Technical Innovation in Steelwork Connections - Butler Fasteners ...

Technical Innovation in Steelwork Connections - Butler Fasteners ...

Technical Innovation in Steelwork Connections - Butler Fasteners ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Technical</strong> <strong>Innovation</strong> <strong>in</strong><br />

<strong>Steelwork</strong> <strong>Connections</strong><br />

Established 1934

L<strong>in</strong>dapter - <strong>Technical</strong> <strong>Innovation</strong> <strong>in</strong> <strong>Steelwork</strong> <strong>Connections</strong><br />

2<br />

Tel: +44 (0) 1274 521444 www.l<strong>in</strong>dapter.com

Established <strong>in</strong> 1934 as a small<br />

family bus<strong>in</strong>ess L<strong>in</strong>dapter has now<br />

become the market leader <strong>in</strong><br />

steelwork fix<strong>in</strong>gs with a worldwide<br />

reputation; export account<strong>in</strong>g for<br />

an <strong>in</strong>creas<strong>in</strong>g portion of our<br />

bus<strong>in</strong>ess. L<strong>in</strong>dapter abides by<br />

a policy which <strong>in</strong>cludes strict<br />

adherence to quality control and EHS procedures;<br />

also offer<strong>in</strong>g first class customer service us<strong>in</strong>g state<br />

of the art equipment. Cont<strong>in</strong>ual improvement of<br />

both products and policies ensures that L<strong>in</strong>dapter<br />

cont<strong>in</strong>ues to be at the forefront <strong>in</strong> the marketplace.<br />

All enquiries are dealt with on an <strong>in</strong>dividual basis<br />

ensur<strong>in</strong>g that customers receive the correct<br />

technical support together with project specific<br />

draw<strong>in</strong>gs <strong>in</strong> either 2D or 3D formats together with<br />

itemised parts list; all part of a free comprehensive<br />

service.<br />

For situations where standard products are just not<br />

enough the R & D facility can design and develop<br />

new special products to suit <strong>in</strong>dividual applications.<br />

Whatever the application all products will meet<br />

L<strong>in</strong>dapters own exact<strong>in</strong>g standards ensur<strong>in</strong>g that<br />

they are safe, quick and easy to <strong>in</strong>stall sav<strong>in</strong>g the<br />

customer both time and money by reduc<strong>in</strong>g<br />

<strong>in</strong>stalled costs. As the vast majority of L<strong>in</strong>dapter<br />

products require no site drill<strong>in</strong>g or weld<strong>in</strong>g steel<br />

sections can, if and when necessary, be reused<br />

ensur<strong>in</strong>g both current and future environmental and<br />

susta<strong>in</strong>ability issues can be met.<br />

Founder<br />

Henry L<strong>in</strong>dsay<br />

In the plant on the opposite page many different<br />

L<strong>in</strong>dapter applications are outl<strong>in</strong>ed.<br />

Tel: +44 (0) 1274 521444 www.l<strong>in</strong>dapter.com<br />

3

Index<br />

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2<br />

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4<br />

Service and Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6<br />

Quality and Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7<br />

2 Cavity Fix<strong>in</strong>gs<br />

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40<br />

Type HB - Hollo-Bolt ® . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41<br />

Type LB 2 - L<strong>in</strong>dibolt 2 ® . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44<br />

Typical Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45<br />

1 <strong>Steelwork</strong> Fix<strong>in</strong>gs<br />

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8<br />

Girder Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10<br />

Bolt Length / Tail Length / Installation . . . . . . . . . . . . . . . . . . . . . . . .11<br />

Type A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12<br />

Type B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13<br />

Accessories for Type A and B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14<br />

Plate and Pack<strong>in</strong>g Details for Type A and B . . . . . . . . . . . . . . . . . . . .15<br />

Type AF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16<br />

Type CF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17<br />

Accessories for Type AF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18<br />

Plate and Pack<strong>in</strong>g Details for Type AF and CF . . . . . . . . . . . . . . . . . .19<br />

Type LR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20<br />

Type D2 and Type D3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21<br />

Accessories for Type LR, D2 and D3 . . . . . . . . . . . . . . . . . . . . . . . . .22<br />

Plate and Pack<strong>in</strong>g Details for Type LR, D2 and D3 . . . . . . . . . . . . . . .23<br />

Type LS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24<br />

Accessories / Plate and Pack<strong>in</strong>g Details for Type LS . . . . . . . . . . . . .25<br />

Type BR and Type RC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26<br />

Accessories / Plate and Pack<strong>in</strong>g Details for Type BR . . . . . . . . . . . . .27<br />

Type L<strong>in</strong>dapter-HD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28<br />

Type BSNT and Type BSLN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30<br />

Type F9 and Type HW/HC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31<br />

Type SC and Type LP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32<br />

Type FC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33<br />

Loads and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34<br />

<strong>Technical</strong> Enquiry Fax . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35<br />

Typical Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36<br />

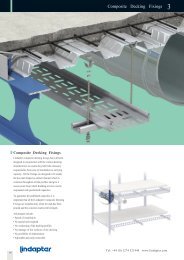

3 Composite Deck<strong>in</strong>g Fix<strong>in</strong>gs<br />

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46<br />

Type AW - Alphawedge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47<br />

Type MW2 - Multiwedge 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48<br />

Type TR60 and Type VN - V-Nut . . . . . . . . . . . . . . . . . . . . . . . . . . . .49<br />

Type SD2 - Slimdek 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50<br />

Type TC - Toggle Clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51<br />

Deck<strong>in</strong>g Fix<strong>in</strong>gs Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52<br />

4<br />

Tel: +44 (0) 1274 521444 www.l<strong>in</strong>dapter.com

4 Support Fix<strong>in</strong>gs<br />

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54<br />

Type FLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55<br />

Type FL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56<br />

Type LC and Type SW - Swivel Unit . . . . . . . . . . . . . . . . . . . . . . . . . .57<br />

Type F3 and Type F3-BICC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58<br />

Type SH and Type HW / HC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59<br />

Type Z10 and Type HCW30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60<br />

Type HCW31 and Type WF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61<br />

Type HCW34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62<br />

Purl<strong>in</strong> Profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62<br />

Typical Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63<br />

6 Appendix<br />

Section Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68<br />

General Enquiries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70<br />

Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71<br />

Factors of safety shown <strong>in</strong> this catalogue are typical values and<br />

vary with different products from 2:1 to 5:1.<br />

Stated tighten<strong>in</strong>g torques must not be exceeded.<br />

Disclaimer<br />

L<strong>in</strong>dapter International supplies components <strong>in</strong> good faith, on the<br />

assumption that customers fully understand the load<strong>in</strong>gs, safety factors<br />

and physical parameters of the products <strong>in</strong>volved. Customers or users<br />

who are unaware or unsure of any details should refer to L<strong>in</strong>dapter<br />

International before use. Responsibility for loss, damage, or other<br />

consequences of mis-use cannot be accepted. L<strong>in</strong>dapter makes every<br />

effort to ensure that technical specifications and other product<br />

descriptions are correct. ‘Specification’ shall mean the specification<br />

(relat<strong>in</strong>g to the use of the materials) set out <strong>in</strong> the quotation given by the<br />

Seller to the Buyer. Responsibility for errors or omissions cannot be<br />

accepted. All dimensions stated are subject to production tolerances -<br />

if <strong>in</strong> doubt please check with L<strong>in</strong>dapter.<br />

5 Floor Fix<strong>in</strong>gs<br />

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64<br />

Type FF - Floorfast ® . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65<br />

Type GF - Grate-Fast ® . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66<br />

Type GF3030 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67<br />

Applications<br />

All the applications featured <strong>in</strong> the catalogue are based on real<br />

projects. More <strong>in</strong>formation about these can be found on our website<br />

www.l<strong>in</strong>dapter.com.<br />

© L<strong>in</strong>dapter 2009 © L<strong>in</strong>dapter International<br />

© L<strong>in</strong>dapter is a registered trade mark<br />

In the <strong>in</strong>terests of improv<strong>in</strong>g the quality and performance of L<strong>in</strong>dapter<br />

products, we reserve the right to make specification changes without<br />

prior notice.<br />

Tel: +44 (0) 1274 521444 www.l<strong>in</strong>dapter.com<br />

5

Service and Support<br />

Research and Development<br />

To meet the needs of a fast chang<strong>in</strong>g world L<strong>in</strong>dapter’s Research and<br />

Development Department works to develop new generic products.<br />

The team is supported by the latest computer aided design (CAD)<br />

techniques such as 3D modell<strong>in</strong>g, rapid prototyp<strong>in</strong>g and f<strong>in</strong>ite element<br />

analysis; new products are tested <strong>in</strong> house on L<strong>in</strong>dapter’s own 1,000kN<br />

hydraulic test mach<strong>in</strong>e.<br />

This unique technical expertise is supported by L<strong>in</strong>dapter’s collaboration<br />

with respected companies and organisations such as Corus, Mannesmann,<br />

The Steel Construction Institute, CIDECT as well as many lead<strong>in</strong>g<br />

universities and approval bodies.<br />

Eng<strong>in</strong>eered Solutions<br />

Develop<strong>in</strong>g products that meet the needs of a particular project is<br />

another L<strong>in</strong>dapter strength.<br />

The service offered to clients <strong>in</strong>cludes:<br />

• Design and development of custom products for unique projects<br />

• Individual test runs and reports<br />

• Detailed draw<strong>in</strong>gs and/or solid models<br />

• Full strength and performance analysis<br />

• Trial runs and on site consultation<br />

Bespoke solution<br />

for sign fix<strong>in</strong>gs<br />

Customer <strong>Technical</strong> Support<br />

For our exist<strong>in</strong>g product range L<strong>in</strong>dapter’s <strong>Technical</strong> Sales and Support<br />

Department offers customers full support for any project, large or small;<br />

this free of charge service <strong>in</strong>cludes:<br />

• Assembly solutions optimised for cost and performance<br />

• Load analysis on L<strong>in</strong>dapter connections<br />

• 2D AutoCAD and 3D SolidWorks draw<strong>in</strong>gs<br />

• Bills of Materials<br />

• Coat<strong>in</strong>g and corrosion recommendations<br />

• On site technical advice and support<br />

• Contractor tra<strong>in</strong><strong>in</strong>g<br />

• CPD Presentations<br />

Sample Project<br />

Seedhill Bridge, Lancashire, England<br />

Bridge refurbishment:<br />

Due to the age and condition of the structure the use of welded shear<br />

studs was not possible. Instead modified Hollo-Bolts ® were used which<br />

enabled the bridge deck refurbishment to be completed on time and to<br />

specification.<br />

Special Hollo-Bolt ®<br />

For further <strong>in</strong>formation regard<strong>in</strong>g this project see website<br />

www.l<strong>in</strong>dapter.com.<br />

Standard Hollo-Bolt ®<br />

6<br />

Tel: +44 (0) 1274 521444 www.l<strong>in</strong>dapter.com

Quality and Approvals<br />

Quality<br />

Product quality is one of the ma<strong>in</strong> life l<strong>in</strong>es<br />

of the L<strong>in</strong>dapter philosophy, the entire<br />

company is particularly dedicated to this<br />

aspect. L<strong>in</strong>dapter has been accredited to<br />

BS EN ISO 9001 s<strong>in</strong>ce 1986.<br />

Approvals<br />

L<strong>in</strong>dapter has been trad<strong>in</strong>g <strong>in</strong>ternationally for many years respect<strong>in</strong>g<br />

the market differences around the world. The relevant <strong>in</strong>ternational<br />

authorities have granted many product approvals over time.<br />

The catalogue refers to them product by product.<br />

Approvals for construction<br />

The Deutsches Institut für Bautechnik, Berl<strong>in</strong> is a body<br />

which approves products and materials for use <strong>in</strong><br />

structural eng<strong>in</strong>eer<strong>in</strong>g applications <strong>in</strong> the construction<br />

and civil eng<strong>in</strong>eer<strong>in</strong>g <strong>in</strong>dustries <strong>in</strong> Germany.<br />

Lloyds Register Type Approved products have been<br />

subjected to tensile, frictional, shear, vibration and<br />

shock tests, witnessed and verified by Lloyds<br />

Register.<br />

The TÜV is the certify<strong>in</strong>g authority for safety,<br />

quality and environmental protection <strong>in</strong> Germany.<br />

Det Norske Veritas has approved the use of L<strong>in</strong>dapter<br />

products <strong>in</strong> lift<strong>in</strong>g applications. This <strong>in</strong>cludes their use<br />

on both mobile and fixed offshore <strong>in</strong>stallations.<br />

Q 05143<br />

Approvals for spr<strong>in</strong>kler products<br />

The American Insurance Association, Factory Mutual,<br />

offers an approval which is recognised by the fire<br />

protection <strong>in</strong>dustry world-wide.<br />

Verband der Schadenversicherer e.V. is a German<br />

<strong>in</strong>surance association who also offers a rigorous<br />

approval for products used <strong>in</strong> the fire protection<br />

<strong>in</strong>dustry.<br />

These approvals serve to re<strong>in</strong>force L<strong>in</strong>dapter’s extensive <strong>in</strong>-house<br />

test<strong>in</strong>g procedures. L<strong>in</strong>dapter products are tested so that the user can<br />

be confident whether specify<strong>in</strong>g or us<strong>in</strong>g that L<strong>in</strong>dapter products will<br />

perform as per the <strong>in</strong>formation detailed <strong>in</strong> this catalogue. Loads<br />

published are the product safe work<strong>in</strong>g loads, tak<strong>in</strong>g <strong>in</strong>to account a<br />

factor of safety.<br />

Corrosion Protection<br />

L<strong>in</strong>dapter products are delivered as standard either bright z<strong>in</strong>c plated<br />

or hot dip galvanised. Various other coat<strong>in</strong>gs and alternative materials<br />

are available upon request for most products <strong>in</strong>clud<strong>in</strong>g:<br />

• Sheradis<strong>in</strong>g<br />

• Mechanical galvanis<strong>in</strong>g<br />

• Plastic coat<strong>in</strong>g<br />

• Special pa<strong>in</strong>t coat<strong>in</strong>g<br />

• Delta seal<br />

• Delta tone<br />

• Sheraplex<br />

• Sta<strong>in</strong>less steel<br />

L<strong>in</strong>dapter is a member of the follow<strong>in</strong>g organisations:<br />

British Constructional<br />

<strong>Steelwork</strong> Association<br />

The Steel Construction<br />

Institute<br />

The Build<strong>in</strong>g Services Research<br />

and Information Association<br />

Tel: +44 (0) 1274 521444 www.l<strong>in</strong>dapter.com<br />

7

<strong>Steelwork</strong> Fix<strong>in</strong>gs 1<br />

<strong>Steelwork</strong> Fix<strong>in</strong>gs<br />

L<strong>in</strong>dapter <strong>Steelwork</strong> Fix<strong>in</strong>gs can be used <strong>in</strong> a wide<br />

variety of applications for connect<strong>in</strong>g together steel<br />

sections of whatever shape and size; uppermost <strong>in</strong><br />

this section is the Girder Clamp which, as with<br />

most L<strong>in</strong>dapter products, needs no on site drill<strong>in</strong>g<br />

or weld<strong>in</strong>g sav<strong>in</strong>g both time and money by reduc<strong>in</strong>g<br />

<strong>in</strong>stalled costs. Numerous world wide project<br />

successes have demonstrated that this is ideally<br />

suited for both new construction and refurbishment<br />

of exist<strong>in</strong>g structures.<br />

Advantages<br />

• Reduces design time<br />

• Guaranteed loads and approvals<br />

• No on-site drill<strong>in</strong>g or weld<strong>in</strong>g<br />

• ‘Hot Work<strong>in</strong>g’ not required<br />

• Less work at height<br />

• Only hand tools required to <strong>in</strong>stall<br />

• Site adjustable<br />

• Power not required<br />

• Ability to deconstruct and multi-cycle<br />

rather than demolish<br />

Markets <strong>in</strong>clude:<br />

• Plant Eng<strong>in</strong>eer<strong>in</strong>g<br />

• Chemical and Petro-chemical Industry<br />

• Materials Handl<strong>in</strong>g<br />

• Structural Eng<strong>in</strong>eer<strong>in</strong>g<br />

• Civil Eng<strong>in</strong>eer<strong>in</strong>g<br />

• Facades<br />

• Theatre Equipment<br />

• Transportation<br />

• Offshore<br />

Applications <strong>in</strong>clude:<br />

• Steel Constructions<br />

• Cranes<br />

• Lift<strong>in</strong>g Beams<br />

• Pipe Supports<br />

• Towers and Masts<br />

9

Girder Clamps <strong>Steelwork</strong> Fix<strong>in</strong>gs 1<br />

Components of a Girder Clamp<br />

1. Standard Grade 8 Hex Nut<br />

2. Standard Hardened Washer<br />

3. L<strong>in</strong>dapter Clamp<br />

Dependent on the application different clamps could be used i.e.<br />

Types A, B, BR, AF, LR, LS, D2 or D3.<br />

4. Pack<strong>in</strong>g Piece<br />

In comb<strong>in</strong>ation with the clamps mentioned above these parts<br />

<strong>in</strong>crease the tail length to enable the product to sit correctly on the<br />

beam.<br />

5. Location Plate (can be supplied if required)<br />

This is an essential part of the girder clamp assembly that enables<br />

all the components to be located <strong>in</strong> the correct position. The hole<br />

centres and plate thickness are calculated to suit the <strong>in</strong>dividual<br />

application.<br />

6. L<strong>in</strong>dapter Clamp<br />

This can be of a similar type as 3 (above), although certa<strong>in</strong> products<br />

are designed to specifically work together i.e. A + B.<br />

7. Standard Grade 8.8 Hex Bolt or Setscrew<br />

5<br />

1<br />

2<br />

3<br />

4<br />

Loads<br />

The table beneath shows tensile and frictional load capabilities for a<br />

standard four bolt Girder Clamp us<strong>in</strong>g 4 bolts and 8 clamps at a 90°<br />

crossover angle. L<strong>in</strong>dapter is only too pleased to carry out all design work<br />

for <strong>in</strong>dividual connections free of charge based on the follow<strong>in</strong>g details:<br />

• Load per connection<br />

• Size and type of both beams<br />

• Angle of crossover<br />

• Distance between beams<br />

• Incl<strong>in</strong>ation of beams<br />

6<br />

7<br />

Clamps Types A, B, BR, LR Type AF<br />

Bolt size M12 M16 M20 M24 M24 M24<br />

Bolt grade 8.8 8.8 8.8 8.8 8.8 10.9<br />

Tensile / for 4 bolts kN 23.2 29.2 59.0 78.8 160.0 250.0 1)<br />

Friction / for 4 bolts kN 1.4 3.0 6.0 9.0 60.0 2) 70.0 2)<br />

Torque Nm 69 147 285 491 800 1000<br />

1) Factor of safety 3.2:1<br />

2) Factor of safety 2:1<br />

All loads are based on actual test data hav<strong>in</strong>g a factor of safety for friction aga<strong>in</strong>st slip and for tensile aga<strong>in</strong>st ultimate failure<br />

(typically 5:1). Use of lower safety factor is not recommended.<br />

Approvals<br />

All approvals apply to Girder Clamps us<strong>in</strong>g types A and B only, <strong>in</strong> sizes from M12 to M24 Further <strong>in</strong>formation is available upon request.<br />

10<br />

Tel: +44 (0) 1274 521444 www.l<strong>in</strong>dapter.com

Bolt Length / Tail Length / Installation <strong>Steelwork</strong> Fix<strong>in</strong>gs 1<br />

Bolt length calculation for a<br />

standard L<strong>in</strong>dapter Girder Clamp,<br />

example shows Type A and B M20<br />

Tail length<br />

The different tail length can be identified by a code of dimples<br />

underneath the clamps.<br />

To calculate the bolt length all parts the bolt will go through have to<br />

be added up. The next longer standard bolt length should be used.<br />

0.5 · bolt Ø<br />

as bolt protrusion<br />

10<br />

One dimple:<br />

tail length short (s)<br />

Height of nut<br />

16<br />

+ Washer<br />

3<br />

+ T of top clamp<br />

+ Top section<br />

20<br />

12.5<br />

Two dimples:<br />

tail length medium (m)<br />

+ Plate thickness<br />

12<br />

+ Lower section<br />

10<br />

+ T of lower clamp<br />

10<br />

Three dimples:<br />

tail length long (l )<br />

=<br />

93.5<br />

Next standard<br />

bolt length<br />

=<br />

100.0<br />

Correct <strong>in</strong>stallation of types A and B<br />

show<strong>in</strong>g type A as an example<br />

Parallel flanges<br />

90º 90º<br />

Maximum tail length tolerance of -1mm (up to M16) and -1.5mm (M20, M24) before apply<strong>in</strong>g the torque is acceptable.<br />

Tapered flanges<br />

90º<br />

Type A <strong>Steelwork</strong> Fix<strong>in</strong>gs 1<br />

Type A<br />

Malleable iron, bright z<strong>in</strong>c plated / hot dip galvanised<br />

Nose<br />

Recess<br />

Clamp<strong>in</strong>g Area K<br />

Skirt<br />

Tail<br />

T<br />

V<br />

Y<br />

X<br />

Z<br />

Typical Applications<br />

(see also page 36-39)<br />

<strong>Steelwork</strong> clamp with recessed top to hold the bolt head captive whilst<br />

the nut is tightened. The skirt prevents the clamp rotat<strong>in</strong>g dur<strong>in</strong>g<br />

<strong>in</strong>stallation. Suitable for flanges up to 8°.<br />

The clamp is <strong>in</strong>stalled correctly when the area ‘K’ grips the flange.<br />

The tail must be chosen to suit the thickness of the flange be<strong>in</strong>g<br />

gripped. For correct tail length/pack<strong>in</strong>g comb<strong>in</strong>ations please see<br />

page 15.<br />

Safe Work<strong>in</strong>g Loads<br />

Dimensions<br />

Product Bolt 8.8 (5:1 Factor of Safety) Tail Length V<br />

Code Z Tensile / 1 Bolt Frictional / 2 Bolts Torque Y X short medium long T Width<br />

kN kN Nm mm mm mm mm mm mm mm<br />

A08 M8 1.0 - 6 16 8 - 4 - 4 20<br />

A10 M10 1.5 - 20 20 11 4 5 7 5 26<br />

A12 M12 5.8 0.7 69 26 13 4.5 6 9.5 6 29<br />

A16 M16 7.3 1.5 147 30 16 5.5 8 11 8 36<br />

A20 M20 14.7 3 285 36 19 7 10 12.5 10 46<br />

A24 M24 19.7 4.5 491 48 25 9 12 16 12 55<br />

For higher loads the type AF should be used (see page 16).<br />

Order example: A16 medium HDG<br />

12<br />

Tel: +44 (0) 1274 521444 www.l<strong>in</strong>dapter.com

Type B <strong>Steelwork</strong> Fix<strong>in</strong>gs 1<br />

Type B<br />

Malleable iron, bright z<strong>in</strong>c plated / hot dip galvanised<br />

Nose<br />

Flat Top<br />

Clamp<strong>in</strong>g<br />

Area K<br />

Skirt<br />

Tail<br />

Z<br />

T<br />

V<br />

Y<br />

X<br />

<strong>Steelwork</strong> clamp with flat top which allows the bolt head or<br />

nut to be rotated. Suitable for use with all bolts, studs, tie<br />

rods and J-bolts, and flanges up to 8°.<br />

The clamp is <strong>in</strong>stalled correctly when the area ‘K’ grips the<br />

flange. The tail must be chosen to suit the thickness of the<br />

flange be<strong>in</strong>g gripped. For correct tail length/pack<strong>in</strong>g<br />

comb<strong>in</strong>ations please see page 15.<br />

Typical Applications<br />

(see also page 36-39)<br />

Safe Work<strong>in</strong>g Loads<br />

Dimensions<br />

Product Bolt 8.8 (5:1 Factor of Safety) Tail Length V<br />

Code Z Tensile / 1 Bolt Frictional / 2 Bolts Torque Y X short medium long T Width<br />

kN kN Nm mm mm mm mm mm mm mm<br />

B08 M8 1.0 - 6 16 8 - 4 - 8 20<br />

B10 M10 1.5 - 20 20 11 4 5 7 10 26<br />

B12 M12 5.8 0.7 69 26 13 4.5 6 9.5 12 29<br />

B16 M16 7.3 1.5 147 30 16 5.5 8 11 16 36<br />

B20 M20 14.7 3 285 36 19 7 10 12.5 20 46<br />

B24 M24 19.7 4.5 491 48 25 9 12 16 24 55<br />

For higher loads the type AF should be used (see page 16).<br />

Order example: B16 medium HDG<br />

Tel: +44 (0) 1274 521444 www.l<strong>in</strong>dapter.com<br />

13

Accessories for Type A and B <strong>Steelwork</strong> Fix<strong>in</strong>gs 1<br />

Type CW - Clipped Washer<br />

Mild Steel, bright z<strong>in</strong>c plated /<br />

hot dip galvanised<br />

Pack<strong>in</strong>g used to adjust the tail length of the clamp to meet<br />

differ<strong>in</strong>g beam flange thicknesses.<br />

Y<br />

Z<br />

X<br />

T<br />

Product Bolt Dimensions<br />

Code Z Y X T Width<br />

mm mm mm mm<br />

CW08 M8 4 9,5 2 19<br />

CW10 M10 5 14 2 25<br />

CW12 M12 6 19.5 2.5 31<br />

CW16 M16 8 17.5 3 38<br />

CW20 M20 10 22 4 44<br />

CW24 M24 12 29 4 57<br />

Order example: CW08 BZP<br />

Type P1 short / P2 short<br />

Mild Steel, malleable iron,<br />

bright z<strong>in</strong>c plated / hot dip galvanised<br />

Pack<strong>in</strong>g used to adjust the tail length of the clamp to meet<br />

differ<strong>in</strong>g beam flange thicknesses.<br />

Y<br />

Z<br />

T P1<br />

T P2<br />

X<br />

Product Bolt Dimensions<br />

Code Z Y X T P1 T P2 Width<br />

P1 P2 mm mm mm mm mm<br />

P1S08 P2S08 M8 4 10 4 8 21<br />

P1S10 P2S10 M10 5 13 5 10 24<br />

P1S12 P2S12 M12 6 16 6 12 30<br />

P1S16 P2S16 M16 8 21 8 16 35<br />

P1S20 P2S20 M20 10 23 10 20 43<br />

P1S24 P2S24 M24 12 32 12 24 54<br />

Order example: P1S16 HDG<br />

Type T<br />

Malleable iron, bright z<strong>in</strong>c plated /<br />

hot dip galvanised<br />

To fill the nose of type A and B mak<strong>in</strong>g it horizontal. For parallel flanges<br />

only. The thickness ‘T’ should be added for tail length and bolt length<br />

calculations. The product is for aesthetic purposes only and technically<br />

not necessary.<br />

Type W<br />

Mild Steel, malleable iron, bright z<strong>in</strong>c plated /<br />

hot dip galvanised<br />

Washer to fill the recess of type A to enable the nut to be tightened.<br />

When calculat<strong>in</strong>g the bolt length please add ‘T’.<br />

Z<br />

Z<br />

T<br />

T<br />

Product Bolt Dimensions<br />

Code Z T<br />

mm<br />

T12 M12 3<br />

T16 M16 4<br />

T20 M20 5<br />

T24 M24 6.5<br />

Order example: T12 BZP<br />

Product Bolt Dimensions<br />

Code Z T<br />

mm<br />

W08 M8 4<br />

W10 M10 5.5<br />

W12 M12 6.5<br />

W16 M16 8<br />

W20 M20 9.5<br />

Order example: W08 BZP<br />

14<br />

Tel: +44 (0) 1274 521444 www.l<strong>in</strong>dapter.com

Plate and Pack<strong>in</strong>g Details for Type A and B <strong>Steelwork</strong> Fix<strong>in</strong>gs 1<br />

Location and End Plates<br />

L 1<br />

L 1<br />

l 1M<br />

l 1M<br />

b 1 b 1<br />

L 1 =<br />

L 2 =<br />

l 1M , l 2M =<br />

b 1 , b 2 =<br />

d =<br />

s =<br />

Plate length<br />

Plate width<br />

Hole centres<br />

Flange width<br />

Hole Ø<br />

Plate thickness<br />

d<br />

b 2<br />

l 2M<br />

L 2<br />

l2M<br />

d<br />

L2<br />

Location Plate<br />

Plate Dimensions<br />

Material: Mild Steel Grade S275 JR (for other grades please contact L<strong>in</strong>dapter)<br />

End Plate<br />

Location Plate End Plate 1)<br />

Plate<br />

Plate<br />

Bolt Hole Ø Thickness Hole Centres Length/Width Thickness Hole Centre Length Hole Centre Width<br />

Z d s l 1M , l 2M m<strong>in</strong> L 1 , m<strong>in</strong> L 2 s l 1M m<strong>in</strong> L 1 m<strong>in</strong> l 2M m<strong>in</strong> L 2<br />

mm mm mm mm mm mm mm mm mm<br />

M8 9 6 b + 9 b + 36 10 b 1 + 9 b 1 + 36 40 l 2M + 40<br />

M10 11 8 b + 11 b + 44 12 b 1 + 11 b 1 + 44 50 l 2M + 40<br />

M12 13 8 b + 13 b + 54 12 b 1 + 13 b 1 + 54 60 l 2M + 50<br />

M16 18 10 b + 18 b + 70 15 b 1 + 18 b 1 + 70 70 l 2M + 60<br />

M20 22 12 b + 22 b + 88 20 b 1 + 22 b 1 + 88 90 l 2M + 70<br />

M24 26 15 b + 26 b + 104 25 b 1 + 26 b 1 + 104 110 l 2M + 90<br />

1) Dependant on the use of the end plate the thickness might need to be <strong>in</strong>creased.<br />

Calculation of bolt length see page 11<br />

Tail Length / Pack<strong>in</strong>g Comb<strong>in</strong>ations<br />

for Types A & B<br />

For beams up to and <strong>in</strong>clud<strong>in</strong>g 5° slope<br />

Flange<br />

Types A & B<br />

Thickness M12 M16 M20 M24<br />

mm A,B CW P1S P2S A,B CW P1S P2S A,B CW P1S P2S A,B CW P1S P2S<br />

5 s - - - s - - - - - - - - -<br />

6 m - - - s - - - - - - - - -<br />

7 s 1 - - m - - - s - - - - - -<br />

8 s 1 - - m - - - s - - - - - -<br />

9 m 1 - - s 1 - - m - - - s - - -<br />

10 l - - - l - - - m - - - s - - -<br />

11 m 2 - - l - - - s 1 - - m - - -<br />

12 l 1 - - s 2 - - s 1 - - m - - -<br />

1 3 s 1 1 - l - - - ss - 1 1 - - -<br />

14 s 1 1 - l 1 - - m 1 - - s 1 - -<br />

15 l 2 - - s 3 - - s 2 - - l - - -<br />

16 l - 1 - m - 1 - s 2 - - l - - -<br />

17 m 2 1 - l 2 - - s - 1 - s 2 - -<br />

18 m - - 1 l 2 - - m 2 - - s 2 - -<br />

1 9 s 1 - 1 l - 1 - s 3 - - l 1 - -<br />

2 0 s 1 - 1 l 3 - - m - 1 - l 1 - -<br />

2 1 m 1 - 1 l 3 - - s 1 1 - s - 1 -<br />

22 l - - 1 l 1 1 - m 3 - - s - 1 -<br />

23 s - 1 1 l 1 1 - l - 1 - m - 1 -<br />

Tail Length / Pack<strong>in</strong>g Comb<strong>in</strong>ations<br />

for Types A & B<br />

For IPN-Beams of an 8° slope<br />

Types A & B<br />

IPN M12 M16 M20 M24<br />

Profile A,B CW P1S P2S A,B CW P1S P2S A,B CW P1S P2S A,B CW P1S P2S<br />

80 - - - - - - - - - - - -<br />

100 - - - - - - - - - - - -<br />

120 s - - - - - - - - - - - -<br />

140 s - - - - - - - - - - - -<br />

1 6 0 m - - - s - - - - - -<br />

1 8 0 m - - - s - - - - - -<br />

200 s 1 - - - - - - - - - - -<br />

220 s 1 - - - - - - - - - - -<br />

2 4 0 m 1 - - m - - - s - - -<br />

2 6 0 m 1 - - m - - - s - - -<br />

280 l - - - - - - - - - s - - -<br />

300 s - 1 - - - - m - - - s - - -<br />

320 m 2 - - l - - - m - - - s - - -<br />

340 l 1 - - l - - - s 1 - - - - -<br />

360 s 1 1 - - - - l - - - m - - -<br />

380 m 3 - - s - 1 - l - - - m - - -<br />

400 l 2 - - l 1 - - - - - s 1 - -<br />

425 - - - m - 1 - - - - - - -<br />

450 - - - m - 1 - - - - - - -<br />

475 - - - - - - - - - l - - -<br />

500 - - - - - - - - - l - - -<br />

550 - - - - - - - - - - - -<br />

600 - - - - - - - - - - - -<br />

2 4 m - 1 1 m - - 1 m 1 1 - m - 1 -<br />

2 5 s 1 1 1 l 2 1 - s 2 1 - s 1 1 -<br />

2 6 s 1 1 1 l 2 1 - s 2 1 - s 1 1 -<br />

28 l - 1 1 s 2 - 1 m 2 1 - l - 1 -<br />

30 m - - 2 l 1 - 1 m - - 1 s 2 1 -<br />

For thicker flanges please contact L<strong>in</strong>dapter.<br />

s = short m = medium l = long P1S = P1 short P2S = P2 short = Type not applicable = Please contact L<strong>in</strong>dapter<br />

Tel: +44 (0) 1274 521444 www.l<strong>in</strong>dapter.com<br />

15

Type AF <strong>Steelwork</strong> Fix<strong>in</strong>gs 1<br />

Type AF<br />

SG iron, hot dip galvanised<br />

Without washer: For bolt grade 8.8<br />

Recess<br />

Nose<br />

Skirt<br />

Tail<br />

With washer Type AFW<br />

Flat Top<br />

T<br />

V<br />

Y<br />

X<br />

With washer <strong>in</strong>verted Type AFW<br />

for bolt grade 10.9 with larger hexagons<br />

(M12 - M20)<br />

Z<br />

Typical Applications<br />

(see also page 36-39)<br />

High friction clamp with recessed top to hold bolt head captive whilst<br />

the nut is tightened. Can be comb<strong>in</strong>ed with type CF. The skirt prevents<br />

the clamp rotat<strong>in</strong>g dur<strong>in</strong>g <strong>in</strong>stallation. The tail of the AF spans across<br />

slotted holes. For flanges up to 10°. Washer type AFW available<br />

(see illustration).<br />

For correct tail length/pack<strong>in</strong>g comb<strong>in</strong>ations please see page 18.<br />

Safe Work<strong>in</strong>g Loads<br />

(5:1) Factor of Safety (2:1) Dimensions<br />

Product Bolt Tensile / 1 Bolt Frictional 1) / 2 Bolts Tail Length V T<br />

Code Z Grade Pa<strong>in</strong>ted <strong>Steelwork</strong> 2) Galv. <strong>Steelwork</strong> Torque Y X short medium Type AF Type AF with AFW Width<br />

kN kN kN Nm mm mm mm mm mm mm mm<br />

AF12 M12 8.8 8.5 3.4 3.9 90 29 27 5 12.5 17 22 39<br />

AF16 M16 8.8 16.0 8.0 10.0 240 35 37 8 15 22 27 49<br />

AF20 M20 8.8 26.3 13.0 16.0 470 40 39 10 18 25 31 56<br />

AF24 M24 8.8 40.0 24.0 30.0 800 48 60 15 30 32 42 82<br />

AF12 M12 10.9 4) 10.0 4.0 5.2 130 29 27 5 12.5 17 22 39<br />

AF16 M16 10.9 4) 19.5 11.0 12.0 300 35 37 8 15 22 27 49<br />

AF20 M20 10.9 4) 30.0 20.0 25.0 647 40 39 10 18 25 31 56<br />

AF24 M24 10.9 4) 62.5 3) 28.0 35.0 1000 48 60 15 30 32 42 82<br />

1) Frictional Load figures are based on Type AF and Location plates <strong>in</strong> hot dip galvanised f<strong>in</strong>ish<br />

2) Shot blast and pa<strong>in</strong>ted steelwork<br />

3) 3.2:1 factor of safety<br />

4) For HR or HV bolts (hot dip galvanised and lubricated) please refer to manufacturers’ recommendation for torque figures.<br />

Order example: AF12 short<br />

16<br />

Tel: +44 (0) 1274 521444 www.l<strong>in</strong>dapter.com

Type CF <strong>Steelwork</strong> Fix<strong>in</strong>gs 1<br />

Type CF<br />

SG iron, hot dip galvanised<br />

Nose<br />

Anti-rotation mark<strong>in</strong>gs<br />

Legs<br />

Y<br />

X<br />

Y<br />

X<br />

m<strong>in</strong> T<br />

max T<br />

V<br />

m<strong>in</strong> t<br />

Z<br />

max t<br />

Z<br />

Typical Applications<br />

(see also page 36-39)<br />

High friction clamp which hooks over flanges of I-beams, angles and<br />

channels. L<strong>in</strong>dapter mark<strong>in</strong>gs act as a unique anti-rotation device.<br />

Can be comb<strong>in</strong>ed with all L<strong>in</strong>dapter Girder Clamp products <strong>in</strong>clud<strong>in</strong>g<br />

type AF.<br />

Safe Work<strong>in</strong>g Loads<br />

(5:1) factor of safety (2:1)<br />

Product Bolt 8.8 Tensile / 1 Bolt Frictional 1) / 2 Bolts Dimensions<br />

Code Z Pa<strong>in</strong>ted <strong>Steelwork</strong> 2) Galv. <strong>Steelwork</strong> Torque Y X t T V Width<br />

kN kN kN Nm mm mm mm mm mm mm<br />

CF12 M12 8.5 3.4 3.9 90 32 14 6 - 13 21 - 29 25 46<br />

CF16 M16 16.0 8.0 10.0 240 44 18 8 - 16 25 - 33 32 56<br />

CF20 M20 26.3 13.0 16.0 470 53 22 10 - 19 30 - 41 45 65<br />

CF Comb<strong>in</strong>ations with other L<strong>in</strong>dapter Clamps<br />

kN kN kN Nm<br />

CF / A 3) M12 5.8 0.7 0.7 69<br />

CF / A 3) M16 7.3 1.5 1.7 147<br />

CF / A 3) M20 14.7 3 3.0 285<br />

CF / AF M12 8.5 3.4 3.9 90<br />

CF / AF M16 16.0 8.0 10.0 240<br />

CF / AF M20 26.3 13.0 16.0 470<br />

Order example: CF12<br />

1) Frictional load figures are based on type CF and location plate <strong>in</strong> HDG f<strong>in</strong>ish<br />

2) Shot blast and pa<strong>in</strong>ted steelwork<br />

3) Also applies to type B, BR, LR, D2 or D3<br />

Tel: +44 (0) 1274 521444 www.l<strong>in</strong>dapter.com<br />

17

Accessories for Type AF <strong>Steelwork</strong> Fix<strong>in</strong>gs 1<br />

Type AFCW<br />

Mild Steel, hot dip galvanised<br />

Product Bolt Dimensions<br />

Code Z Y X T Width<br />

mm mm mm mm<br />

AF12CW M12 7 33 2 40<br />

T<br />

AF16CW M16 8 40 2 50<br />

Y<br />

X<br />

AF20CW M20 9.5 40.5 2 55<br />

Pack<strong>in</strong>g used to adjust the tail length of<br />

the clamp to meet differ<strong>in</strong>g beam flange<br />

thicknesses; has a slight bend along its<br />

centre l<strong>in</strong>e which flattens out dur<strong>in</strong>g<br />

<strong>in</strong>stallation.<br />

Z<br />

Order example: AF12CW<br />

Type AFP1 / AFP2<br />

Mild Steel, hot dip galvanised<br />

Product Bolt Dimensions<br />

Y<br />

X<br />

T<br />

Code Z Y X T P1 T P2 Width<br />

P1 P2 mm mm mm mm mm<br />

AF12P1 AF12P2 M12 7 33 5 10 40<br />

AF16P1 AF16P2 M16 8 42 5 10 52<br />

Z<br />

AF20P1 AF20P2 M20 9.5 45.5 5 10 56<br />

AF24P1 AF24P2 M24 12 73 5 10 85<br />

Pack<strong>in</strong>g used to adjust the tail<br />

length of the clamp to meet<br />

differ<strong>in</strong>g beam flange thicknesses.<br />

Order example: AF12P1<br />

Type AFW<br />

SG iron, malleable iron, hot dip galvanised<br />

Z<br />

T<br />

Product Bolt Dimensions<br />

Code Z T<br />

mm<br />

AFW12 M12 5<br />

AFW16 M16 5<br />

AFW20 M20 6<br />

AFW24 M24 10<br />

Washer fill<strong>in</strong>g the recess of the type AF.<br />

Additionally it features two projections<br />

which, when the AFW is <strong>in</strong>verted, will<br />

captivate the larger hexagons of 10.9<br />

bolts. (M12 – M20 only).<br />

T<br />

Order example: AFW12<br />

M24 version has no projections.<br />

Z<br />

18<br />

Tel: +44 (0) 1274 521444 www.l<strong>in</strong>dapter.com

Plate and Pack<strong>in</strong>g Details for Type AF and CF <strong>Steelwork</strong> Fix<strong>in</strong>gs 1<br />

Location and End Plates<br />

L 1<br />

L 1<br />

l 1M<br />

l 1M<br />

b 1 b 1<br />

L 1 =<br />

L 2 =<br />

l 1M , l 2M =<br />

b 1 , b 2 =<br />

d =<br />

s =<br />

Plate length<br />

Plate width<br />

Hole centres<br />

Flange width<br />

Hole Ø<br />

Plate thickness<br />

d<br />

b 2<br />

l 2M<br />

L 2 l2M L 2<br />

d<br />

Location Plate<br />

End Plate<br />

Plate Dimensions<br />

Material: Mild Steel Grade S355 JR (for other grades please contact L<strong>in</strong>dapter)<br />

Plate<br />

Location Plate End Plate 1)<br />

Bolt Hole Ø Thickness Hole Centres Length/Width Thickness Hole Centre Length Hole Centre Width<br />

Z d s l 1M , l 2M m<strong>in</strong> L 1 , m<strong>in</strong> L 2 s l 1M m<strong>in</strong> L 1 m<strong>in</strong> l 2M m<strong>in</strong> L 2<br />

mm mm mm mm mm mm mm mm mm<br />

M12 13 10 b + 13 b + 90 15 b 1 + 13 b 1 + 90 80 l 2M + 80<br />

M16 18 15 b + 18 b + 110 25 b 1 + 18 b 1 + 110 100 l 2M + 100<br />

M20 22 20 b + 22 b + 130 30 b 1 + 22 b 1 + 130 180 l 2M + 180<br />

M24 26 25 b + 26 b + 180 40 b 1 + 26 b 1 + 180 200 l 2M + 200<br />

1) Dependant on the use of the end plate the thickness might need to be <strong>in</strong>creased.<br />

2) For comb<strong>in</strong>ations of Type CF with A, B and BR see page 15 and for types D2, D3 and LR see page 23.<br />

Plate<br />

Calculation of bolt length see page 11<br />

Tail Length / Pack<strong>in</strong>g Comb<strong>in</strong>ations for Types AF<br />

Parallel flanges and beams of up to 10º slope<br />

Flange<br />

Type AF<br />

Thickness M12 M16 M20 M24<br />

mm AF AFCW AFP1 AFP2 AF AFCW AFP1 AFP2 AF AFCW AFP1 AFP2 AF AFP1 AFP2<br />

Flange<br />

Type AF<br />

Thickness M12 M16 M20 M24<br />

mm AF AFCW AFP1 AFP2 AF AFCW AFP1 AFP2 AF AFCW AFP1 AFP2 AF AFP1 AFP2<br />

5 s - - - - - - - - - - - 2 8 m - 1 1 s - - 2 m - - 1<br />

6 s - - - - - - - - - - - 2 9 m 1 1 1 m - 1 1 m - - 1 m - -<br />

7 s 1 - - s - - - - - - - - 3 0 s - 1 2 m - 1 1 m 1 - 1 m - -<br />

8 s 1 - - s - - - - - - - - 3 1 s - 1 2 m - 1 1 m 1 - 1 m -<br />

9 s 2 - - s - - - s - - - - - 3 2 m - - 2 m 1 1 1 m - 1 1 m 1<br />

1 0 s - 1 - s 1 - - s - - - 3 3 m- - - 2 m 1 1 1 m - 1 1 m 1<br />

1 1 s 3 - - s 1 - - s - - - 3 4 m- -1 - 2 m - - 2 m - 1 1 m 1 -<br />

1 2 s 1 1 - s 2 - - s 1 - - 3s 5- -s - - 3 m - - 2 s - 1 2 m 1 -<br />

1 3 m - - - s - 1 - s 1 - - s -3 -6 s - - 3 m - - 2 m 1 1 1 m 1 -<br />

1 4 m 1 - - s 3 - - s 2 - - s 3- 7-<br />

m - 1 2 m 1 - 2 m - - 2 m 1 -<br />

1 5 s - - 1 m - - - s - 1 - s - - 3 8 m - 1 2 s - - 3 m - - 2<br />

1 6 m 2 - - m - - - s 3 - - s - 3-<br />

9 m 1 1 2 m - 1 2 m - - 2 m -<br />

1 7 m - 1 - m 1 - - m - - - s - - 4 0 s - 1 3 m - 1 2 m 1 - 2 m - 1<br />

1 8 m - 1 - s - - 1 m - - - s 1 - 4 1 s - 1 3 m - 1 2 m 1 - 2 m - 1<br />

1 9 m 1 1 - m - 1 - m - - - s 1 - 4 2 m - - 3 m 1 1 2 m - 1 2 m - 1<br />

20 s - 1 1 m - 1 - m 1 - - s 1 - 4 3 m - - 3 s - 1 3 m - 1 2 m 1 1<br />

2 1 m 2 1 - m - 1 - m 1 - - s 1 - 4 4 m 1 - 3 m - - 3 m - 1 2 m 1 1<br />

2 2 m 2 1 - m 1 1 - m 2 - 4 5 s- - - s4 1 m --<br />

- 3 m 1 1 2 m 1 1<br />

2 3 m - - 1 m 1 1 - m - 1 - 4 6 s - -1<br />

4 m - - 3 m 1 1 2 m 1 1<br />

2 4 m 1 - 1 m - - 1 m 1 1 - 4 7 ms - 1 - 3 m1<br />

1 - 3 m - - 3 m 1 1<br />

2 5 s - - 2 m - - 1 m 1 1 - s - 1 4 8 m - 1 3 s - - 4 m - - 3<br />

26 m 2 - 1 m - - 1 s 1 1 1 s - 1 4 9 s - 1 4 m - 1 3 m - - 3 m -<br />

2 7 m 2 - 1 m 1 - 1 s 1 1 51 0 sm - - 1 -4 m - 1 3 m 1 - 3 m - 2<br />

s = short m = medium = Type not applicable<br />

Tel: +44 (0) 1274 521444 www.l<strong>in</strong>dapter.com<br />

19

Type LR <strong>Steelwork</strong> Fix<strong>in</strong>gs 1<br />

Type LR<br />

Malleable iron, bright z<strong>in</strong>c plated / hot dip galvanised<br />

Nose<br />

Saddle<br />

Slot<br />

Leg<br />

Clip<br />

Tail<br />

max Y<br />

m<strong>in</strong> X<br />

max T<br />

m<strong>in</strong> V<br />

Z<br />

m<strong>in</strong> Y<br />

max X<br />

m<strong>in</strong> T<br />

Typical Applications<br />

(see also page 36-39)<br />

max V<br />

Self adjust<strong>in</strong>g clamp for various flange thicknesses and slopes up<br />

to 15°. The leg of the saddle prevents the clamp rotat<strong>in</strong>g dur<strong>in</strong>g<br />

<strong>in</strong>stallation. The LR tail spans slotted holes. For thicker flanges<br />

pack<strong>in</strong>gs P1 long and P2 long are available. For correct tail<br />

length/pack<strong>in</strong>g comb<strong>in</strong>ations please see page 23.<br />

Z<br />

Safe Work<strong>in</strong>g Loads<br />

Product Bolt 8.8 (5:1 Factor of Safety) Clamp<strong>in</strong>g Range Dimensions<br />

Code Z Tensile / 1 Bolt Frictional / 2 Bolts Torque V Y X T Width with Saddle<br />

kN kN Nm mm mm mm mm mm<br />

LR10 M10 1.5 - 20 3 - 10 21 - 24 24 - 26 21 - 24 33<br />

LR12 M12 5.8 0.7 69 3 - 12 26 - 29 25 - 31 25 - 29 39<br />

LR16 M16 7.3 1.5 147 3 - 16 30 - 35 34 - 37 30 - 36 46<br />

LR20 M20 14.7 3 285 3 - 20 42 - 49 46 - 51 41 - 48 57<br />

LR24 M24 19.7 4.5 491 3 - 24 47 - 57 52 - 58 44 - 54 76<br />

Order example: LR10 BZP<br />

20<br />

Tel: +44 (0) 1274 521444 www.l<strong>in</strong>dapter.com

Type D2 / Type D3 <strong>Steelwork</strong> Fix<strong>in</strong>gs 1<br />

Type D2<br />

Malleable iron, bright z<strong>in</strong>c plated,<br />

hot dip galvanised<br />

S<br />

Nose<br />

Recess<br />

T<br />

Clamp<strong>in</strong>g<br />

Area K<br />

Setscrew<br />

Tail<br />

Y<br />

X<br />

V<br />

Skirt<br />

Z<br />

Type D3<br />

Malleable iron, bright z<strong>in</strong>c plated,<br />

hot dip galvanised<br />

Flat Top<br />

Z<br />

S<br />

T<br />

V<br />

Y<br />

X<br />

Adjustable clamps <strong>in</strong>corporate a setscrew to accommodate a wide<br />

range of flange thicknesses. Type D2 has a recessed head to hold the<br />

bolt head captive. The skirt prevents the clamp rotat<strong>in</strong>g dur<strong>in</strong>g<br />

<strong>in</strong>stallation. For flanges up to 5°. For thicker flanges pack<strong>in</strong>gs P1 long<br />

and P2 long are available. For correct tail length/pack<strong>in</strong>g comb<strong>in</strong>ations<br />

please see page 23.<br />

Typical Applications<br />

(see also page 36-39)<br />

Correct Installation: Setscrew S needs to be adjusted so that V is<br />

1mm shorter than the flange thickness prior to <strong>in</strong>stallation. Adjust the<br />

setscrew after <strong>in</strong>stallation so that the bolt Z is 90° to the clamp and the<br />

clamp contacts the flange with area ‘K’ only.<br />

Safe Work<strong>in</strong>g Loads<br />

Product Bolt 8.8 (5:1 Factor of Safety) Clamp<strong>in</strong>g Range Dimensions<br />

Code Z Tensile / 1 Bolt Frictional / 2 Bolts Torque V 1) V 2) Y X S T Width<br />

kN kN Nm mm mm mm mm mm mm mm<br />

D210 M10 1.5 - 20 5 - 10 10 - 20 20 20 M6 5 26<br />

D212 M12 5.8 0.7 69 5 - 10 10 - 22 26 25 M6 6 29<br />

D216 M16 7.3 1.5 147 6.5 - 13 13 - 20 30 30 M8 8 35<br />

D220 M20 14.7 3 285 8.5 - 17 17 - 24 36 35 M10 10 42<br />

D224 M24 19.7 4.5 491 10 - 19 19 - 30 48 49 M12 12 54<br />

D312 M12 5.8 0.7 69 5 - 10 10 - 22 26 25 M6 12 29<br />

D316 M16 7.3 1.5 147 6.5 - 13 13 - 20 30 30 M8 16 35<br />

1) Setscrew S <strong>in</strong>serted from above.<br />

2) Setscrew S <strong>in</strong>serted from below.<br />

Order example: D210 BZP<br />

Tel: +44 (0) 1274 521444 www.l<strong>in</strong>dapter.com<br />

21

Accessories for Type LR, D2 and D3 <strong>Steelwork</strong> Fix<strong>in</strong>gs 1<br />

Type P1 long / P2 long<br />

Mild Steel, malleable iron, bright z<strong>in</strong>c plated / hot dip galvanised<br />

Product Bolt Dimensions<br />

Code Z Y X T P1 T P2 Width<br />

P1 P2 mm mm mm mm mm<br />

P1L10 P2L10 M10 5 24 5 10 24<br />

Y<br />

X<br />

T P1<br />

T P2<br />

P1L12 P2L12 M12 6 32 6 12 30<br />

P1L16 P2L16 M16 8 40 8 16 35<br />

P1L20 P2L20 M20 10 47 10 20 43<br />

Z<br />

P1L24 P2L24 M24 12 64 12 24 54<br />

Pack<strong>in</strong>g used to adjust the tail length of<br />

the clamp to meet differ<strong>in</strong>g beam flange<br />

thicknesses.<br />

Order example: P1L10 BZP<br />

Type T<br />

Malleable iron, bright z<strong>in</strong>c plated /<br />

hot dip galvanised<br />

T<br />

Product Bolt Dimensions<br />

Code Z T<br />

mm<br />

T12 M12 3<br />

T16 M16 4<br />

Z<br />

T20 M20 5<br />

To fill the nose of type D2 and D3 mak<strong>in</strong>g it<br />

horizontal. For parallel flanges only.<br />

The thickness ‘T’ should be added for tail<br />

length and bolt length calculations. The product<br />

is for aesthetic purposes only and technically<br />

not necessary.<br />

T24 M24 6.5<br />

Order example: T12 BZP<br />

Type W<br />

Mild Steel, bright z<strong>in</strong>c plated /<br />

hot dip galvanised<br />

Product Bolt Dimensions<br />

T<br />

Code Z T<br />

mm<br />

W08 M8 4<br />

W10 M10 5.5<br />

W12 M12 6.5<br />

W16 M16 8<br />

W20 M20 9.5<br />

Washer to fill the recess of type D2 to<br />

enable the nut to be tightened. When<br />

calculat<strong>in</strong>g the bolt length please add ‘T’.<br />

Z<br />

Order example: W08 BZP<br />

22<br />

Tel: +44 (0) 1274 521444 www.l<strong>in</strong>dapter.com

Plate and Pack<strong>in</strong>g Details for Type LR, D2 and D3 <strong>Steelwork</strong> Fix<strong>in</strong>gs 1<br />

Location and End Plates<br />

L 1<br />

L 1<br />

l 1M<br />

l 1M<br />

b 1 b 1<br />

L 1 =<br />

L 2 =<br />

l 1M , l 2M =<br />

b 1 , b 2 =<br />

d =<br />

s =<br />

Plate length<br />

Plate width<br />

Hole centres<br />

Flange width<br />

Hole Ø<br />

Plate thickness<br />

d<br />

b 2<br />

l 2M<br />

L 2<br />

l2M<br />

d<br />

L2<br />

Plate Dimensions<br />

Material: Mild Steel Grade S275 JR<br />

Location Plate<br />

End Plate<br />

Location Plate End Plate 1)<br />

Plate<br />

Plate<br />

Bolt Hole Ø Thickness Hole Centres Length/Width Thickness Hole Centre Length Hole Centre Width<br />

Z d s l 1M , l 2M m<strong>in</strong> L 1 , m<strong>in</strong> L 2 s l 1M m<strong>in</strong> L 1 m<strong>in</strong> l 2M m<strong>in</strong> L 2<br />

mm mm mm mm mm mm mm mm mm<br />

M10 11 12 b + 11 b + 66 15 b 1 + 11 b 1 + 66 70 l 2M + 50<br />

M12 13 12 b + 13 b + 81 15 b 1 + 13 b 1 + 81 80 l 2M + 60<br />

M16 18 15 b + 18 b + 105 20 b 1 + 18 b 1 + 105 100 l 2M + 70<br />

M20 22 20 b + 22 b + 132 25 b 1 + 22 b 1 + 132 120 l 2M + 90<br />

M24 26 25 b + 26 b + 156 30 b 1 + 26 b 1 + 156 150 l 2M + 110<br />

1) Dependant on the use of the end plate the thickness might need to be <strong>in</strong>creased.<br />

Calculation of bolt length see page 11<br />

Tail Length / Pack<strong>in</strong>g Comb<strong>in</strong>ations<br />

for Type LR<br />

Parallel flanges<br />

Tail Length / Pack<strong>in</strong>g Comb<strong>in</strong>ations<br />

for Type D2 & D3<br />

Parallel flanges and beams of up to 5° slope<br />

1 - 2 30 - 40 34 - 46 45 - 52 57 - 64 67 - 78<br />

1 1 2 35 - 45 40 - 52 53 - 60 67 - 74 79 - 90<br />

1 - 3 40 - 50 46 - 58 61 - 68 77 - 84 91 - 102<br />

1) Setscrew S <strong>in</strong>verted.<br />

Tel: +44 (0) 1274 521444 www.l<strong>in</strong>dapter.com<br />

Tail Length / Pack<strong>in</strong>g Comb<strong>in</strong>ations<br />

for Type LR<br />

For IPN-Beams of an 8° slope<br />

Type M 10 M 12 M 16 M 20 M 24<br />

IPN M10 M12 M16 M20 M24<br />

Comb<strong>in</strong>ations<br />

Clamp<strong>in</strong>g Range<br />

Profile LR P1L P2L LR P1L P2L LR P1L P2L LR P1L P2L LR P1L P2L<br />

L R P 1 L P 2 L m 80 m 1 - m - m - - m - - m m- - m - - m m<br />

1 - - 3 - 10 3 - 12 3 - 16 3 - 20 3 - 24<br />

100 1 - - 1 - - - - - - - -<br />

1 1 - 8 - 15 9 - 18 11 - 24 13 - 30 15 - 36<br />

120 1 - - 1 - - 1 - - - - - -<br />

140 1 - - 1 - - 1 - - - - - -<br />

1 - 1 13 - 20 15 - 24 19 - 32 23 - 40 27 - 48<br />

1 6 0 1 - - 1 - - 1 - - 1 - -<br />

1 1 1 18 - 25 21 - 30 27 - 40 33 - 50 39 - 60<br />

1 8 0 1 - - 1 - - 1 - - 1 - -<br />

1 - 2 23 - 30 27 - 36 35 - 48 43 - 60 51 - 72<br />

2 0 0 1 - - 1 - - 1 - - 1 - -<br />

1 1 2 28 - 35 33 - 42 43 - 56 53 - 70 63 - 84<br />

2 2 0 1 - - 1 - - 1 - - 1 - - 1 - -<br />

1 - 3 33 - 40 39 - 48 51 - 64 63 - 80 75 - 96<br />

2 4 0 1 1 - 1 - - 1 - - 1 - - 1 - -<br />

2 6 0 1 1 - 1 - - 1 - - 1 - - 1 - -<br />

2 8 0 1 1 - 1 1 - 1 - - 1 - - 1 - -<br />

3 0 0 1 1 - 1 1 - 1 - - 1 -<br />

3 2 0 1 1 - 1 1 - 1 - - 1 -<br />

3 4 0 1 1 - 1 1 - 1 - - 1 -<br />

3 6 0 1 - 1 1 1 - 1 1 - 1 -<br />

Type M 10 M 12 M 16 M 20 M 24<br />

3 8 0 1 - 1 1 1 - 1 1 - 1 -<br />

D2 D2 / D3 D2 / D3 D2 D2<br />

4 0 0 1 - 1 1 1 - 1 1 - 1 -<br />

Comb<strong>in</strong>ations<br />

Clamp<strong>in</strong>g Range<br />

4 2 5 1 - 1 1 - 1 1 1 - 1 1<br />

D P 1 L P 2 L m m 4 m 5 0 m1 - 1 m m m 1 m- 1 m1 1 - m 1 1<br />

1 1) - - 5 - 10 5 - 10 6.5 - 13 8.5 - 17 10 - 19<br />

4 7 5 1 1 1 1 - 1 1 1 - 1 1<br />

5 0 0 1 1 1 1 - 1 1 1 - 1 1<br />

1 - - 10 - 20 10 - 22 13 - 20 17 - 24 19 - 30<br />

5 5 0 1 1 1 1 1 1 1 - 1 1 1<br />

1 1 - 15 - 25 16 - 28 21 - 28 27 - 34 31 - 42<br />

600 - - 1 1 1 1 - 1 1 1 - 1 1 -<br />

1 - 1 20 - 30 22 - 34 29 - 36 37 - 44 43 - 54<br />

P1L = P1 long P2L = P2 long = Type not applicable<br />

1 1 1 25 - 35 28 - 40 37 - 44 47 - 54 55 - 66<br />

For thicker flanges please contact L<strong>in</strong>dapter.<br />

23

Type LS <strong>Steelwork</strong> Fix<strong>in</strong>gs 1<br />

Type LS<br />

Cast Sta<strong>in</strong>less Steel equivalent to Grade 316<br />

Nose<br />

Tail<br />

m<strong>in</strong> Y<br />

max X<br />

max T<br />

m<strong>in</strong> V<br />

Z<br />

max Y<br />

m<strong>in</strong> X<br />

m<strong>in</strong> T<br />

Typical Applications<br />

(see also page 36-39)<br />

max V<br />

Self adjust<strong>in</strong>g clamp for various flange thicknesses and slopes up to 10°.<br />

The special serrations on the tail prevent the clamp rotat<strong>in</strong>g dur<strong>in</strong>g<br />

<strong>in</strong>stallation. The LS tail spans over slotted holes.<br />

Z<br />

Safe Work<strong>in</strong>g Load<br />

Clamp<strong>in</strong>g<br />

Product Bolt A4-70 (5:1) Factor of Safety (2:1) Range Dimensions<br />

Code Z Tensile / 1 Bolt Frictional / 2 Bolts Torque V Y X T Width<br />

kN kN Nm mm mm mm mm mm<br />

LS10 M10 3.0 1.5 40 3 - 15 17 - 19 18 - 24 16 - 21 38<br />

LS12 M12 7.0 2.0 80 3 - 20 16 - 22 18 - 29 17 - 23 40<br />

LS16 M16 10.0 3.0 200 3 - 25 22 - 25 27 - 37 20 - 28 55<br />

LS20 M20 18.0 5.0 400 3 - 30 24 - 31 25 - 42 23 - 32 60<br />

Order example: LS10<br />

24<br />

Tel: +44 (0) 1274 521444 www.l<strong>in</strong>dapter.com

Accessories / Plate and Pack<strong>in</strong>g Details for Type LS <strong>Steelwork</strong> Fix<strong>in</strong>gs 1<br />

Accessories<br />

Pack<strong>in</strong>gs are available upon request.<br />

Location and End Plates<br />

L 1<br />

L 1<br />

l 1M<br />

l 1M<br />

b 1 b 1<br />

L 1 =<br />

L 2 =<br />

l 1M , l 2M =<br />

b 1 , b 2 =<br />

d =<br />

s =<br />

Plate length<br />

Plate width<br />

Hole centres<br />

Flange width<br />

Hole Ø<br />

Plate thickness<br />

d<br />

b 2<br />

l 2M<br />

L 2<br />

l2M<br />

d<br />

L2<br />

Location Plate<br />

End Plate<br />

Plate Dimensions<br />

Material: Mild Steel Grade S275 JR or S355 JR<br />

Location Plate End Plate 1)<br />

Plate Thickness<br />

Plate Thickness<br />

Bolt Hole Ø S275 S355 Hole Centres Length/Width S275 S355 Hole Centre Length Hole Centre Width<br />

Z d s s l 1M , l 2M m<strong>in</strong> L 1 , m<strong>in</strong> L 2 s s l 1M m<strong>in</strong> L 1 m<strong>in</strong> l 2M m<strong>in</strong> L 2<br />

mm mm mm mm mm mm mm mm mm mm mm<br />

M10 11 8 8 b + 11 b + 70 12 12 b + 11 b + 70 80 l 2M + 60<br />

M12 13 12 10 b + 13 b + 80 20 15 b + 13 b + 80 80 l 2M + 60<br />

M16 18 15 12 b + 18 b + 100 25 20 b + 18 b + 100 110 l 2M + 80<br />

M20 22 20 15 b + 22 b + 130 30 25 b + 22 b + 130 120 l 2M + 90<br />

1) Dependant on the use of the end plate the thickness might need to be <strong>in</strong>creased.<br />

Calculation of bolt length see page 11<br />

Tel: +44 (0) 1274 521444 www.l<strong>in</strong>dapter.com<br />

25

Type BR / Type RC <strong>Steelwork</strong> Fix<strong>in</strong>gs 1<br />

Type BR<br />

Malleable iron, bright z<strong>in</strong>c plated / hot dip galvanised<br />

Nose<br />

Flat Top<br />

Clamp<strong>in</strong>g<br />

Area K<br />

Skirt<br />

Z<br />

Tail<br />

T<br />

V<br />

Y<br />

X<br />

Versatile clamp for steel beams or rails. The skirt prevents the clamp<br />

rotat<strong>in</strong>g dur<strong>in</strong>g <strong>in</strong>stallation. The BR tail spans slotted holes.<br />

Suitable for flanges up to 8°.<br />

Safe Work<strong>in</strong>g Loads<br />

Dimensions<br />

Product Bolt 8.8 (5:1 Factor of Safety) Tail Length V<br />

Code Z Tensile / 1 Bolt Frictional / 2 Bolts Torque Y X short medium T Width<br />

kN kN Nm mm mm mm mm mm mm<br />

BR12 12 5.8 0.7 69 26 13 4 6 13 29<br />

BR16 16 7.3 1.5 147 30 16 6 8 16 35<br />

BR20 20 14.7 3 285 36 19 7 10 19 42<br />

BR24 24 19.7 4.5 491 48 25 9 12 25 54<br />

Order example: BR12 short HDG<br />

Type RC<br />

Forged steel, corrosion protection as required<br />

Nose<br />

Hole to suit<br />

M12-M24<br />

Skirt<br />

Tail<br />

Special clamp to secure rails<br />

or steel beams of 10mm or<br />

greater. Pack<strong>in</strong>gs are available<br />

for thicker flanges. The RC tail<br />

spans slotted holes.<br />

Suitable for flanges up to 5°.<br />

The product will be drilled to<br />

suit hole size and position<br />

requirements of the<br />

applications.<br />

X<br />

L<br />

W<br />

H<br />

V<br />

M<strong>in</strong>. Safe Work<strong>in</strong>g Load 1)<br />

Product Bolt 8.8 (5:1 Factor of Safety) Dimensions<br />

Code Z Tensile / 1 Bolt Torque Tail Length V X L H Width W<br />

kN Nm mm mm mm mm mm<br />

RCS12 M12 2.6 69 10 6.5 - 26.5 76 29 50<br />

RCS16 M16 4.0 147 10 9 - 24 76 29 50<br />

RCS20 M20 9.6 285 10 11 - 22 76 29 50<br />

RCS24 M24 12.3 491 10 13 - 20 76 29 50<br />

1) The safe work<strong>in</strong>g load depends on the position of the bolt hole. The greater dimension X the lower the load.<br />

Order example: RCS12 HDG with dimension X = ______ mm<br />

26<br />

Tel: +44 (0) 1274 521444 www.l<strong>in</strong>dapter.com

Accessories / Plate and Pack<strong>in</strong>g Details for Type BR <strong>Steelwork</strong> Fix<strong>in</strong>gs 1<br />

Type CW - Clipped Washer<br />

Mild Steel, bright z<strong>in</strong>c plated /<br />

hot dip galvanised<br />

Y<br />

X<br />

T<br />

Product Bolt Dimensions<br />

Code Z Y X T Width<br />

mm mm mm mm<br />

CW12 M12 6 19.5 2.5 31<br />

Z<br />

CW16 M16 8 17.5 3 38<br />

CW20 M20 10 22 4 44<br />

CW24 M24 12 29 4 57<br />

Pack<strong>in</strong>g used to adjust the tail length of the clamp to meet<br />

differ<strong>in</strong>g beam flange thicknesses.<br />

Order example: CW12 BZP<br />

Type P1 short / P2 short<br />

Mild Steel, malleable iron,<br />

bright z<strong>in</strong>c plated / hot dip galvanised<br />

Y<br />

Z<br />

T P1<br />

T P2<br />

X<br />

Product Bolt Dimensions<br />

Code Z Y X T P1 T P2 Width<br />

P1 P2 mm mm mm mm mm<br />

P1S12 P2S12 M12 6 16 6 12 30<br />

P1S16 P2S16 M16 8 21 8 16 35<br />

P1S20 P2S20 M20 10 23 10 20 43<br />

P1S24 P2S24 M24 12 32 12 24 54<br />

Pack<strong>in</strong>g used to adjust the tail length of the clamp to meet<br />

differ<strong>in</strong>g beam flange thicknesses.<br />

Order example: P1S12 BZP<br />

For Type BR please see the follow<strong>in</strong>g:<br />

• Location and End Plates, page 15<br />

• Calculation of bolt length, page 11<br />

• For beams with slopes of up to 8º please use the table for beams of up to 5º slope (see page 15).<br />

NB: The flange thickness refers to t 1 .<br />

Type BR is only available with tail length ‘short’ and ‘medium’.<br />

b<br />

h<br />

t 1<br />

Tel: +44 (0) 1274 521444 www.l<strong>in</strong>dapter.com<br />

27

90%).$!04%2 4%%,7/2+)8). 1<br />

'D;0 49/,;?0=<br />

Malleable iron, SG iron, corrosion protection as requested<br />

L<strong>in</strong>dapter-HD<br />

Plug<br />

Leg<br />

Skirt<br />

Nose<br />

L<strong>in</strong>dapter-HD Spr<strong>in</strong>g Clip<br />

Elastomer Spr<strong>in</strong>g<br />

The rail clamps Type L<strong>in</strong>dapter HD and L<strong>in</strong>dapter HD Spr<strong>in</strong>g facilitate<br />

precise alignment of the rails by allow<strong>in</strong>g a high degree of stepless lateral<br />

adjustability.<br />

<strong>Technical</strong> Data<br />

Suitable for all rails with tapered flanges and crane speeds of up to<br />

60m/m<strong>in</strong>. For wheel loads above 400kN or lateral loads higher than<br />

wheel loads please contact L<strong>in</strong>dapter.<br />

Product<br />

Code<br />

Clip<br />

Type<br />

Bolt 8.8<br />

Z<br />

Normal<br />

Lateral Conditions<br />

SWL* Torque<br />

kN Nm<br />

High<br />

Lateral Conditions<br />

SWL* Torque<br />

kN Nm<br />

Leg<br />

V<br />

mm<br />

Stud<br />

Length H<br />

mm<br />

Lateral Adjustm.<br />

max L<br />

mm<br />

Dimensions<br />

Plate Width<br />

m<strong>in</strong> A<br />

mm<br />

Distances<br />

2)<br />

X<br />

2)<br />

Y<br />

mm mm<br />

Width<br />

W<br />

mm<br />

HD20 H<br />

HD20 S<br />

HD20 SP<br />

HD20 S-P<br />

HD20 SP-P<br />

Hard<br />

Soft<br />

Spr<strong>in</strong>g<br />

Soft & Pad<br />

Spr<strong>in</strong>g & Pad<br />

M20<br />

M20<br />

M20<br />

M20<br />

M20<br />

22.5 185<br />

22.5 185<br />

22.5 185<br />

22.5 185<br />

22.5 185<br />

46 450<br />

46 450<br />

46 450<br />

46 450<br />

46 450<br />

F - 8<br />

F - 5<br />

F - 7<br />

F<br />

1)<br />

F - 2<br />

1)<br />

F + 38<br />

F + 40<br />

F + 40<br />

F + 45<br />

F + 45<br />

+ 11.5<br />

+ 11.5<br />

+ 11.5<br />

+ 11.5<br />

+ 11.5<br />

B + 137<br />

B + 137<br />

B + 137<br />

B + 137<br />

B + 137<br />

30 27<br />

30 27<br />

30 27<br />

30 27<br />

30 27<br />

74<br />

74<br />

74<br />

74<br />

74<br />

*<br />

HD24 H<br />

HD24 S<br />

HD24 SP<br />

HD24 S-P<br />

HD24 SP-P<br />

Hard<br />

Soft<br />

Spr<strong>in</strong>g<br />

Soft & Pad<br />

Spr<strong>in</strong>g & Pad<br />

M24<br />

M24<br />

M24<br />

M24<br />

M24<br />

40 320<br />

40 320<br />

40 320<br />

40 320<br />

40 320<br />

60 760<br />

60 760<br />

60 760<br />

60 760<br />

60 760<br />

F - 8<br />

F - 4<br />

F - 7<br />

F + 1<br />

F - 2<br />

1)<br />

1)<br />

F + 41<br />

F + 43<br />

F + 43<br />

F + 48<br />

F + 48<br />

+ 8<br />

+ 8<br />

+ 8<br />

+ 8<br />

+ 8<br />

B + 130<br />

B + 130<br />

B + 130<br />

B + 130<br />

B + 130<br />

30 27<br />

30 27<br />

30 27<br />

30 27<br />

30 27<br />

74<br />

74<br />

74<br />

74<br />

74<br />

NB: Leg length V for use with rail sections only with tapered base. For parallel sections please refer to L<strong>in</strong>dapter.<br />

Order example: HD20 H HDG for rail: ________<br />

28<br />

Tel: +44 (0) 1274 521444 www.l<strong>in</strong>dapter.com

90%).$!04%2 4%%,7/2+)8). 1<br />

49/,;?0=<br />

L<strong>in</strong>dapter-HD: Variation Hard Clip<br />

Leg length V should be selected to clamp rail down tightly and allow no<br />

vertical rail movement. Not to be used when the rail is supported by a<br />

resilient pad.<br />

H<br />

F<br />

V<br />

Y<br />

X<br />

B<br />

A<br />

L<strong>in</strong>dapter-HD: Variation Soft Clip<br />

Leg length V should be selected to allow vertical rail movement caused<br />

by rail wave, whilst hold<strong>in</strong>g the rail <strong>in</strong> precise alignment laterally. Rail<br />

ends need to be fixed.<br />

H<br />

F<br />

V<br />

Y<br />

X<br />

B<br />

A<br />

49/,;?0=&;=492<br />

The spr<strong>in</strong>g clip version <strong>in</strong>corporates an elastomer spr<strong>in</strong>g <strong>in</strong>to the nose<br />

of the product, designed to provide some vertical restra<strong>in</strong>t to the rail<br />

whilst still allow<strong>in</strong>g the rail to lift with rail wave.<br />

The elastomer spr<strong>in</strong>g is manufactured from high density synthetic<br />

polymer which has a Shore A hardness of 94.97. The spr<strong>in</strong>g is<br />

unaffected by salt water and most chemicals and has a high resistance<br />

to abrasion.<br />

H<br />

Y<br />

X<br />

F<br />

B<br />

A<br />

V<br />

Resilient Pad<br />

Both the spr<strong>in</strong>g and soft clips can be used with a resilient pad to<br />

decrease track runn<strong>in</strong>g noise /structural vibration, level out irregular<br />

contact between surface and rail and to spread wheel load evenly over<br />

a wider area.<br />

Resilient Pad<br />

The Resilient Pad is manufactured by:<br />

Both the spr<strong>in</strong>g and soft clips can be used with a resilient pad to<br />

decrease track runn<strong>in</strong>g noise /structural vibration, level out irregular<br />

contact between surface and rail and to spread wheel load evenly over<br />

a wider area.<br />

For further <strong>in</strong>formation on Fabreeka® rail pads, visit www.fabreeka.com.<br />

Resilient Pad<br />

V<br />

Installation<br />

1. Position clip on bolt or stud. Place<br />

the plug <strong>in</strong> 3 o’clock position and<br />

tighten the nut.<br />

2. Rotate the built <strong>in</strong> nut profile <strong>in</strong> a<br />

clockwise direction from the 3<br />

o’clock position to locate the clip<br />

aga<strong>in</strong>st the rail and laterally adjust<br />

the rail if required.<br />

3. Apply the recommended torque to<br />

the hexagon nut.<br />

W<br />

+L<br />

-L<br />

Tel: +44 (0) 1274 521444 www.l<strong>in</strong>dapter.com<br />

29

Type BSNT / Type BSLN <strong>Steelwork</strong> Fix<strong>in</strong>gs 1<br />

Type BSNT<br />

Malleable iron, bright z<strong>in</strong>c plated / hot dip galvanised<br />

Nose<br />

Flat Top<br />

Z<br />

T<br />

Y<br />

X<br />

Special clamp for <strong>in</strong>stallation of beams flange to flange. The location<br />

plate is substituted by a connect<strong>in</strong>g frame made of steel flats equall<strong>in</strong>g<br />

the flange thicknesses <strong>in</strong> height. The clamps are welded to this frame.<br />

Safe Work<strong>in</strong>g Loads<br />

Product Bolt 8.8 (5:1 Factor of Safety) Dimensions<br />

Code Z Tensile / 1 Bolt Torque Y X T Width<br />

kN Nm mm mm mm mm<br />

BSNT12 M12 5.8 69 26 13 16 29<br />

BSNT16 M16 7.3 147 30 16 20 35<br />

BSNT20 M20 14.7 285 36 19 24 42<br />

BSNT24 M24 19.7 491 48 25 32 54<br />

Order example: BSNT12 HDG<br />

Type BSLN<br />

Malleable iron, bright z<strong>in</strong>c plated / hot dip galvanised<br />

Extended Nose<br />

Flat Top<br />

Skirt<br />

Z<br />

Tail<br />

T<br />

K<br />

Y<br />

X<br />

V<br />

Special clamp designed with longer nose to extend the contact area<br />

with the steel section. For parallel flanges only. Can be used with types<br />

CW, P1 short, P2 short.<br />

Safe Work<strong>in</strong>g Load<br />

Dimensions<br />

Product Bolt 8.8 (5:1 Factor of Safety) Tail Length<br />

Code Z Tensile / 1 Bolt Torque Y X V T Width<br />

kN Nm mm mm mm mm mm<br />

BSLN12 M12 5.8 69 45.5 15.5 6 17 28<br />

BSLN16 M16 7.3 147 44 17 11 16 32<br />

Order example: BSLN12 HDG<br />

30<br />

Tel: +44 (0) 1274 521444 www.l<strong>in</strong>dapter.com

Type F9 / Type HW/HC <strong>Steelwork</strong> Fix<strong>in</strong>gs 1<br />

Type F9<br />

Malleable iron, bright z<strong>in</strong>c plated / hot dip galvanised<br />

Nut<br />

Bolt<br />

Z<br />

S<strong>in</strong>gle Leg<br />

V<br />

Jaws<br />

W<br />

X<br />

T<br />

V<br />

Double Leg<br />

Flange Clamp for connect<strong>in</strong>g all types of parallel runn<strong>in</strong>g steelwork with<br />

flanges of the same width. Can be used with bolts or alternatively with<br />

threaded rod.<br />

Not suitable for tapered flanges.<br />

Product Code<br />

Safe Work<strong>in</strong>g Loads<br />

with without Bolt 4.6 (5:1 Factor of Safety) Clamp<strong>in</strong>g Range Dimensions<br />

Bolt Bolt Z Tensile / 1 Bolt Torque W X V T Width<br />

kN Nm mm mm mm mm mm<br />

F910NC F910NB M10 2 20 19 - 42 25 13 19 24<br />

F912NC F912NB M12 2.8 39 26 - 60 35 17 24 30<br />

F916NC F916NB M16 5.6 93 29 - 69 43 21 28 35<br />

F920NC F920NB M20 8.4 177 32 - 82 51 25 35 44<br />

F924NC F924NB M24 14.0 235 45 - 95 76 38 55 63<br />

Order example: F910NC HDG<br />

Type HW/HC<br />

Malleable iron, bright z<strong>in</strong>c plated /<br />

hot dip galvanised<br />

X<br />

Z<br />

Hemispherical Washer<br />

W2<br />

W1<br />

L<br />

Y<br />

10°<br />

Hemispherical Cup<br />

For vertical suspension on angled surface of up to 10° sw<strong>in</strong>g either side of<br />

the vertical. The hemispherical washer (HW) can be used without the cup.<br />

Loads are subject to applications, please contact L<strong>in</strong>dapter.<br />

Dimensions<br />

Product Code Hemispherical Washer Hemispherical Cup Hemispherical Washer & Cup<br />

Hemispherical Washer Hemispherical Cup X W 1 Y W 2 R L<br />

mm mm mm mm mm mm<br />

Order example: HC10 BZP<br />

HW06 - 19 9 - - - -<br />

HW08 - 22 10 - - - -<br />

HW10 HC10 25 12 32 12 13 14<br />

HW12 HC12 29 12 35 12 14 16<br />

HW16 HC16 34 16 41 16 17 19<br />

HW20 HC20 44 19 54 19 22 24<br />

HW24 HC24 57 25 67 25 29 32<br />

Tel: +44 (0) 1274 521444 www.l<strong>in</strong>dapter.com<br />

31

Type SC / Type LP <strong>Steelwork</strong> Fix<strong>in</strong>gs 1<br />

Type SC / Type LP<br />

Corrosion Protection as required<br />

Bespoke units for multiple applications with vertical load, loads at an angle and rotation of up to 360°. Shown are typical applications, other loads and<br />

designs available. All loads subject to suitability of support<strong>in</strong>g section.<br />

Type SC<br />

Type SC<br />

Shackle Clamp with 4 Bolts<br />