Advances in the Development of Therapeutic Monoclonal Antibodies

Advances in the Development of Therapeutic Monoclonal Antibodies

Advances in the Development of Therapeutic Monoclonal Antibodies

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

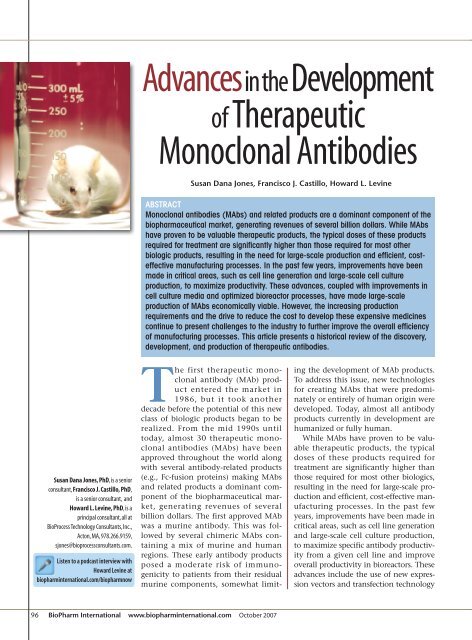

<strong>Advances</strong> <strong>in</strong><strong>the</strong> <strong>Development</strong><br />

<strong>of</strong> <strong>Therapeutic</strong><br />

<strong>Monoclonal</strong> <strong>Antibodies</strong><br />

Susan Dana Jones, Francisco J. Castillo, Howard L. Lev<strong>in</strong>e<br />

ABSTRACT<br />

<strong>Monoclonal</strong> antibodies (MAbs) and related products are a dom<strong>in</strong>ant component <strong>of</strong> <strong>the</strong><br />

biopharmaceutical market, generat<strong>in</strong>g revenues <strong>of</strong> several billion dollars. While MAbs<br />

have proven to be valuable <strong>the</strong>rapeutic products, <strong>the</strong> typical doses <strong>of</strong> <strong>the</strong>se products<br />

required for treatment are significantly higher than those required for most o<strong>the</strong>r<br />

biologic products, result<strong>in</strong>g <strong>in</strong> <strong>the</strong> need for large-scale production and efficient, costeffective<br />

manufactur<strong>in</strong>g processes. In <strong>the</strong> past few years, improvements have been<br />

made <strong>in</strong> critical areas, such as cell l<strong>in</strong>e generation and large-scale cell culture<br />

production, to maximize productivity. These advances, coupled with improvements <strong>in</strong><br />

cell culture media and optimized bioreactor processes, have made large-scale<br />

production <strong>of</strong> MAbs economically viable. However, <strong>the</strong> <strong>in</strong>creas<strong>in</strong>g production<br />

requirements and <strong>the</strong> drive to reduce <strong>the</strong> cost to develop <strong>the</strong>se expensive medic<strong>in</strong>es<br />

cont<strong>in</strong>ue to present challenges to <strong>the</strong> <strong>in</strong>dustry to fur<strong>the</strong>r improve <strong>the</strong> overall efficiency<br />

<strong>of</strong> manufactur<strong>in</strong>g processes. This article presents a historical review <strong>of</strong> <strong>the</strong> discovery,<br />

development, and production <strong>of</strong> <strong>the</strong>rapeutic antibodies.<br />

Susan Dana Jones, PhD, is a senior<br />

consultant, Francisco J. Castillo, PhD,<br />

is a senior consultant, and<br />

Howard L. Lev<strong>in</strong>e, PhD, is a<br />

pr<strong>in</strong>cipal consultant, all at<br />

BioProcess Technology Consultants, Inc.,<br />

Acton, MA, 978.266.9159,<br />

sjones@bioprocessconsultants.com.<br />

Listen to a podcast <strong>in</strong>terview with<br />

Howard Lev<strong>in</strong>e at<br />

biopharm<strong>in</strong>ternational.com/biopharmnow<br />

The first <strong>the</strong>rapeutic monoclonal<br />

antibody (MAb) product<br />

entered <strong>the</strong> market <strong>in</strong><br />

1986, but it took ano<strong>the</strong>r<br />

decade before <strong>the</strong> potential <strong>of</strong> this new<br />

class <strong>of</strong> biologic products began to be<br />

realized. From <strong>the</strong> mid 1990s until<br />

today, almost 30 <strong>the</strong>rapeutic monoclonal<br />

antibodies (MAbs) have been<br />

approved throughout <strong>the</strong> world along<br />

with several antibody-related products<br />

(e.g., Fc-fusion prote<strong>in</strong>s) mak<strong>in</strong>g MAbs<br />

and related products a dom<strong>in</strong>ant component<br />

<strong>of</strong> <strong>the</strong> biopharmaceutical market,<br />

generat<strong>in</strong>g revenues <strong>of</strong> several<br />

billion dollars. The first approved MAb<br />

was a mur<strong>in</strong>e antibody. This was followed<br />

by several chimeric MAbs conta<strong>in</strong><strong>in</strong>g<br />

a mix <strong>of</strong> mur<strong>in</strong>e and human<br />

regions. These early antibody products<br />

posed a moderate risk <strong>of</strong> immunogenicity<br />

to patients from <strong>the</strong>ir residual<br />

mur<strong>in</strong>e components, somewhat limit<strong>in</strong>g<br />

<strong>the</strong> development <strong>of</strong> MAb products.<br />

To address this issue, new technologies<br />

for creat<strong>in</strong>g MAbs that were predom<strong>in</strong>ately<br />

or entirely <strong>of</strong> human orig<strong>in</strong> were<br />

developed. Today, almost all antibody<br />

products currently <strong>in</strong> development are<br />

humanized or fully human.<br />

While MAbs have proven to be valuable<br />

<strong>the</strong>rapeutic products, <strong>the</strong> typical<br />

doses <strong>of</strong> <strong>the</strong>se products required for<br />

treatment are significantly higher than<br />

those required for most o<strong>the</strong>r biologics,<br />

result<strong>in</strong>g <strong>in</strong> <strong>the</strong> need for large-scale production<br />

and efficient, cost-effective manufactur<strong>in</strong>g<br />

processes. In <strong>the</strong> past few<br />

years, improvements have been made <strong>in</strong><br />

critical areas, such as cell l<strong>in</strong>e generation<br />

and large-scale cell culture production,<br />

to maximize specific antibody productivity<br />

from a given cell l<strong>in</strong>e and improve<br />

overall productivity <strong>in</strong> bioreactors. These<br />

advances <strong>in</strong>clude <strong>the</strong> use <strong>of</strong> new expression<br />

vectors and transfection technology<br />

96 BioPharm International www.biopharm<strong>in</strong>ternational.com October 2007

<strong>Monoclonal</strong> <strong>Antibodies</strong><br />

Figure 1. Annual approval <strong>of</strong> recomb<strong>in</strong>ant biologic products and<br />

monoclonal antibody products. 2,3 The total number <strong>of</strong> biologics, <strong>in</strong>clud<strong>in</strong>g<br />

MAb products, approved by FDA for market each year s<strong>in</strong>ce 1982 is<br />

shown <strong>in</strong> green. MAb product approvals only are shown <strong>in</strong> black.<br />

Antibody-related products such as Fc fusions, eng<strong>in</strong>eered antibody<br />

fragments, or o<strong>the</strong>r products derived from antibodies but not conta<strong>in</strong><strong>in</strong>g<br />

an antibody b<strong>in</strong>d<strong>in</strong>g region are not <strong>in</strong>cluded <strong>in</strong> <strong>the</strong> MAb figures. However,<br />

those products are <strong>in</strong>cluded <strong>in</strong> <strong>the</strong> total product figures.<br />

14<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

82 84 86 88 90 92 94 96 98 0 2 4 6<br />

Total biologics<br />

<strong>in</strong>clud<strong>in</strong>g MAbs<br />

MAbs<br />

to improve cell l<strong>in</strong>e generation; novel parental<br />

cell l<strong>in</strong>es that have been selected or designed<br />

to grow to maximum density and productivity<br />

under standard bioreactor conditions; and<br />

high-throughput, robust screen<strong>in</strong>g technologies<br />

to select <strong>the</strong> highest produc<strong>in</strong>g clones rapidly<br />

and more effectively. As a result, <strong>the</strong><br />

production <strong>of</strong> cell l<strong>in</strong>es express<strong>in</strong>g multigram<br />

quantities <strong>of</strong> antibody per liter <strong>of</strong> culture<br />

medium is now rout<strong>in</strong>e.<br />

These advances, coupled with improvements<br />

<strong>in</strong> cell culture media and greatly optimized<br />

bioreactor processes, have made <strong>the</strong><br />

large-scale production <strong>of</strong> MAbs economically<br />

viable. However, <strong>the</strong> <strong>in</strong>creas<strong>in</strong>g production<br />

requirements and <strong>the</strong> drive to reduce <strong>the</strong><br />

cost to develop <strong>the</strong>se expensive medic<strong>in</strong>es<br />

cont<strong>in</strong>ue to present challenges to <strong>the</strong> <strong>in</strong>dustry<br />

to fur<strong>the</strong>r improve <strong>the</strong> overall efficiency<br />

<strong>of</strong> manufactur<strong>in</strong>g processes. These challenges<br />

<strong>in</strong>clude <strong>the</strong> need to streaml<strong>in</strong>e downstream<br />

process<strong>in</strong>g to enable <strong>the</strong> process<strong>in</strong>g <strong>of</strong><br />

<strong>in</strong>creased product quantities; <strong>the</strong> implementation<br />

<strong>of</strong> Quality by Design (QbD) and o<strong>the</strong>r<br />

new regulatory concepts to reduce <strong>the</strong> cost<br />

and development timel<strong>in</strong>es for MAb products<br />

without adversely affect<strong>in</strong>g <strong>the</strong>ir quality;<br />

<strong>the</strong> need for high-concentration product<br />

formulations with sufficient stability to<br />

address <strong>the</strong> <strong>in</strong>creas<strong>in</strong>g doses <strong>of</strong> antibody<br />

products; and <strong>the</strong> development <strong>of</strong> alternative<br />

delivery systems.<br />

DISCOVERY OF ANTIBODY THERAPEUTICS<br />

In 1984, Kohler and Milste<strong>in</strong> received <strong>the</strong><br />

Nobel Prize <strong>in</strong> Medic<strong>in</strong>e for <strong>the</strong>ir pioneer<strong>in</strong>g<br />

work on <strong>the</strong> production <strong>of</strong> MAbs. 1 One<br />

<strong>of</strong> <strong>the</strong> most significant advantages <strong>of</strong> this<br />

new technology over traditional techniques<br />

for produc<strong>in</strong>g antibodies was <strong>the</strong><br />

development <strong>of</strong> an immortalized cell l<strong>in</strong>e<br />

creat<strong>in</strong>g a cont<strong>in</strong>uous source <strong>of</strong> <strong>the</strong> same<br />

antibody with a s<strong>in</strong>gle antigen specificity.<br />

This enabled <strong>the</strong> development <strong>of</strong> highly<br />

specific antibodies directed toward a s<strong>in</strong>gle<br />

epitope on <strong>the</strong> target antigen. Initially,<br />

MAbs were used as laboratory reagents, but<br />

<strong>the</strong>y were quickly adopted as cl<strong>in</strong>ical diagnostic<br />

reagents, and eventually as <strong>the</strong>rapeutic<br />

agents. The development <strong>of</strong><br />

<strong>the</strong>rapeutic MAbs commenced <strong>in</strong> <strong>the</strong> early<br />

1980s and by 1986 <strong>the</strong> first monoclonal<br />

antibody for human use—Orthoclone<br />

OKT3 (Ortho Pharmaceuticals)—was<br />

approved for <strong>the</strong> prevention <strong>of</strong> kidney transplant<br />

rejection. Follow<strong>in</strong>g <strong>the</strong> approval <strong>of</strong><br />

OKT3, <strong>the</strong> enthusiasm for MAbs as <strong>the</strong>rapeutic<br />

products grew with <strong>the</strong> next wave <strong>of</strong> antibody<br />

products generally be<strong>in</strong>g developed as<br />

anticancer agents. Several <strong>of</strong> <strong>the</strong>se products<br />

were approved <strong>in</strong> <strong>the</strong> US and Europe <strong>in</strong> <strong>the</strong><br />

mid to late 1990s, a trend that cont<strong>in</strong>ues to<br />

grow today. S<strong>in</strong>ce <strong>the</strong> commercialization <strong>of</strong><br />

<strong>the</strong> first <strong>the</strong>rapeutic MAbs, <strong>the</strong>se products<br />

have become a dom<strong>in</strong>ant component <strong>of</strong> <strong>the</strong><br />

biopharmaceutical market, represent<strong>in</strong>g<br />

approximately 20% <strong>of</strong> all biologic products,<br />

with comb<strong>in</strong>ed revenues <strong>of</strong> over $20 billion<br />

<strong>in</strong> 2006. 4 The growth <strong>of</strong> MAb products over<br />

<strong>the</strong> past 25 years, as shown <strong>in</strong> Figure 1, confirms<br />

<strong>the</strong> importance <strong>of</strong> <strong>the</strong>se products and<br />

also shows that MAbs represent a significant<br />

subset <strong>of</strong> all biopharmaceuticals on <strong>the</strong> market<br />

and <strong>in</strong> development. With over 300 antibody<br />

products currently <strong>in</strong> development,<br />

this unique and effective category <strong>of</strong> <strong>the</strong>rapeutic<br />

compounds is poised to grow significantly<br />

<strong>in</strong> <strong>the</strong> com<strong>in</strong>g years.<br />

MOLECULAR STRUCTURES OF<br />

ANTIBODIES:THEN AND NOW<br />

Mur<strong>in</strong>e <strong>Antibodies</strong><br />

The <strong>in</strong>itial technology for produc<strong>in</strong>g MAbs<br />

98 BioPharm International www.biopharm<strong>in</strong>ternational.com October 2007

<strong>Monoclonal</strong> <strong>Antibodies</strong><br />

<strong>in</strong>volved fus<strong>in</strong>g <strong>in</strong>dividual antibody-secret<strong>in</strong>g<br />

spleen cells from immunized mice with a<br />

mur<strong>in</strong>e myeloma cell l<strong>in</strong>e to generate<br />

immortalized cell l<strong>in</strong>es that secreted <strong>in</strong>dividual,<br />

or monoclonal, antibodies. Hence, <strong>the</strong><br />

first MAbs developed for use as potential<br />

human <strong>the</strong>rapeutics were mur<strong>in</strong>e antibodies.<br />

While <strong>in</strong>itial <strong>in</strong>terest <strong>in</strong> <strong>the</strong>se mur<strong>in</strong>e MAbs<br />

was high and several companies began<br />

develop<strong>in</strong>g products based on this technology,<br />

OKT3 was <strong>the</strong> only mur<strong>in</strong>e monoclonal<br />

antibody that was approved for human <strong>the</strong>rapeutic<br />

use. Despite <strong>the</strong> fact that OKT3 has<br />

been moderately successful <strong>in</strong> <strong>the</strong> market,<br />

<strong>the</strong> use <strong>of</strong> mur<strong>in</strong>e MAbs as <strong>the</strong>rapeutic<br />

agents quickly ran <strong>in</strong>to many roadblocks.<br />

One <strong>of</strong> <strong>the</strong> potential advantages <strong>of</strong> MAbs as<br />

<strong>the</strong>rapeutic agents is <strong>the</strong>ir long circulat<strong>in</strong>g<br />

half-life, allow<strong>in</strong>g <strong>the</strong>m to provide a <strong>the</strong>rapeutic<br />

effect <strong>in</strong> patients over several days.<br />

However, when mur<strong>in</strong>e MAbs were repeatedly<br />

adm<strong>in</strong>istered to humans dur<strong>in</strong>g cl<strong>in</strong>ical<br />

trials, it was observed that <strong>the</strong> half-life<br />

decreased and <strong>the</strong> products became less<br />

effective with each <strong>in</strong>jection. This was<br />

because <strong>of</strong> <strong>the</strong> immunogenicity <strong>of</strong> mur<strong>in</strong>e<br />

prote<strong>in</strong>s <strong>in</strong> humans and <strong>the</strong> rapid development<br />

<strong>of</strong> a human antimur<strong>in</strong>e antibody<br />

(HAMA) response <strong>in</strong> <strong>the</strong> patients. This<br />

HAMA response neutralized <strong>the</strong> effectiveness<br />

<strong>of</strong> <strong>the</strong> mur<strong>in</strong>e antibodies and resulted <strong>in</strong><br />

<strong>the</strong>ir rapid clearance from <strong>the</strong> body. For<br />

example, it has been reported that OKT3 can<br />

elicit a HAMA response <strong>in</strong> up to 86% <strong>of</strong><br />

patients treated, lead<strong>in</strong>g to some limitations<br />

<strong>in</strong> its efficacy. 5<br />

Chimeric <strong>Antibodies</strong><br />

To overcome <strong>the</strong> HAMA responses occur<strong>in</strong>g<br />

from <strong>the</strong> usage <strong>of</strong> mur<strong>in</strong>e MAbs as <strong>the</strong>rapeutics,<br />

several approaches were developed <strong>in</strong> an<br />

attempt to make MAbs more human-like and<br />

less immunogenic. In <strong>the</strong> early 1990s,<br />

molecular biology techniques enabled <strong>the</strong><br />

creation <strong>of</strong> “chimeric” antibodies by l<strong>in</strong>k<strong>in</strong>g<br />

<strong>the</strong> mur<strong>in</strong>e genes encod<strong>in</strong>g <strong>the</strong> antigenb<strong>in</strong>d<strong>in</strong>g<br />

portion <strong>of</strong> <strong>the</strong> antibody (<strong>the</strong> variable<br />

region) to <strong>the</strong> genes encod<strong>in</strong>g <strong>the</strong> constant<br />

region <strong>of</strong> human immunoglobul<strong>in</strong> light and<br />

heavy cha<strong>in</strong>s. Because over 75% <strong>of</strong> <strong>the</strong> prote<strong>in</strong><br />

sequence <strong>of</strong> <strong>the</strong> result<strong>in</strong>g chimeric antibodies<br />

was <strong>of</strong> human orig<strong>in</strong>, <strong>the</strong>se chimeric<br />

MAbs elicited much lower HAMA responses<br />

<strong>in</strong> patients. Moreover, because <strong>the</strong> antibody<br />

Future <strong>the</strong>rapeutic monoclonal antibody<br />

products will be predom<strong>in</strong>antly<br />

humanized or fully human.<br />

constant region <strong>in</strong> <strong>the</strong>se chimeric antibodies<br />

is human, it is capable <strong>of</strong> activat<strong>in</strong>g o<strong>the</strong>r<br />

components <strong>of</strong> <strong>the</strong> human immune system<br />

to potentially create more effective <strong>the</strong>rapeutic<br />

agents. Many <strong>of</strong> <strong>the</strong> MAbs approved for<br />

commercialization <strong>in</strong> <strong>the</strong> 1990s and early<br />

2000s were chimeric antibodies, <strong>in</strong>clud<strong>in</strong>g<br />

<strong>the</strong> highly successful anticancer antibodies<br />

Rituxan (approved <strong>in</strong> 1997) and Erbitux<br />

(approved <strong>in</strong> 2004), as well as <strong>the</strong> anti<strong>in</strong>flammatory<br />

product Remicade (approved<br />

<strong>in</strong> 1998). Chimeric antibody products are<br />

superior to mur<strong>in</strong>e antibody products but<br />

<strong>the</strong>y still pose a moderate risk <strong>of</strong> immunogenicity<br />

to patients from <strong>the</strong>ir residual<br />

mur<strong>in</strong>e components. Therefore, antibody<br />

eng<strong>in</strong>eer<strong>in</strong>g approaches that fur<strong>the</strong>r reduce<br />

<strong>the</strong> mur<strong>in</strong>e component or that remove<br />

immunogenic portions <strong>of</strong> <strong>the</strong> chimeric antibody,<br />

have been developed and used to generate<br />

fully “humanized” antibody products.<br />

Humanized <strong>Antibodies</strong><br />

In 1991, Prote<strong>in</strong> Design Labs (PDL) developed<br />

and patented <strong>the</strong> first technology for successfully<br />

humaniz<strong>in</strong>g MAbs. 6 The antigen b<strong>in</strong>d<strong>in</strong>g<br />

specificity <strong>of</strong> any antibody is determ<strong>in</strong>ed by<br />

<strong>the</strong> am<strong>in</strong>o acids present <strong>in</strong> three dist<strong>in</strong>ct<br />

highly variable regions per antibody cha<strong>in</strong>,<br />

referred to as complementarity determ<strong>in</strong><strong>in</strong>g<br />

regions (CDRs), and located <strong>in</strong> a more conserved<br />

framework sequence <strong>in</strong> <strong>the</strong> variable<br />

regions. Therefore, PDL scientists developed<br />

methods for eng<strong>in</strong>eer<strong>in</strong>g an antibody gene <strong>in</strong><br />

which <strong>the</strong> CDRs <strong>of</strong> a human antibody gene<br />

were replaced by those from <strong>the</strong> CDR <strong>of</strong> a<br />

mur<strong>in</strong>e MAb gene. The result<strong>in</strong>g humanized<br />

antibody has <strong>the</strong> same antigen b<strong>in</strong>d<strong>in</strong>g properties<br />

as <strong>the</strong> orig<strong>in</strong>al mur<strong>in</strong>e antibody but<br />

conta<strong>in</strong>s m<strong>in</strong>imal mur<strong>in</strong>e sequences and,<br />

<strong>the</strong>refore, elicits a lower HAMA response <strong>in</strong><br />

patients. The CDR-grafted human antibody<br />

can be used as is or, <strong>in</strong> cases where aff<strong>in</strong>ity <strong>of</strong><br />

<strong>the</strong> chimeric antibody is slightly reduced<br />

from <strong>the</strong> orig<strong>in</strong>al mur<strong>in</strong>e antibody, additional<br />

BioPharm International www.biopharm<strong>in</strong>ternational.com October 2007 99

<strong>Monoclonal</strong> <strong>Antibodies</strong><br />

Table 1. Comparison <strong>of</strong> sales for antibody-based anti-<strong>in</strong>flammatory products<br />

Product<br />

Company<br />

Year<br />

approved<br />

2006 sales worldwide<br />

($ million) Market share<br />

Humira Abbott 2002 2,000 15.8%<br />

Remicade Johnson & Johnson 1998 4,253 33.7%<br />

Enbrel Amgen 1998 4,379 34.7%<br />

changes can be made <strong>in</strong> <strong>the</strong> antibody<br />

sequence to rega<strong>in</strong> or enhance its b<strong>in</strong>d<strong>in</strong>g<br />

properties. Like chimeric antibodies, humanized<br />

antibodies can activate o<strong>the</strong>r parts <strong>of</strong> <strong>the</strong><br />

immune system to create a more effective<br />

product. Several humanized antibody products<br />

are currently on <strong>the</strong> market, <strong>in</strong>clud<strong>in</strong>g<br />

Synagis (approved <strong>in</strong> 1998), Hercept<strong>in</strong><br />

(approved <strong>in</strong> 1998), Mylotarg (approved <strong>in</strong><br />

2000), Xolair (approved <strong>in</strong> 2003), and Avast<strong>in</strong><br />

(approved <strong>in</strong> 2004).<br />

In addition to <strong>the</strong> production <strong>of</strong> chimeric<br />

and humanized antibodies, o<strong>the</strong>r technologies<br />

have been developed to help m<strong>in</strong>imize<br />

<strong>the</strong> HAMA response <strong>in</strong> patients. These<br />

<strong>in</strong>clude human eng<strong>in</strong>eer<strong>in</strong>g or deimmunization,<br />

<strong>in</strong> which am<strong>in</strong>o acids on <strong>the</strong> surface <strong>of</strong><br />

<strong>the</strong> mur<strong>in</strong>e variable region that are known to<br />

be effective immunogenic sequences are<br />

changed to <strong>the</strong>ir non-immunogenic human<br />

counterpart, leav<strong>in</strong>g <strong>the</strong> o<strong>the</strong>r non-immunogenic<br />

mur<strong>in</strong>e sequences unchanged. 7 The<br />

advantage <strong>of</strong> this approach is that <strong>the</strong> structural<br />

<strong>in</strong>tegrity <strong>of</strong> <strong>the</strong> variable region is better<br />

ma<strong>in</strong>ta<strong>in</strong>ed and reduction <strong>of</strong> aff<strong>in</strong>ity for <strong>the</strong><br />

target is m<strong>in</strong>imized.<br />

Fully Human <strong>Antibodies</strong><br />

The latest advancement <strong>in</strong> creat<strong>in</strong>g less<br />

immunogenic <strong>the</strong>rapeutic antibody products<br />

is <strong>the</strong> ability to generate fully human MAbs.<br />

Several technologies exist to develop fully<br />

human antibodies, each fall<strong>in</strong>g <strong>in</strong>to one <strong>of</strong><br />

<strong>the</strong> two general classes—<strong>in</strong> vivo approaches<br />

us<strong>in</strong>g a mur<strong>in</strong>e system <strong>in</strong> which <strong>the</strong><br />

immunoglobul<strong>in</strong> genes have been replaced by<br />

<strong>the</strong>ir human counterparts or <strong>in</strong> vitro<br />

approaches us<strong>in</strong>g libraries conta<strong>in</strong><strong>in</strong>g millions<br />

<strong>of</strong> variations <strong>of</strong> antibody sequences coupled<br />

with a mechanism to express and screen <strong>the</strong>se<br />

antibodies <strong>in</strong> vitro. Humira (approved <strong>in</strong> 2004)<br />

is <strong>the</strong> first fully human antibody to be<br />

approved. This anti-TNF-α antibody was first<br />

identified by scientists at Cambridge<br />

Antibody Technology (CAT, now part <strong>of</strong><br />

AstraZeneca) us<strong>in</strong>g an <strong>in</strong> vitro<br />

molecular eng<strong>in</strong>eer<strong>in</strong>g technology<br />

known as phage display. In <strong>the</strong> marketplace,<br />

this human MAb competes<br />

with Enbrel, an Fc fusion<br />

prote<strong>in</strong>, and Remicade, a chimeric<br />

antibody. The power <strong>of</strong> <strong>the</strong> fully<br />

human antibody platform can be<br />

seen <strong>in</strong> <strong>the</strong> sales figures for <strong>the</strong>se<br />

three products. Although Humira was<br />

approved four years later than <strong>the</strong> o<strong>the</strong>r products,<br />

it has successfully taken a significant<br />

market share from <strong>the</strong>m, garner<strong>in</strong>g almost<br />

16% market share <strong>in</strong> 2006. Worldwide sales <strong>in</strong><br />

2006 for all three products are shown <strong>in</strong><br />

Table 1.<br />

Many antibody products currently <strong>in</strong> early<br />

cl<strong>in</strong>ical development are fully human,<br />

because <strong>the</strong> technologies that enable <strong>the</strong><br />

generation <strong>of</strong> human antibodies are now<br />

accessible through partnerships or licens<strong>in</strong>g<br />

from <strong>the</strong> companies that have developed<br />

<strong>the</strong>se approaches. Moreover, <strong>the</strong> expectation<br />

<strong>in</strong> <strong>the</strong> medical and regulatory community is<br />

that companies will use <strong>the</strong> best approach<br />

for <strong>the</strong>ir product to achieve humanization.<br />

There will be exceptions to this generalization,<br />

for example when a short half life is<br />

desired or when a toxic or radioactive payload<br />

is l<strong>in</strong>ked to <strong>the</strong> antibody, but for<br />

unmodified <strong>the</strong>rapeutic antibody products<br />

<strong>the</strong> <strong>in</strong>dustry standard has changed; most<br />

future antibody products will be humanized<br />

or fully human antibodies.<br />

Most MAb products are naked antibodies,<br />

which rely on ei<strong>the</strong>r block<strong>in</strong>g an important<br />

biological function or on activat<strong>in</strong>g <strong>the</strong><br />

immune system, to elicit a <strong>the</strong>rapeutic effect.<br />

However, antibodies are also well suited as<br />

target<strong>in</strong>g agents to deliver potent chemo- or<br />

radioactive agents specifically to target cells.<br />

For example, Mylotarg conta<strong>in</strong>s a cytotoxic<br />

compound conjugated to a monoclonal antibody.<br />

This immunoconjugate product is<br />

designed to deliver <strong>the</strong> potent cytotoxic<br />

compound selectively to cancer cells. The<br />

radio-immunoconjugate products Zeval<strong>in</strong><br />

and Bexxar (both anti-CD20 MAbs), deliver<br />

radioisotopes for <strong>the</strong> treatment <strong>of</strong> lymphoma.<br />

Both <strong>the</strong>se products are mur<strong>in</strong>e antibodies<br />

because <strong>the</strong> human or humanized<br />

forms <strong>of</strong> <strong>the</strong>se products would b<strong>in</strong>d to and<br />

target not only <strong>the</strong> CD20 positive target cells<br />

but also those cells that conta<strong>in</strong> <strong>the</strong> IgG<br />

100 BioPharm International www.biopharm<strong>in</strong>ternational.com October 2007

<strong>Monoclonal</strong> <strong>Antibodies</strong><br />

receptors that function to enable antibodies<br />

to recruit additional immune system components<br />

to <strong>the</strong> site <strong>of</strong> a foreign antigen. By<br />

<strong>in</strong>advertently target<strong>in</strong>g <strong>the</strong>se cells, human<br />

antibody-based radio-immunoconjugates<br />

could do more harm to nontarget cell types<br />

than to <strong>the</strong> targeted cancer cell.<br />

All <strong>of</strong> <strong>the</strong> above technologies now allow<br />

<strong>the</strong> generation <strong>of</strong> better designed antibody<br />

products with fully human sequences and<br />

optimized function. Comb<strong>in</strong><strong>in</strong>g <strong>in</strong> vivo and <strong>in</strong><br />

vitro discovery and molecular eng<strong>in</strong>eer<strong>in</strong>g<br />

technologies allows exquisite control <strong>of</strong> <strong>the</strong><br />

antibody sequences and properties that was<br />

not possible 20 years ago. New approaches for<br />

<strong>the</strong> rapid production <strong>of</strong> cell l<strong>in</strong>es suitable for<br />

large-scale commercial production have<br />

enabled <strong>the</strong> development <strong>of</strong> MAb <strong>the</strong>rapies to<br />

treat myriad diseases and made <strong>the</strong>se products<br />

available to an <strong>in</strong>creas<strong>in</strong>g number <strong>of</strong> patients.<br />

In addition to enabl<strong>in</strong>g more efficient and<br />

economic production <strong>of</strong> MAbs, <strong>the</strong> above<br />

antibody eng<strong>in</strong>eer<strong>in</strong>g technologies, coupled<br />

with advances <strong>in</strong> cell culture production discussed<br />

below, have greatly <strong>in</strong>creased our ability<br />

to control or alter <strong>the</strong> properties <strong>of</strong> <strong>the</strong><br />

result<strong>in</strong>g antibodies. For example, <strong>the</strong> extent<br />

<strong>of</strong> glycosylation, which can <strong>in</strong>crease effector<br />

function and <strong>the</strong>reby <strong>in</strong>crease product efficacy,<br />

can be controlled by both cell l<strong>in</strong>e eng<strong>in</strong>eer<strong>in</strong>g<br />

and cell culture technologies.<br />

In <strong>the</strong> future, human cell l<strong>in</strong>es may<br />

replace CHO and o<strong>the</strong>r mammalian<br />

cell l<strong>in</strong>es for <strong>the</strong> production <strong>of</strong> MAbs.<br />

MARKET DEMANDS AND<br />

CELL LINE PRODUCTIVITY<br />

One challeng<strong>in</strong>g feature <strong>of</strong> most <strong>the</strong>rapeutic<br />

antibody products is that <strong>the</strong> doses required<br />

for <strong>the</strong>se products are much higher than for<br />

o<strong>the</strong>r biologic products. To meet <strong>the</strong> large<br />

annual production requirements for <strong>the</strong>se<br />

products, companies have made substantial<br />

progress <strong>in</strong> develop<strong>in</strong>g more efficient and costeffective<br />

methods for manufactur<strong>in</strong>g antibody<br />

products. When antibody products were first<br />

developed and approved, expression levels <strong>of</strong><br />

MAbs were typically on <strong>the</strong> order <strong>of</strong> 100–500<br />

milligrams per liter. Even as recently as five<br />

years ago, antibody titers <strong>in</strong> excess <strong>of</strong> 1 g/L<br />

were not common and many MAb products<br />

were launched us<strong>in</strong>g production cell l<strong>in</strong>es and<br />

manufactur<strong>in</strong>g processes that produced<br />

approximately 0.5–1.0 g/L antibody. 8 As MAb<br />

products became successful <strong>in</strong> <strong>the</strong> marketplace<br />

and as <strong>the</strong> demands for new products<br />

<strong>in</strong>creased, newer methods <strong>of</strong> generat<strong>in</strong>g highexpress<strong>in</strong>g<br />

antibody production cell l<strong>in</strong>es and<br />

<strong>of</strong> cultur<strong>in</strong>g <strong>the</strong>se cell l<strong>in</strong>es for maximum productivity<br />

have been developed. Today’s technologies<br />

are enabl<strong>in</strong>g antibody production <strong>in</strong><br />

<strong>the</strong> bioreactor <strong>of</strong> 5 g/L or more. 9 <strong>Advances</strong> <strong>in</strong><br />

cell l<strong>in</strong>e generation over <strong>the</strong> past decade<br />

<strong>in</strong>clude new expression vectors and transfection<br />

technology to <strong>in</strong>troduce <strong>the</strong> genes <strong>in</strong>to<br />

cells; novel parental cell l<strong>in</strong>es that have been<br />

selected or designed to grow to maximum<br />

density; and robust screen<strong>in</strong>g technologies<br />

that <strong>in</strong> comb<strong>in</strong>ation can enable rapid generation<br />

<strong>of</strong> production cell l<strong>in</strong>es.<br />

ADVANCES IN THE GENERATION<br />

OF PRODUCTION CELL LINES<br />

Today’s MAbs must be manufactured us<strong>in</strong>g<br />

reliable production cell l<strong>in</strong>es capable <strong>of</strong> produc<strong>in</strong>g<br />

sufficient quantities <strong>of</strong> product to<br />

meet <strong>the</strong> market demand. For most products,<br />

this means that antibody titers <strong>in</strong> <strong>the</strong> bioreactor<br />

must be greater than 1 g/L <strong>in</strong> a fedbatch<br />

process <strong>in</strong>itially and 3–5 g/L follow<strong>in</strong>g<br />

process optimization. To achieve <strong>the</strong>se levels<br />

<strong>of</strong> productivity, it is necessary to quickly<br />

develop a cell l<strong>in</strong>e express<strong>in</strong>g reasonably<br />

high quantities <strong>of</strong> antibody for early precl<strong>in</strong>ical,<br />

formulation, and analytical validation<br />

studies that can be fur<strong>the</strong>r optimized to<br />

achieve <strong>the</strong> desired productivity levels. If <strong>the</strong><br />

productivity <strong>of</strong> <strong>the</strong> <strong>in</strong>itial cell l<strong>in</strong>e is high<br />

enough, it can even be used to support <strong>in</strong>itial<br />

cl<strong>in</strong>ical development <strong>of</strong> <strong>the</strong> product.<br />

Once <strong>the</strong> <strong>in</strong>itial cell l<strong>in</strong>e is established, a production<br />

cell l<strong>in</strong>e exhibit<strong>in</strong>g <strong>the</strong> highest possible<br />

level <strong>of</strong> production <strong>of</strong> functional<br />

antibody and capable <strong>of</strong> support<strong>in</strong>g commercial<br />

production at a reasonable cost can be<br />

developed. In today’s highly competitive<br />

market, it is important to complete <strong>the</strong> <strong>in</strong>itial<br />

stages <strong>of</strong> cell l<strong>in</strong>e development as quickly<br />

and efficiently as possible to enable early<br />

entry <strong>in</strong>to human cl<strong>in</strong>ical trials but equally<br />

important is to devote sufficient time and<br />

resources to <strong>the</strong> full development and optimization<br />

<strong>of</strong> <strong>the</strong> commercial cell l<strong>in</strong>e so that<br />

BioPharm International www.biopharm<strong>in</strong>ternational.com October 2007 101

<strong>Monoclonal</strong> <strong>Antibodies</strong><br />

The use <strong>of</strong> parental cell l<strong>in</strong>es adapted to<br />

grow <strong>in</strong> suspension and serum-free<br />

media can reduce development times.<br />

a suitable cell l<strong>in</strong>e is available for commercial<br />

production as soon as possible.<br />

High-Express<strong>in</strong>g Cell L<strong>in</strong>es<br />

To create a production cell l<strong>in</strong>e for a specific<br />

antibody, expression vectors conta<strong>in</strong><strong>in</strong>g <strong>the</strong><br />

heavy- and light-cha<strong>in</strong> genes under control<br />

<strong>of</strong> strong mammalian promoters are <strong>in</strong>troduced<br />

<strong>in</strong>to <strong>the</strong> parental cell l<strong>in</strong>e. Usually, a<br />

selectable marker is also <strong>in</strong>cluded so that<br />

cells conta<strong>in</strong><strong>in</strong>g <strong>the</strong> gene can be easily<br />

selected by add<strong>in</strong>g a drug or substance to <strong>the</strong><br />

culture that causes <strong>the</strong> cell to require <strong>the</strong><br />

activity <strong>of</strong> <strong>the</strong> selectable marker. The driv<strong>in</strong>g<br />

factors beh<strong>in</strong>d <strong>the</strong> selection <strong>of</strong> a particular<br />

cell clone dur<strong>in</strong>g cell l<strong>in</strong>e generation is <strong>the</strong><br />

expression level <strong>of</strong> <strong>the</strong> recomb<strong>in</strong>ant prote<strong>in</strong>,<br />

which is measured <strong>in</strong>dependently <strong>of</strong> <strong>the</strong><br />

selection, and <strong>the</strong> time that it takes to obta<strong>in</strong><br />

a cell l<strong>in</strong>e that expresses enough product to<br />

enable noncl<strong>in</strong>ical and cl<strong>in</strong>ical development.<br />

Technologies that <strong>in</strong>crease <strong>the</strong> percentage <strong>of</strong><br />

transfectants with high expression levels will<br />

reduce <strong>the</strong> time needed to identify a production<br />

cell l<strong>in</strong>e because <strong>the</strong> high-express<strong>in</strong>g<br />

clones will be easier to select without hav<strong>in</strong>g<br />

to screen thousands <strong>of</strong> <strong>in</strong>dividual clones.<br />

Recent advances <strong>in</strong> cell l<strong>in</strong>e generation<br />

<strong>in</strong>clude technologies that <strong>in</strong>crease this percentage,<br />

as well as sophisticated and automated<br />

approaches to screen<strong>in</strong>g that enable<br />

more <strong>in</strong>dividual transfectants to be screened<br />

for expression levels. 10,12,15,16<br />

Production levels <strong>in</strong> <strong>the</strong> bioreactor are a<br />

function <strong>of</strong> specific productivity—<strong>the</strong> density<br />

to which <strong>the</strong> cells can grow and <strong>the</strong><br />

longevity <strong>of</strong> <strong>the</strong> culture. Before actual test<strong>in</strong>g<br />

<strong>in</strong> <strong>the</strong> bioreactor, expression levels are determ<strong>in</strong>ed<br />

<strong>in</strong> small culture vessels, from multiwell<br />

plates to shake flasks. Levels <strong>of</strong> 15–20<br />

picograms <strong>of</strong> antibody/cell/day (pcd) are<br />

considered appropriate for <strong>in</strong>itial transfectants,<br />

with greater productivity aris<strong>in</strong>g from<br />

optimized cell culture conditions, secondary<br />

transfections, or amplification <strong>of</strong> <strong>the</strong> transfected<br />

antibody genes us<strong>in</strong>g selective pressure.<br />

Us<strong>in</strong>g parental cell l<strong>in</strong>es adapted to<br />

grow <strong>in</strong> suspension and serum-free media<br />

reduces development times and <strong>in</strong>creases <strong>the</strong><br />

likelihood <strong>of</strong> reach<strong>in</strong>g high cell densities<br />

dur<strong>in</strong>g manufactur<strong>in</strong>g and high product<br />

yields <strong>in</strong> <strong>the</strong> grams-per-liter level.<br />

Selection Systems<br />

One <strong>of</strong> <strong>the</strong> earliest effective methods for<br />

transfection, selection, and amplification <strong>of</strong><br />

foreign genes <strong>in</strong> mammalian cells was developed<br />

<strong>in</strong> 1981 by scientists at Columbia<br />

University us<strong>in</strong>g dihydr<strong>of</strong>olate reductase<br />

(DHFR) selection. In this method, a parental<br />

mammalian cell l<strong>in</strong>e deficient <strong>in</strong> <strong>the</strong> enzyme<br />

DHFR is transfected with an expression vector<br />

conta<strong>in</strong><strong>in</strong>g <strong>the</strong> DHFR gene under control<br />

<strong>of</strong> a relatively weak promoter and <strong>the</strong> antibody<br />

(or o<strong>the</strong>r prote<strong>in</strong>) genes under control<br />

<strong>of</strong> a strong promoter. 11 By perform<strong>in</strong>g multiple<br />

rounds <strong>of</strong> amplification and selection <strong>of</strong><br />

cells <strong>in</strong> <strong>the</strong> presence <strong>of</strong> <strong>the</strong> folate analog<br />

methotrexate (MTX), a potent <strong>in</strong>hibitor <strong>of</strong><br />

DHFR, production cell l<strong>in</strong>es with relatively<br />

high levels <strong>of</strong> expression <strong>of</strong> <strong>the</strong> foreign genes<br />

can be obta<strong>in</strong>ed. The orig<strong>in</strong>al patents for this<br />

technology have now expired but it is still<br />

widely used to generate antibody production<br />

cell l<strong>in</strong>es. However, because each amplification<br />

cycle requires 12 weeks to complete and<br />

up to five cycles or more, about one year<br />

total may be necessary to obta<strong>in</strong> a clone<br />

with acceptably high expression levels.<br />

Never<strong>the</strong>less, <strong>the</strong> DHFR system is effective<br />

and has been used <strong>in</strong> conjunction with o<strong>the</strong>r<br />

aspects <strong>of</strong> cell l<strong>in</strong>e development to achieve<br />

multigram-per-liter expression levels <strong>of</strong> MAb.<br />

Also, alternative systems requir<strong>in</strong>g less time<br />

to reach maximal expression have been<br />

developed. For example, <strong>the</strong> glutam<strong>in</strong>e syn<strong>the</strong>tase<br />

selection system, developed by scientists<br />

at Celltech (now Lonza), can achieve<br />

production clones with higher levels <strong>of</strong> antibody<br />

or prote<strong>in</strong> expression <strong>in</strong> 4–6 months. 12<br />

Glutam<strong>in</strong>e syn<strong>the</strong>tase (GS) is <strong>the</strong> enzyme<br />

responsible for <strong>the</strong> biosyn<strong>the</strong>sis <strong>of</strong> glutam<strong>in</strong>e<br />

from glutamate and ammonia. This<br />

enzymatic reaction provides <strong>the</strong> only pathway<br />

for glutam<strong>in</strong>e formation <strong>in</strong> a mammalian<br />

cell. Therefore, <strong>in</strong> <strong>the</strong> absence <strong>of</strong><br />

glutam<strong>in</strong>e <strong>in</strong> <strong>the</strong> growth medium, <strong>the</strong> GS<br />

enzyme is essential for <strong>the</strong> survival <strong>of</strong> <strong>the</strong><br />

mammalian cells <strong>in</strong> culture. Some mammalian<br />

cell l<strong>in</strong>es, such as <strong>the</strong> mur<strong>in</strong>e cell<br />

104 BioPharm International www.biopharm<strong>in</strong>ternational.com October 2007

<strong>Monoclonal</strong> <strong>Antibodies</strong><br />

Figure 2. In matrix attachment region (MAR) technology, MAR elements are<br />

<strong>in</strong>serted <strong>in</strong>to expression vectors surround<strong>in</strong>g <strong>the</strong> desired transgene and impose<br />

an open chromat<strong>in</strong> configuration on <strong>the</strong> nearby chromat<strong>in</strong>. This open structure<br />

allows RNA polymerase and o<strong>the</strong>r transcription factors to access <strong>the</strong><br />

transcriptional promoters and enhancers found with<strong>in</strong> <strong>the</strong> expression vector and<br />

<strong>the</strong>reby enables greater levels <strong>of</strong> transcription. This leads to <strong>in</strong>creased productspecific<br />

translation and a higher yield <strong>in</strong> a greater percentage <strong>of</strong> transfected<br />

cells. Figure provided courtesy <strong>of</strong> Selexis SA.<br />

‘Closed’<br />

chromat<strong>in</strong><br />

Promoters/<br />

enhancers<br />

‘Open’<br />

chromat<strong>in</strong><br />

chromat<strong>in</strong><br />

‘Closed’<br />

MAR<br />

l<strong>in</strong>es NSO or SP2/0 widely used for antibody<br />

production, do not express sufficient<br />

GS to survive without added glutam<strong>in</strong>e.<br />

With <strong>the</strong>se cell l<strong>in</strong>es, a transfected GS gene<br />

can function as a selectable marker by permitt<strong>in</strong>g<br />

growth <strong>in</strong> a glutam<strong>in</strong>e-free<br />

medium. Ch<strong>in</strong>ese hamster ovary (CHO)<br />

cells, also widely used for antibody and<br />

o<strong>the</strong>r recomb<strong>in</strong>ant prote<strong>in</strong> production,<br />

conta<strong>in</strong> sufficient active GS to survive<br />

without exogenous glutam<strong>in</strong>e. 13 In <strong>the</strong>se<br />

cases <strong>the</strong> specific GS <strong>in</strong>hibitor, methion<strong>in</strong>e<br />

sulphoxim<strong>in</strong>e (MSX), can be used to<br />

<strong>in</strong>hibit endogenous GS activity such that<br />

only transfectants with additional GS activity<br />

can survive. GS selection can be used to<br />

select high-express<strong>in</strong>g cell l<strong>in</strong>es without<br />

amplification, which reduces <strong>the</strong> time compared<br />

to <strong>the</strong> DHFR selection approach. The<br />

GS system has enabled <strong>the</strong> rapid identification<br />

and selection <strong>of</strong> production cell l<strong>in</strong>es<br />

that express up to 20–50 pcd and multiple<br />

grams per liter <strong>of</strong> product as part <strong>of</strong> an<br />

overall cell culture process development<br />

effort. Accord<strong>in</strong>g to Lonza, more than 85<br />

global pharmaceutical companies are currently<br />

us<strong>in</strong>g this technology to create production<br />

cell l<strong>in</strong>es and five products us<strong>in</strong>g<br />

<strong>the</strong> GS system have been approved for<br />

commercial sale, <strong>in</strong>clud<strong>in</strong>g Synagis and<br />

Zenapax. The GS technology is available<br />

for licens<strong>in</strong>g from Lonza for <strong>the</strong> use <strong>in</strong><br />

research and commercial applications,<br />

mak<strong>in</strong>g it widely available for <strong>the</strong><br />

development <strong>of</strong> MAb products. 14<br />

Improv<strong>in</strong>g Gene Expression<br />

Ano<strong>the</strong>r recent approach to improve<br />

expression <strong>of</strong> antibody genes <strong>in</strong> <strong>the</strong><br />

<strong>in</strong>itially transfected cells is to ensure<br />

that <strong>the</strong> genes are <strong>in</strong>tegrated <strong>in</strong>to<br />

regions <strong>of</strong> <strong>the</strong> chromat<strong>in</strong>, which are<br />

easily available to <strong>the</strong> enzymes that<br />

transcribe <strong>the</strong> gene <strong>in</strong>to RNA, <strong>the</strong>reby<br />

<strong>in</strong>creas<strong>in</strong>g <strong>the</strong> rate <strong>of</strong> transcription.<br />

The transfection <strong>of</strong> a mammalian cell<br />

generally results <strong>in</strong> <strong>the</strong> <strong>in</strong>tegration <strong>of</strong><br />

<strong>the</strong> DNA <strong>in</strong>to <strong>the</strong> chromat<strong>in</strong> <strong>in</strong> one or<br />

more random locations. Because most<br />

<strong>of</strong> <strong>the</strong> genome is not transcriptionally<br />

active, <strong>the</strong>re is a high likelihood that<br />

<strong>in</strong>tegration will occur <strong>in</strong> regions that<br />

are not able to transcribe high levels<br />

<strong>of</strong> <strong>the</strong> antibody genes. Target<strong>in</strong>g <strong>the</strong><br />

expression plasmid to locations on <strong>the</strong> chromat<strong>in</strong><br />

that are known to be transcriptionally<br />

active and accessible to <strong>the</strong> necessary<br />

enzymes would <strong>in</strong>crease <strong>the</strong> expression <strong>of</strong><br />

all genes <strong>in</strong>tegrated at <strong>the</strong>se sites. Although<br />

this is an excellent concept <strong>in</strong> <strong>the</strong>ory,<br />

homologous recomb<strong>in</strong>ation or targeted <strong>in</strong>tegration<br />

has not been widely adapted <strong>in</strong> practice<br />

because <strong>of</strong> <strong>the</strong> lack <strong>of</strong> <strong>in</strong>formation<br />

about which sites are good locations for<br />

<strong>in</strong>tegration and <strong>the</strong> need to have unique<br />

plasmids and cell l<strong>in</strong>es that are able to perform<br />

<strong>the</strong> recomb<strong>in</strong>ation.<br />

Ra<strong>the</strong>r than target<strong>in</strong>g a specific site <strong>in</strong> <strong>the</strong><br />

chromat<strong>in</strong> for <strong>in</strong>tegration, an alternative<br />

approach is to <strong>in</strong>clude elements on <strong>the</strong><br />

expression plasmid. This will cause <strong>the</strong> random<br />

<strong>in</strong>tegration site to become transcriptionally<br />

active and available to <strong>the</strong> enzymes<br />

that transcribe <strong>the</strong> genes. There have been<br />

several reports <strong>of</strong> such genetic elements that<br />

enable <strong>the</strong> <strong>in</strong>tegrated plasmid to create a<br />

transcriptionally active region at any <strong>in</strong>tegration<br />

location on <strong>the</strong> chromosome and to<br />

enable higher transcription levels <strong>in</strong> a higher<br />

percentage <strong>of</strong> transfectants. Two types <strong>of</strong> elements<br />

that function to create a region <strong>of</strong><br />

transcriptionally active chromat<strong>in</strong> are <strong>the</strong><br />

ubiquitous chromat<strong>in</strong> open<strong>in</strong>g elements<br />

(UCOE) and <strong>the</strong> matrix attachment regions<br />

(MAR) elements. 15,16 These genetic elements<br />

have different mechanisms <strong>of</strong> action but<br />

both work to <strong>in</strong>crease <strong>the</strong> expression levels<br />

106 BioPharm International www.biopharm<strong>in</strong>ternational.com October 2007

<strong>Monoclonal</strong> <strong>Antibodies</strong><br />

<strong>of</strong> l<strong>in</strong>ked genes that are transfected on <strong>the</strong><br />

same plasmid as <strong>the</strong> MAR or UCOE.<br />

The use <strong>of</strong> MAR elements for improv<strong>in</strong>g<br />

expression has been commercialized by<br />

Selexis. The company has developed a set <strong>of</strong><br />

expression vectors and transfection technologies<br />

(<strong>the</strong> “MARtech” technology) that use<br />

<strong>the</strong>se elements to <strong>in</strong>crease <strong>the</strong> percentage <strong>of</strong><br />

cells express<strong>in</strong>g <strong>the</strong> desired gene. As shown<br />

schematically <strong>in</strong> Figure 2, <strong>the</strong> MAR elements<br />

are <strong>in</strong>serted <strong>in</strong>to an expression vector such<br />

that <strong>the</strong> gene for <strong>the</strong> desired product is surrounded<br />

by <strong>the</strong>se elements to impose an<br />

open chromat<strong>in</strong> configuration, <strong>the</strong>reby<br />

allow<strong>in</strong>g RNA polymerase and o<strong>the</strong>r transcription<br />

factors to access <strong>the</strong> transcriptional<br />

promoters and enhancers found <strong>in</strong> <strong>the</strong><br />

expression vector. For this reason, MARtech<br />

<strong>in</strong>creases <strong>the</strong> number <strong>of</strong> <strong>in</strong>dependently transformed<br />

cells that express <strong>the</strong> desired prote<strong>in</strong><br />

and enables expression levels <strong>in</strong> <strong>the</strong> <strong>in</strong>itial<br />

transfectants <strong>of</strong> as much as 50–70 pcd. Selexis<br />

claims that MARtech allows for generation <strong>of</strong><br />

clonal mammalian production cell l<strong>in</strong>es <strong>in</strong><br />

about 10 weeks. Many companies have<br />

begun explor<strong>in</strong>g <strong>the</strong> use <strong>of</strong> MARtech to<br />

enable rapid generation <strong>of</strong> high produc<strong>in</strong>g<br />

cell l<strong>in</strong>es for <strong>the</strong>ir antibody products. Later<br />

this year <strong>the</strong> first product us<strong>in</strong>g this technology<br />

will enter cl<strong>in</strong>ical trials. 17<br />

UCOE technology, now available through<br />

Millipore Corporation, provides an<br />

approach to <strong>in</strong>creas<strong>in</strong>g gene expression similar<br />

to that <strong>of</strong> <strong>the</strong> MARtech technology. The<br />

UCOE elements are functionally similar to<br />

MAR elements although <strong>the</strong>ir composition<br />

and structure are different. 16 UCOE consists<br />

<strong>of</strong> regions that are rich <strong>in</strong> <strong>the</strong> sequence CpG,<br />

and that <strong>in</strong>crease <strong>the</strong> accessibility <strong>of</strong> <strong>the</strong> surround<strong>in</strong>g<br />

chromat<strong>in</strong>. Therefore, a s<strong>in</strong>gle<br />

UCOE element can be <strong>in</strong>cluded on an<br />

expression vector and can <strong>in</strong>crease <strong>the</strong><br />

expression levels <strong>of</strong> l<strong>in</strong>ked genes. There is<br />

less commercial experience with UCOE elements<br />

than with MAR elements, but <strong>the</strong><br />

<strong>in</strong>tent is to <strong>of</strong>fer <strong>the</strong> technology to companies<br />

for use <strong>in</strong> research and <strong>in</strong> commercial<br />

production cell l<strong>in</strong>e generation.<br />

ADVANCES IN CELL CULTURE TECHNOLOGY<br />

Host cell l<strong>in</strong>es currently used to produce<br />

commercial MAb products <strong>in</strong>clude mur<strong>in</strong>e<br />

hybridoma and myeloma cell l<strong>in</strong>es, CHO cell<br />

l<strong>in</strong>es, and one human cell l<strong>in</strong>e (Table 2).<br />

Table 2. Host cell types used <strong>in</strong> <strong>the</strong> manufacture <strong>of</strong> commercial MAbs<br />

Cell l<strong>in</strong>e Species Number <strong>of</strong> products<br />

Hybridoma Mur<strong>in</strong>e 5<br />

SP2/0 myeloma Mur<strong>in</strong>e 5<br />

NS0 myeloma Mur<strong>in</strong>e 3<br />

O<strong>the</strong>r myeloma Mur<strong>in</strong>e 1<br />

Ch<strong>in</strong>ese hamster ovary (CHO) Hamster 10<br />

EBV-transformed B cell Human 1<br />

E. coli Microbial 1<br />

Those antibody products produced <strong>in</strong><br />

hybridoma cell l<strong>in</strong>es generally have lower<br />

dose requirements than o<strong>the</strong>rs and are also<br />

older than those produced us<strong>in</strong>g highly eng<strong>in</strong>eered<br />

systems such as CHO, NSO, or SP2/0.<br />

The s<strong>in</strong>gle product produced <strong>in</strong> a human cell<br />

l<strong>in</strong>e may represent a trend <strong>in</strong> com<strong>in</strong>g years<br />

as o<strong>the</strong>rs develop human cell l<strong>in</strong>es capable <strong>of</strong><br />

produc<strong>in</strong>g antibody products at high levels.<br />

While <strong>the</strong> use <strong>of</strong> mur<strong>in</strong>e cell l<strong>in</strong>es still prevails<br />

<strong>in</strong> commercial processes, <strong>the</strong> use <strong>of</strong><br />

CHO cells for produc<strong>in</strong>g commercial products<br />

is grow<strong>in</strong>g and most antibody products<br />

currently <strong>in</strong> development are produced from<br />

CHO or human cell l<strong>in</strong>es.<br />

Hybridoma Technology<br />

MAbs were first produced from hybridomas<br />

consist<strong>in</strong>g <strong>of</strong> a mur<strong>in</strong>e B cell produc<strong>in</strong>g a<br />

specific antibody fused to an immortal<br />

mur<strong>in</strong>e lymphoid cell l<strong>in</strong>e. Initially, MAbs<br />

were produced by <strong>in</strong>ject<strong>in</strong>g a hybridoma cell<br />

l<strong>in</strong>e <strong>in</strong>to <strong>the</strong> abdomen <strong>of</strong> pristane-primed<br />

mice, <strong>in</strong> which <strong>the</strong> cells could grow to a significant<br />

level. As <strong>the</strong> hybridoma cells grow<br />

<strong>in</strong> <strong>the</strong> abdomen, MAb-rich ascites fluid accumulates.<br />

The ascites fluid can <strong>the</strong>n be collected<br />

by withdraw<strong>in</strong>g it with needles at<br />

several day <strong>in</strong>tervals. The collected ascites<br />

fluid is very complex <strong>in</strong> composition and<br />

highly contam<strong>in</strong>ated, but frequently<br />

conta<strong>in</strong>s antibody concentrations approach<strong>in</strong>g<br />

1 g/L or greater. This process is widely<br />

used for <strong>the</strong> production <strong>of</strong> small to moderate<br />

amounts <strong>of</strong> antibodies for multiple applications<br />

and one commercial antibody product<br />

is produced today us<strong>in</strong>g this technology.<br />

The limitations <strong>of</strong> large-scale production<br />

<strong>in</strong> <strong>the</strong> abdomens <strong>of</strong> mice were quickly realized<br />

and scientists turned <strong>the</strong>ir efforts to use<br />

BioPharm International www.biopharm<strong>in</strong>ternational.com October 2007 107

<strong>Monoclonal</strong> <strong>Antibodies</strong><br />

Fed-batch processes are<br />

readily scaled-up to commercial<br />

volumes and represent <strong>the</strong> primary<br />

method <strong>in</strong> use today.<br />

<strong>in</strong> vitro culture as an alternative to replace <strong>in</strong><br />

vivo production <strong>in</strong> ascites. These <strong>in</strong>itial<br />

efforts focused on grow<strong>in</strong>g hybridomas <strong>in</strong><br />

culture, under conditions enabl<strong>in</strong>g <strong>the</strong> same<br />

high level <strong>of</strong> antibody expression as seen <strong>in</strong><br />

<strong>the</strong> ascites fluid. Initial studies characterized<br />

and compared <strong>the</strong> growth <strong>of</strong> hybridomas<br />

and production <strong>of</strong> antibodies <strong>in</strong> ei<strong>the</strong>r batch<br />

suspension cultures us<strong>in</strong>g stirred tanks and<br />

airlift fermentors or <strong>in</strong> perfusion cultures<br />

us<strong>in</strong>g a variety <strong>of</strong> methods for cell retention.<br />

From simple batch cultures, <strong>the</strong> use <strong>of</strong> controlled<br />

feed<strong>in</strong>g, also know as fed-batch,<br />

evolved as extremely successful <strong>in</strong> <strong>in</strong>creas<strong>in</strong>g<br />

maximum cell concentrations, culture<br />

longevities, and correspond<strong>in</strong>g product<br />

titers. Fed-batch is <strong>the</strong> primary mode <strong>of</strong> biopharmaceutical<br />

production used today, both<br />

for antibodies and o<strong>the</strong>r recomb<strong>in</strong>ant prote<strong>in</strong><br />

products.<br />

Hybridoma technology enabled <strong>the</strong> creation<br />

and production <strong>of</strong> MAbs for research,<br />

analytical use, and as limited-dose <strong>the</strong>rapeutic<br />

products. However, <strong>the</strong>se cell l<strong>in</strong>es are<br />

generally difficult to eng<strong>in</strong>eer for high levels<br />

<strong>of</strong> prote<strong>in</strong> expression and usually grow to<br />

only moderate densities <strong>in</strong> bioreactors.<br />

Hence, although <strong>the</strong>se cells are designed to<br />

produce antibodies, <strong>in</strong> many cases <strong>the</strong>y do<br />

so at levels that are too low to be optimal for<br />

manufactur<strong>in</strong>g today’s MAbs.<br />

Us<strong>in</strong>g CHO Cells as Production Hosts<br />

To circumvent <strong>the</strong> limitations <strong>of</strong> hybridomas<br />

for MAb production, scientists began experiment<strong>in</strong>g<br />

with alternative production hosts<br />

that could be grown to higher densities and<br />

transfected with <strong>the</strong> antibody genes to<br />

enable higher cellular productivity. The<br />

mur<strong>in</strong>e myeloma cell l<strong>in</strong>es NSO and SP2/0<br />

were among <strong>the</strong> first used to produce recomb<strong>in</strong>ant<br />

MAbs. At <strong>the</strong> same time, o<strong>the</strong>rs began<br />

exam<strong>in</strong><strong>in</strong>g CHO cell l<strong>in</strong>es. The CHO cell<br />

l<strong>in</strong>es proved to be a suitable production host<br />

for antibodies. Today, <strong>the</strong> vast majority <strong>of</strong><br />

biologic products made <strong>in</strong> mammalian cells<br />

are produced us<strong>in</strong>g a CHO host cell l<strong>in</strong>e.<br />

Because <strong>of</strong> <strong>the</strong> widespread adoption <strong>of</strong> this<br />

host cell, <strong>the</strong> growth characteristics, metabolism,<br />

behavior <strong>in</strong> bioreactors, virulence factors,<br />

and <strong>the</strong> likely host-cell related<br />

impurities that might be <strong>in</strong> a process or<br />

product are well understood. Moreover,<br />

because <strong>the</strong>re is a strong regulatory history<br />

<strong>of</strong> CHO cells, more and more products <strong>in</strong><br />

development are now made us<strong>in</strong>g CHO cells.<br />

Human Cell L<strong>in</strong>es<br />

While <strong>the</strong> use <strong>of</strong> CHO cells as production<br />

hosts cont<strong>in</strong>ues, o<strong>the</strong>r cell l<strong>in</strong>es, especially<br />

human cell l<strong>in</strong>es, are be<strong>in</strong>g developed as alternative<br />

hosts. For example, <strong>the</strong> PER.C6 cell l<strong>in</strong>e<br />

developed by Crucell, has been shown to produce<br />

antibodies at levels similar to or even<br />

greater than CHO cell l<strong>in</strong>es. 18 One potential<br />

advantage <strong>of</strong> products produced <strong>in</strong> <strong>the</strong>se cell<br />

l<strong>in</strong>es is that <strong>the</strong> glycosylation patterns and<br />

o<strong>the</strong>r post-translational modifications <strong>of</strong> antibodies<br />

produced <strong>in</strong> <strong>the</strong>m may be more similar<br />

to human antibodies. Therefore, <strong>the</strong> PER.C6<br />

cell l<strong>in</strong>e and o<strong>the</strong>r human cell l<strong>in</strong>es may<br />

prove to be reliable, safe, scalable, and economical<br />

alternatives to <strong>the</strong> CHO cell l<strong>in</strong>es currently<br />

<strong>in</strong> use for <strong>the</strong> production <strong>of</strong> MAbs.<br />

Chemically Def<strong>in</strong>ed Media<br />

Current regulatory requirements strongly discourage<br />

or ban <strong>the</strong> use <strong>of</strong> any products <strong>in</strong> <strong>the</strong><br />

culture media that are derived from animals,<br />

especially from bov<strong>in</strong>e sources. Therefore, <strong>the</strong><br />

use <strong>of</strong> bov<strong>in</strong>e serum, commonly used earlier<br />

<strong>in</strong> mammalian cell culture, has been discont<strong>in</strong>ued<br />

and significant efforts have been<br />

directed towards <strong>the</strong> development <strong>of</strong> cell culture<br />

media, that is free from animal-derived<br />

products. There is a grow<strong>in</strong>g trend toward <strong>the</strong><br />

use <strong>of</strong> chemically def<strong>in</strong>ed media. In such<br />

media, recomb<strong>in</strong>ant prote<strong>in</strong>s such as IGF-1,<br />

transferr<strong>in</strong>, <strong>in</strong>sul<strong>in</strong>, or o<strong>the</strong>rs may be <strong>in</strong>cluded<br />

to provide <strong>the</strong> necessary signals for cell<br />

growth. When used, <strong>the</strong> recomb<strong>in</strong>ant human<br />

versions <strong>of</strong> <strong>the</strong>se prote<strong>in</strong>s are preferred. To<br />

fur<strong>the</strong>r m<strong>in</strong>imize <strong>the</strong> risk associated with <strong>the</strong><br />

addition <strong>of</strong> animal-derived components, CHO<br />

and o<strong>the</strong>r production host cell l<strong>in</strong>es used for<br />

antibody production are now selected for<br />

<strong>the</strong>ir ability to grow and produce product at<br />

high levels <strong>in</strong> chemically def<strong>in</strong>ed media.<br />

110 BioPharm International www.biopharm<strong>in</strong>ternational.com October 2007

<strong>Monoclonal</strong> <strong>Antibodies</strong><br />

Significant efforts are be<strong>in</strong>g devoted<br />

to <strong>the</strong> cont<strong>in</strong>uous improvement<br />

<strong>in</strong> <strong>the</strong> safety and quality <strong>of</strong> MAbs.<br />

Several different chemically def<strong>in</strong>ed media are<br />

now commercially available from a variety <strong>of</strong><br />

vendors. However, most companies <strong>in</strong>volved<br />

<strong>in</strong> <strong>the</strong> development <strong>of</strong> MAb products today<br />

have developed proprietary cell culture media<br />

and growth conditions suitable for production<br />

<strong>of</strong> <strong>the</strong>ir particular monoclonal antibody<br />

at high titers.<br />

Along with improvements and ref<strong>in</strong>ements<br />

<strong>in</strong> expression systems and cell l<strong>in</strong>es<br />

for MAb production, <strong>the</strong>re have also been<br />

significant advances <strong>in</strong> cell culture conditions<br />

over <strong>the</strong> past 20 years to fur<strong>the</strong>r optimize<br />

antibody production. 19,20 The<br />

optimization <strong>of</strong> fed-batch processes has<br />

<strong>in</strong>creased antibody titers <strong>in</strong> culture orders <strong>of</strong><br />

magnitude so that expression levels <strong>of</strong><br />

greater than 1 g/L are frequently achieved.<br />

Perfusion Technology<br />

One <strong>in</strong>itial approach to <strong>in</strong>crease <strong>the</strong> yield <strong>of</strong><br />

antibody products from a s<strong>in</strong>gle bioreactor<br />

was <strong>the</strong> use <strong>of</strong> perfusion technology <strong>in</strong> which<br />

<strong>the</strong> media is cont<strong>in</strong>uously removed from <strong>the</strong><br />

bioreactor and replaced with fresh media.<br />

Perfusion technology is based on <strong>the</strong> rationale<br />

that cells <strong>in</strong> culture could cont<strong>in</strong>ue to<br />

produce antibody over several weeks if <strong>the</strong><br />

conditioned media, conta<strong>in</strong><strong>in</strong>g <strong>the</strong> antibody<br />

product along with potentially growth limit<strong>in</strong>g<br />

metabolites, were replaced regularly with<br />

fresh media and growth factors. Years <strong>of</strong> comparative<br />

work have shown that perfusion cultures<br />

can achieve higher volumetric<br />

productivities than fed-batch cultures at <strong>the</strong><br />

expense <strong>of</strong> lower product titers per liter <strong>of</strong><br />

medium consumed. Moreover, <strong>the</strong> cont<strong>in</strong>uously<br />

chang<strong>in</strong>g media conditions and long<br />

culture times required for perfusion production<br />

frequently lead to <strong>in</strong>consistent processes,<br />

variable glycosylation, and o<strong>the</strong>r post-translational<br />

modifications <strong>in</strong> <strong>the</strong> product over time<br />

<strong>in</strong> culture. The risk <strong>of</strong> contam<strong>in</strong>ation also<br />

<strong>in</strong>creases. Perfusion operations tend to be<br />

complex, difficult to scale up, and generally<br />

less robust than fed-batch processes. 21,22<br />

Therefore, fed-batch culture is now <strong>the</strong><br />

method <strong>of</strong> choice for robust, reproducible,<br />

and reliable manufactur<strong>in</strong>g processes. While<br />

<strong>the</strong> capital <strong>in</strong>vestments <strong>in</strong> a manufactur<strong>in</strong>g<br />

facility us<strong>in</strong>g fed-batch culture are higher<br />

than those for a perfusion-based facility, <strong>the</strong><br />

overall cost <strong>of</strong> goods for fed-batch and perfusion<br />

processes are similar. While both culture<br />

technologies are successfully used today by<br />

commercial manufacturers, <strong>the</strong> biopharmaceutical<br />

<strong>in</strong>dustry is converg<strong>in</strong>g on <strong>the</strong> use <strong>of</strong><br />

fed-batch suspension cultures <strong>in</strong> stirred-tank<br />

bioreactors with controlled feed<strong>in</strong>g.<br />

FUTURE CHALLENGES IN<br />

ANTIBODY MANUFACTURING<br />

The advances <strong>in</strong> cell l<strong>in</strong>e generation and cell<br />

culture described above have enabled<br />

companies to produce monoclonal antibodies<br />

at very high expression levels. As a result,<br />

early concerns that <strong>the</strong> <strong>in</strong>dustry would not be<br />

able to meet <strong>the</strong> grow<strong>in</strong>g production<br />

demands <strong>of</strong> MAbs have subsided. While <strong>the</strong>se<br />

significant improvements <strong>in</strong> upstream<br />

production have resulted <strong>in</strong> <strong>the</strong> ability to<br />

express MAbs at levels approach<strong>in</strong>g 10 g/L,<br />

<strong>the</strong> capacity and ability <strong>of</strong> downstream<br />

processes to handle <strong>the</strong>se high quantities <strong>of</strong><br />

antibody has been stra<strong>in</strong>ed. The compet<strong>in</strong>g<br />

demands <strong>of</strong> grow<strong>in</strong>g production requirements<br />

and reduced cost to <strong>the</strong> patient present<br />

challenges to <strong>the</strong> <strong>in</strong>dustry to make<br />

manufactur<strong>in</strong>g processes even more efficient.<br />

Improvements <strong>in</strong> chromatography media for<br />

antibody purification have resulted <strong>in</strong> media<br />

with higher capacities, faster throughput, and<br />

improved contam<strong>in</strong>ant clearance. Significant<br />

efforts are currently be<strong>in</strong>g devoted to<br />

develop<strong>in</strong>g alternative techniques to improve<br />

downstream process<strong>in</strong>g to enable <strong>the</strong> efficient<br />

process<strong>in</strong>g <strong>of</strong> high levels <strong>of</strong> antibody, enhance<br />

process robustness and yields, and reduce<br />

overall manufactur<strong>in</strong>g costs. Companies<br />

today are striv<strong>in</strong>g to <strong>in</strong>corporate Quality by<br />

Design and o<strong>the</strong>r new regulatory concepts<br />

<strong>in</strong>to <strong>the</strong> development <strong>of</strong> MAb products to<br />

fur<strong>the</strong>r reduce <strong>the</strong> cost and development<br />

timel<strong>in</strong>es for <strong>the</strong>se products. The<br />

manufacturers are also striv<strong>in</strong>g to develop<br />

f<strong>in</strong>al product formulations conta<strong>in</strong><strong>in</strong>g high<br />

concentrations <strong>of</strong> antibody with sufficient<br />

stability to address <strong>the</strong> <strong>in</strong>creas<strong>in</strong>g doses <strong>of</strong><br />

antibody products without adversely<br />

impact<strong>in</strong>g <strong>the</strong> quality <strong>of</strong> <strong>the</strong>se products. ◆<br />

112 BioPharm International www.biopharm<strong>in</strong>ternational.com October 2007

<strong>Monoclonal</strong> <strong>Antibodies</strong><br />

REFERENCES<br />

1. Kohler G, Milste<strong>in</strong> C. Cont<strong>in</strong>uous cultures <strong>of</strong> fused<br />

cells secret<strong>in</strong>g antibody <strong>of</strong> predef<strong>in</strong>ed specificity.<br />

Nature. 1975;256(5517):495–7.<br />

2. Available from FDA, CDER, 2003. <strong>Therapeutic</strong><br />

Biological Products Approval. Available on<br />

http://fda.gov/cder/biologics/biologics_table.htm<br />