AF-BELT - Veolia Water Solutions & Technologies

AF-BELT - Veolia Water Solutions & Technologies

AF-BELT - Veolia Water Solutions & Technologies

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

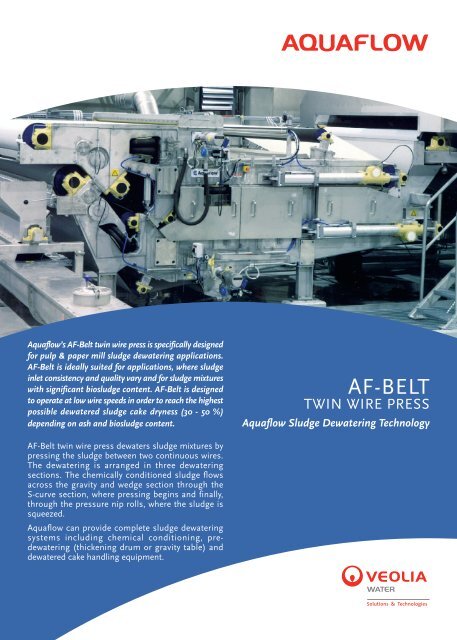

Aquaflow’s <strong>AF</strong>-Belt twin wire press is specifically designed<br />

for pulp & paper mill sludge dewatering applications.<br />

<strong>AF</strong>-Belt is ideally suited for applications, where sludge<br />

inlet consistency and quality vary and for sludge mixtures<br />

with significant biosludge content. <strong>AF</strong>-Belt is designed<br />

to operate at low wire speeds in order to reach the highest<br />

possible dewatered sludge cake dryness (30 - 50 %)<br />

depending on ash and biosludge content.<br />

<strong>AF</strong>-<strong>BELT</strong><br />

TWIN WIRE PRESS<br />

Aquaflow Sludge Dewatering Technology<br />

<strong>AF</strong>-Belt twin wire press dewaters sludge mixtures by<br />

pressing the sludge between two continuous wires.<br />

The dewatering is arranged in three dewatering<br />

sections. The chemically conditioned sludge flows<br />

across the gravity and wedge section through the<br />

S-curve section, where pressing begins and finally,<br />

through the pressure nip rolls, where the sludge is<br />

squeezed.<br />

Aquaflow can provide complete sludge dewatering<br />

systems including chemical conditioning, predewatering<br />

(thickening drum or gravity table) and<br />

dewatered cake handling equipment.

Easily changeable foils enhance the water removal and<br />

support the wire. Effective side seals allow a thick sludge<br />

cake and clear filtrate.<br />

Final sludge pressing between the high pressure nip<br />

roll pairs.<br />

design and operational benefits:<br />

• Suitable for mixtures of biological, fibreous,<br />

deinking and chemical sludges<br />

• A wide inlet consistency range of 0.5 - 10 %<br />

• A high sludge thickness and effective pressing<br />

due to a slow wire speed<br />

• The completely sealed side structure allows<br />

a thick sludge cake and clear filtrate with<br />

minimum spills<br />

• A compact design including a flocculator and<br />

thickening drum<br />

• Flexibility for process variations<br />

• Easy start-up and operation<br />

• A quick wire change either with a continuous or<br />

wire joint cloth<br />

• A low specific energy consumption (~5 kWh/BDt)<br />

• Fully automatic control options<br />

• Option: Central lubrication and effective wire<br />

washing with automatically brushed shower pipes<br />

<strong>AF</strong>-Belt is available in 2.0 and 2.8 meter wire<br />

widths to accommodate a wide range of design<br />

capacities. <strong>AF</strong>-Belt is constructed from stainless<br />

steel with a simple robust frame which provides<br />

an extremely rigid structure to maintain the<br />

roll alignment and to reduce the life cycle<br />

maintenance costs.<br />

Aquaflow provides full mechanical and<br />

performance guarantees for <strong>AF</strong>-Belt. We can<br />

also provide complete sludge dewatering<br />

systems including chemical conditioning and<br />

pre-dewatering to add value to your treatment<br />

systems.<br />

Currently more than 200 <strong>AF</strong>-Belt twin wire<br />

presses are successfully operating throughout<br />

the world in the sludge dewatering applications<br />

of the pulp and paper industry.<br />

Headbox Wedge zone S-Rolls Nip-Rolls Discharge<br />

doctor<br />

Aquaflow Ltd.<br />

P.O. Box 116, 57101 Savonlinna, Finland<br />

Tel. +358 (0) 207 441 600, Fax +358 (0) 207 441 699<br />

www.aquaflow.fi