Nuclear Plant Journal Nuclear Plant Journal - Digital Versions

Nuclear Plant Journal Nuclear Plant Journal - Digital Versions

Nuclear Plant Journal Nuclear Plant Journal - Digital Versions

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Nuclear</strong><br />

<strong>Plant</strong><br />

<strong>Journal</strong><br />

New <strong>Plant</strong>s &<br />

Vendor Advertorial Issue<br />

July-August 2009<br />

Volume 27 No. 4<br />

Indian Point, USA<br />

ISSN: 0892-2055

KEY QUESTION FOR THE FUTURE<br />

How can I improve<br />

plant performance?<br />

Look to AREVA NP for the engineering expertise to<br />

deliver a full spectrum of innovative, integrated solutions.<br />

For your peace of mind, we have the right resources to deliver the best value and quality engineering<br />

solutions. With U.S. market leadership and global resources, AREVA NP provides unmatched project<br />

expertise and predictable cost and schedule performance. With the opening of our BWR Center of<br />

Excellence in San Jose, we deliver complete, plant-wide engineering solutions to improve performance.<br />

Expect certainty. Count on AREVA NP. www.us.areva.com<br />

© Copyright 2009 AREVA NP Inc.

©2009 EDF Group<br />

EDF’s Flamanville construction site for a new EPR TM nuclear energy facility (June 2009).<br />

Your Partner for New <strong>Nuclear</strong> Energy. Today.<br />

For those companies looking at new nuclear, UniStar <strong>Nuclear</strong> Energy provides economies of<br />

scale and scope through coordinated and systematic development of a standardized fleet of<br />

AREVA EPR TM new nuclear energy facilities.<br />

To find out more about UniStar, call 410.470.4400 or visit www.unistarnuclear.com.<br />

For information on AREVA’s U.S. EPR TM technology, visit www.us.areva.com<br />

For monthly photo updates of construction progress, send your e-mail address to info@unistarnuclear.com.

<strong>Nuclear</strong> <strong>Plant</strong> <strong>Journal</strong><br />

July-August 2009, Volume 27 No. 4<br />

27th Year of Publication<br />

®<br />

New <strong>Plant</strong>s &<br />

Vendor Advertorial<br />

<strong>Nuclear</strong> <strong>Plant</strong> <strong>Journal</strong> is published by<br />

EQES, Inc.six times a year in February,<br />

April, June, August, October and December<br />

(Directory).<br />

The subscription rate for non-qualified<br />

readers in the United States is $150.00<br />

for six issues per year. The additional air<br />

mail cost for non-U.S. readers is $30.00.<br />

Payment may be made by American<br />

Express ® , Master Card ® , VISA ® or check<br />

and should accompany the order. Checks<br />

not drawn on a United States bank should<br />

include an additional $45.00 service fee.<br />

All inquiries should be addressed to<br />

<strong>Nuclear</strong> <strong>Plant</strong> <strong>Journal</strong>, 799 Roosevelt<br />

Road, Building 6, Suite 208, Glen Ellyn,<br />

IL 60137-5925; Phone: (630) 858-6161,<br />

ext. 103; Fax: (630) 858-8787.<br />

*Current Circulation:<br />

Total: 12,000<br />

Utilities: 4,600<br />

*All circulation information is subject to<br />

BPA Worldwide, Business audit.<br />

Authorization to photocopy articles is<br />

granted by EQES, Inc. provided that<br />

payment is made to the Copyright<br />

Clearance Center, 222 Rosewood Drive,<br />

Danvers, MA 01923; Phone: (978) 750-<br />

8400, Fax: (978) 646-8600. The fee code<br />

is 0892-2055/02/$3.00+$.80.<br />

© Copyright 2009 by EQES, Inc.<br />

<strong>Nuclear</strong> <strong>Plant</strong> <strong>Journal</strong> is a registered<br />

trademark of EQES, Inc.<br />

Printed in the USA.<br />

Staff<br />

Senior Publisher and Editor<br />

Newal K. Agnihotri<br />

Publisher and Sales Manager<br />

Anu Agnihotri<br />

Editorial & Marketing Assistant<br />

Michelle Gaylord<br />

Administrative Assistant<br />

QingQing Zhu<br />

Articles & Reports<br />

Bedrock of U.S. Energy Security 28<br />

By Michael Wallace, Constellation Energy<br />

<strong>Nuclear</strong> Renaissance is Alive 30<br />

By Michael Kansler, Entergy <strong>Nuclear</strong><br />

123 Agreement Challenges 35<br />

By David Mulford, Credit Suisse<br />

Optimal Operation Through R&D 42<br />

By David Modeen, Electric Power Research Institute<br />

Industry Innovations<br />

Commitment to Innovation 50<br />

By John Mahoney, Richard Swanson, Beverly Good,<br />

Glenroy Smith and Dan Keuter, Entergy <strong>Nuclear</strong><br />

Next Generation Core Designs 55<br />

By James Tusar, Exelon <strong>Nuclear</strong><br />

<strong>Plant</strong> Profile<br />

Continual Strong Performance 60<br />

By Tyler Lamberts, Entergy <strong>Nuclear</strong> Operations, Inc.<br />

Departments<br />

New Energy News 8<br />

Utility, Industry & Corporation 12<br />

New Products, Services & Contracts 20<br />

New Documents 24<br />

Meeting & Training Calendar 26<br />

<strong>Journal</strong> Services<br />

List of Advertisers 6<br />

Advertiser Web Directory 40<br />

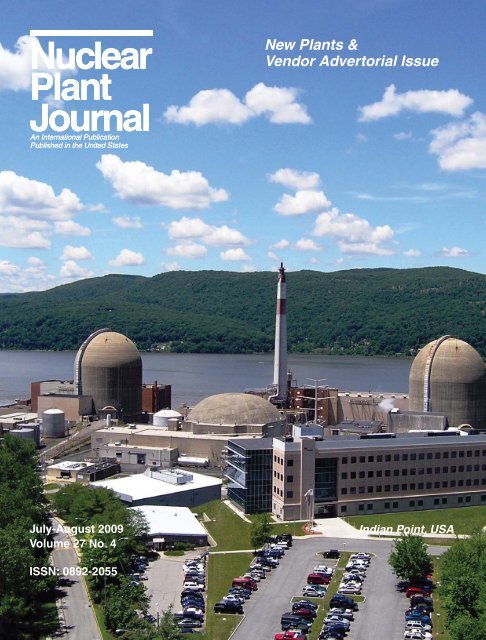

On The Cover<br />

Indian Point Energy Center is located in New York. Both units have pressurized<br />

water reactors. Unit 2 has a net generating capacity of 1,035 MWe and<br />

Unit 3 has 1,070 MWe. See page 60 for a profi le.<br />

Mailing Identification Statement<br />

<strong>Nuclear</strong> <strong>Plant</strong> <strong>Journal</strong> (ISSN 0892-2055) is published bimonthly in February, April,<br />

June, August, October and December by EQES, Inc., 799 Roosevelt Road, Building<br />

6, Suite 208, Glen Ellyn, IL 60137-5925. The printed version of the <strong>Journal</strong> is available<br />

cost-free to qualified readers in the United States and Canada. The digital version is<br />

available to qualified readers worldwide. The subscription rate for non-qualified readers<br />

is $150.00 per year. The cost for non-qualified, non-U.S. readers is $180.00. Periodicals (permit<br />

number 000-739) postage paid at the Glen Ellyn, IL 60137 and additional mailing offices. POSTMAS-<br />

TER: Send address changes to <strong>Nuclear</strong> <strong>Plant</strong> <strong>Journal</strong> (EQES, Inc.), 799 Roosevelt Road, Building 6,<br />

Suite 208, Glen Ellyn, IL 60137-5925.<br />

<strong>Nuclear</strong> <strong>Plant</strong> <strong>Journal</strong>, July-August 2009 www.<strong>Nuclear</strong><strong>Plant</strong><strong>Journal</strong>.com 5

List of Advertisers & NPJ Rapid Response<br />

Page Advertiser Contact Fax/Email<br />

58-59 American Crane & Equipment Corporation Karen Norheim (610) 385-6061<br />

2, 37 AREVA NP, Inc. Donna Gaddy-Bowen (434) 832-3840<br />

3 Corys Thunder, Inc. Jody Ryan (912) 729-1502<br />

51, 64 Curtiss-Wright Flow Control Corporation Arlene Corkhill (714) 528-0128<br />

22-23 Day & Zimmermann Power Services David Bronczyk (215) 656-2624<br />

25 Divesco, Inc. Susan Kay Fisher (601) 932-5698<br />

38-39 EXCEL Services Corporation Donald R. Hoffman (301) 984-7600<br />

27 Exelon <strong>Nuclear</strong> Marshall Murphy (630) 657-4320<br />

21 G. D. Barri & Associates, Inc. Georgia D. Barri (623) 773-2924<br />

41 Holtec International Joy Russell (856) 797-0909<br />

21 NPTS, Inc. Rebecca Broman (716) 876-8004<br />

46-47 <strong>Nuclear</strong> Logistics Inc. Craig Irish (978) 250-0245<br />

49 OECD <strong>Nuclear</strong> Energy Agency (NEA) Solange Quarmeau 33 1 45 24 11 10<br />

18-19 Sargent & Lundy LLC Patricia Andersen (312) 269-3680<br />

14-15 Tetra Tech Talia Starkey (626) 470-2132<br />

7 The Babcock & Wilcox Company Natalie Cutler nacutler@babcock.com<br />

32-33 The Babcock & Wilcox Company Heidi Brizendine habrizendine2@babcock.com<br />

52-53 The Shaw Group Inc.,<br />

<strong>Nuclear</strong> Power Division Holly Nava (856) 482-3155<br />

4, 43 UniStar <strong>Nuclear</strong> Energy Mary Klett (410) 470-5606<br />

44-45 Valtimet Wendy McGowan (423) 585-4215<br />

11 Western Space and Marine, Inc. Scott Millard (805) 968-0027<br />

62-63 Westinghouse Electric Company LLC Karen Fischetti (412) 374-3244<br />

9 Zachry <strong>Nuclear</strong> Engineering, Inc Lisa Apicelli (860) 446-8292<br />

Advertisers’ fax numbers may be used with the form at the bottom of the page. Advertisers’ web sites are listed in<br />

the Web Directory Listings on page 40.<br />

<strong>Nuclear</strong> <strong>Plant</strong> <strong>Journal</strong> Rapid Response Fax Form<br />

July-August 2009 <strong>Nuclear</strong> <strong>Plant</strong> <strong>Journal</strong><br />

To: _________________________ Company: __________________ Fax: ___________________<br />

From: _______________________ Company: __________________ Fax: ___________________<br />

Address:_____________________ City: _______________________ State: _____ Zip: _________<br />

Phone: ______________________ E-mail: _____________________<br />

I am interested in obtaining information on: __________________________________________________<br />

Comments: _____________________________________________________________________________<br />

6 www.<strong>Nuclear</strong><strong>Plant</strong><strong>Journal</strong>.com <strong>Nuclear</strong> <strong>Plant</strong> <strong>Journal</strong>, July-August 2009

New Energy<br />

Civil <strong>Nuclear</strong><br />

Cooperation<br />

Remarks by President Barack Obama<br />

in Hradcany Square, Prague, Czech<br />

Republic on April 5, 2009:<br />

“To achieve a global ban on<br />

nuclear testing, my administration will<br />

immediately and aggressively pursue<br />

U.S. ratification of the Comprehensive<br />

Test Ban Treaty (CTBT). After more than<br />

five decades of talks, it is time for the<br />

testing of nuclear weapons to finally be<br />

banned.<br />

And to cut off the building blocks<br />

needed for a bomb, the United States will<br />

seek a new treaty that verifiably ends the<br />

production of fissile materials intended<br />

for use in state nuclear weapons. If we<br />

are serious about stopping the spread of<br />

these weapons, then we should put an end<br />

to the dedicated production of weaponsgrade<br />

materials that create them. That’s<br />

the first step.<br />

Second, together we will strengthen<br />

the <strong>Nuclear</strong> Non-Proliferation Treaty as a<br />

basis for cooperation.<br />

The basic bargain is sound: Countries<br />

with nuclear weapons will move towards<br />

disarmament, countries without nuclear<br />

weapons will not acquire them, and all<br />

countries can access peaceful nuclear<br />

energy. To strengthen the treaty, we<br />

should embrace several principles. We<br />

need more resources and authority to<br />

strengthen international inspections. We<br />

need real and immediate consequences<br />

for countries caught breaking the rules or<br />

trying to leave the treaty without cause.<br />

And we should build a new<br />

framework for civil nuclear cooperation,<br />

including an international fuel bank,<br />

so that countries can access peaceful<br />

power without increasing the risks of<br />

proliferation. That must be the right<br />

of every nation that renounces nuclear<br />

weapons, especially developing countries<br />

embarking on peaceful programs. And<br />

no approach will succeed if it’s based on<br />

the denial of rights to nations that play by<br />

the rules. We must harness the power of<br />

nuclear energy on behalf of our efforts to<br />

combat climate change, and to advance<br />

peace opportunity for all people.”<br />

Clean Energy Park<br />

AREVA, Duke Energy, UniStar<br />

<strong>Nuclear</strong> Energy announced the start of<br />

negotiations to develop an EPR reactor<br />

for America’s first Clean Energy Park.<br />

AREVA will be coordinating the<br />

technical analyses needed to prepare the<br />

plant construction permit and licensing<br />

application which will be examined by<br />

the <strong>Nuclear</strong> Regulatory Commission.<br />

Duke will manage the project,<br />

provide project oversight and serve as<br />

the applicant for any NRC licensing<br />

applications.<br />

Unistar will provide its services and<br />

expertise for the pre-certification process<br />

of the EPR. It has also expressed<br />

interest in having a stake in the future<br />

nuclear power plants.<br />

The 3700-acre Clean Energy Park in<br />

which the plant could be built is located<br />

on a Department of Energy site in Piketon,<br />

Ohio. Duke Energy, AREVA, UniStar<br />

<strong>Nuclear</strong> Energy, USEC Inc. and the<br />

Southern Ohio Diversification Initiative<br />

announced that they have formed an<br />

alliance to pursue its development.<br />

Contact: Susan Hess, telephone:<br />

(434) 832-2379, email: Susan.Hess@<br />

areva.com.<br />

Scalable <strong>Nuclear</strong><br />

Reactor<br />

The Babcock & Wilcox Company<br />

(B&W) plans to deploy a North Americanmanufactured,<br />

scalable nuclear reactor.<br />

The B&W mPower reactor design is<br />

a passively safe Advanced Light Water<br />

Reactor (ALWR) with a below-ground<br />

containment structure. This optimized<br />

ALWR represents true Generation III++<br />

nuclear technology that B&W believes<br />

can be certified, manufactured and<br />

operated within today’s existing U.S.<br />

regulatory, industrial supply chain and<br />

utility operational infrastructure.<br />

The new reactor will incorporate<br />

important design and operational attributes<br />

that will make it attractive for both<br />

existing nuclear operating utilities as well<br />

as other customers seeking to diversify<br />

their power generation portfolio.<br />

The scalable nature of nuclear plants<br />

built around the B&W mPower reactor<br />

would provide customers with practical<br />

power increments of 125 MWe to meet<br />

local energy needs within power grid and<br />

plant site constraints.<br />

B&W expects the use of proven<br />

ALWR design features, together with a<br />

passive safety philosophy, to minimize<br />

plant licensing challenges, enhance safety<br />

performance and contribute to reliable<br />

plant operation.<br />

The <strong>Nuclear</strong> Steam Supply System<br />

(NSSS) would be manufactured in<br />

existing B&W facilities in North America<br />

and then rail-shipped to construction<br />

sites.<br />

B&W has formed a new business<br />

unit, B&W Modular <strong>Nuclear</strong> Energy,<br />

LLC, to lead the development, licensing<br />

and delivery of B&W mPower reactor<br />

projects.<br />

Contact: Jud Simmons, telephone:<br />

(434) 522-6462, email: hjsimmons@<br />

babcock.com.<br />

(Continued on page 10)<br />

8 www.<strong>Nuclear</strong><strong>Plant</strong><strong>Journal</strong>.com <strong>Nuclear</strong> <strong>Plant</strong> <strong>Journal</strong>, July-August 2009

SPECIAL ADVERTISING SECTION<br />

Zachry offers full-service capabilities in<br />

emerging U.S. nuclear market<br />

At the dawn of a new generation of nuclear<br />

power, Zachry uses its time-tested skills and<br />

innovative thinkers to take nuclear into the<br />

future. With full-service engineering and<br />

construction capabilities, Zachry, including<br />

its subsidiaries Zachry <strong>Nuclear</strong>, Inc. comprising<br />

Zachry <strong>Nuclear</strong> Engineering, Inc. and Zachry<br />

<strong>Nuclear</strong> Construction, Inc., brings 85 years of<br />

construction expertise together with more<br />

than 30 years of industry-specific engineering<br />

knowledge.<br />

Zachry <strong>Nuclear</strong><br />

“Zachry <strong>Nuclear</strong> is an exciting, emerging player<br />

in the construction and engineering services<br />

portions of the nuclear industry,” said Keith<br />

Manning, Zachry <strong>Nuclear</strong> chairman. “Zachry’s<br />

80-plus years of building major generation<br />

units coupled with the strong technical service<br />

capabilities of Zachry <strong>Nuclear</strong> Engineering is<br />

proving to be a formidable combination.”<br />

The formation of Zachry <strong>Nuclear</strong> and the full<br />

integration of Zachry <strong>Nuclear</strong> Engineering gives<br />

customers the unique option of a full EPC firm,<br />

providing services ranging from early design<br />

through startup.<br />

“We build on our strong culture of safety,<br />

collaboration and values in the revitalization of<br />

the nuclear industry,” Manning said. “We stand<br />

ready to serve our customers with cost-effective,<br />

high-quality engineering, project management<br />

and construction of both ongoing plant<br />

modifications and new build nuclear.”<br />

Zachry <strong>Nuclear</strong> Engineering<br />

Zachry <strong>Nuclear</strong> Engineering provides engineering,<br />

design and project management services to the<br />

nuclear power industry through the skills<br />

of experienced mechanical, electrical, controls,<br />

civil and structural design professionals. Engineers<br />

in both the Groton, Conn. and Chicago, Ill. offices<br />

are experienced in power plant systems,<br />

engineering analysis and modification package<br />

development.<br />

“Zachry enjoys a long history of private<br />

ownership with shared values,” said Mark Mills,<br />

president of Zachry <strong>Nuclear</strong> Engineering. “We<br />

look forward to a bright future and to strengthening<br />

our relationships and capabilities with the<br />

current fleet of operating nuclear facilities.”<br />

Zachry <strong>Nuclear</strong> Construction<br />

Zachry <strong>Nuclear</strong> Construction, based in San Antonio,<br />

brings decades of experience in the power industry<br />

to the forefront of nuclear unit construction. As<br />

a top-ranked power provider, Zachry has led the<br />

industry in quality, service and integrity for more<br />

than 50 years.<br />

“This industry represents a significant opportunity<br />

for growth over the short- and long-term horizon<br />

and is well-suited to Zachry’s existing strengths<br />

in large-scale engineering and construction,” said<br />

Ed Bardgett, president of Zachry <strong>Nuclear</strong>.<br />

A true EPC provider, Zachry is engaged in the<br />

planning, building and renewing of the world’s<br />

most critical infrastructures including emerging<br />

energy, power, cement, refining and nuclear<br />

facilities. Zachry remains a family-owned,<br />

privately held company whose values—Safety,<br />

Commitment, Trust, Integrity, Service, Economy and<br />

Skill—lead every decision, every time. Founded<br />

in 1924, Zachry’s long list of experience has led<br />

to more than 6,000 completed projects in the<br />

United States and abroad.<br />

As a collaborative, practical and visionary force,<br />

Zachry is one of the largest direct-hire, merit-shop<br />

contractors in the United States. Engineering<br />

News-Record (ENR) ranks San Antonio-based<br />

Zachry No. 23 in the Top 400 Contractors 2009;<br />

No. 44 in the Top 500 Design Firms 2009; and as<br />

a top firm in the power, fossil fuel and nuclear<br />

markets. Please visit www.zhi.com for more<br />

information.<br />

Our force is built on decades of safely completing jobs with trust and integrity. As you look for a strong<br />

partner to plan, build or renew your nuclear project, turn to Zachry — we are your vision for the future.<br />

www.zhi.com<br />

<strong>Nuclear</strong> <strong>Plant</strong> <strong>Journal</strong>, July-August 2009 www.<strong>Nuclear</strong><strong>Plant</strong><strong>Journal</strong>.com 9

New Energy...<br />

Continued from page 8<br />

Netherlands Power<br />

Station<br />

DELTA, Netherlands, will launch<br />

the procedure that will eventually lead<br />

to the application for a permit to build<br />

a second nuclear power station near the<br />

existing one at Borssele, Netherlands.<br />

The site has been specifically earmarked<br />

for this purpose. The procedure will be set<br />

in motion by the submission of a start-up<br />

memorandum to the Ministry of Housing,<br />

Spatial Planning and the Environment.<br />

The nuclear power plant is expected to be<br />

operational in 2018.<br />

“We definitely need nuclear power,<br />

says DELTA’s CEO, Peter Boerma. By<br />

2020 all of us will be using more electricity<br />

than is generated. CO 2<br />

emissions too are<br />

increasing.”<br />

Contact: M. van Zuilen, telephone: 31<br />

118 88 20 41, email: persvoorlichting@<br />

delta.nl.<br />

<strong>Nuclear</strong> Cooperation<br />

Agreement<br />

United Kingdom’s Foreign &<br />

Commonwealth Office Secretary, David<br />

Miliband, commented on the signing of<br />

a <strong>Nuclear</strong> Cooperation Agreement with<br />

Jordan on June 22, 2009.<br />

“The treaty between the UK and<br />

Jordan commits the UK to helping Jordan<br />

develop its civil nuclear program. If we<br />

are to move the world to a low carbon<br />

economy, then nuclear power needs to<br />

be an important part of the energy mix.<br />

But it needs to be developed in a safe and<br />

secure way, and the UK is pleased to be<br />

working with Jordan to achieve this.”<br />

Contact: telephone: 00 44 20 7008<br />

1500.<br />

American Energy Act<br />

U.S. Congressman Mike Pence,<br />

Chairman of the House Republican<br />

Conference, made the following<br />

statement on the floor of the U.S. House<br />

of Representatives regarding House<br />

Republicans’ American Energy Act:<br />

“The American economy is hurting.<br />

Gasoline prices are on the rise, utility rates<br />

threaten to go higher and pose an even<br />

greater hardship on working families. The<br />

American people are looking for answers<br />

to these times and the challenges we face<br />

in energy.<br />

“Our energy solution focuses more<br />

on domestic exploration for oil and<br />

natural gas, a renewed commitment to<br />

build 100 nuclear power plants in the<br />

next 20 years, investments in renewables,<br />

alternative energy technologies and<br />

creating incentives for conservation.<br />

“The American people want energy<br />

independence and a cleaner environment<br />

without a national energy tax. The<br />

American Energy Act offered by House<br />

Republicans is the answer the American<br />

people are looking for.”<br />

Contact: Matt Lloyd, telephone:<br />

(202) 226-9000, email: matt.lloyd@mail.<br />

house.gov.<br />

STP 3&4<br />

NRG Energy’s nuclear development<br />

initiative, South Texas Project 3&4 (STP<br />

3&4), was selected as one of only four<br />

nuclear development projects advanced<br />

by the Department of Energy in its<br />

nuclear loan guarantee program (out of 18<br />

total applications). This initiative is being<br />

pursued through <strong>Nuclear</strong> Innovation<br />

North America LLC (NINA), the joint<br />

venture with Toshiba Corporation.<br />

Contact: David Knox, telephone:<br />

713.795.6106, email: David.Knox@<br />

nrgenergy.com.<br />

2010 Budget Legislation<br />

The U.S. House Energy and Water<br />

Appropriations Subcommittee approved<br />

fiscal year 2010 budget legislation.<br />

The following is a statement from Alex<br />

Flint, the <strong>Nuclear</strong> Energy Institute’s<br />

senior vice president for governmental<br />

affairs, commenting on nuclear-related<br />

provisions in the spending bill:<br />

“NEI is heartened that the<br />

committee increased, by $51 million,<br />

the administration’s budget request for<br />

the <strong>Nuclear</strong> Power 2010 program that<br />

is a cost-shared, industry-government<br />

partnership designed to reduce the<br />

technical and regulatory uncertainties<br />

associated with construction of advanced<br />

nuclear power plant designs. Still, the<br />

committee designation of $71 million<br />

falls well short of the $121 million that the<br />

industry intends to invest in the program<br />

in fiscal 2010. We had expected DOE to<br />

match that commitment to complete this<br />

program.<br />

“NEI is also pleased that funding for<br />

next-generation nuclear plants would rise<br />

to $245 million, a 36 percent increase<br />

from the current year. We welcome the<br />

federal investment in next-generation<br />

nuclear plants as recognition of nuclear<br />

energy’s long-term role as a clean<br />

electricity source.<br />

“This budget plan, while it has a<br />

number of positive aspects, could better<br />

reflect the reality that nuclear energy is<br />

our nation’s only expandable large-scale<br />

energy source capable of producing<br />

electricity around the clock without<br />

emitting air pollutants or greenhouse<br />

gases.<br />

“The government can and should<br />

do more to encourage construction of<br />

the first group of the many new nuclear<br />

plants that our nation needs to stimulate<br />

economic growth, create jobs and help<br />

meet the threat of global climate change.<br />

Federal investment in nuclear energy has<br />

proven its worth many times over.”<br />

Contact: telephone: 202.739.8000.<br />

Calvert Cliffs<br />

The Maryland Public Service<br />

Commission (PSC) issued a final order<br />

approving an application for a Certificate<br />

of Public Convenience and Necessity<br />

(CPCN) for a proposed new nuclear<br />

energy facility at Calvert Cliffs in Lusby,<br />

Maryland. The application was submitted<br />

by UniStar <strong>Nuclear</strong> Energy, LLC, a<br />

strategic joint venture of Constellation<br />

Energy and EDF Group.<br />

10 www.<strong>Nuclear</strong><strong>Plant</strong><strong>Journal</strong>.com <strong>Nuclear</strong> <strong>Plant</strong> <strong>Journal</strong>, July-August 2009

On June 1, 2009 Bechtel Construction<br />

Company and the Building and<br />

Construction Trades Department (BCTD),<br />

AFL-CIO, the National Construction<br />

Alliance II and all affiliated international<br />

unions announced the approval of a<br />

Project Labor Agreement (PLA) for the<br />

construction of Calvert Cliffs Unit 3.<br />

The 1,600-megawatt reactor is<br />

proposed to be built next to Constellation<br />

Energy’s existing Calvert Cliffs facility<br />

in Southern Maryland, and would<br />

create up to 4,000 construction jobs and<br />

approximately 400 permanent jobs.<br />

Contact: Lori Vidil, telephone: (410)<br />

470-7433.<br />

University Program<br />

Awards<br />

U.S. Energy Secretary Steven Chu<br />

announced nearly $9 million in awards to<br />

support the next generation of American<br />

nuclear energy development. Under the<br />

<strong>Nuclear</strong> Energy Universities Program, the<br />

Department of Energy will provide $2.9<br />

million in scholarships and fellowships to<br />

86 U.S. nuclear science and engineering<br />

(NS&E) students, and will offer more<br />

than $6 million in grants to 29 U.S.<br />

universities and colleges in 23 states.<br />

The Department is awarding 70<br />

scholarships to U.S. undergraduate<br />

students and 16 fellowships to U.S.<br />

graduate students. Each scholarship<br />

student will receive $5,000 to provide<br />

cost of his or her education for the next<br />

year. Fellowship recipients will receive<br />

$50,000 a year over three years to help pay<br />

for their graduate studies and research.<br />

Students are expected to receive their<br />

award funds by September 30, 2009.<br />

More information about the <strong>Nuclear</strong><br />

Energy Universities Program, including a<br />

list of students selected for scholarships<br />

and fellowships and a list of selected<br />

universities, is available at http://www.<br />

nuclear.energy.gov/.<br />

Contact: telephone: (202) 856-4940,<br />

fax: (202) 586-5823.<br />

<br />

SPECIAL ADVERTISING SECTION<br />

Reactor Pool Vacuum System Proves<br />

Beneficial<br />

<strong>Nuclear</strong> power generation plants have<br />

realized significant savings in critical path<br />

outage time, personnel radiation exposure<br />

and associated costs through use of the<br />

system in reactor pools during refueling<br />

outages.<br />

The idea for LUVS (Lightweight<br />

Underwater Vacuum System) came in<br />

the late 1990’s from a worker at the Palo<br />

Verde <strong>Nuclear</strong> Generating Station, which<br />

is the nation’s largest nuclear power<br />

plant. While at PVNGS, Troy Wilfong,<br />

a senior radiation protection technician,<br />

was frustrated with current technology at<br />

the time. Wilfong researched, prototyped<br />

and tested the system that won a <strong>Nuclear</strong><br />

Steam Supply System TIP (Top Industry<br />

Practice) award and was granted a U.S.<br />

Patent in 2002.<br />

Troy Wilfong<br />

examines a LUVS<br />

Control Pendant<br />

Western Space and Marine, Inc. of<br />

Goleta, California refined the design and<br />

produces the commercial LUVS package<br />

that is now in use at many nuclear<br />

stations across the country. Exelon,<br />

Duke Energy, Florida Power and Light,<br />

Entergy, Dominion, Progress Energy and<br />

British Energy all have taken advantage<br />

of the LUVS technology to enhance their<br />

operations.<br />

The system is a compact, submersible<br />

vacuuming system that is much easier<br />

and faster to deploy than other vacuum<br />

systems. It has been used to recover<br />

objects ranging in weight from 2 grams<br />

to 1 kg, although it can retrieve much<br />

lighter and heavier objects. The LUVS<br />

can capture particles down to a size of<br />

100 microns, making it ideal for difficult<br />

decontamination tasks such as vacuuming<br />

rust, fuel particles, hot spots and crud<br />

deposits.<br />

The successful use of the LUVS has<br />

mitigated the disadvantages associated<br />

with using remote grippers and other<br />

existing vacuum systems. The system<br />

greatly reduces the possibility of dropping<br />

objects below the core barrel flow plate<br />

by lifting the objects into the vacuum<br />

system. The average time to deploy and<br />

recover foreign objects using the LUVS<br />

system has been about an hour or less,<br />

compared to up to 24 hours or more of<br />

critical path time using remote grippers<br />

or hose-connected underwater vacuum<br />

systems. Fewer man-hours expended<br />

results in less personnel exposure and<br />

lower outage expense.<br />

For more information contact WSM<br />

(805) 968-3831 or e-mail at luvs_info@<br />

wsminc.com<br />

LUVS<br />

Save Critical Path<br />

Outage Time & Money<br />

Reduce Exposure<br />

with WSM’s<br />

Lightweight<br />

Underwater<br />

Vacuum<br />

System<br />

“The perfect object<br />

retrieval system”<br />

FOSAR<br />

ALARA<br />

Fast, easy debris<br />

removal in liquid<br />

filled tanks<br />

U.S. Patent No. 6,352,645<br />

WESTERN SPACE & MARINE, INC<br />

53 Aero Camino<br />

Goleta, CA 93117<br />

(805) 968-3831<br />

FAX (805) 968-0027<br />

www.wsminc.com<br />

luvs_info@wsminc.com<br />

<strong>Nuclear</strong> <strong>Plant</strong> <strong>Journal</strong>, July-August 2009 www.<strong>Nuclear</strong><strong>Plant</strong><strong>Journal</strong>.com 11

Utility, Industry & Corporation<br />

Utility<br />

Climate Control<br />

DTE Energy Chairman and CEO<br />

Anthony F. Earley, Jr. said that for the U.S.<br />

to achieve ambitious targets of reducing<br />

carbon dioxide emissions, nuclear energy<br />

will be one of the most effective climate<br />

control strategies for the nation’s electric<br />

utilities.<br />

Speaking at The National Summit,<br />

a three-day meeting in Detroit featuring<br />

prominent business, government and<br />

academic leaders, Earley said that nuclear<br />

energy will play a crucial role not only<br />

in addressing global climate change, but<br />

also in meeting the country’s growing<br />

electricity needs.<br />

“<strong>Nuclear</strong> energy provides clean,<br />

reasonably priced electricity at extremely<br />

high levels of safety and reliability,” he<br />

said. “In 2008, the U.S. fleet of nuclear<br />

plants operated at just over 90 percent<br />

capacity - the highest level ever. <strong>Nuclear</strong><br />

power has proven itself safe, clean,<br />

reliable and affordable. And that’s with<br />

a generation of plants designed in the<br />

1960s and 1970s.”<br />

Contact: telephone: (313) 235-5555.<br />

Power Uprates<br />

An approximate 38-megawatt increase<br />

in output at an Exelon <strong>Nuclear</strong> plant in<br />

June, 2009 launched a series of planned<br />

power uprates across the company’s<br />

nuclear fleet that will generate between<br />

1,300 and 1,500 megawatts of additional<br />

generation capacity within eight years<br />

without turning a spade of earth, Exelon<br />

<strong>Nuclear</strong> President and Chief <strong>Nuclear</strong><br />

Officer Charles (Chip) Pardee said.<br />

The first of the new, carbon-free<br />

nuclear megawatts was officially confirmed<br />

following equipment upgrades at Exelon’s<br />

Quad Cities nuclear plant near Cordova,<br />

Illinois. Other uprate projects are<br />

underway and Exelon plans to have the<br />

full measure of new megawatts on the<br />

grid by 2017.<br />

Contact: Marshall Murphy, telephone:<br />

(630) 657-4206.<br />

Industry<br />

Transuranic Waste<br />

Cleanup of the nation’s defenserelated<br />

transuranic (TRU) waste has<br />

reached an important milestone. The<br />

first shipment of remote-handled (RH)<br />

TRU waste from Los Alamos National<br />

Laboratory (LANL) in New Mexico<br />

arrived safely in June, 2009 at the US.<br />

Department of Energy’s (DOE) Waste<br />

Isolation Pilot <strong>Plant</strong> (WIPP) in the<br />

southeast corner of the state.<br />

WIPP’s mission includes the safe<br />

disposal of two types of defense-related<br />

transuranic waste, contact-handled (CH)<br />

and RH. The waste consists of tools,<br />

rags, protective clothing, sludges, soil<br />

and other materials contaminated with<br />

radioactive elements that have atomic<br />

numbers greater than uranium.<br />

Contact: Roger Nelson, telephone:<br />

(575) 234-7213.<br />

Quality Assurance<br />

Guidance<br />

EPRI’s Joint Utility Task Group<br />

(JUTG), together with the American<br />

Society of Mechanical Engineers’ <strong>Nuclear</strong><br />

Quality Assurance Committee, developed<br />

criteria that will be included in the 2009<br />

Addenda to ASME’s NQA-1 standard,<br />

and will subsequently be endorsed by<br />

the <strong>Nuclear</strong> Regulatory Commission.<br />

The NQA-1 Standard will be the baseline<br />

quality assurance requirement for all new<br />

nuclear construction in the United States,<br />

and is currently the baseline quality<br />

assurance standard used by more than<br />

35% of the operating nuclear units in the<br />

United States. The NQA-1 2009 Addenda<br />

is scheduled for publication this summer.<br />

Working to a compressed schedule,<br />

the team developed criteria that are<br />

not only consistent with existing<br />

federal regulations and EPRI guidance<br />

originally developed for licensees, but<br />

are also designed to meet the needs of<br />

manufacturers and non-commercial<br />

power sectors of the industry (such as<br />

the Department of Energy) that employ<br />

the NQA-1 Standard to ensure effective<br />

quality assurance.<br />

Contact: Marc Tannenbaum, telephone:<br />

(704) 595-2110, email: mtannenbaum@<br />

epri.com.<br />

Memorandum<br />

During a visit to Rome in May, 2009<br />

to participate in the G8 Energy Ministers’<br />

Meeting, Japan’s Minister of Economy,<br />

Trade and Industry Toshihiro Nikai and<br />

Italian Economic Development Minister<br />

Claudio Scajola signed a memorandum<br />

of nuclear cooperation.<br />

The memorandum pledges that the<br />

two ministries would work together to<br />

develop nuclear power generation in the<br />

Republic of Italy. Italy had deactivated all<br />

its reactors two decades ago after a public<br />

referendum that banned the use of nuclear<br />

power in the country.<br />

The cooperative activities listed in<br />

the memorandum include: (1) exchanging<br />

information, (2) supporting preparation<br />

for and carrying out of development<br />

of nuclear generation, (3) developing<br />

human resources, (4) supporting nuclear<br />

public information activities and (5) other<br />

activities for the promotion of peaceful<br />

uses of nuclear energy to be decided by<br />

both sides. The term of the memorandum<br />

is initially three years, and is subject to<br />

extension upon mutual agreement.<br />

Contact: Japan Atomic Industrial<br />

Forum, Japan, website: www.jaif.or.jp/<br />

english.<br />

Yucca Mountain Hearing<br />

The <strong>Nuclear</strong> Regulatory Commission’s<br />

Atomic Safety and Licensing<br />

Boards (ASLBs) have granted a hearing<br />

on the Yucca Mountain license application,<br />

admitting eight petitioners as parties<br />

and a total of 299 contentions on safety<br />

and environmental issues.<br />

In a 153-page order issued, the<br />

ASLBs, designated as “construction<br />

authorization boards,” granted the<br />

petitions to intervene filed by the states<br />

of Nevada and California; the <strong>Nuclear</strong><br />

Energy Institute; Nye County, Nevada;<br />

Clark County, Nevada; White Pine<br />

12 www.<strong>Nuclear</strong><strong>Plant</strong><strong>Journal</strong>.com <strong>Nuclear</strong> <strong>Plant</strong> <strong>Journal</strong>, July-August 2009

County, Nevada; Inyo County, California;<br />

and a joint petition filed by Churchill,<br />

Esmeralda, Lander and Mineral counties,<br />

Nevada. The Boards ruled that these<br />

petitioners demonstrated standing and<br />

raised at least one admissible contention<br />

regarding the application.<br />

Contact: telephone: (301) 415-8200,<br />

email: OPA.Resource@nrc.gov.<br />

Corporation<br />

Safety I&C Agreement<br />

AREVA and VNIIAES, Russia,<br />

signed a cooperation agreement in the<br />

field of safety Instrumentation and<br />

Control (I&C) systems for the first four<br />

VVER-type reactors to be built in Russia<br />

as part of the country’s new build fleet<br />

program. The agreement refers to two new<br />

1200 MWe reactors on the Novovoronezh<br />

and Leningrad existing sites, located<br />

respectively in the west and south-west<br />

of Russia. In the frame of this agreement,<br />

the companies signed a first engineering<br />

contract as well as a letter of intent (LOI)<br />

for the delivery of contracts to come.<br />

Contact: Julien Duperray, telephone:<br />

33 1 34 96 12 15.<br />

Transport Operation<br />

The largest transport operation in<br />

the history of Babcock Noell GmbH,<br />

Germany, has been successfully completed.<br />

The containment liner planned by Babcock<br />

Noell for a new-build nuclear power<br />

station was transported by sea from Poland<br />

to Finland.<br />

On May 4, 2009, the containment<br />

liner for the nuclear power station in<br />

Olkiluoto arrived on the construction site<br />

in good order. The component, including<br />

its transport substructure, weighs 350<br />

tons and is 15 m tall. The diameter of the<br />

dome is 47 m.<br />

In Finland, the 200 ton dome was<br />

lifted off the pontoon and the transport<br />

substructure using an enormous crawler<br />

crane before being carefully transported<br />

to the pre-assembly site in a 10-hour<br />

operation at a maximu speed of 30 m per<br />

hour, and lowered into place.<br />

The schedule of the milestones for<br />

loading, shipping, unloading and release<br />

for further work was stuck to exactly, so<br />

that the planned date for lifting the dome<br />

into place to complete the containment<br />

at the end of August 2009 is now almost<br />

within reach.<br />

Contact: telephone: 49 931 9030,<br />

fax: 49 931 9036000, email: info@<br />

babcocknoell.de.<br />

Expansion<br />

In order to meet the continued<br />

demands of the power generation market<br />

and to position the company for growth<br />

within the southeastern United States,<br />

Burns and Roe Enterprises, Inc.<br />

announced that the firm is expanding their<br />

Southeastern operations and opening a<br />

new office to be located in Chattanooga,<br />

Tennessee.<br />

The opening of this office is the<br />

most recent step in a series of corporate<br />

strategic initiatives to increase the firm’s<br />

public, private and federal government<br />

service capabilities throughout the US<br />

and worldwide. Approximately 20 to 40<br />

employees are being hired or transferred<br />

to the Chattanooga office as part of this<br />

initial expansion. This staffing expected<br />

to increase over the next six months to a<br />

year as business opportunities materialize.<br />

Current plans call for the hiring of up to<br />

100 to 200 additional staff in the future.<br />

Contact: Donald Flood, telephone:<br />

(201) 986-4623.<br />

Acquisition<br />

Curtiss-Wright Flow Control Company,<br />

the flow control segment of Curtiss-Wright<br />

Corporation, has acquired the assets of<br />

Modumend, Inc. for $2 million. Modumend<br />

repairs and refurbishes obsolete power<br />

supplies for both foreign and domestic<br />

clients in the nuclear, fossil and non-power<br />

industries. It will be integrated into Curtiss-<br />

Wright Flow Control Company <strong>Nuclear</strong><br />

Group within the Scientech business unit.<br />

Contact: Sharon L. Dey, telephone:<br />

(703) 286-2011, email: sdey@<br />

curtisswright.com.<br />

Technology Corporation<br />

Curtiss-Wright Flow Control<br />

Company has acquired all of the stock<br />

of Northeast Technology Corporation<br />

(NETCO) and an exclusive worldwide<br />

license of the NETCO Snap-In<br />

technology for a total of $3.5 million<br />

in cash. NETCO provides engineering<br />

analysis, software development,<br />

laboratory testing services and in-plant<br />

testing, and specializes in spent fuel<br />

management for the nuclear power<br />

industry. NETCO will become part of<br />

Curtiss-Wright Flow Control Company<br />

<strong>Nuclear</strong> Group’s Scientech business unit.<br />

Contact: Sharon L. Dey, telephone:<br />

(703) 286-2011, email: sdey@<br />

curtisswright.com.<br />

Health Physics Support<br />

Argonne National Laboratory (ANL)<br />

has awarded DeNuke a competitively bid<br />

Basic Ordering Agreement for health<br />

physics support over the next year, with<br />

three one year options. The objective of<br />

the statement of work is to support ANL<br />

in carrying out specific work projects<br />

funded by the American Recovery and<br />

Reinvestment Act (ARRA) of 2009.<br />

DeNuke will provide DOE Core Qualified<br />

Radiation Control Technicians (RCTs),<br />

RCT supervisors, and Health Physicists<br />

who will perform radiological safety<br />

monitoring, documentation, and related<br />

services for the duration of those ARRA<br />

funded projects.<br />

Contact: Fred Gardner, email:<br />

fgardner@denuke.com.<br />

Development Agreement<br />

GE Hitachi <strong>Nuclear</strong> Energy (GEH)<br />

announced it has signed a nuclear power<br />

plant development agreement with<br />

India’s top engineering and construction<br />

company, Larsen & Toubro Ltd. (L&T).<br />

The agreement with L&T is an<br />

important part of GEH’s strategy to<br />

establish an extensive network of local<br />

suppliers to help build a future GEHdesigned<br />

Advanced Boiling Water<br />

Reactor (ABWR) power station in India.<br />

The power station is one of several being<br />

planned by India to increase the country’s<br />

nuclear generation capacity more than<br />

tenfold over the next two decades—<br />

from 4.1 GW to 60 GW by 2030. The<br />

nuclear power initiative is a key part of<br />

India’s broader plan to expand its energy<br />

infrastructure to meet the country’s<br />

surging demands for electricity.<br />

GEH’s MOU with L&T is one of<br />

the first preliminary nuclear technology<br />

trade agreements to be announced by a<br />

U.S.-majority owned company since the<br />

United States and India adopted a civilian<br />

nuclear energy accord in October 2008.<br />

Contact: Ned Glascock, telephone:<br />

(910) 675-5729, email: Edward.<br />

glascock@ge.com.<br />

(Continued on page 16)<br />

<strong>Nuclear</strong> <strong>Plant</strong> <strong>Journal</strong>, July-August 2009 www.<strong>Nuclear</strong><strong>Plant</strong><strong>Journal</strong>.com 13

SPECIAL ADVERTISING SECTION<br />

For more information: nuclear@tetratech.com<br />

NUCLEAR SERVICES<br />

<strong>Nuclear</strong> power is the only technology ready to meet the<br />

global demand for base load energy in an environmentally<br />

responsible way. Tetra Tech recognizes the important role<br />

nuclear power will play in maintaining a diverse energy mix<br />

and developing energy independence. With 10,000 of the best<br />

and brightest professionals in science and engineering,<br />

including more than 500 nuclear specialists in the United<br />

States and Canada, Tetra Tech offers smart, efficient solutions<br />

that make a difference in a complex world.<br />

Tetra Tech covers the entire project lifecycle by providing a range<br />

of nuclear services including site investigation and preparation;<br />

licensing and permitting; consulting; engineering, procurement,<br />

and construction (EPC); training; operations and maintenance;<br />

and decommissioning. We offer a team of proven industry<br />

leaders with the experience to deliver complex projects on<br />

time and within budget, throughout North America and abroad.<br />

Tetra Tech is consistently ranked among the Top 10 Design<br />

Firms and among the Top 8 <strong>Nuclear</strong> Waste Cleanup firms<br />

in the United States.<br />

Tetra Tech leads the nation in nuclear power plant license<br />

renewal services and has prepared license applications<br />

for 7 new nuclear power plant projects. Tetra Tech also provides<br />

complete fuel cycle services including services to support<br />

mining and milling uranium ore, used fuel recycling, enrichment,<br />

conversion, and advanced reactors. We offer comprehensive<br />

industry-recognized services throughout all types and phases<br />

of nuclear projects, including services for nuclear power plants<br />

and nuclear waste treatment and handling facilities.<br />

Tetra Tech experts have been involved with the design and<br />

construction of more than 30 nuclear power facilities over the<br />

past four decades, and have participated in the refurbishment<br />

of the OPG nuclear units in Canada. We are also at the forefront<br />

of developing and deploying small reactor technologies.<br />

Tetra Tech is well positioned to support the continued growth<br />

of the global nuclear industry.<br />

Project Development & Consulting Services<br />

<br />

<br />

<br />

<br />

<br />

<br />

Program Management<br />

Risk Management<br />

Project Integration<br />

Procurement and Supply Chain Management<br />

Configuration Management<br />

Licensing, Permitting, and Regulatory Compliance<br />

Engineering & Design Services<br />

<br />

<br />

<br />

<br />

<br />

<br />

Environmental and Geotechnical Services<br />

<strong>Plant</strong> Structures, Systems, and Components Design<br />

Used Fuel Facilities Design<br />

Independent Engineer Services<br />

3-D Modeling and Analysis<br />

Small and Advanced Reactor Design<br />

Construction Services<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Constructability Review and Oversight<br />

New <strong>Plant</strong> Site Preparation<br />

Construction/Construction Management<br />

Modularization<br />

Turn-key Support Facility Construction<br />

Site Remediation<br />

Labor and Resource Management<br />

Operations, Training & Maintenance Services<br />

<br />

<br />

<br />

<br />

Development of Training Programs and Materials<br />

Uranium Facilities Support<br />

Operating <strong>Plant</strong> Modification Package Preparation<br />

Used Fuel Disposition and Handling<br />

Quality Services<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

NQA-1 Quality Assurance Program – Appendix B<br />

Compliant<br />

ASME Section III, Division 3, Class TC<br />

Transportation Containment<br />

ASME Section III, Division 1, Components<br />

Audits and Surveillance<br />

CSA Z299.2 – Design<br />

CSA N286.2 – Design QA<br />

CSA N286.1 – Procurement QA<br />

ISO-9001<br />

CANPAC Audited<br />

14 www.<strong>Nuclear</strong><strong>Plant</strong><strong>Journal</strong>.com <strong>Nuclear</strong> <strong>Plant</strong> <strong>Journal</strong>, July-August 2009

RENEWABLE ENERGY FOR A COMPLEX WORLD<br />

Wind, solar, nuclear, geothermal, and bioenergy—these sources offer clean and sustainable alternatives to help meet the world’s<br />

rising energy demands. For nuclear energy projects, Tetra Tech provides a wide range of services including licensing, site preparation,<br />

nuclear modifications, risk analysis, nuclear materials management, engineering-procurement-construction (EPC) services,<br />

and decontamination and decommissioning services. Tetra Tech provides clear solutions in consulting, engineering, program<br />

management, construction, and technical services worldwide. www.tetratech.com

Corporation...<br />

Continued from page 13<br />

Certified Supplier<br />

L-3 MAPPS, Canada, was named an<br />

AREVA Certified Supplier for its nuclear<br />

power plant simulators and services.<br />

Michael Chatlani, vice president of<br />

marketing & sales for L-3 MAPPS Power<br />

Systems and Simulation, accepted the<br />

award from AREVA’s chief executive<br />

officer Anne Lauvergeon in a ceremony<br />

held in Washington D.C. on June 4,<br />

2009.<br />

The AREVA Certified Supplier seal<br />

of approval reflects 25 different criteria<br />

that AREVA requires of its key suppliers,<br />

such as:<br />

• the quality of the products and/or<br />

services,<br />

• the capacity to offer the best market<br />

price and production schedules,<br />

• dedication to project management,<br />

safety, security, and the protection of<br />

the environment,<br />

• development potential in R&D and<br />

innovation, the commercial approach<br />

and capacity to tackle new markets.<br />

Contact: André Rochon, telephone:<br />

514-787-4953.<br />

Simulator Order<br />

L-3 MAPPS, Canada, has won<br />

a second simulator order for China’s<br />

Hongyanhe nuclear power plant from<br />

Liaoning Hongyanhe <strong>Nuclear</strong> Power<br />

Co. Ltd. (LHNPC), the plant owner and<br />

operator. The second simulator is for<br />

operator training for Hongyanhe plant’s<br />

third and fourth units. Preparatory work<br />

on the simulator will start immediately,<br />

and it is expected to be in service in the<br />

spring of 2011.<br />

L-3 MAPPS is providing the process<br />

simulation and virtual back-up panels<br />

while China Techenergy Co. Ltd. (CTEC)<br />

supplies the non-safety <strong>Digital</strong> Control<br />

System (DCS), emergency control room<br />

panels and the staging facility in Beijing<br />

where the simulator will be integrated<br />

and tested prior to delivery to LHNPC.<br />

Japan’s Mitsubishi Electric Corporation<br />

(MELCO) will provide the simulator’s<br />

safety DCS. As units 3 and 4 are twins<br />

of the first two units under construction<br />

at the Hongyanhe site, the plant process<br />

simulation will be based on the models<br />

for the Hongyanhe full scope simulator<br />

for units 1 and 2 which are already under<br />

development by L-3 MAPPS.<br />

Contact: André Rochon, telephone:<br />

514-787-4953.<br />

Asset Management<br />

UK government policy is encouraging<br />

a low carbon economy where nuclear<br />

energy along with other low carbon<br />

energy sources such as renewables,<br />

have a critical role to play in providing<br />

a balanced energy mix for the UK’s<br />

energy needs. The recent acquisition of<br />

British Energy by EDF provides a strong<br />

commitment to the nuclear new build<br />

program, and a need to demonstrate to<br />

stakeholders and the wider community,<br />

that current and planned nuclear assets<br />

are managed safely and appropriately.<br />

In a process lasting two years, British<br />

Energy benchmarked its business against<br />

the BSI Publicly Available Specification<br />

55 (PAS 55-1:2008), provided through<br />

Lloyd’s Register EMEA, United<br />

Kingdom, for asset management. Applying<br />

this specification at all of its nuclear<br />

power stations, British Energy is the first<br />

nuclear operator to successfully achieve<br />

this certification, an approach that has<br />

helped manage the return to service of its<br />

reactors at Hartlepool and Heysham.<br />

Contact: Jason Knights, telephone:<br />

44 (0)20 7423 1741, email: jason.<br />

knights@lr.org.<br />

New U.S. Subsidiary<br />

Robatel announced the formation of<br />

a wholly owned U.S. subsidiary, Robatel<br />

Technologies LLC, based in Roanoke,<br />

Virginia.<br />

Robatel Technologies LLC will<br />

target the U.S. commercial and federal<br />

nuclear markets with an initial focus on<br />

the Department of Energy MOX project<br />

located at the Savannah River site in<br />

Aiken, South Carolina.<br />

Robatel Technologies will initially<br />

offer design engineering and fabrication of<br />

nuclear fuel casks, glove boxes, modular<br />

hot cells, heavy shielded components and<br />

specialty turnkey installations associated<br />

with nuclear fuel or waste processing.<br />

Contact: Teo Grochowski, Jr.,<br />

telephone: (540) 989.2878.<br />

Environmental<br />

Qualification Testing<br />

Scientech, a provider of Environmental<br />

Qualification services to the global<br />

nuclear power industry, announced its<br />

recent agreement with ATS (Assurance<br />

Technical Services, Inc.) to become the<br />

exclusive provider of harsh environmental<br />

qualification testing in support of Scientech’s<br />

Environmental Qualification Services.<br />

This agreement adds a specialized<br />

capacity to successfully meet the more<br />

extreme postulated accident requirements<br />

for new Generation III+ nuclear reactor<br />

designs currently being qualified.<br />

Contact: Tom Bernacki, telephone:<br />

(860) 409-0513, email: tbernacki@<br />

curtisswright.com.<br />

Radiation Monitoring<br />

Thermo Fisher Scientific Inc. announced<br />

that its Radiation Measurement<br />

and Security Instruments (RMSI) business<br />

has completed its 12th annual radiation<br />

monitoring techniques training course<br />

outside of Kiev, Ukraine, and within the<br />

vicinity of the Chernobyl nuclear power<br />

plant. The seminar and workshop (May<br />

31-June 6, 2009) was designed to provide<br />

participants with the latest guidance<br />

on environmental, source, personnel and<br />

equipment monitoring in case of a nuclear<br />

or other radiological emergency.<br />

The session’s field exercise segment<br />

took place in the Exclusion Zone which<br />

is the 30-km (19-mile) area surrounding<br />

the site of the Chernobyl nuclear<br />

power reactor that experienced a major<br />

radiological disaster in 1986.<br />

Contact: Nicole Kelly, telephone:<br />

(440) 703-1511, email: Nicole.kelly@<br />

thermofi sher.com.<br />

Waste Storage<br />

Waste Control Specialists LLC<br />

(WCS) announced that on June 8, 2009<br />

its Andrews County facility began storing<br />

low-level radioactive waste received<br />

from Studsvik, Inc., a Tennessee-based<br />

waste processor. The interim storage at<br />

WCS’ facility in Andrews County of this<br />

thermally processed Class B and Class C<br />

low-level radioactive waste will greatly<br />

reduce the risk and administrative burden<br />

of generators when compared to the use<br />

of multiple storage facilities across the<br />

United States.<br />

While the interim storage of the<br />

Studsvik material is authorized under<br />

16 www.<strong>Nuclear</strong><strong>Plant</strong><strong>Journal</strong>.com <strong>Nuclear</strong> <strong>Plant</strong> <strong>Journal</strong>, July-August 2009

WCS’ storage license, the Texas Low-<br />

Level Radioactive Waste Compact<br />

Commission (Compact Commission)<br />

must approve any permanent disposal<br />

of the material at the Compact waste<br />

disposal facility in Andrews.<br />

Contact: Rickey Dailey, telephone:<br />

(512) 708-8655.<br />

Vacuum System<br />

In April, 2009, Florida Power and<br />

Light took delivery of their third Western<br />

Space and Marine, Inc. (WSM) LUVS<br />

Lightweight Underwater Vacuum System.<br />

Bob Hanke of Florida Power and Light<br />

reports to WSM that the LUVS equipment<br />

is a very effective tool for general foreign<br />

object removal and especially in dry cask<br />

work. This fourth generation design will<br />

be used for training purposes at St. Lucy<br />

and Turkey Point facilities.<br />

Contact: Scott Millard, telephone:<br />

(805) 968-3831, e-mail at luvs_info@<br />

wsminc.com<br />

AP1000 in India<br />

Westinghouse Electric Company<br />

will begin discussions with <strong>Nuclear</strong><br />

Power Corporation of India Ltd., (NPCIL)<br />

with a goal of reaching agreement on the<br />

deployment of Westinghouse AP1000<br />

nuclear power plants in India.<br />

The announcement followed signing<br />

of a memorandum of understanding by<br />

Dr. S. K. Jain, Chairman and Managing<br />

Director of NPCIL, and Westinghouse<br />

President and CEO Aris S. Candris. In<br />

making the announcement, Dr. Candris<br />

said it is logical for the two companies<br />

to work together to further expand India’s<br />

already robust nuclear power industry.<br />

Contact: Vaughn Gilbert, telephone:<br />

(412) 374-3896, email: gilberhv@<br />

westinghouse.com.<br />

Chief Information Officer<br />

Dr. Gerard Macioce has been<br />

appointed to the position of Chief<br />

Information Officer at Westinghouse<br />

Electric Company. Dr. Macioce<br />

previously served as the director, Systems<br />

Enterprise Integration for <strong>Nuclear</strong> Power<br />

<strong>Plant</strong>s at Westinghouse.<br />

In his new role, Dr. Macioce will be<br />

responsible for the overall development<br />

and implementation of the IT strategic<br />

plan to support Westinghouse’s global<br />

operations. He will ensure that highpriority<br />

business initiatives are enabled<br />

with both strategic and cost-effective<br />

IT delivery systems and skilled<br />

professionals.<br />

Dr. Macioce holds a PH.D. in Information<br />

Systems and Communications.<br />

Dr. Macioce is a certified Project Management<br />

Professional and a member of<br />

Duquesne University’s Information Management<br />

Systems Advisory Board.<br />

Contact: Vaughn Gilbert, telephone:<br />

(412) 374-3896, email: gilberhv@<br />

westinghouse.com.<br />

N-Vision Winners<br />

Westinghouse Electric Company<br />

announced its winning entries for its<br />

N-Vision Forms of Energy Contest. The<br />

High School winning video came from<br />

Butler Senior High School located in<br />

Butler, Pennsylvania, and was produced<br />

by the school’s 11th and 12th grade<br />

Television Production class. The Middle<br />

School winning video came from<br />

McKinley Middle School in Racine,<br />

Wisconsin.<br />

Administered through the company’s<br />

speaker’s bureau, N-Vision, the contest<br />

is designed to encourage young persons<br />

to think about energy in the context<br />

of worldwide political, economic and<br />

environmental realities.<br />

Specific guidelines can be found on<br />

the Contest Application on Westinghouse’s<br />

website at: www.westinghousenuclear.<br />

com and under the “Community” section/<br />

Student Video Contest on Forms of<br />

Energy.<br />

Contact: Vaughn Gilbert, telephone:<br />

(412) 374-3896, email: gilberhv@<br />

westinghouse.com.<br />

Westinghouse Japan<br />

Westinghouse Electric Company<br />

announced the formation of Westinghouse<br />

Electric Japan, a new organization<br />

that will provide a single focal point for<br />

all Westinghouse products and services<br />

manufactured, sold or procured in Japan.<br />

Westinghouse also announced that it has<br />

appointed Jack B. Allen, currently senior<br />

vice president of Westinghouse Electric<br />

Company, as president and CEO of the<br />

new entity.<br />

In making the announcement,<br />

Westinghouse President and CEO Aris<br />

Candris said the formation of Westinghouse<br />

Electric Japan is consistent with<br />

Westinghouse’s effort to build closer relationships<br />

with an expanding global customer<br />

base.<br />

Contact: Thomas Meston, telephone:<br />

( 412) 298-6350, email: mestontm@<br />

westinghouse.com.<br />

Zachry <strong>Nuclear</strong><br />

Engineering<br />

Zachry announces that Proto-<br />

Power Corporation, a leading nuclear<br />

engineering firm, has become Zachry<br />

<strong>Nuclear</strong> Engineering, Inc. with its full<br />

integration into the Zachry family of<br />

companies under the subsidiary, Zachry<br />

<strong>Nuclear</strong>, Inc.<br />

Zachry <strong>Nuclear</strong> Engineering will<br />

join Zachry <strong>Nuclear</strong> Construction,<br />

Inc. of San Antonio, to form Zachry<br />

<strong>Nuclear</strong>, combining 34 years of nuclear<br />

design experience and 85 years of power<br />

construction expertise. Together they<br />

will provide services from design to<br />

construction in one of the world’s most<br />

vital power industries.<br />

Zachry <strong>Nuclear</strong> Engineering will be<br />

managed by Mark B. Mills, president;<br />

Robert J. Atkisson, director, business<br />

development; Paul H. Collette, director,<br />

engineering; and Thomas F. McCarthy,<br />

director, projects. Kenneth A. Ewell,<br />

former president of Proto-Power, has<br />

been promoted to chief nuclear officer of<br />

Zachry <strong>Nuclear</strong>.<br />

Contact: Lydia Adams, telephone:<br />

(210) 588-6795, email: adamslr@zhi.<br />

com.<br />

<br />

<strong>Nuclear</strong> <strong>Plant</strong> <strong>Journal</strong>, July-August 2009 www.<strong>Nuclear</strong><strong>Plant</strong><strong>Journal</strong>.com 17

SPECIAL ADVERTISING SECTION<br />

18 www.<strong>Nuclear</strong><strong>Plant</strong><strong>Journal</strong>.com <strong>Nuclear</strong> <strong>Plant</strong> <strong>Journal</strong>, July-August 2009

New Products, Services & Contracts<br />

New Products<br />

Power <strong>Plant</strong> Control<br />

Alstom has launched ALSPA ® Series<br />

6, a new suite of power plant control and<br />

automation technology that uses the latest<br />

state-of-the-art technology to give power<br />

plant operators complete and efficient<br />

control of their plant – from individual<br />

equipment such as turbines, right through<br />

to the whole power station.<br />

The ALSPA ® Series 6 Control<br />

System takes advantage of Alstom’s<br />

extensive experience in power plant<br />

control, integrating the latest technologies<br />

for the benefit of the customer. ALSPA ®<br />

Series 6 encompasses all the operation,<br />

management, maintenance, automation<br />

and safety functions that a modern power<br />

plant needs.<br />

Central to Series 6 is ALSPA ®<br />

CONTROPLANTTM, the state-of-theart<br />

plant automation system, based on<br />

a flexible, modular and open real-time<br />

architecture (based on Ethernet Power<br />

Link) and designed in line with the trend<br />

toward increasing data centralisation.<br />

ALSPA ® CONTROPLANT TM can be<br />

used from small systems to large complex<br />

systems in power station or industrial<br />

applications to control, optimise and<br />

protect all types of power plants and their<br />

turbines – whether thermal, hydro or<br />

nuclear.<br />

Contact: Susanne Shields, telephone:<br />

33 1 41 49 27 22, email: susanne.shields@<br />

power.alstom.com.<br />

Multi-Channel Analyzer<br />

The ORTEC ® business unit of<br />

AMETEK Advanced Measurement<br />

Technology (AMT) has introduced the<br />

DigiDART-LF, a portable “SMART”<br />

multi-channel analyzer (MCA) for<br />

sodium iodide (NaI TI), lanthanum<br />

bromide (LaBr 3<br />

:Ce) and other scintillation<br />

detectors.<br />

The rugged, lightweight DigiDART-<br />

LF is completely operable without a PC.<br />

It can perform a variety of measurements<br />

directly in the field or on site and store<br />

a large amount of spectra in an internal<br />

memory. Its built-in backlit LCD display<br />

and control keypad create a live display<br />

as data is acquired. An advanced, lowpower<br />

design provides the DigiDART-LF<br />

with digital stability, high data throughput<br />

and up to twelve hours of operational life<br />

from a single battery charge.<br />

Contact: Susie Brockman, telephone:<br />

(865) 483-2124.<br />

Spectrometer<br />

ORTEC® announced the release<br />

of the DigiBASE-E, an all-in-one highperformance<br />

<strong>Digital</strong> Gamma Spectrometer<br />

for scintillation detectors, built into a<br />

standard 14-pin photomultiplier tube<br />

base.<br />

The DigiBASE-E can operate<br />

at ultrahigh count-rates, consuming<br />

very low power. High maximum<br />

throughput is available through the use<br />

of a new trapezoidal filter with lower<br />

dead-time per processed pulse. The<br />

instrument features an Ethernet (PoE)<br />

communications interface from which<br />

it can be conveniently powered, making<br />

network implementation simple.<br />

The DigiBASE-E can be used in a<br />

wide variety of radiation spectroscopy<br />

applications and features both the<br />

conventional pulse height analysis mode<br />

of data acquisition as well as the powerful<br />

list mode. Flexibility in data acquisition<br />

gating logic and the provision of a 32-bit<br />

counter channel makes the DigiBASE-E<br />

a drop-in solution for a wide variety of<br />

application situations.<br />

Contact: Susie Brockman, telephone:<br />

(865) 483-2124.<br />

Air Purifying Respirator<br />

UniTech Services Group added<br />

the MAXAIR Powered Air Purifying<br />

Respirator (PAPR) to its line of nuclear<br />

protection products. MAXAIR provides<br />

superior respiratory protection anywhere<br />

workers may be exposed to heat stress<br />

or contaminated air. Its design provides<br />

complete protection from airborne<br />

particulates and splashes. UniTech is the<br />

exclusive authorized nuclear industry<br />

distributor of the NIOSH-approved<br />

powered air-purifying respirator.<br />

The MAXAIR system features a<br />

helmet, disposable HE filter, filter cover,<br />

and choice of disposable cuff or shroud.<br />

LED visual safety indicators display realtime<br />

information on remaining battery<br />

life and airflow. Compared to traditional<br />

PAPRs, MAXAIR is 33% lighter, making<br />

it more comfortable to wear for long<br />

periods of time. Its patented hose-free<br />

design allows for increased freedom of<br />

movement and prevents workers from<br />

getting caught or snagged on objects in<br />

the work area.<br />

Contact: Gregg Johnstone, telephone:<br />

(413) 543-6911, email: GJohnstone@<br />

unitech.ws.<br />

Services<br />

Design & Construction<br />

Tetra Tech experts are involved<br />

with the design and construction of more<br />

than 20 nuclear power facilities. Current<br />

staff includes engineers, consultants, and<br />

construction and procurement specialists<br />

experienced with the unique requirements<br />

of the industry. Tetra Tech has the<br />

proven tools and processes to support<br />

20 www.<strong>Nuclear</strong><strong>Plant</strong><strong>Journal</strong>.com <strong>Nuclear</strong> <strong>Plant</strong> <strong>Journal</strong>, July-August 2009

Quality<br />

Excellence<br />

all levels of nuclear quality assurance<br />

services including an approved ASME<br />

NQA-1 Quality Program and an ASME<br />

Section III, Division 1 and Division 3<br />

Quality Program supporting its N-Stamp<br />

Certificates.<br />

Tetra Tech is a provider of nuclear<br />

power plant re-licensing services in<br />

the United States, a provider to both<br />

utilities and other engineering firms in<br />

the preparation of license applications for<br />

new nuclear power plants.<br />

Contact: Talia Starkey, telephone:<br />

(626) 470-2332, email: talia.starkey@<br />

tetratech.com.<br />

Contracts<br />

Steam Generator<br />

Replacement<br />

AREVA, teaming up with Korean<br />

contractor, DAELIM Industrial Co.,<br />

Ltd., has been awarded a contract by<br />

Korea Hydro & <strong>Nuclear</strong> Power Co., Ltd.<br />

(KHNP), South Korean nuclear power<br />

plants operator to replace the 6 steam<br />

generators on the Ulchin 1 & 2 NPPs<br />

during outages planned for 2011 and<br />

2012.<br />

For the purposes of this project,<br />

a consortium has been set up, jointly<br />

by AREVA and DAELIM. AREVA as<br />

Original Equipment Manufacturer will<br />

lead the consortium and perform the<br />

primary system and licensing operations<br />

in cooperation with KHNP and Korea<br />

Power Engineering Co., Inc. (KOPEC).<br />

DAELIM will implement all the<br />

secondary and local activities associated<br />

with this project.<br />

Contact: Julien Duperray, telephone:<br />

33 1 34 96 12 15.<br />

MJ09.indd 53<br />