI, AC Class 6, Imperial CI/CL<br />

MAX WORKING PRESSURE: 16 BAR • SETTING GAP: 19mm • TOLERANCE ON ANGULAR DEFLECTION:<br />

6 DEGREES • EXPANSION AND CONTRACTION RANGE: 0-10 mm • RECOMMENDED BOLT TORQUE: 60-80 mm<br />

1

RANGER STEPPED<br />

COUPLINGS<br />

KLAMFLEX Ranger Stepped Ranger Couplings are<br />

designed to join pipes of various outside diameters<br />

with different nominal bores.<br />

KLAMFLEX Ranger Stepped Ranger Couplings can<br />

connect steel, ductile iron, UPVC, cast iron, asbestos<br />

cement and other rigid pipe materials.<br />

Corrosion protection is available in Fusion Bonded<br />

Epoxy and Red Oxide Primer as standard. Optional<br />

coatings to customer specifications are available on<br />

request.<br />

Gasket material is EPDM and designed to provide a<br />

leak tight seal across the O.D. range allowing for thermal<br />

expansion and contraction of the pipe. It is<br />

strongly recommended that the rubber sealing gaskets<br />

are well lubricated with a suitable non toxic soap solution<br />

before the introduction of the pipe.<br />

This practice will obviate the need for re-tightening<br />

the fasteners after pressure testing, and further facilitate<br />

the seating of the joint components.<br />

NOMINAL<br />

BORE<br />

(mm)<br />

PIPE OD RANGE<br />

(mm)<br />

APPROX<br />

MASS (kg)<br />

50/65 59-72 / 72-85<br />

2.6<br />

80/100 88-103 / 109-128<br />

4.6<br />

100/125 109-128 / 138-151 5.2<br />

125/150 138- 153 / 159-182 6.4<br />

150/175 159-210 / 192-210 7.2<br />

175/200 192-210 / 218-235 12.4<br />

200/200+ 218-232 / 230-247 16.8<br />

250/250+ 250- 267 / 272-289 22.4<br />

2

RANGER END CAPS<br />

KLAMFLEX Ranger End Caps are manufactured<br />

from our Ranger Couplings, therefore giving you<br />

the versatility of using them on a variety of different<br />

pipe OD’s and materials.<br />

KLAMFLEX Ranger End Caps are therefore suitable<br />

for all popular standard pipe sizes ranging<br />

from 50mm to 300mm and are designed for the<br />

use in air, water, sewer, and gas pipelines up to 16<br />

Bar.<br />

KLAMFLEX Ranger End Caps are supplied with<br />

and EPDM rubber seal and coating can either be<br />

Red Oxide or Fusion Bonded Epoxy.<br />

KLAMFLEX Ranger End Caps can be manufactured<br />

with double sleeves to prevent end pullout on<br />

PE, HDPE and GRP pipes.<br />

RANGER END CAPS<br />

NOM. BORE<br />

(mm)<br />

50/2<br />

65/2.5<br />

803<br />

100/4<br />

125/5<br />

150/6<br />

175/7<br />

200/8<br />

225/9<br />

250/10<br />

250/10<br />

300/12<br />

PIPE O.D.<br />

RANGE<br />

(mm)<br />

59-72<br />

72-85<br />

88-103<br />

109-128<br />

138-153<br />

159-182<br />

192-210<br />

218-235<br />

230-247<br />

250-267<br />

272-289<br />

322-332<br />

APPROX<br />

MASS (kg)<br />

3.1<br />

3.3<br />

4.5<br />

4.9<br />

5.2<br />

7.4<br />

9.6<br />

10.6<br />

17.4<br />

18.8<br />

17.1<br />

24.2<br />

PIPE MATERIAL SUITABILITY<br />

STEEL (imperial+metric), UPVC, DI, CI, AC (imperial), ABS/DWV<br />

STEEL (imperial+metric), UPVC, DI, CI, AC (imperial), ABS/DWV<br />

STEEL (imperial+metric), UPVC, DI, CI, AC (imperial), ABS/DWV<br />

STEEL (imperial+metric), UPVC, DI, CI, AC (cod), AC (imperial)<br />

STEEL (imperial+metric), UPVC, DI, CI, AC (cod), AC (imperial)<br />

STEEL (imperial+metric), UPVC, DI, CI, AC (cod), AC (cid), AC (imperial)<br />

STEEL (imperial+metric), UPVC, CI, AC (imperial)<br />

STEEL (imperial+metric), UPVC, DI, CI, AC (cod), AC (cid), AC (imperial), GRP<br />

STEEL (imperial+metric), DI, AC (cod), AC (cid), AC (imperial)<br />

STEEL (imperial+metric), UPVC, AC (cid)<br />

STEEL (imperial+metric), UPVC, DI, CI, AC (cod), AC (cid), AC (imperial), GRP<br />

STEEL (imperial+metric), UPVC, DI, AC (cid 24), GRP<br />

MAX WORKING PRESSURE: 16 BAR • RECOMMENDED BOLT TORQUE: 60-80 mm<br />

3

GRIPPER COUPLINGS<br />

KLAMFLEX Gripper Couplings are designed to<br />

resist end pullout on PE and PVC pipes, it is the<br />

fastening action of the Gripper Rings that secures<br />

the Coupling onto the pipe resisting end pullout.<br />

KLAMFLEX Gripper Couplings are manufactured<br />

from Ductile Iron, Gasket material is<br />

EPDM, Gripper Ring material is Brass, and coating<br />

is Fusion Bonded Epoxy.<br />

Sizes are available for the following pipe<br />

outside diameters:<br />

NOMINAL<br />

BORE<br />

(mm)<br />

PIPE OD RANGE<br />

(mm)<br />

50 63<br />

7<br />

APPROX<br />

MASS (kg)<br />

80 90<br />

11<br />

100 110<br />

13<br />

150 160<br />

25<br />

4

KLAMFLEX DEDICATED<br />

COUPLINGS<br />

KLAMFLEX Dedicated Couplings join pipes of<br />

the same outside diameter. Couplings up to 324mm<br />

OD are delivered pre-assembled. Larger sizes are<br />

delivered ready for site assembly on the pipe.<br />

KLAMFLEX Couplings can be manufactured to<br />

suit both metric and imperial dimensions for Steel,<br />

uPVC, Ductile Iron, G.R.P., Fibre Cement,<br />

Stainless Steel, Aluminium Alloys and virtually all<br />

other rigid pipe materials.<br />

<strong>Klamflex</strong> Couplings can be manufactured with<br />

double sleeves to prevent end pull out on HDPE<br />

and GRP pipes.<br />

The sizes shown in the schedules of dimensions are<br />

for guide purposes. KLAMFLEX’S manufacturing<br />

methods enable us to supply any size, including<br />

non-standard sizes.<br />

KLAMFLEX Couplings are pressure rated to the<br />

appropriate pipe standards. Working pressure is<br />

generally two-thirds of maximum test pressure<br />

shown in the schedules of dimensions. These<br />

pressures apply to a buried line with adequate<br />

thrust blocks or to pipelines above ground<br />

anchored at ends and at all changes of direction also<br />

secured against side thrusts at each joint.<br />

KLAMFLEX Couplings, though capable of<br />

accommodating reasonable expansion and contraction,<br />

do not mechanically prevent separation of<br />

pipe ends subject to end thrust, and this must be<br />

prevented by other means. To prevent separation of<br />

pipe ends, harness assemblies consisting of lugs for<br />

welding to adjacent pipes, and connecting tie rods<br />

can be supplied. Pipes must be anchored against<br />

end load, particularly when the pipeline is laid<br />

above ground. A buried pipeline normally needs<br />

anchoring only at abrupt changes in direction and at<br />

junctions or stop ends.<br />

Gaskets are of a EPDM rubber and are suitable for<br />

water and sewerage services, chemicals and dilute<br />

acids in the temperature range –50°C to +90°C.<br />

Other sealing materials can be used, increasing<br />

temperature range to greater than 90°C. These<br />

materials are available on request.<br />

<strong>Klamflex</strong> Gaskets and Epoxy coatings are<br />

certified non toxic for potable water in accordance<br />

with BS 6920.<br />

5

One method of preventing pipe separation is the use of a<br />

harness assembly, consisting of lugs for welding to steel<br />

pipes and restraining tie rods. Cast iron pipes can sometimes<br />

be harnessed through the use of additional flanges cast onto<br />

the pipe ends.<br />

In most cases we can also supply KLAMFLEX Flange<br />

Adaptors complete with harness assembly. Four or more<br />

flange bolts are replaced with long tie bolts.<br />

N.B.<br />

KLAMFLEX HARNESSED COUPLINGS<br />

KLAMFLEX Pipe Couplings supply the lugs, nuts,<br />

bolts and the couplings/adaptor between coupling<br />

and plinth to permit full assembly of all bolts.<br />

KLAMFLEX CENTRE REGISTER<br />

The centre sleeve can be supplied with or without internal<br />

centre register studs. The registers provide a locating stop to<br />

centre the coupling which facilitates the laying of long pipe<br />

runs. Centre registers also prevent the possibility of the<br />

coupling creeping at positions where there are continual<br />

axial movements. Couplings without centre register are<br />

necessary for fitting closing lengths on a pipeline, or for<br />

withdrawing any particular length for cleaning or inspection.<br />

Locating plugs may be fitted to couplings to act as<br />

removable centre registers, thus providing the advantage of<br />

both types.<br />

KLAMFLEX Centre registers are used in couplings above<br />

ground where there may be a tendency for the coupling to<br />

creep e.g. on an incline.<br />

KLAMFLEX Centre registers are of two types: A (from<br />

350mm) removable, used where the coupling can be moved<br />

along the pipe to allow the pipe to be inspected, and B (all<br />

sizes) fixed, used where there is no need to remove couplings.<br />

KLAMFLEX ANCHORED COUPLINGS<br />

With brackets welded to the centre sleeve, couplings can be<br />

bolted directly to the supporting structure. Brackets are<br />

designed to withstand the thrust produced by maximum<br />

angularity and will support a 10m long pipe full of water (up<br />

to DN 1 500mm)<br />

We recommend the use of locating centre registers with<br />

anchored couplings to help resist pipe movement. On steep<br />

slopes, special consideration should be given to anchorage.<br />

N.B.<br />

1.<br />

2.<br />

3.<br />

Harness rods are not normally used with<br />

anchored couplings.<br />

Anchor brackets are not designed to withstand<br />

the full longitudinal or lateral forces produced<br />

by internal pressure.<br />

Ensure that sufficient clearance is allowed<br />

between coupling and plinth to permit full<br />

assembly of all bolts.<br />

Where locating plugs are used, the setting gap should be<br />

increased by 9,5mm for sizes up to 324mm and 12.5mm for<br />

sizes above 324mm OD to avoid contact with the plugs.<br />

6

KLAMFLEX DEDICATED COUPLINGS<br />

DUCTILE IRON PIPE ISO 2531:1991 BS 4772:1988<br />

FOR 10 & 16 BAR WORKING PRESSURE<br />

NOM<br />

BORE<br />

PIPE<br />

OD<br />

TOLERANCE<br />

ON PIPE OD<br />

FOR PREPARED<br />

END<br />

MINIMUM<br />

PIPE END<br />

PREPARED<br />

LENGTH<br />

L<br />

OD OF<br />

ENDRING<br />

(mm) (mm) (mm) (mm) (mm) (mm) (mm)<br />

80<br />

100<br />

125<br />

150<br />

200<br />

250<br />

300<br />

350<br />

400<br />

450<br />

500<br />

600<br />

700<br />

800<br />

900<br />

1000<br />

1100<br />

1200<br />

1400<br />

1600<br />

1800<br />

2000<br />

98<br />

118<br />

141<br />

170<br />

222<br />

274<br />

326<br />

378<br />

429<br />

480<br />

532<br />

635<br />

738<br />

842<br />

945<br />

1048<br />

1152<br />

1255<br />

1468<br />

1668<br />

1875<br />

2082<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

-3.0<br />

-3.0<br />

-3.0<br />

-3.0<br />

-3.5<br />

-3.5<br />

-3.5<br />

-3.5<br />

-4.0<br />

-4.0<br />

-4.0<br />

-4.5<br />

-4.5<br />

-4.5<br />

-5.0<br />

-5.0<br />

-6.0<br />

-6.0<br />

-6.0<br />

-6.0<br />

-6.0<br />

-6.0<br />

100<br />

100<br />

100<br />

100<br />

100<br />

100<br />

100<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150/ 300<br />

150/ 300<br />

158<br />

200<br />

220<br />

260<br />

308<br />

364<br />

414<br />

480<br />

531<br />

582<br />

634<br />

737<br />

840<br />

944<br />

1047<br />

1150<br />

1268<br />

1371<br />

1578<br />

1784<br />

1989<br />

2196<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

262<br />

262<br />

262<br />

262<br />

262<br />

262<br />

262<br />

262<br />

262<br />

262<br />

262<br />

262<br />

262<br />

262/ 450<br />

262/ 450<br />

102<br />

102<br />

102<br />

102<br />

102<br />

102<br />

102<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178/356<br />

178/ 356<br />

A<br />

COUPLING<br />

LENGTH<br />

B<br />

SLEEVE<br />

WIDTH<br />

D<br />

STANDARD<br />

TEST PRESSURE<br />

AT:<br />

10 bar<br />

working<br />

pressure<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

16 bar<br />

working<br />

pressure<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

APPROX.<br />

MASS<br />

(kg)<br />

3.6<br />

4.4<br />

6.1<br />

6<br />

7.9<br />

10.6<br />

11.7<br />

29.4<br />

33.7<br />

37<br />

41.3<br />

47.9<br />

56.4<br />

64<br />

70.6<br />

78.3<br />

115<br />

124.9<br />

144.2<br />

164.3<br />

TBA<br />

TBA<br />

FOR COUPLINGS OF 25 AND 40 BAR WORKING PRESSURE PLEASE CONTACT KLAMFLEX<br />

THE ABOVE TABLE INCLUDES SAMPLES OF THE SIZES AVAILABLE, PLEASE CONTACT KLAMFLEX FOR ANY OTHER SIZES UP TO<br />

3500mm.<br />

7

KLAMFLEX DEDICATED COUPLINGS<br />

STEEL PIPES: ISO 2531:1991 BS 4772:1988<br />

FOR 10 & 16 BAR WORKING PRESSURE<br />

NOM<br />

BORE<br />

PIPE<br />

OD<br />

TOLERANCE<br />

ON PIPE OD<br />

FOR PREPARED<br />

END<br />

MINIMUM<br />

PIPE END<br />

PREPARED<br />

LENGTH<br />

OD OF<br />

ENDRING<br />

COUPLING<br />

LENGTH<br />

SLEEVE<br />

WIDTH<br />

STANDARD<br />

TEST PRESSURE<br />

AT:<br />

APPROX.<br />

MASS<br />

L A B D<br />

10 bar 16 bar<br />

working working<br />

(mm) (mm) (mm) (mm) (mm) (mm) (mm) pressure pressure (kg)<br />

50<br />

65<br />

80<br />

100<br />

125<br />

150<br />

150<br />

200<br />

225<br />

250<br />

250<br />

300<br />

350<br />

400<br />

450<br />

500<br />

550<br />

600<br />

650<br />

700<br />

750<br />

800<br />

850<br />

900<br />

950<br />

1000<br />

1050<br />

1100<br />

1200<br />

1200<br />

1400<br />

1400<br />

1500<br />

1600<br />

1600<br />

1800<br />

1800<br />

2000<br />

2100<br />

2200<br />

2400<br />

2700<br />

60.3<br />

76.1<br />

88.9<br />

114.3<br />

139.7<br />

165.1<br />

168.3<br />

219.1<br />

244.5<br />

267<br />

273<br />

323.9<br />

355.6<br />

406.4<br />

457<br />

508<br />

559<br />

609.6<br />

660<br />

711.2<br />

762<br />

812.8<br />

864<br />

914.4<br />

965<br />

1016<br />

1067<br />

1118<br />

1219<br />

1235<br />

1420<br />

1422<br />

1520<br />

1620<br />

1626<br />

1820<br />

1829<br />

2020<br />

2120<br />

2230<br />

2440<br />

2740<br />

+0.8<br />

+0.8<br />

+0.8<br />

+0.8<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+3<br />

+3<br />

+3<br />

+3<br />

+3<br />

+3<br />

+3<br />

+3<br />

+3<br />

-0.8<br />

-0.8<br />

-0.8<br />

-0.8<br />

-0.8<br />

-0.8<br />

-0.8<br />

-0.8<br />

-0.8<br />

-0.8<br />

-0.8<br />

-0.8<br />

-1.6<br />

-1.6<br />

-1.6<br />

-1.6<br />

-1.6<br />

-1.6<br />

-1.6<br />

-1.6<br />

-1.6<br />

-1.6<br />

-1.6<br />

-1.6<br />

-1.6<br />

-1.6<br />

-1.6<br />

-1.6<br />

-1.6<br />

-1.6<br />

-3<br />

-3<br />

-3<br />

-3<br />

-3<br />

-3<br />

-3<br />

-3<br />

-3<br />

-3<br />

-3<br />

-3<br />

100<br />

100<br />

100<br />

100<br />

100<br />

100<br />

100<br />

100<br />

100<br />

100<br />

100<br />

100<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150/ 300<br />

150/ 300<br />

150/ 300<br />

150/ 300<br />

150/ 300<br />

134<br />

150<br />

158<br />

174<br />

220<br />

246<br />

246<br />

308<br />

338<br />

360<br />

364<br />

414<br />

458<br />

509<br />

559<br />

610<br />

661<br />

712<br />

762<br />

814<br />

864<br />

915<br />

966<br />

1017<br />

1067<br />

1118<br />

1169<br />

1220<br />

1335<br />

1351<br />

1536<br />

1538<br />

1636<br />

1736<br />

1742<br />

1936<br />

1945<br />

2134<br />

2234<br />

2344<br />

2554<br />

2854<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

262<br />

262<br />

262<br />

262<br />

262<br />

262<br />

262<br />

262<br />

262<br />

262<br />

262<br />

262<br />

262<br />

262<br />

262<br />

262<br />

262<br />

262<br />

262<br />

262<br />

262<br />

262<br />

262<br />

262<br />

262<br />

262/ 450<br />

262/ 450<br />

262/ 450<br />

262/ 450<br />

262/ 450<br />

83<br />

102<br />

102<br />

102<br />

102<br />

102<br />

102<br />

102<br />

102<br />

102<br />

102<br />

102<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178/ 356<br />

178/ 356<br />

178/ 356<br />

178/ 356<br />

178/ 356<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

2.2<br />

2.7<br />

3.3<br />

4<br />

6.1<br />

5.4<br />

5.4<br />

7.9<br />

10.6<br />

11.4<br />

10.6<br />

11.6<br />

28<br />

31.3<br />

35.5<br />

39.6<br />

42.9<br />

46.3<br />

49.4<br />

53.7<br />

58<br />

61.3<br />

65.4<br />

68.6<br />

72.9<br />

76<br />

79.4<br />

83.6<br />

121.8<br />

123.2<br />

140.4<br />

140.7<br />

150.2<br />

160<br />

160.6<br />

178.7<br />

179.4<br />

TBA<br />

TBA<br />

TBA<br />

TBA<br />

TBA<br />

FOR COUPLINGS OF 25 AND 40 BAR WORKING PRESSURE PLEASE CONTACT KLAMFLEX<br />

THE ABOVE TABLE INCLUDES SAMPLES OF THE SIZES AVAILABLE, PLEASE CONTACT KLAMFLEX FOR ANY OTHER SIZES UP TO<br />

3500mm.<br />

8

NOM<br />

BORE<br />

PIPE<br />

OD<br />

TOLERANCE<br />

ON PIPE OD<br />

FOR PREPARED<br />

END<br />

KLAMFLEX DEDICATED COUPLINGS<br />

uPVC PIPES: SABS 966:1976 ISO 161:1978<br />

FOR 10 & 16 BAR WORKING PRESSURE<br />

MINIMUM<br />

PIPE END<br />

PREPARED<br />

LENGTH<br />

OD OF<br />

ENDRING<br />

COUPLING<br />

LENGTH<br />

SLEEVE<br />

WIDTH<br />

STANDARD<br />

TEST PRESSURE<br />

AT:<br />

APPROX.<br />

MASS<br />

L A B D<br />

10 bar 16 bar<br />

working working<br />

(mm) (mm) (mm) (mm) (mm) (mm) (mm) pressure pressure (kg)<br />

100 110 +1.0 -1.0 100 163 178 102 15 24 4.2<br />

140 140 +1.0 -1.0 100 220 178 102 15 24 6.1<br />

160 160 +1.0 -1.0 100 242 178 102 15 24 5.9<br />

175 177.8 +1.0 -1.0 100 267 178 102 15 24 7.5<br />

180 180 +1.0 -1.0 100 267 178 102 15 24 9.6<br />

200 200 +1.0 -1.0 100 289 178 102 15 24 10<br />

225 225 +1.0 -1.0 100 318 178 102 15 24 10.4<br />

250 250 +1.0 -1.0 100 343 178 102 15 24 10.9<br />

280 280 +1.0 -1.0 100 373 178 102 15 24 11.1<br />

315 315 +1.0 -1.0 100 408 178 102 15 24 11.9<br />

400 400 +1.0 -1.0 150 502 262 178 15 24 31<br />

500 500 +1.0 -1.0 150 602 262 178 15 24 39.2<br />

FOR COUPLINGS OF 25 AND 40 BAR WORKING PRESSURE PLEASE CONTACT KLAMFLEX<br />

THE ABOVE TABLE INCLUDES SAMPLES OF THE SIZES AVAILABLE, PLEASE CONTACT KLAMFLEX FOR ANY OTHER SIZES UP TO<br />

2000MM.<br />

NOM<br />

BORE<br />

KLAMFLEX DEDICATED COUPLINGS<br />

FIBRE CEMENT PIPE FOR COD AND CID PIPE: SABS 1223:1985 ISO 160:1980<br />

PIPE<br />

OD<br />

TOLERANCE<br />

ON PIPE OD<br />

FOR PREPARED<br />

END<br />

FOR 10 & 16 BAR WORKING PRESSURE<br />

MINIMUM<br />

PIPE END<br />

PREPARED<br />

LENGTH<br />

OD OF<br />

ENDRING<br />

COUPLING<br />

LENGTH<br />

SLEEVE<br />

WIDTH<br />

STANDARD<br />

TEST PRESSURE<br />

AT:<br />

10 bar<br />

16 bar<br />

APPROX.<br />

MASS<br />

L A B D working working<br />

(mm) (mm) (mm) (mm) (mm) (mm) (mm) pressure pressure (kg)<br />

50<br />

100<br />

150<br />

150<br />

250<br />

300<br />

300<br />

300<br />

600<br />

600<br />

600<br />

600<br />

1100<br />

96<br />

122<br />

168<br />

177<br />

286<br />

328<br />

340<br />

345<br />

667<br />

699<br />

727<br />

755<br />

1188<br />

+0.6<br />

+0.6<br />

+0.6<br />

+0.6<br />

+0.6<br />

+0.6<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.2<br />

-0.0<br />

-0.0<br />

-0.0<br />

-0.0<br />

-0.0<br />

-0.0<br />

-0.0<br />

-0.0<br />

-0.0<br />

-0.0<br />

-0.0<br />

-0.0<br />

-0.0<br />

100<br />

100<br />

100<br />

100<br />

100<br />

100<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

158<br />

200<br />

246<br />

267<br />

379<br />

421<br />

442<br />

442<br />

769<br />

801<br />

829<br />

857<br />

1304<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

262<br />

262<br />

262<br />

262<br />

262<br />

262<br />

262<br />

102<br />

102<br />

102<br />

102<br />

102<br />

102<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

178<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

3.6<br />

4.4<br />

5.4<br />

6.1<br />

12<br />

13.9<br />

27.1<br />

27.5<br />

50<br />

52.9<br />

55.7<br />

57.5<br />

118.1<br />

FOR COUPLINGS OF 25 AND 40 BAR WORKING PRESSURE PLEASE CONTACT KLAMFLEX<br />

THE ABOVE TABLE INCLUDES SAMPLES OF THE SIZES AVAILABLE, PLEASE CONTACT KLAMFLEX FOR ANY OTHER SIZES UP TO<br />

2000MM.<br />

9

KLAMFLEX STEPPED<br />

COUPLINGS<br />

Where pipe ends of different outside diameters<br />

have to be connected, stepped couplings can be<br />

provided. These normally cover the difference<br />

between the outside diameters of pipes of different<br />

materials of construction with a common nominal<br />

bore, or pipes of the same materials having different<br />

nominal bores.<br />

It is advisable to mark the pipe a known distance<br />

from the end when fitting a step coupling to enable<br />

inspection of movement. This will allow the<br />

inspector to ensure that no telescoping along the<br />

smaller diameter pipe has occurred.<br />

When this fitting is used as a coupling between two<br />

pipes with diameter differences exceeding 25mm<br />

it is essential to ensure that the stepped coupling<br />

cannot be forced along the smaller diameter pipe.<br />

Scheduled sizes will not normally require such<br />

precautions, but others may.<br />

Regular inspection of a pipe previously marked, is<br />

normally all that is required. Alternatively, where<br />

this cannot be arranged, a mechanical means<br />

should be employed.<br />

Pressure rating for stepped couplings are<br />

equivalent to the rating specified in the straight<br />

coupling schedules, for the larger of the two OD's.<br />

In the case of ductile iron, AC and uPVC pipes, the<br />

pressure rating will match the pipe rating.<br />

KLAMFLEX Stepped Couplings can be<br />

manufactured with full sleeves to prevent end<br />

pullout on PE, HDPE and GRP pipes.<br />

10

Where pipe OD sizes are negligible<br />

KLAMFLEX STEPPED COUPLIINGS<br />

NOM<br />

BORE<br />

PIPE 1<br />

NOM<br />

BORE<br />

PIPE 2<br />

PIPE<br />

OD1<br />

PIPE<br />

OD2<br />

DESCRIPTION<br />

L<br />

MIN<br />

A1 A2 B<br />

D<br />

MAX TEST<br />

PRESSURE<br />

(mm)<br />

50<br />

140<br />

200<br />

315<br />

300<br />

600<br />

700<br />

1000<br />

(mm)<br />

65<br />

160<br />

200<br />

300<br />

300<br />

600<br />

700<br />

1000<br />

(mm)<br />

60.3<br />

140<br />

200<br />

315<br />

353<br />

651<br />

760<br />

1062<br />

(mm)<br />

76.1<br />

160<br />

219<br />

324<br />

365<br />

672<br />

784<br />

1084<br />

(mm)<br />

STEEL/STEEL<br />

uPVC/uPVC<br />

uPVC/STEEL<br />

uPVC/STEEL<br />

FC30/FC24<br />

FC18/FC12<br />

FC18/FC12<br />

FC12/FC06<br />

(mm)<br />

100<br />

100<br />

100<br />

100<br />

120<br />

140<br />

140<br />

160<br />

(mm)<br />

133<br />

224<br />

292<br />

407<br />

458<br />

756<br />

875<br />

1177<br />

(mm)<br />

148<br />

246<br />

311<br />

419<br />

470<br />

777<br />

889<br />

1199<br />

(mm)<br />

172<br />

172<br />

172<br />

172<br />

260<br />

260<br />

260<br />

260<br />

(mm)<br />

102 x 6.4<br />

102 x 7.2<br />

102 x 8.7<br />

102 x 8.7<br />

178 x 8.7<br />

178 x 8.7<br />

178 x 11.1<br />

178 x 11.1<br />

(bar)<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

Where the pipe OD differs to a greater extent a profile plate is used<br />

KLAMFLEX STEPPED COUPLIINGS<br />

NOM<br />

BORE<br />

PIPE 1<br />

NOM<br />

BORE<br />

PIPE 2<br />

PIPE<br />

OD1<br />

PIPE<br />

OD2<br />

DESCRIPTION<br />

L<br />

MIN<br />

A1<br />

A2<br />

B<br />

D<br />

MAX TEST<br />

PRESSURE<br />

(mm)<br />

65<br />

160<br />

150<br />

250<br />

355<br />

600<br />

700<br />

1100<br />

(mm)<br />

80<br />

150<br />

200<br />

250<br />

350<br />

600<br />

750<br />

1100<br />

(mm)<br />

76.1<br />

160<br />

177<br />

273<br />

355<br />

610<br />

711<br />

1118<br />

(mm)<br />

96<br />

174<br />

232<br />

318<br />

378<br />

672<br />

762<br />

1188<br />

(mm)<br />

STEEL/FC<br />

uPVC/FC18<br />

FC/FC<br />

STEEL/FC36<br />

uPVC/DI<br />

STEEL/FC18<br />

STEEL/DI<br />

FC/STEEL<br />

(mm)<br />

100<br />

100<br />

100<br />

100<br />

120<br />

150<br />

150<br />

160<br />

(mm)<br />

148<br />

246<br />

270<br />

367<br />

460<br />

714<br />

815<br />

1233<br />

(mm)<br />

170<br />

266<br />

324<br />

410<br />

483<br />

776<br />

877<br />

1303<br />

(mm)<br />

188<br />

190<br />

190<br />

190<br />

270<br />

270<br />

270<br />

276<br />

(mm)<br />

110<br />

112<br />

112<br />

112<br />

188<br />

188<br />

188<br />

194<br />

(bar)<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

FOR COUPLINGS OF 25 AND 40 BAR WORKING PRESSURE PLEASE CONTACT KLAMFLEX<br />

THE ABOVE TABLE INCLUDES SAMPLES OF THE SIZES AVAILABLE, PLEASE CONTACT KLAMFLEX FOR ANY OTHER SIZES<br />

UP TO 2000MM.<br />

11

RANGER FLANGE ADAPTORS<br />

KLAMFLEX Ranger Flange Adaptors, are designed to<br />

join pipes of various outside diameters with the same or<br />

different nominal bore. The ability of KLAMFLEX<br />

Ranger Flange Adaptors to join dissimilar pipe materials<br />

is a bonus feature in both repair or permanent situations.<br />

Corrosion protection for KLAMFLEX Ranger Flange<br />

Adaptor Products is available in Fusion Bonded Epoxy,<br />

Red Oxide Primer and Galvanised finish as standard.<br />

Optional coatings to customer specifications are available<br />

on request.<br />

KLAMFLEX Ranger Flange Adaptors have application<br />

in the reticulation of potable water, waste water and<br />

sewage as well as in the marine, mining, oil, gas and<br />

general engineering sectors.<br />

Moulded, circumferentially ribbed or specially profiled<br />

gaskets, generally in EPDM or NBR materials, provide for<br />

smooth installation by minimising contact friction.<br />

KLAMFLEX Ranger Gaskets are designed to provide a<br />

leak tight seal across the O.D. range per nominal size and<br />

still allow for thermal expansion and contraction of the<br />

pipe up to 5mm per gasket, facilitated through gasket<br />

deformation.<br />

To facilitate installation and avoid possible creep under<br />

rising load, it is strongly recommended that the<br />

KLAMFLEX Ranger Rubber Sealing Gaskets are well<br />

lubricated with a suitable non toxic soap solution before<br />

the introduction of the pipe.<br />

KLAMFLEX RANGER FLANGE ADAPTOR<br />

NOM. BORE<br />

(mm/inch)<br />

50/2<br />

65/2.5<br />

80/3<br />

100/4<br />

125/5<br />

150/6<br />

175/7<br />

200/8<br />

250/10<br />

300/12<br />

300/12<br />

350/14<br />

400/16<br />

450/18<br />

500/20”<br />

600/24<br />

PIPE O.D. APPROX<br />

RANGE (mm) MASS (kg)<br />

59-72<br />

72-85<br />

88-103<br />

109-128<br />

138-153<br />

159-182<br />

192-210<br />

218-235<br />

250-267<br />

272-289<br />

315-332<br />

322-340<br />

374-391<br />

417-437<br />

480-500<br />

526-546<br />

630-650<br />

3.4<br />

3.8<br />

5.4<br />

5.4<br />

6.8<br />

8<br />

9<br />

9.8<br />

16.2<br />

15.2<br />

22.4<br />

19<br />

25.4<br />

28.6<br />

32.8<br />

41.2<br />

51<br />

FLANGE DRILLING COMPATIBILITY<br />

50mm: BS 10 Table D,E, & F: ANSI 150: BS4504: 6/3, 10/3, 16/3.<br />

SABS 1123: 600/3, 1000/3, 1600/3<br />

65mm: BS 10 Table F: BS4504:10/3, 16/3: SABS 1123:1000/3, 1600/3<br />

80mm: BS 10 Table D,E, & F: ANSI 150: BS4504: 6/3, 10/3, 16/3.<br />

SABS 1123: 600/3, 1000/3, 1600/3<br />

100mm: BS 10 Table D,E, & F: ANSI 150: BS4504:10/3, 16/3.<br />

SABS 1123: 1000/3, 1600/3<br />

125mm: BS 10 Table D,E, & F: ANSI 150: BS4504: 6/3, 10/3, 16/3.<br />

SABS 1123: 600/3, 1000/3, 1600/3.<br />

150mm: BS 10 Table D & E: ANSI 150: BS4504: 10/3, 16/3.<br />

SABS 1123: 1000/3, 1600/3.<br />

200mm: BS 10 Table D & E: ANSI 150: BS4504: 10/3, 16/3.<br />

SABS 1123: 1000/3, 1600/3.<br />

200mm: BS 10 Table D & E: ANSI 150: BS4504: 10/3, 16/3.<br />

SABS 1123: 1000/3, 1600/3.<br />

250mm: BS 10 Table E: BS4504: 10/3, 16/3. SABS 1123: 1000/3, 1600/3.<br />

PN 10, PN 16, TABLE D & E<br />

PN 10, PN 16, TABLE E, ANSI 150 lb<br />

PN 10, PN 16<br />

PN 10, PN 16<br />

PN 10, PN 16<br />

PN 10, PN 16, ANSI 150 lb<br />

PN 10, PN 16, ANSI 150 lb<br />

MAX WORKING PRESSURE: 16 BAR • SETTING GAP: 19mm • TOLERANCE ON ANGULAR DEFLECTION:<br />

3 DEGREES • EXPANSION AND CONTRACTION RANGE: 0-5 mm • RECOMMENDED BOLT TORQUE: 60-80 mm<br />

12

KLAMFLEX DEDICATED<br />

FLANGE ADAPTORS<br />

KLAMFLEX Dedicated Flange Adaptors are<br />

manufactured to join plain-ended pipe to flanged<br />

valves, fittings and pipes, obviating difficulties<br />

usually experienced with rigid connections.<br />

KLAMFLEX Dedicated Flange Adaptors are<br />

supplied to suit the pressure rating of the flange.<br />

The overall pressure rating of the assembled<br />

adaptor will be equal to that of the lower rated<br />

component, either pipe of flange.<br />

<strong>Klamflex</strong> Restraint Flange Adaptors can also be<br />

supplied where end pull out is of concern.<br />

When ordering KLAMFLEX Dedicated Flange<br />

Adaptors the following information is required<br />

to avoid the possibility of error in flange selections:<br />

•Pipe outside diameter.<br />

•Nominal bore of the flanged fitting.<br />

•Table drilling with standard applicable.<br />

The thickness of KLAMFLEX Flanges will not<br />

necessarily be the same as the mating flange due<br />

to the fact that the flange of the Flange Adaptor<br />

will not be subject to the full end or side thrust,<br />

most of which is absorbed by the flexibility in<br />

the rubber gaskets.<br />

Refer to column “T” on pages 13-14.<br />

KLAMFLEX Flange Adaptors can be manufactured<br />

with full sleeves to prevent end pullout on<br />

PE, HDPE and GRP pipes.<br />

13

T<br />

KLAMFLEX FLANGE ADAPTORS : STEEL PIPES<br />

FLANGES DRILLED PN10 OR PN16, 1000/3 OR 1600/3 (BS10: A,D,E)<br />

AND ANSI 125/ 150<br />

NOM<br />

BORE<br />

PIPE<br />

OD<br />

TOLERANCE<br />

ON PIPE OD<br />

FOR DISTANCE L<br />

MINIMUM<br />

LENGTH<br />

PREPARED<br />

PIPE END<br />

OD OF<br />

ENDRING<br />

FLANGE<br />

ADAPTOR<br />

LENGTH<br />

TABLE<br />

FLANGE<br />

THICKNESS<br />

APPROX.<br />

MASS<br />

L<br />

A<br />

B<br />

T<br />

(mm) (mm) (mm) (mm) (mm) (mm) (mm) (kg)<br />

50<br />

65<br />

80<br />

100<br />

125<br />

150<br />

150<br />

200<br />

250<br />

250<br />

300<br />

350<br />

400<br />

450<br />

500<br />

600<br />

700<br />

800<br />

900<br />

1000<br />

1200<br />

1400<br />

1600<br />

1800<br />

2000<br />

2000<br />

60.3<br />

76.1<br />

88.9<br />

114.3<br />

139.7<br />

165.1<br />

168.3<br />

219.1<br />

267<br />

273<br />

323.9<br />

355.6<br />

406.4<br />

457<br />

508<br />

610<br />

711<br />

813<br />

914<br />

1016<br />

1219<br />

1420<br />

1620<br />

1820<br />

2020<br />

2032<br />

+0.8<br />

+0.8<br />

+0.8<br />

+0.8<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+1.6<br />

+3<br />

+3<br />

+3<br />

+3<br />

-0.8<br />

-0.8<br />

-0.8<br />

-0.8<br />

-0.8<br />

-0.8<br />

-0.8<br />

-0.8<br />

-0.8<br />

-0.8<br />

-0.8<br />

-1.6<br />

-1.6<br />

-1.6<br />

-1.6<br />

-1.6<br />

-1.6<br />

-1.6<br />

-1.6<br />

-1.6<br />

-1.6<br />

-3<br />

-3<br />

-3<br />

-3<br />

-3<br />

100<br />

100<br />

100<br />

100<br />

100<br />

100<br />

100<br />

100<br />

100<br />

100<br />

100<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150/ 300<br />

150/ 300<br />

134<br />

150<br />

165<br />

191<br />

220<br />

246<br />

246<br />

308<br />

360<br />

364<br />

414<br />

458<br />

509<br />

559<br />

610<br />

712<br />

813<br />

915<br />

1016<br />

1118<br />

1335<br />

1536<br />

1736<br />

1936<br />

2134<br />

2146<br />

152<br />

102<br />

102<br />

102<br />

104<br />

106<br />

106<br />

106<br />

109<br />

109<br />

109<br />

153<br />

154<br />

154<br />

155<br />

155<br />

155<br />

155<br />

155<br />

157<br />

165<br />

175<br />

190<br />

190<br />

190/ 290<br />

190/ 290<br />

12<br />

12<br />

12<br />

12<br />

14<br />

16<br />

16<br />

16<br />

19<br />

19<br />

19<br />

23<br />

24<br />

24<br />

25<br />

25<br />

25<br />

25<br />

25<br />

27<br />

35<br />

45<br />

60<br />

60<br />

60<br />

60<br />

3.1<br />

3.4<br />

3.9<br />

4.5<br />

6.5<br />

7.5<br />

7.5<br />

10<br />

15.5<br />

14.6<br />

17.3<br />

33.5<br />

39.6<br />

45.5<br />

55.6<br />

70.6<br />

71.6<br />

84.4<br />

90.1<br />

118.6<br />

198<br />

275.9<br />

439.1<br />

494.1<br />

TBA<br />

TBA<br />

FOR COUPLINGS OF 25 AND 40 BAR WORKING PRESSURE PLEASE CONTACT KLAMFLEX<br />

The above table includes samples of the sizes available, please contact KLAMFLEX for any other sizes up to 3500mm.<br />

14

KLAMFLEX FLANGE ADAPTORS: DUCTILE IRON PIPES<br />

FLANGES DRILLED PN10 OR PN16, 1000/3 OR 1600/3 (BS10: A,D,E)<br />

AND ANSI 125/ 150<br />

NOM<br />

BORE<br />

PIPE<br />

OD<br />

TOLERANCE<br />

ON PIPE OD<br />

FOR DISTANCE L<br />

MINIMUM<br />

LENGTH<br />

PREPARED<br />

PIPE END<br />

OD OF<br />

ENDRING<br />

FLANGE<br />

ADAPTOR<br />

LENGTH<br />

TABLE<br />

FLANGE<br />

THICKNESS<br />

APPROX.<br />

MASS<br />

L<br />

(mm) (mm) (mm) (mm) (mm) (mm) (mm) (kg)<br />

100<br />

150<br />

200<br />

250<br />

300<br />

350<br />

400<br />

450<br />

500<br />

600<br />

700<br />

800<br />

900<br />

1000<br />

1200<br />

1400<br />

1600<br />

1800<br />

2000<br />

118<br />

170<br />

222<br />

274<br />

326<br />

378<br />

429<br />

480<br />

532<br />

635<br />

738<br />

842<br />

945<br />

1048<br />

1255<br />

1462<br />

1668<br />

1875<br />

2082<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

+1.0<br />

-3.0<br />

-3.0<br />

-3.5<br />

-3.5<br />

-3.5<br />

-3.5<br />

-4.0<br />

-4.0<br />

-4.0<br />

-4.5<br />

-4.5<br />

-4.5<br />

-5.0<br />

-5.0<br />

-6.0<br />

-6.0<br />

-6.0<br />

-6.0<br />

-6.0<br />

100<br />

100<br />

100<br />

100<br />

100<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150/300<br />

200<br />

260<br />

308<br />

364<br />

414<br />

480<br />

531<br />

582<br />

634<br />

737<br />

840<br />

944<br />

1047<br />

1150<br />

1371<br />

1578<br />

1784<br />

1989<br />

2196<br />

102<br />

106<br />

106<br />

109<br />

109<br />

153<br />

154<br />

154<br />

155<br />

155<br />

155<br />

155<br />

155<br />

157<br />

165<br />

175<br />

190<br />

190<br />

190/290<br />

12<br />

16<br />

16<br />

19<br />

19<br />

23<br />

24<br />

24<br />

25<br />

25<br />

25<br />

25<br />

25<br />

27<br />

35<br />

45<br />

60<br />

60<br />

60<br />

4.5<br />

7.8<br />

9.8<br />

14.7<br />

17.1<br />

32<br />

37.5<br />

42.9<br />

52.5<br />

66.5<br />

66.5<br />

77.9<br />

82.1<br />

108.7<br />

180.3<br />

244.1<br />

382.7<br />

TBA<br />

TBA<br />

A<br />

B<br />

T<br />

FOR COUPLINGS OF 25 AND 40 BAR WORKING PRESSURE PLEASE CONTACT KLAMFLEX<br />

The above table includes samples of the sizes available, please contact KLAMFLEX for any other sizes up to 3500mm.<br />

KLAMFLEX STEPPED<br />

FLANGE ADAPTORS<br />

KLAMFLEX RESTRAINT<br />

FLANGE ADAPTORS<br />

KLAMFLEX Stepped Flange Adaptors can be manufactured<br />

where pipe nominal bore is larger (as indicated<br />

above) or smaller than flange nominal bore.<br />

KLAMFLEX Restraint Flange adaptors can be<br />

manufactured where end pull out is of concern.<br />

15

KLAMFLEX GRIPPER<br />

FLANGE ADAPTORS<br />

<strong>Klamflex</strong> Gripper Flange Adaptors are designed<br />

to resist end pullout on PE and HDPE pipes, it is<br />

the fastening action of the Gripper Ring that<br />

secures the Flange Adaptor onto the pipe<br />

resisting end pullout.<br />

<strong>Klamflex</strong> Gripper Flange Adaptors are manufactured<br />

from Ductile Iron, Gasket material is<br />

EPDM, Gripper Ring material is Brass, and<br />

coating is Fusion Bonded Epoxy.<br />

Sizes are available for the following pipe<br />

outside diameters:<br />

NOMINAL BORE<br />

(mm)<br />

PIPE OD RANGE<br />

(mm)<br />

APPROX<br />

MASS (kg)<br />

FLANGE<br />

DRILLING<br />

50mm 63mm 3.6 PN10/16<br />

80mm 90mm 5.4 PN10/16<br />

100mm 110mm 6.4 PN10/16<br />

150mm 160mm 12.8 PN10/16<br />

150mm 180mm 12.8 PN10/16<br />

200mm 200mm 16 PN10/16<br />

200mm 225mm 18 PN10/16<br />

250mm 250mm 25 PN16<br />

250mm 280mm 28.2 PN16<br />

300mm 315mm 38 PN16<br />

16

KLAMFLEX<br />

DISMANTLING JOINTS<br />

Manufactured to AWWA C219 under quality<br />

management systems accredited to ISO<br />

9001:2000, the KLAMFLEX Dismantling<br />

Joint assembly is a double flanged composite<br />

fitting featuring a telescopic action between a<br />

flanged spigot and a flange adaptor. The joint is<br />

designed to provide longitudinal adjustment in<br />

flanged pipe systems. Dismantling Joints<br />

provide a simple method for the installation and<br />

removal of flanged valves, pumps, flow meters,<br />

flanged pipes and pipe fittings. Tie rods are<br />

provided for final anchoring and location and<br />

these also double as mating flange jointing<br />

bolts, reducing the number of these required.<br />

The Dismantling Joint range from<br />

KLAMFLEX extends from 50mm to 2000mm<br />

and whilst the chart indicates flange ratings of<br />

PN10/16, all common drillings are available in<br />

pressures up to 40 BAR. The range indicated<br />

overleaf is typical and KLAMFLEX can<br />

manufacture to specific customer<br />

specifications and dimensions, on request.<br />

Thickness of <strong>Klamflex</strong> flanges will not<br />

necessarily be the same as the mating flange.<br />

Flanges and flange adaptors will not be subject<br />

to full end or side thrust, most of which is<br />

absorbed by the flexibility in the rubber gaskets.<br />

Pipe end should be smooth, with no seams,<br />

score marks, dents or ovality.<br />

Installation is extremely simple and is generally<br />

done with the flange adaptor end connected to<br />

the valve or other appurtenance. In cases where<br />

a full faced flange is required, for example on<br />

wafer butterfly valves, the joint is simply turned<br />

round to use the spigot flange instead.<br />

17

A<br />

SPIGOT PIECE<br />

DRILLING SPECIFICATION<br />

VALVE OR FLANGED END<br />

B<br />

END RINGS TO BE SCALLOPED TO ACCOMODATE TIE RODS<br />

B<br />

VALVE OR FLANGED END<br />

C<br />

D<br />

H<br />

NOMINAL<br />

BORE<br />

OF<br />

JOINT<br />

FLANGE<br />

PN<br />

RATING<br />

SPIGOT<br />

PIPE<br />

O.D.<br />

+/-<br />

SPIGOT<br />

PIPE<br />

WALL<br />

THICK<br />

C<br />

SPIGOT<br />

LENGTH<br />

INCLUDING<br />

FLANGE<br />

B<br />

ADAPTOR &<br />

SPIGOT<br />

FLANGE<br />

THICKNESS<br />

H<br />

MIN<br />

LENGTH<br />

OF<br />

JOINT<br />

C + D<br />

RECOM.<br />

JOINT<br />

LENGTH<br />

H<br />

MAX<br />

LENGTH<br />

OF<br />

JOINT<br />

(mm) (bar) (mm) (mm) (mm) (mm) (mm)<br />

(mm)<br />

(mm) (kg)<br />

TIE<br />

ROD<br />

QTY<br />

L<br />

X<br />

A<br />

TIE ROD<br />

LENGTH<br />

APPROX<br />

MASS<br />

50<br />

65<br />

80<br />

100<br />

125<br />

150<br />

200<br />

200<br />

250<br />

250<br />

300<br />

300<br />

350<br />

350<br />

400<br />

400<br />

450<br />

450<br />

500<br />

500<br />

600<br />

600<br />

700<br />

700<br />

800<br />

800<br />

900<br />

900<br />

1000<br />

1000<br />

1200<br />

1200<br />

1400<br />

1400<br />

1600<br />

1600<br />

1800<br />

1800<br />

2000<br />

2000<br />

PN 10/16<br />

PN 10/16<br />

PN 10/16<br />

PN 10/16<br />

PN 10/16<br />

PN 10/16<br />

PN 10<br />

PN 16<br />

PN 10<br />

PN 16<br />

PN 10<br />

PN 16<br />

PN 10<br />

PN 16<br />

PN 10<br />

PN 16<br />

PN 10<br />

PN 16<br />

PN 10<br />

PN 16<br />

PN 10<br />

PN 16<br />

PN 10<br />

PN 16<br />

PN 10<br />

PN 16<br />

PN 10<br />

PN 16<br />

PN 10<br />

PN 16<br />

PN 10<br />

PN 16<br />

PN 10<br />

PN 16<br />

PN 10<br />

PN 16<br />

PN 10<br />

PN 16<br />

PN 10<br />

PN 16<br />

60<br />

76<br />

89<br />

114<br />

140<br />

165<br />

219<br />

219<br />

273<br />

273<br />

324<br />

324<br />

356<br />

356<br />

406<br />

406<br />

457<br />

457<br />

508<br />

508<br />

610<br />

610<br />

711<br />

711<br />

813<br />

813<br />

914<br />

914<br />

1016<br />

1016<br />

1219<br />

1219<br />

1420<br />

1420<br />

1620<br />

1620<br />

1820<br />

1820<br />

2020<br />

2020<br />

3.2<br />

3.2<br />

3.2<br />

3.9<br />

4.2<br />

4.2<br />

4.5<br />

4.5<br />

4.5<br />

4.5<br />

4.5<br />

4.5<br />

4.5<br />

4.5<br />

4.5<br />

4.5<br />

4.5<br />

4.5<br />

4.5<br />

4.5<br />

4.5<br />

4.5<br />

6.0<br />

6.0<br />

6.0<br />

6.0<br />

6.0<br />

6.0<br />

6.0<br />

6.0<br />

8.0<br />

8.0<br />

8.0<br />

10.0<br />

10.0<br />

10.0<br />

10.0<br />

10.0<br />

12.0<br />

12.0<br />

165<br />

165<br />

165<br />

165<br />

165<br />

165<br />

165<br />

165<br />

175<br />

175<br />

175<br />

175<br />

250<br />

250<br />

250<br />

250<br />

250<br />

250<br />

250<br />

250<br />

250<br />

250<br />

250<br />

250<br />

250<br />

250<br />

250<br />

250<br />

260<br />

260<br />

280<br />

280<br />

310<br />

310<br />

350<br />

350<br />

350<br />

350<br />

350<br />

350<br />

12<br />

12<br />

12<br />

12<br />

14<br />

16<br />

16<br />

16<br />

19<br />

19<br />

19<br />

19<br />

23<br />

23<br />

24<br />

24<br />

24<br />

24<br />

25<br />

25<br />

25<br />

25<br />

25<br />

25<br />

25<br />

25<br />

25<br />

25<br />

27<br />

27<br />

35<br />

35<br />

45<br />

45<br />

60<br />

60<br />

60<br />

60<br />

60<br />

60<br />

165<br />

165<br />

165<br />

165<br />

165<br />

165<br />

165<br />

165<br />

175<br />

175<br />

175<br />

175<br />

250<br />

250<br />

250<br />

250<br />

250<br />

250<br />

250<br />

250<br />

250<br />

250<br />

250<br />

250<br />

250<br />

250<br />

250<br />

250<br />

260<br />

260<br />

280<br />

280<br />

310<br />

310<br />

350<br />

350<br />

350<br />

350<br />

350<br />

350<br />

185<br />

185<br />

185<br />

185<br />

185<br />

185<br />

185<br />

185<br />

195<br />

195<br />

195<br />

195<br />

275<br />

275<br />

275<br />

275<br />

275<br />

275<br />

275<br />

275<br />

275<br />

275<br />

275<br />

275<br />

275<br />

275<br />

275<br />

275<br />

290<br />

290<br />

310<br />

310<br />

340<br />

340<br />

380<br />

380<br />

380<br />

380<br />

380<br />

380<br />

205<br />

205<br />

205<br />

205<br />

205<br />

205<br />

205<br />

205<br />

215<br />

215<br />

215<br />

215<br />

300<br />

300<br />

300<br />

300<br />

300<br />

300<br />

300<br />

300<br />

300<br />

300<br />

300<br />

300<br />

300<br />

300<br />

300<br />

300<br />

320<br />

320<br />

340<br />

340<br />

370<br />

370<br />

410<br />

410<br />

410<br />

410<br />

410<br />

410<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

6<br />

7<br />

7<br />

7<br />

7<br />

8<br />

8<br />

9<br />

9<br />

8<br />

8<br />

11<br />

11<br />

12<br />

12<br />

M16<br />

M16<br />

M16<br />

M16<br />

M16<br />

M20<br />

M20<br />

M20<br />

M20<br />

M24<br />

M20<br />

M24<br />

M20<br />

M24<br />

M24<br />

M27<br />

M24<br />

M27<br />

M24<br />

M30<br />

M27<br />

M33<br />

M27<br />

M33<br />

M30<br />

M36<br />

M30<br />

M36<br />

M33<br />

M39<br />

M36<br />

M45<br />

M39<br />

M45<br />

M45<br />

M52<br />

M45<br />

M52<br />

M45<br />

M56<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

300<br />

300<br />

300<br />

300<br />

300<br />

320<br />

320<br />

320<br />

330<br />

350<br />

330<br />

350<br />

420<br />

450<br />

450<br />

460<br />

450<br />

470<br />

450<br />

490<br />

480<br />

520<br />

480<br />

520<br />

500<br />

550<br />

510<br />

570<br />

560<br />

610<br />

610<br />

680<br />

670<br />

730<br />

750<br />

820<br />

770<br />

850<br />

750<br />

890<br />

9<br />

10<br />

12<br />

13<br />

16<br />

23<br />

31<br />

33<br />

34<br />

38<br />

43<br />

44<br />

49<br />

71<br />

77<br />

88<br />

95<br />

99<br />

111<br />

131<br />

135<br />

175<br />

168<br />

184<br />

200<br />

220<br />

225<br />

245<br />

298<br />

331<br />

496<br />

559<br />

610<br />

665<br />

1250<br />

1320<br />

1300<br />

1500<br />

1490<br />

1750<br />

FOR COUPLINGS OF 25 & 40 BAR WORKING PRESSURE PLEASE CONTACT KLAMFLEX<br />

THE ABOVE TABLE INCLUDES SAMPLES OF THE SIZES AVAILABLE, PLEASE CONTACT KLAMFLEX FOR ANY OTHER SIZES.<br />

18

SHOULDERED COUPLING<br />

KLAMFLEX general purpose Shouldered<br />

Couplings are manufactured in accordance with<br />

SANS 815 and can be used on shouldered end<br />

pipes for various applications.<br />

Materials of construction<br />

Body – Ductile Iron (ASTM A536 Grade 65-45-12)<br />

Bolts & Nuts – Carbon Steel (GR 8.8 ASTM A183)<br />

Gaskets – EPDM (ASTM D2000)<br />

NOMINAL<br />

BORE<br />

(mm)<br />

PIPE OD<br />

(mm)<br />

WORKING<br />

PRESSURE<br />

(Mpa)<br />

BOLT<br />

SIZE<br />

(mm)<br />

OD<br />

(mm)<br />

ID<br />

(mm)<br />

L<br />

(mm)<br />

H<br />

(mm)<br />

APPROX<br />

MASS<br />

(Kg)<br />

50 60.3 4.0 M10x55 97 61 132 48 0.9<br />

80 88.9 4.0 M12x85 127 90.6 170 48 1.30<br />

100 114.3 3.5 M12x85 156 115.6 206 52 1.80<br />

150 165.1 3.5 M16x100 212 167 273 52 2.50<br />

200 219.1 3.0 M20x110 280 221 346 60 5.10<br />

19

KLAMFLEX<br />

JUNIOR COUPLINGS<br />

A small bore product range specifically<br />

designed for use on plain ended steel service<br />

lines, comprising of:<br />

SIZE RANGE<br />

• Junior Straight Couplings<br />

• Junior Straight Couplings with<br />

Integral gripper rings<br />

• Male/Female Junior Couplings<br />

• Male/Female Junior Couplings<br />

with integral gripper rings<br />

• Junior Tee Pieces<br />

• Junior Tees with integral gripper rings<br />

• Junior Repair Clamps<br />

• Junior Repair Clamp with Tee Outlet<br />

15-50 mm<br />

15-50 mm<br />

15-50mm<br />

15-50 mm<br />

15-25 mm<br />

15-25 mm<br />

15-50mm<br />

15-25mm<br />

All products feature cast construction &<br />

galvanised finish for long term corrosion<br />

protection. An extremely simple jointing<br />

method which eliminates the need for on site<br />

pipe threading.<br />

20

KLAMFLEX SOCKET<br />

STEEL FITTINGS<br />

<strong>Klamflex</strong> Socket Steel Fittings are available<br />

in all types of steel fittings such as Bends,<br />

Tees, Reducers, and Crosses, and are manufactured<br />

by welding half a <strong>Klamflex</strong> Coupling<br />

to the ends of a steel fitting.<br />

Bolts and nuts and not studs are used in the<br />

couplings, this ensures easy replacement of<br />

damaged fasteners. <strong>Klamflex</strong> also makes use<br />

of a profile plate and not lugs that are welded<br />

to the steel fitting to accommodate the tightening<br />

process.<br />

Installation is effected by simply inserting the<br />

plain ended pipe into the <strong>Klamflex</strong> Pipe<br />

Coupling and tightening the bolts.<br />

The use of these fittings will result in significant<br />

cost savings as only one piece of equipment<br />

is being purchased instead of separate<br />

fittings and couplings.<br />

21

PIPE OUTSIDE DIAMETERS OF COMMON PIPE MATERIALS<br />

ALL DIMENSIONS ARE IN MILLIMETRES (mm)<br />

PIPE NOMINAL BORE<br />

mm<br />

inches<br />

STEEL BS 1387<br />

STEEL SABS 62 MEDIUM<br />

max<br />

15<br />

0.5<br />

21.3<br />

21.7<br />

20<br />

0.75<br />

26.9<br />

27.2<br />

25<br />

1<br />

33.7<br />

34.2<br />

32<br />

1.25<br />

42.4<br />

42.9<br />

40<br />

1.5<br />

48.3<br />

48.8<br />

50<br />

2<br />

60.3<br />

60.8<br />

65<br />

2.5<br />

76.1<br />

76.6<br />

80<br />

3<br />

88.9<br />

89.5<br />

100<br />

4<br />

114.3<br />

114.9<br />

125<br />

5<br />

139.7<br />

140.6<br />

150<br />

6<br />

165.1<br />

166.1<br />

175<br />

7<br />

200<br />

8<br />

225<br />

9<br />

250<br />

10<br />

300<br />

12<br />

350<br />

14<br />

400<br />

16<br />

450<br />

18<br />

500<br />

20<br />

550<br />

22<br />

600<br />

24<br />

650<br />

26<br />

700<br />

28<br />

750<br />

30<br />

800<br />

32<br />

850<br />

34<br />

900<br />

36<br />

1000<br />

40<br />

1050<br />

42<br />

1100<br />

44<br />

1200<br />

48<br />

1300<br />

52<br />

1400 1500<br />

56<br />

STEEL SABS 719<br />

219.1 273.1 323.9 355.6 406.4 457 508 559 610 660 711 762 813 864 914 1016 1067 1118 1219 1321 1422<br />

STEEL ISO 4200 SER 1<br />

21.3 26.9 33.7 42.4 48.3 60.3 76.1 88.9 114.3 139.7 168.3 219.1 273.0 323.9 355.6 406.4 457 508 610 711 813 914 1016 1067 1118 1219 1422<br />

STEEL API 5 L<br />

21.4 26.7 33.4 42.4 48.3 60.3 73.0 88.9 114.3 141.3 168.3 219.1 273.1 323.9 355.6 406.4 457.2 508 559 609.6 660.4 711.2 762 812.8 863.6 914.4 1016 1066.8 1117.6 1219.2 1320.8 1422.4<br />

STEEL BS 3600/3601<br />