General Delivery Specifications for Machinery and Equipment - Bosch

General Delivery Specifications for Machinery and Equipment - Bosch

General Delivery Specifications for Machinery and Equipment - Bosch

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>General</strong> <strong>Delivery</strong><br />

<strong>Specifications</strong><br />

<strong>for</strong><br />

<strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong><br />

<strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong> (MAE) <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong><br />

can also be found at<br />

www.boschnasuppliers.com<br />

Reference: - OP4.7.04.004<br />

Robert <strong>Bosch</strong> Corporation<br />

April, 2005

April<br />

2005 <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong>

<strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong><br />

<strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong><br />

Sections 1 - 9<br />

Revision 4 - April, 2005<br />

All prior editions are obsolete <strong>and</strong> should not be used.<br />

This document is controlled by:<br />

Robert <strong>Bosch</strong> Corporation<br />

ChW/BPS-LS (Industrial Engineering)<br />

8101 Dorchester Rd.<br />

Charleston, SC 29418<br />

(843) 760 - 7659<br />

wolfgang.hasper@us.bosch.com<br />

It is the user's responsibility to assure that only the latest revision of this st<strong>and</strong>ard is used.<br />

SUPANAGEMENT

BOSCH <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong> <strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong><br />

CHANGES MADE TO THE GENERAL DELIVERY SPECIFICATIONS SECTIONS 1-9<br />

Page Section Changes<br />

April 1, 2005<br />

2-3..5 2.2 Restructured section in order to match the Review<br />

Checklist.<br />

2-3 2.2.1 Moved Lean Manufacturing statement (BPS) to 2.2.2a.<br />

2-4 2.2.2 Added review of special attention points.<br />

4-3 4.1.2 Added awareness statement (AC has some different<br />

drawing st<strong>and</strong>ards).<br />

5-2 5.3.1 Additional in<strong>for</strong>mation on drawing <strong>for</strong>mats<br />

5-2 5.3.2 All software shall be licensed<br />

5-3 5.5.2 Additional b) trans<strong>for</strong>mer capacity (deleted in 5.5.5 a))<br />

5-4 5.5.5 c) Restated receptacle requirements<br />

5.5.5 Added f) Safety awareness statement.<br />

5-5 5.6.3 Entire paragraph rewritten.<br />

5-5 5.6.6 Added: str<strong>and</strong>ed copper, calibration fluids<br />

5-6 5.6.7 Plants can have different wire colors as per NFPA 79.<br />

5-6 5.8 Added Data Management <strong>and</strong> Networking.<br />

6-3 6.3.2 Entire paragraph rewritten.<br />

6-4 6.5.2 Changed changeover time according to BPS.<br />

6-5 6.7.1 Deleted modem, added Remote Access requirement.<br />

3 Sec. 7 Restructured Check Sheet: added numbering column <strong>and</strong><br />

reference column, separated “yes” column <strong>for</strong> Pre <strong>and</strong> Final<br />

Acceptance<br />

4 Sec. 7 Moved electrical cabinet clearance to Electrical Design.<br />

7 thru 10 Sec. 7 Section 5: Electrical Design completely revised.<br />

9 Sec. 7 Added Data Management <strong>and</strong> Networking.<br />

9 Sec. 7 Added to Gage Capability: alternatives a) <strong>and</strong> b).<br />

Sec. 9<br />

Sec. 9<br />

Sec. 9<br />

Sec. 9<br />

Sec. 9<br />

Sec. 9<br />

Appendix 2.1 - Deleted Modem, added Network<br />

requirements.<br />

Appendix 2.2 - Changed 1.1 to BPS Assessment.<br />

Appendix 2.3 - Replaced by BPS Investment Assessment.<br />

Appendix 4.1 - Added contact <strong>for</strong> <strong>Bosch</strong> Rexroth <strong>and</strong><br />

<strong>Bosch</strong> Power Tools.<br />

Appendix 5.2 - Added Special Attention Points <strong>for</strong><br />

<strong>Equipment</strong> Suppliers.<br />

Appendix 6.2 – Added in<strong>for</strong>mation regarding latest<br />

German/English issue.<br />

Changes<br />

Page 1 of 1

BOSCH <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong> <strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong> Apr. 1, 2005<br />

Other pages of the GDS available <strong>for</strong> viewing:<br />

- COVER PAGE<br />

- SECTIONS 1-9 OWNER’S PAGE<br />

- CHANGES MADE TO SECTIONS 1-9<br />

TABLE OF CONTENTS<br />

SECTION 1 - GENERAL PROCEDURES<br />

Page<br />

1.1 Preface........................................................................................................... 1-2<br />

1.2 Formal Quotation Requirements................................................................. 1-2<br />

1.3 Order <strong>and</strong> Alterations .................................................................................. 1-6<br />

1.4 Work on Buyer’s Facility ............................................................................. 1-6<br />

1.5 Payment Schedule......................................................................................... 1-7<br />

SECTION 2 - PROJECT MANAGEMENT<br />

2.1 Project Timing .............................................................................................. 2-2<br />

* 2.2 Design Review Requirements....................................................................... 2-3<br />

SECTION 3 - SAFETY AND HEALTH STANDARDS<br />

3.1 <strong>General</strong> ......................................................................................................... 3-2<br />

3.2 <strong>General</strong> St<strong>and</strong>ards........................................................................................ 3-2<br />

3.3 Noise St<strong>and</strong>ard.............................................................................................. 3-3<br />

3.4 Environmental Considerations .................................................................... 3-3<br />

Table of Contents - i

BOSCH <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong> <strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong> Apr. 1, 2005<br />

SECTION 4 - MECHANICAL DESIGN<br />

Page<br />

* 4.1 Mechanical Design Guidelines ..................................................................... 4-2<br />

4.2 Floor Plan Layout......................................................................................... 4-5<br />

4.3 Ergonomic Guidelines .................................................................................. 4-6<br />

4.4 Pneumatic Controls ...................................................................................... 4-7<br />

4.5 Lubrication ................................................................................................... 4-9<br />

4.6 Paint .............................................................................................................. 4-9<br />

SECTION 5 - ELECTRICAL DESIGN<br />

5.1 St<strong>and</strong>ards ...................................................................................................... 5-2<br />

5.2 Control Systems Overview ........................................................................... 5-2<br />

* 5.3 Documentation.............................................................................................. 5-2<br />

5.4 Functional ..................................................................................................... 5-2<br />

* 5.5 <strong>Equipment</strong>..................................................................................................... 5-3<br />

* 5.6 Wiring Methods............................................................................................ 5-5<br />

5.7 Programmable Logic Controllers <strong>and</strong> Computers ..................................... 5-6<br />

* 5.8 Data Management <strong>and</strong> Networking............................................................. 5-6<br />

SECTION 6 - QUALITY STANDARDS & RUN-OFF CONDITIONS<br />

6.1 <strong>General</strong>.......................................................................................................... 6-2<br />

6.2 Guidelines <strong>for</strong> Statistical Evaluation ........................................................... 6-2<br />

* 6.3 Gage, Process <strong>and</strong> Machine Capability....................................................... 6-3<br />

6.4 Gage Scale <strong>and</strong> Signal Output ..................................................................... 6-3<br />

* 6.5 <strong>Equipment</strong> Effectiveness <strong>and</strong> Durability Demonstrations ......................... 6-4<br />

6.6 Run-off Conditions ....................................................................................... 6-4<br />

* 6.7 Software Validation...................................................................................... 6-5<br />

SECTION 7 - PRE/FINAL ACCEPTANCE<br />

7.1 <strong>General</strong>.......................................................................................................... 7-2<br />

* 7.2 Pre/Final Acceptance Checklist ................................................................... 7-3<br />

Table of Contents - ii

BOSCH <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong> <strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong> Apr. 1, 2005<br />

SECTION 8 - DOCUMENTATION & SHIPPING INSTRUCTIONS<br />

Page<br />

8.1 Machine Documents ....................................................................................8-2<br />

8.2 Shipping Instructions ..................................................................................8-3<br />

8.3 Ocean Freight Shipping . ............................................................................8-3<br />

8.4 Package Identification .................................................................................8-4<br />

8.5 Shipping Documentation.............................................................................8-4<br />

8.6 Invoicing.......................................................................................................8-5<br />

SECTION 9 - APPENDICES<br />

*<br />

*<br />

*<br />

*<br />

*<br />

*<br />

• Appendix 1.1<br />

• Appendix 2.1<br />

• Appendix 2.2<br />

• Appendix 2.3<br />

• Appendix 4.1<br />

• Appendix 4.2<br />

• Appendix 5.1<br />

• Appendix 5.2<br />

• Appendix 6.1<br />

• Appendix 6.2<br />

• Appendix 8.1<br />

<strong>General</strong> Terms <strong>and</strong> Conditions <strong>for</strong> the Purchase of Capital<br />

<strong>Equipment</strong><br />

Machine Data Sheet<br />

Design Review Checklist<br />

Investment Assessment<br />

US Contacts <strong>for</strong> <strong>Bosch</strong> Products<br />

Workplace Measurements<br />

Control Systems Overview <strong>for</strong>m<br />

Special Attention Points <strong>for</strong> <strong>Equipment</strong> Suppliers<br />

Parts to Produce <strong>for</strong> Total Test, Sample Size<br />

Technical Availability<br />

Documentation<br />

SECTION 10 - ATTACHMENTS (PLANT SPECIFIC)<br />

(See Section <strong>for</strong> details)<br />

Table of Contents - iii

BOSCH <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong> <strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong> Apr. 1, 2005<br />

SECTION 1 - GENERAL PROCEDURES<br />

TABLE OF CONTENTS<br />

1.1 Preface. ...................................................................................................................1-2<br />

1.2 Formal Quotation Requirements ...........................................................................1-2<br />

1.2.1...... <strong>General</strong>.......................................................................................................1-2<br />

1.2.2...... Parameters of Quote <strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong> ...................................1-3<br />

1.2.3...... Itemized Prices...........................................................................................1-4<br />

1.2.4...... Proposal Description ..................................................................................1-5<br />

1.2.5...... Project Completion.....................................................................................1-5<br />

1.3 Order <strong>and</strong> Alterations ............................................................................................1-6<br />

1.4 Work at Buyer’s Facility ........................................................................................1-6<br />

1.5 Payment Schedule...................................................................................................1-7<br />

Page<br />

<strong>General</strong> Procedures - 1 - 1

BOSCH <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong> <strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong> Apr. 1, 2005<br />

SECTION 1 - GENERAL PROCEDURES<br />

1.1 Preface<br />

This specification has been written to present Robert <strong>Bosch</strong> Corporation/Affiliate’s<br />

(hereinafter referred to as ‘<strong>Bosch</strong>’) requirements <strong>for</strong> industrial equipment in an orderly<br />

manner.<br />

Supplier <strong>and</strong> any subsequent suppliers shall comply with this specification <strong>and</strong> with "<strong>General</strong><br />

Terms <strong>and</strong> Conditions <strong>for</strong> the Purchase of Capital <strong>Equipment</strong>" (see Appendix 1.1).<br />

It is not intended to limit or inhibit development in industrial equipment design. Functional<br />

design of equipment shall be the equipment supplier’s responsibility. The application of<br />

"Lean <strong>Equipment</strong> Design" principles is required.<br />

If the supplier interprets the requirements of this document or any <strong>Bosch</strong> specification to be<br />

in conflict with Federal or State regulations, it is the supplier’s responsibility to get<br />

clarification from <strong>Bosch</strong>’s Project Engineer.<br />

Deviations to specifications provided herein may be allowed when necessary, <strong>and</strong> agreed<br />

upon in writing by Project Engineer. Copy to Purchasing.<br />

Individual locations may have plant specific requirements which can be found in<br />

Section 10.<br />

1.2 Formal Quotation Requirements<br />

1.2.1 <strong>General</strong><br />

Request <strong>for</strong> Quotations (RFQ) are originated by the Project Engineer <strong>and</strong> transmitted<br />

through the Purchasing Department to the equipment supplier. The Project Engineer<br />

shall provide process <strong>and</strong> equipment specifications adequate to define <strong>Bosch</strong>'s<br />

requirements <strong>for</strong> the particular equipment under consideration. Quotes must be<br />

returned to Purchasing Department <strong>and</strong> must have <strong>Bosch</strong> RFQ<br />

number. All paper quotations must be submitted in triplicate. Electronically<br />

submitted quotes need buyer's permission.<br />

<strong>General</strong> Procedures - 1 - 2

BOSCH <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong> <strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong> Apr. 1, 2005<br />

1.2.2 Parameters of Quote <strong>for</strong> <strong>Machinery</strong> & <strong>Equipment</strong><br />

a) All production machinery must comply with <strong>General</strong> <strong>Delivery</strong><br />

<strong>Specifications</strong>.<br />

The quotation must include this statement:<br />

“We agree to con<strong>for</strong>m to <strong>Bosch</strong>’s <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong> - <strong>for</strong><br />

machinery <strong>and</strong> equipment”.<br />

If this is not possible, a request <strong>for</strong> specific deviations must be included in<br />

the quotation <strong>and</strong> written approval of the deviations requested must be<br />

obtained from the Project Engineer or his/her immediate supervisor be<strong>for</strong>e<br />

an order can be accepted.<br />

b) The following in<strong>for</strong>mation to be included:<br />

• <strong>Bosch</strong> RFQ Number<br />

• Part name(s), number(s), <strong>and</strong>/or identification number.<br />

• Name of Project Engineer requesting the quote.<br />

• Machine tool equipment supplier’s quotation number <strong>and</strong> date.<br />

c) The quotation shall include firm delivery dated from the date of purchase<br />

order.<br />

d) Document requirements:<br />

All drawings, documentation, etc., as per Section 8 shall be supplied in<br />

English.<br />

e) Must provide special foundation or other site requirements in quote.<br />

f) A basic timeline containing critical milestones is to be provided with the<br />

quote.<br />

<strong>General</strong> Procedures - 1 - 3

BOSCH <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong> <strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong> Apr. 1, 2005<br />

1.2.3 Itemized Prices<br />

The following shall be itemized <strong>and</strong> separately priced on the quote:<br />

a) Basic machine<br />

b) Special Machine Options<br />

c) Fixtures/Workholding<br />

d) Perishable Tools (if requested).<br />

e) Charges, if any, <strong>for</strong> engineering, source code, drawings, or service<br />

in<strong>for</strong>mation.<br />

f) Auxiliary equipment of a separable nature, such as: Hydraulics, Air<br />

H<strong>and</strong>ling, Coolant Filtration, Conveyors, etc.<br />

g) Environmental <strong>and</strong> health control devices. This would include but not be<br />

limited to chip removal, mist, <strong>and</strong> vacuum equipment.<br />

h) Electrical <strong>and</strong> electronic controls.<br />

i) Automatic gaging <strong>and</strong> size control (if requested).<br />

j) Spare parts package.<br />

k) Machine run-off costs.<br />

l) Service <strong>and</strong> installation charges (if required).<br />

m) Cost of training.<br />

n) Warranty In<strong>for</strong>mation.<br />

<strong>General</strong> Procedures - 1 - 4

BOSCH <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong> <strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong> Apr. 1, 2005<br />

1.2.4 Proposal Description<br />

1.2.4.1 The items quoted shall be accurately described by proposal drawings<br />

<strong>and</strong>/or text. Data on obtainable production rates, (in pcs./hr. @ 85%<br />

utilization), estimated power consumption, maximum change-over times,<br />

buffer capacity between stations, <strong>and</strong> process <strong>and</strong> gage capabilities shall be<br />

included where applicable. Complete cycle detail is required on each<br />

station. Estimated coolant, water, steam, compressed air, gas, etc.,<br />

consumption <strong>and</strong>/or flow rates required at machine must be included.<br />

1.2.4.2 Number of pieces that will be run-off <strong>for</strong> each part number is defined in<br />

Appendix 6.1. These are the quantity of parts that will be run at no charge<br />

as part of the quote package, <strong>and</strong> are expected to be good parts per <strong>Bosch</strong>’s<br />

requirements. Pieces required <strong>for</strong> set-up, tryout, or to qualify equipment<br />

shall be supplied by <strong>Bosch</strong>.<br />

1.2.4.3 In<strong>for</strong>mation required <strong>for</strong> Control System Overview (Appendix 5.1) should<br />

be included in proposal as much as possible. In<strong>for</strong>mation not available at<br />

time of proposal must be submitted along with concept approval drawings.<br />

1.2.4.4 The supplier shall in<strong>for</strong>m the Project Engineer of any known or suspected<br />

by-products of machine fluids used which may be hazardous to health.<br />

1.2.5 Project Completion<br />

At the completion of each project, parts, drawings <strong>and</strong> support documentation<br />

belonging to <strong>Bosch</strong> to be entirely returned.<br />

<strong>General</strong> Procedures - 1 - 5

BOSCH <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong> <strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong> Apr. 1, 2005<br />

1.3 Order <strong>and</strong> Alterations<br />

1.3.1 Purchase orders <strong>and</strong> amendments to purchase orders are issued by <strong>Bosch</strong> through the<br />

Purchasing Department only. No statement of intent to purchase or to amend an<br />

existing order is a commitment by <strong>Bosch</strong> until issued by the Purchasing Department.<br />

1.3.2 When the product design is changed, new prints will be submitted to the equipment<br />

supplier by the Project Engineer, with a written request to quote modification of the<br />

equipment under construction required to comply with the revised product design;<br />

including changes to price <strong>and</strong> delivery. After approval of the proposed modification<br />

by <strong>Bosch</strong>, an amendment will be issued by the Purchasing Department to cover the<br />

additional costs.<br />

1.3.3 Acknowledgment of the order acceptance <strong>and</strong> confirmation of delivery or price shall<br />

be received by the <strong>Bosch</strong> Purchasing Department <strong>and</strong> the Project Engineer<br />

responsible as soon as possible, but not later than three weeks after receipt of<br />

purchase order by the equipment manufacturer.<br />

1.4 Work at Buyer’s Facility (See also Section 9: <strong>General</strong> Terms <strong>and</strong> Conditions <strong>for</strong> the<br />

Purchase of Capital <strong>Equipment</strong> (Appendix 1.1))<br />

1.4.1 <strong>Equipment</strong> supplier to provide installation supervision or instruction to assure that<br />

equipment is installed properly <strong>and</strong> fulfills requirements of the warranty.<br />

1.4.2 All equipment suppliers must sign <strong>and</strong> adhere to each facilities’ Contractor Safety<br />

Declaration. This requires the supplier to follow plant-specific lock out, tag out<br />

requirement, confined space entry, etc.<br />

1.4.3 Welding, cutting, soldering jobs, heating <strong>and</strong> thawing with welding torches, gasoline<br />

or gas burners, etc., are <strong>for</strong>bidden unless specific permits are obtained from <strong>Bosch</strong>.<br />

1.4.4 <strong>Bosch</strong> draws particular attention to the fact that smoking may be restricted or<br />

<strong>for</strong>bidden in certain areas of our plants. Safety glasses <strong>and</strong> appropriate working attire<br />

<strong>and</strong> footwear are required within all <strong>Bosch</strong> facilities. Other safety equipment is as<br />

required by OSHA regulations.<br />

<strong>General</strong> Procedures - 1 - 6

BOSCH <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong> <strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong> Apr. 1, 2005<br />

1.5 Payment Schedule (See also Section 5 <strong>and</strong> 7.3 of <strong>General</strong> Terms <strong>and</strong> Conditions <strong>for</strong> the<br />

Purchase of Capital <strong>Equipment</strong> (Appendix 1.1)).<br />

1.5.1 Robert <strong>Bosch</strong> Corporation payment schedule <strong>for</strong> the Purchase of Capital <strong>Equipment</strong><br />

is as follows:<br />

80% Net 30 of complete purchase price upon <strong>Delivery</strong> of equipment to specified<br />

<strong>Bosch</strong> Facility.<br />

20% Net 30 of complete purchase price upon Final Acceptance at specified <strong>Bosch</strong><br />

Facility.<br />

(See Section 7 <strong>for</strong> Pre-Final Acceptance Checklist.)<br />

<strong>General</strong> Procedures - 1 - 7

BOSCH <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong> <strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong> Apr. 1, 2005<br />

SECTION 2 - PROJECT MANAGEMENT<br />

TABLE OF CONTENTS<br />

2.1 Project Timing ........................................................................................................2-2<br />

Page<br />

2.2 Design Review Requirements.................................................................................2-3<br />

* 2.2.1...... Design Reviews .........................................................................................2-3<br />

* 2.2.2...... First Design Review...................................................................................2-3<br />

* 2.2.3...... Final Design Review ..................................................................................2-4<br />

Project Management - 2 - 5

BOSCH <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong> <strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong> Apr. 1, 2005<br />

SECTION 2 - PROJECT MANAGEMENT<br />

2.1 Project Timing<br />

2.1.1 To ensure equipment delivery meets critical timing phases <strong>and</strong> final shipment dates,<br />

it is the responsibility of the supplier to provide <strong>and</strong> maintain a project time line <strong>and</strong><br />

tracking system.<br />

2.1.2 A draft of this time line is to be provided with the quotation.<br />

The final time line is to be provided to the project engineer within 2 weeks after<br />

receipt of a <strong>for</strong>mal purchase order.<br />

2.1.3 The project time line must be detailed enough to show all critical milestones <strong>and</strong> as a<br />

minimum include the following items:<br />

a) Kick-off meeting<br />

b) Process flow chart<br />

c) Process FMEA review<br />

d) Preliminary design (mechanical <strong>and</strong> electrical)<br />

e) Preliminary design review<br />

f) Purchase of critical long lead-time components<br />

g) Final design (mechanical <strong>and</strong> electrical)<br />

h) Final design review<br />

i) Purchase of remaining material<br />

j) <strong>Equipment</strong> control programming<br />

k) <strong>Equipment</strong> control program review<br />

l) Receipt of purchased/produced components<br />

m) Floor plan layout <strong>and</strong> foundation requirement<br />

n) <strong>Equipment</strong> build/assembly<br />

o) Tryout part availability<br />

p) System tryout <strong>and</strong> debug<br />

- manual mode<br />

- automatic mode<br />

q) Measurement system calibration<br />

r) Preliminary gage capability study<br />

s) Preliminary process capability study<br />

t) Documentation review<br />

Project Management - 2 - 2

BOSCH <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong> <strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong> Apr. 1, 2005<br />

u) Pre-acceptance at supplier<br />

v) Package & ship<br />

w) Installation at <strong>Bosch</strong><br />

x) Tryout <strong>and</strong> debug at <strong>Bosch</strong><br />

y) Final capability studies<br />

z) Final acceptance sign-off<br />

2.1.4 The project time line is to be updated <strong>and</strong> submitted to the project engineer every two<br />

weeks throughout the project life. It is the equipment supplier’s responsibility to<br />

provide any action plan to correct problems that are causing significant shifts in the<br />

time line.<br />

2.2 Design Review Requirements<br />

2.2.1 Design Reviews<br />

* A minimum of two design reviews will be held to insure that the project goals <strong>and</strong><br />

specifications are being met. The actual number of design reviews will be<br />

determined by the project engineer.<br />

* 2.2.2 First Design Review<br />

The first design review will be a comprehensive concept design review <strong>and</strong><br />

preliminary PFMEA (Process Failure Mode <strong>and</strong> Effect Analysis) review.<br />

The following points are to be discussed, whereby the supplier must make available<br />

necessary documents:<br />

* a) Review of relevant topics of the BPS (<strong>Bosch</strong> Production System) Assessment,<br />

Appendix 2.3.<br />

b) A concept drawing of the overall machines. This drawing must show the<br />

overall completed machine or assembly. It must have at least two views, a<br />

plan or top view, <strong>and</strong> one side or elevation view. Sufficient detail must be<br />

shown to convey the overall completed appearance of the equipment including<br />

control panels. It must be drawn to scale <strong>and</strong> show overall dimensions of<br />

height, width, length, location <strong>and</strong> dimensions of auxiliary control cabinets, the<br />

location of the work piece or part, <strong>and</strong> the direction of index travel.<br />

c) Additional concept drawing(s) of all equipment operations <strong>and</strong> processes.<br />

Sufficient detail must be shown to communicate the operation(s) of the<br />

machine. Main components must be shown <strong>and</strong> labeled.<br />

Project Management - 2 - 3

BOSCH <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong> <strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong> Apr. 1, 2005<br />

d) A control system overview which will contain a listing of major components.<br />

e) Material h<strong>and</strong>ling overview.<br />

f) Review of Ergonomics.<br />

g) Hazard assessment of robots <strong>and</strong> hazardous material (MSDS).<br />

* h) Review of Special Attention Points, Appendix 5.2.<br />

i) Machine guarding.<br />

j) A completed Machine Data Sheet, Appendix 2.1.<br />

k) Literature <strong>and</strong> specifications <strong>for</strong> any major machine components that were not<br />

elected from the recommended parts list(s).<br />

l) Approval Prints<br />

The supplier must provide two copies of all of the above documentation. At<br />

the design review, the project engineer <strong>and</strong> the supplier will sign <strong>and</strong> date each<br />

copy of the approval prints to indicate that the concepts have been approved.<br />

Any changes or modifications that are required will be noted on the prints.<br />

A follow-up review may be required to evaluate modifications.<br />

m) Completion of Design Review Checklist, Appendix 2.2.<br />

* 2.2.3 Final Design Review<br />

The final design review will be a review of all engineering documentation <strong>and</strong><br />

PFMEA. This review will be completed be<strong>for</strong>e construction of the equipment<br />

begins.<br />

The supplier must provide the following:<br />

a) Mechanical Assembly <strong>and</strong> Subassembly Drawings<br />

b) Detail Drawings <strong>and</strong> Parts Lists<br />

c) Pneumatic & Hydraulic Schematics <strong>and</strong> Parts Lists<br />

d) Control System Functional (Sequence) Plan<br />

e) Electrical Control System Diagrams, Drawings, & Parts Lists<br />

f) Critical <strong>and</strong> Proprietary Parts<br />

Project Management - 2 - 4

BOSCH <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong> <strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong> Apr. 1, 2005<br />

g) Updated Machine Data Sheet<br />

h) Hazardous Material List<br />

i) Foundation Drawing<br />

j) Approval Prints<br />

k) Anticipated PM Requirements (Labor, Material, & Frequency)<br />

2.2.4 The supplier must provide two copies of all of the above documentation. At the<br />

design review, the project engineer <strong>and</strong> the supplier will sign <strong>and</strong> date each copy<br />

of the approval prints to indicate that the concepts have been approved. Any<br />

changes or modifications that are required will be noted on the prints. A followup<br />

review may be required to evaluate modifications.<br />

Project Management - 2 - 5

BOSCH <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong> <strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong> Apr. 1, 2005<br />

SECTION 3 - SAFETY AND HEALTH STANDARDS<br />

TABLE OF CONTENTS<br />

Page<br />

3.1 <strong>General</strong> ...................................................................................................................3-2<br />

3.2 <strong>General</strong> St<strong>and</strong>ards..................................................................................................3-2<br />

3.3 Noise St<strong>and</strong>ard........................................................................................................3-3<br />

3.4 Environmental Considerations ..............................................................................3-3<br />

Safety <strong>and</strong> Health St<strong>and</strong>ards - 3 - 1

BOSCH <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong> <strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong> Apr. 1, 2005<br />

SECTION 3 - SAFETY AND HEALTH STANDARDS<br />

3.1 <strong>General</strong><br />

<strong>Equipment</strong> must meet the requirements of the Occupational Safety <strong>and</strong> Health Act (latest<br />

amended edition). The OSHA st<strong>and</strong>ards are to be interpreted as minimum requirements.<br />

3.2 <strong>General</strong> St<strong>and</strong>ards<br />

3.2.1 In view of constantly changing laws, regulations, codes, <strong>and</strong> st<strong>and</strong>ards, it is the<br />

responsibility of the supplier to comply with all regulations.<br />

The latest version <strong>and</strong> applicable sections of the following st<strong>and</strong>ards in effect at the<br />

time of the order’s acceptance:<br />

a) Occupational Safety <strong>and</strong> Health Administration, Department of Labor, <strong>General</strong><br />

Industry St<strong>and</strong>ards, Series 1910 (latest revision).<br />

b) American National St<strong>and</strong>ards Institute Codes.<br />

c) National Fire Protection Association (NFPA) Regulations.<br />

d) National Fluid Power Association “Systems St<strong>and</strong>ard <strong>for</strong> Industrial <strong>Machinery</strong>”.<br />

3.2.2 <strong>Equipment</strong> must be designed to accept lockout devices on all energy sources (i.e.<br />

pneumatic, hydraulic, electric) <strong>and</strong> must be labeled.<br />

3.2.3 Additional safety requirements are included in the specific sections <strong>for</strong> electrical,<br />

hydraulic, pneumatic, <strong>and</strong> machine design.<br />

3.2.4 A written risk assessment as per latest ANSI/RIA R15.06 is required <strong>for</strong> all robots<br />

prior to final acceptance.<br />

3.2.5 No asbestos containing materials (ACM) shall be used.<br />

3.2.6 <strong>Equipment</strong> with lasers shall be classified <strong>and</strong> certified to meet applicable St<strong>and</strong>ards<br />

(21 CFR 1010-1050), provide “Laser Product Report” <strong>and</strong> accession number from<br />

the Center <strong>for</strong> Devices <strong>and</strong> Radiological Health (CDRH).<br />

Safety <strong>and</strong> Health St<strong>and</strong>ards - 3 - 2

BOSCH <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong> <strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong> Apr. 1, 2005<br />

3.3 Noise St<strong>and</strong>ard<br />

All steady state or cyclical noise levels produced by machinery or equipment shall not exceed<br />

80dB(A), when running under all anticipated operating conditions while producing parts.<br />

The noise measurement shall be made along the perimeter of the machine at a 3 foot distance<br />

<strong>and</strong> also at the operator(s) position(s).<br />

3.4 Environmental Considerations<br />

(Gases, Fluids, Coolants, Cleaning Solutions, Paints, etc.)<br />

3.4.1 In response to increasingly stringent controls on the use <strong>and</strong> disposal of waste<br />

materials, the supplier shall con<strong>for</strong>m to the following provisions:<br />

a) ISO 14000 Environmental Management System.<br />

b) Material Safety Data Sheet in English must be submitted to the Project Engineer<br />

<strong>for</strong> approval of all material to be used in the machine prior to Preliminary Design<br />

Review. Usage rates of environmentally sensitive chemicals need to be indexed<br />

to some criteria such as production rates.<br />

c) Materials containing PCB (polychlorinated biphenyl) are not allowed<br />

(e.g. capacitors, oil in trans<strong>for</strong>mers, <strong>and</strong> certain hydraulic fluids).<br />

Mercury containing switches/devices are not permitted.<br />

Use of leaded paint is not permitted.<br />

d) The supplier shall notify the Project Engineer of any anticipated levels of<br />

emission from radiation, gases, vapors, fumes, dusts, <strong>and</strong> mists.<br />

e) All chemicals must be recertified to be on the EPA TSCA inventory.<br />

f) <strong>Equipment</strong> shall be designed to contain all process fluids (oil, coolant, etc.) with<br />

no leaks or splashing onto the operator or floor.<br />

3.4.2 An approved material list is available from the Project Engineer upon request.<br />

3.4.3 All equipment that requires ventilation <strong>for</strong> oil/coolant MUST use filtration<br />

equipment. The mist density must not exceed 0.2 mg/m3 at the equipment exhaust.<br />

<strong>Equipment</strong> manufacturers must utilize the filtration technology specified by <strong>Bosch</strong>.<br />

(See plant specific requirements, Section 10 - Attachments)<br />

(See Section 7 <strong>for</strong> Pre-Final Acceptance Checklist.)<br />

Safety <strong>and</strong> Health St<strong>and</strong>ards - 3 - 3

BOSCH <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong> <strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong> Apr. 1, 2005<br />

SECTION 4 - MECHANICAL DESIGN<br />

TABLE OF CONTENTS<br />

Page<br />

4.1 Mechanical Design Guidelines ...............................................................................4-2<br />

4.1.1...... Components ...............................................................................................4-2<br />

* 4.1.2...... Drawing St<strong>and</strong>ards.....................................................................................4-3<br />

4.2 Floor Plan Layout...................................................................................................4-5<br />

4.2.1...... <strong>General</strong> Requirements................................................................................4-5<br />

4.2.2...... Floor Layout Drawings...............................................................................4-5<br />

4.2.3...... Machine Leveling.......................................................................................4-5<br />

4.3 Ergonomic Guidelines ............................................................................................4-6<br />

4.3.1...... Workstations ..............................................................................................4-6<br />

4.3.2...... Workplace Measurement............................................................................4-6<br />

4.3.3...... Task Lighting .............................................................................................4-6<br />

4.3.4...... Controls <strong>and</strong> Indicators...............................................................................4-6<br />

* 4.3.5...... Lifting ........................................................................................................4-6<br />

4.3.6...... Access........................................................................................................4-6<br />

4.4 Pneumatic Controls ................................................................................................4-7<br />

4.4.1...... <strong>General</strong>.......................................................................................................4-7<br />

4.4.2...... <strong>Equipment</strong> Requirements ...........................................................................4-7<br />

4.4.3...... Safety.........................................................................................................4-7<br />

4.5 Lubrication..............................................................................................................4-9<br />

4.6 Paint .... ...................................................................................................................4-9<br />

Mechanical Design - 4 - 1

BOSCH <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong> <strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong> Apr. 1, 2005<br />

SECTION 4 - MECHANICAL DESIGN<br />

4.1 Mechanical Design Guidelines<br />

4.1.1 Components<br />

a) Use of BOSCH Products:<br />

The use of BOSCH products is required <strong>for</strong> special purpose machines. For<br />

In<strong>for</strong>mation <strong>and</strong> Service, contact responsible BOSCH group (see Appendix 4.1)<br />

<strong>for</strong> product overview <strong>and</strong> addresses. If the use of BOSCH products is not<br />

possible, exceptions must be noted at the time of quotation, in exceptional cases<br />

at latest during preliminary design review.<br />

b) Preferred Mechanical/Pneumatic Components:<br />

The use of components readily available within U.S. is required.<br />

(See plant specific requirements, Section 10 - Attachments)<br />

c) Measurement Instruments:<br />

Selection of measurement instruments <strong>and</strong> systems has to include consideration<br />

of calibration requirements. Prior to final selection, the equipment supplier must<br />

communicate to the Project Engineer the necessary procedures, equipment <strong>and</strong><br />

masters. For masters <strong>and</strong> gages, a certification of calibration <strong>and</strong> traceability to<br />

a st<strong>and</strong>ard has to be supplied by the equipment supplier. Masters must be<br />

delivered with the equipment.<br />

(See plant specific requirements, Section 10 - Attachments)<br />

d) Metric Hardware is required. Deviations require approval by the project<br />

engineer.<br />

Mechanical Design - 4 - 2

BOSCH <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong> <strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong> Apr. 1, 2005<br />

4.1.2 Drawing St<strong>and</strong>ards<br />

* See plant specific requirements, Section 10 – Attachments.<br />

a) Language:<br />

All documentation, including drawing remarks, schematic diagrams, parts lists,<br />

PLC programs, etc., must be in English.<br />

b) Dimensions:<br />

To insure uni<strong>for</strong>mity of machine <strong>and</strong> tool design, details should con<strong>for</strong>m to the<br />

International System of Units (SI). English equivalent may be shown in<br />

parenthesis adjacent to the metric dimension. Geometric Dimensioning <strong>and</strong><br />

Tolerancing is preferred.<br />

c) Sizes:<br />

• Mechanical Drawings:<br />

Assembly <strong>and</strong> detail drawings should be drawn on ANSI D or DIN A1.<br />

Multiple detail drawings should be placed on one sheet.<br />

• Parts List (Bill of Materials):<br />

Separate parts lists should be on A size.<br />

d) Drawings Numbers:<br />

Drawings shall contain a BOSCH assigned drawing number in the title block.<br />

Contact Project Engineer <strong>for</strong> numbers.<br />

e) CAD-Drawings:<br />

CAD-drawings are preferred over hardcopy originals. For <strong>for</strong>mat of CAD files<br />

see plant specific requirements, Section 10 - Attachments.<br />

f) Content:<br />

• Mechanical Drawings - consist of the following:<br />

- Main Assembly Drawing<br />

- Assembly Drawings<br />

- Subassembly Drawings<br />

- Detail Drawings<br />

- Parts Lists<br />

Mechanical Design - 4 - 3

BOSCH <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong> <strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong> Apr. 1, 2005<br />

• Pneumatic & Hydraulic Drawings - consist of the following:<br />

- Schematic Diagrams<br />

- Parts List<br />

• Main Assembly Drawing<br />

The main assembly drawing should show the overall completed machine or<br />

assembly. It should have at least two views: plan or top view, <strong>and</strong> one<br />

elevation or side view. Sufficient detail is required on these drawings to<br />

convey the overall completed appearance of the machine, including control<br />

panels. It is m<strong>and</strong>atory that these drawings be drawn to scale <strong>and</strong> show<br />

overall dimensions of height, width, <strong>and</strong> length, location <strong>and</strong> dimensions of<br />

auxiliary control cabinets, the location of the work piece/part, the direction of<br />

index travel, <strong>and</strong> operator location.<br />

• Assembly <strong>and</strong> Subassembly Drawings<br />

It is essential that equipment <strong>and</strong> machine drawings be broken down into<br />

logical assembly <strong>and</strong> subassembly drawings <strong>for</strong> clarity. Each detail shown on<br />

an assembly drawing should have a position number assigned <strong>and</strong> a leader<br />

line pointing to it. The position number corresponds to the same number in<br />

the bill of material/parts list.<br />

• Detail Drawings<br />

Detail drawings show all dimensions <strong>and</strong> tolerances necessary to manufacture<br />

the part. Materials must be designated as per st<strong>and</strong>ard designations such as<br />

AISI, SAE, etc. Heat treatment <strong>and</strong> surface finish requirements need to be<br />

shown in universally accepted designations.<br />

• Parts Lists (Bill of Materials)<br />

All assembly, subassembly, schematic, <strong>and</strong> panel layout drawings, have a<br />

corresponding bill of materials or parts list. The parts list is a list of all<br />

manufactured <strong>and</strong> purchased parts required to complete the “assembly”.<br />

The name <strong>and</strong> part number of the original manufacturer must be shown on<br />

the parts list.<br />

Mechanical Design - 4 - 4

BOSCH <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong> <strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong> Apr. 1, 2005<br />

4.2 Floor Plan Layout<br />

4.2.1 <strong>General</strong> Requirements<br />

The supplier shall be required to furnish preliminary <strong>and</strong> final layout drawings that<br />

define the overall equipment/machinery configuration which shall include but not<br />

limited to the following considerations:<br />

• Overall dimensional size of equipment/machinery (L x W x H)<br />

• Location, size, range of movement, <strong>and</strong> direction of movement of doors <strong>for</strong> all<br />

• Electrical panels<br />

• Access areas<br />

• Access to the required lubrication points (fluid tanks fill <strong>and</strong> drain points, etc.)<br />

• All necessary clearance dimensions shall be shown.<br />

• Location <strong>and</strong> size of support equipment (e.g. filters, pumps, chip carts, mist<br />

collectors, drip pan, etc.).<br />

• Location <strong>and</strong> size of part loading <strong>and</strong> unloading devices.<br />

4.2.2 Floor Layout Drawings<br />

Within thirty (30) days after final drawing approval, the equipment supplier shall<br />

transmit to the Project Engineer a print or a CAD file. For <strong>for</strong>mat of CAD files see<br />

plant specific requirements, Section 10 - Attachments.<br />

4.2.3 Machine Leveling<br />

Machine leveling devices must be supplied with equipment.<br />

Mechanical Design - 4 - 5

BOSCH <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong> <strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong> Apr. 1, 2005<br />

4.3 Ergonomic Guidelines<br />

4.3.1 Workstations<br />

a) If feasible both technically <strong>and</strong> based on the scope of work, operators should be<br />

given the option of either sitting or st<strong>and</strong>ing while per<strong>for</strong>ming their work.<br />

b) Workstations which accommodate a sitting operator should be equipped with an<br />

adjustable chair <strong>and</strong> adjustable footrest.<br />

c) If a conveyor is in front of a workstation where a person is seated, adequate<br />

clearance must be provided under the conveyor <strong>for</strong> the person’s legs.<br />

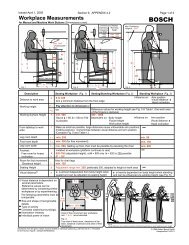

4.3.2 Workplace Measurement<br />

Recommended measurements <strong>for</strong> working height, distance to work area, leg room<br />

<strong>and</strong> area of free movement per workplace are provided in Appendix 4.2.<br />

4.3.3 Task Lighting<br />

a) The following light intensities are required:<br />

• 1,000 lux <strong>for</strong> testing <strong>and</strong> adjusting delicate components.<br />

• 1,500 lux <strong>for</strong> assembling delicate parts <strong>and</strong> electronics.<br />

b) Reflecting workstation surfaces should be avoided.<br />

4.3.4 Controls <strong>and</strong> Indicators<br />

Placement of Controls <strong>and</strong> Indicators should be within operator’s normal reach <strong>and</strong><br />

field of vision. See also Appendix 4.2.<br />

4.3.5 Lifting<br />

* In general, any manual lifting >30 lbs. should be avoided. All heavy or repetitive<br />

lifting (tools, fixture changes, loading, unloading) must be evaluated using the<br />

NIOSH lifting guide. If above the action limit (AL), mechanical lifts are required.<br />

The plant will specify the systems that may be used (supplier, make <strong>and</strong> model). It<br />

should be quoted separately.<br />

4.3.6 Access<br />

a) When a person has to reach a full arm’s length, clearance <strong>for</strong> the body shall be<br />

provided to allow both h<strong>and</strong>s to reach the tools without placing the operator in an<br />

uncom<strong>for</strong>table or hazardous position relative to the surrounding conditions. All<br />

tool changes must be accomplished with both feet of the operator on normal<br />

floor level.<br />

b) The layout of the workstation should provide easy access <strong>for</strong> maintenance,<br />

cleaning, housekeeping, material h<strong>and</strong>ling, etc.<br />

Mechanical Design - 4 - 6

BOSCH <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong> <strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong> Apr. 1, 2005<br />

4.4 Pneumatic Controls<br />

4.4.1 <strong>General</strong><br />

4.4.1.1 Non lubricated compressed air shall be used wherever possible.<br />

4.4.1.2 All types of pneumatic control logic are subject to approval by Project<br />

Engineer. Electrical logic controls are preferred.<br />

4.4.1.3 Pneumatic circuit should be designed to function at minimum 4.5 bar.<br />

6 bar (85 PSI) is st<strong>and</strong>ard plant pressure.<br />

Control voltage <strong>for</strong> solenoid air valves shall be 24V DC.<br />

4.4.2 <strong>Equipment</strong> Requirements<br />

4.4.3 Safety<br />

4.4.2.1 Components<br />

a) Filters, separators, pressure regulators, <strong>and</strong> dryers must be part<br />

of the pneumatic circuit. Automatic water dump traps shall be<br />

used to drain air line filters <strong>and</strong> lubricators.<br />

b) All air cylinders that bottom in rapid travel must be cushioned<br />

to prevent pounding. Deceleration valve shall be used when<br />

cylinder does not bottom in either direction.<br />

c) Lubricators shall be used only when approved by project<br />

engineer. If lubricators must be used, they shall be so mounted<br />

as to assure ample downstream lubrication to those parts being<br />

served by the lubricator.<br />

d) Air discharge to atmosphere shall be provided with mufflers of<br />

sufficient capacity to reduce noise readings to 80 dBA or less<br />

at point of discharge.<br />

4.4.3.1 The main air <strong>and</strong> hydraulic inlet valves should provide a quick means<br />

of shutting off the supply <strong>and</strong> exhausting the downstream system. It<br />

must be in easy reach of the operator <strong>and</strong> designed to be locked out in<br />

the closed position.<br />

Mechanical Design - 4 - 7

BOSCH <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong> <strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong> Apr. 1, 2005<br />

4.4.3.2 Independent of the energy (e.g. electric or pneumatic) used to control<br />

the pneumatic system, no danger shall result from switching on or off<br />

the energy supply, from energy breakdown as well as resumption of<br />

energy (unexpected or intended).<br />

4.4.3.3 To avoid rapid, uncontrolled movements when switching on systems<br />

that employ 3 position valves, a filling circuit/valve shall be used.<br />

4.4.3.4 Construction: Air receivers <strong>and</strong> surge tanks shall be designed:<br />

• To con<strong>for</strong>m to the ASME Unfired Pressure Vessel Code <strong>and</strong> to<br />

applicable governmental pressure vessel codes.<br />

• So that they cannot be dismantled while containing pressure.<br />

• With a separate port of adequate size <strong>for</strong> a safety relief valve.<br />

4.4.3.5 Receivers <strong>and</strong> Surge Tanks shall be permanently marked with<br />

outst<strong>and</strong>ing words reading “CAUTION PRESSURE VESSEL”.<br />

4.4.3.6 Safe Working Range of Adjustable Controls:<br />

Pressure <strong>and</strong> flow control components shall be constructed in a<br />

manner that prevents adjustment outside their safe working range. The<br />

manufacturer’s in<strong>for</strong>mation plate on pressure control components shall<br />

be marked to indicate their minimum <strong>and</strong> maximum pressure limits.<br />

4.4.3.7 Tamper-Resistant Protection:<br />

Where a hazard or damage may result if operating pressures are<br />

exceeded, tamper-resistant (e.g. internal positive stop, nonadjustable,<br />

etc.) overpressure protection must be provided.<br />

4.4.3.8 Cycle Restart:<br />

The equipment cycle may be manually restarted after an emergency<br />

operation, provided resumption does not create a hazard or cause<br />

damage to the equipment or to the work in process. Where continuing<br />

the cycle is not feasible, manual controls shall be provided <strong>for</strong><br />

returning the actuators affected by the emergency control to their cycle<br />

start or other preset position.<br />

4.4.3.9 Emergency Controls:<br />

Emergency controls shall be provided at each operator’s work station.<br />

Mechanical Design - 4 - 8

BOSCH <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong> <strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong> Apr. 1, 2005<br />

4.5 Lubrication<br />

4.6 Paint<br />

If technically possible, maintenance-free components shall be used. If not possible, lubrication<br />

points have to be easily accessible (without removing guards) <strong>and</strong> permanently tagged.<br />

Type of fluid <strong>and</strong> grease should be approved by <strong>Bosch</strong>. Attempts should be made to use<br />

lubricants stocked at <strong>Bosch</strong> sites.<br />

4.6.1 Paint being used must be resistant to oil <strong>and</strong> test fluid <strong>and</strong> also to synthetic coolants<br />

<strong>and</strong> any other consumable liquids with which the equipment may come in contact<br />

with during regular operation.<br />

4.6.2 Machine tool surfaces which come in contact with the workpiece, or surfaces which<br />

might be source of contamination shall not be painted. They might be constructed<br />

by using e.g. stainless steel, chromating, etc., in order to avoid rust or other<br />

degradation.<br />

4.6.3 All heat treat equipment surfaces exposed to high temperature shall be painted with<br />

heat resistant paint. Aluminum paint may be required.<br />

4.6.4 Colors:<br />

USE COLOR STANDARD<br />

<strong>Equipment</strong><br />

(See plant specific requirements, Section 10 - Attachments)<br />

Installations: Sprinkler Lines Red OSHA Red<br />

Gas Lines Yellow OSHA Yellow<br />

4.6.5 All paints shall be lead-free.<br />

(See Section 7 <strong>for</strong> Pre-Final Acceptance Checklist.)<br />

Mechanical Design - 4 - 9

BOSCH <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong> <strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong> Apr. 1, 2005<br />

SECTION 5 - ELECTRICAL DESIGN<br />

TABLE OF CONTENTS<br />

*<br />

*<br />

*<br />

*<br />

*<br />

*<br />

*<br />

Page<br />

5.1 St<strong>and</strong>ards ................................................................................................................5-2<br />

5.2 Control Systems Overview .....................................................................................5-2<br />

5.3 Documentation........................................................................................................5-2<br />

5.3.1...... Drawings....................................................................................................5-2<br />

5.3.2...... Software.....................................................................................................5-2<br />

5.4 Functional ...............................................................................................................5-2<br />

5.4.1...... Safety.........................................................................................................5-2<br />

5.4.2...... Manual Control ..........................................................................................5-2<br />

5.4.3...... Independent Control...................................................................................5-3<br />

5.4.4...... Diagnostics ................................................................................................5-3<br />

5.4.5...... Anti-Repeat................................................................................................5-3<br />

5.4.6...... Control Parameters/Values .........................................................................5-3<br />

5.4.7...... Bus Systems...............................................................................................5-3<br />

5.4.8...... Lamp Test..................................................................................................5-3<br />

5.4.9...... Cycle Counters...........................................................................................5-3<br />

5.5 <strong>Equipment</strong>...............................................................................................................5-3<br />

5.5.1...... Machine Voltage ........................................................................................5-3<br />

5.5.2...... Components ...............................................................................................5-3<br />

5.5.3...... Component Labeling ..................................................................................5-4<br />

5.5.4...... Controller Outputs......................................................................................5-4<br />

5.5.5...... Enclosures..................................................................................................5-4<br />

5.5.6...... Motors........................................................................................................5-5<br />

5.6 Wiring Methods ......................................................................................................5-5<br />

5.6.1...... Grounding..................................................................................................5-5<br />

5.6.2...... Test Points .................................................................................................5-5<br />

5.6.3...... Wire Termination, Labeling .......................................................................5-5<br />

5.6.4...... Splicing......................................................................................................5-6<br />

5.6.5...... Spare Wire .................................................................................................5-6<br />

5.6.6...... Wire Type ..................................................................................................5-6<br />

5.6.7...... Wire Colors................................................................................................5-6<br />

5.6.8...... Flexible Conduit.........................................................................................5-6<br />

5.7 Programmable Logic Controllers <strong>and</strong> Computers ...............................................5-6<br />

* 5.8 Data Management <strong>and</strong> Networking.......................................................................5-6<br />

5.8.1...... Infrastructure <strong>and</strong> Interfaces .......................................................................5-6<br />

5.8.2...... Virus Protection .........................................................................................5-7<br />

5.8.3...... Physical <strong>and</strong> Data Security.........................................................................5-7<br />

5.8.4...... Software.....................................................................................................5-7<br />

Electrical Design - 5 - 1

BOSCH <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong> <strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong> Apr. 1, 2005<br />

SECTION 5 - ELECTRICAL DESIGN<br />

5.1 St<strong>and</strong>ards<br />

All equipment shall con<strong>for</strong>m to the latest NFPA 70 (National Electric Code) <strong>and</strong> NFPA 79<br />

(Electrical St<strong>and</strong>ard <strong>for</strong> Industrial <strong>Machinery</strong>) unless otherwise stated in these specifications.<br />

5.2 Control Systems Overview<br />

A Control Systems Overview <strong>for</strong>m shall be completed when the job is quoted.<br />

(See Appendix 5.1)<br />

5.3 Documentation<br />

*<br />

5.3.1 Drawings<br />

All drawings shall be drawn with CAD <strong>and</strong> drawing files shall be provided in plant<br />

specific <strong>for</strong>mat (See plant specific requirements, Section 10 - Attachments). In<br />

addition, drawings shall also be provided in Adobe Acrobat pdf <strong>for</strong>mat.<br />

Electrical Drawings shall be “A” or “B” size (DIN Size A4 or A3).<br />

*<br />

5.3.2 Software<br />

5.4 Functional<br />

All software needed to use or modify any component of the machine shall be licensed<br />

<strong>and</strong> provided. All software shall be in English. Source code of all software developed<br />

under this purchase order shall be provided <strong>and</strong> becomes the property of <strong>Bosch</strong>.<br />

A functional plan describing sequential operation shall be provided <strong>for</strong> all machines.<br />

5.4.1 Safety<br />

Control of all devices shall be designed such that loss of power in any <strong>for</strong>m<br />

(electrical, pneumatic, hydraulic) shall not present a hazard to personnel or damage<br />

the equipment or work in process. No automatic restart shall occur when power is<br />

resumed.<br />

5.4.2 Manual Control<br />

Manual controls shall be provided <strong>for</strong> tool changing, setup <strong>and</strong> maintenance<br />

operation. The controls shall be interlocked to prevent machine or part damage.<br />

Electrical Design - 5 - 2

BOSCH <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong> <strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong> Apr. 1, 2005<br />

5.4.3 Independent Control<br />

Separate control systems shall be used <strong>for</strong> each individual machine.<br />

5.4.4 Diagnostics<br />

Diagnostic indication shall be provided <strong>for</strong> each possible state of the machine.<br />

5.4.5 Anti-Repeat<br />

On equipment where continuous consecutive cycling is not a normal condition, the<br />

controls shall be designed to prevent such operation.<br />

5.4.6 Control Parameters/Values<br />

Setup parameters which can affect the quality or the cycle time of the station shall be<br />

locked or password protected. Process values which can affect quality shall be<br />

monitored <strong>and</strong> should shut down the machine if not within tolerance.<br />

5.4.7 Field Bus Systems<br />

See plant specific requirements, Section 10 - Attachments.<br />

5.4.8 Lamp Test<br />

All lamps shall have a method of testing <strong>for</strong> defective bulbs.<br />

5.4.9 Cycle Counters<br />

5.5 <strong>Equipment</strong><br />

Both a non-resettable <strong>and</strong> a resettable cycle counter shall be included.<br />

5.5.1 Machine Voltage<br />

The primary voltage <strong>for</strong> machines shall be 480 VAC, 3φ, 60 Hz. Control voltage<br />

shall be regulated 24 VDC. Receptacles <strong>for</strong> 115 VAC shall be st<strong>and</strong>ard US<br />

grounded 3 prong (Some plants have specific requirements <strong>for</strong> machine voltage<br />

tolerances, see Section 10 - Attachments).<br />

5.5.2 Components<br />

*<br />

a) <strong>Equipment</strong> shall be constructed utilizing <strong>Bosch</strong> “Preferred Electrical<br />

Components” (See plant specific requirements, Section 10 - Attachments).<br />

b) Trans<strong>for</strong>mers <strong>and</strong> power supplies shall have 30% excess capacity.<br />

Electrical Design - 5 - 3

BOSCH <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong> <strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong> Apr. 1, 2005<br />

5.5.3 Component Labeling<br />

All functional <strong>and</strong> electrical components shall be permanently labeled with their<br />

corresponding schematic designation.<br />

5.5.4 Controller Outputs<br />

Controller outputs shall have individual over current protection <strong>for</strong> each circuit.<br />

5.5.5 Enclosures<br />

a) Expansion:<br />

Enclosures shall be designed with 20% expansion capability. This shall include<br />

but not be limited to space <strong>for</strong> terminal blocks, relays, breakers, starters,<br />

wireways, <strong>and</strong> controller I/O.<br />

b) Lighting:<br />

Lighting controlled by a door switch shall be provided on enclosures over 0.425<br />

m 3 (15 cu. ft.).<br />

*<br />

c) Programmable Devices:<br />

All enclosures containing a programmable device shall have a 115 VAC GFCI,<br />

receptacle labeled “For programming device only”.<br />

A programming interface shall be readily accessible.<br />

d) Connectors:<br />

Wiring to enclosures not mounted on the machine shall have connectors. Plugs<br />

<strong>and</strong> sockets must be permanently labeled (See plant specific requirements,<br />

Section 10 - Attachments).<br />

e) Location:<br />

* f) Safety:<br />

Bottom of enclosures shall be a minimum of 100 mm above the floor. The<br />

control enclosure should be positioned so that the machine can be observed<br />

while working in the enclosure.<br />

Minimum working space in front of electrical enclosures shall be maintained.<br />

See Section 9 - Appendix 5.2 <strong>for</strong> more detail.<br />

Electrical cabinet doors shall be removable or able to open at least 90 degrees.<br />

Electrical Design - 5 - 4

BOSCH <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong> <strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong> Apr. 1, 2005<br />

5.5.6 Motors<br />

5.6 Wiring Methods<br />

AC motors shall be High Energy Efficient TEFC, 480 VAC, 3φ, 60 Hz. All motors<br />

25hp <strong>and</strong> above shall have continuous conductors from the control enclosure to the<br />

motor. No intermediate terminations are permitted. Such motors shall also have<br />

power factor corrected to above 90%.<br />

5.6.1 Grounding<br />

Trans<strong>for</strong>mers <strong>and</strong> power supplies shall have their neutral or common conductors<br />

grounded at the source. If special earth grounds are necessary, this shall be specified<br />

by the supplier during initial design review <strong>and</strong> detailed in the installation<br />

specifications.<br />

5.6.2 Test Points<br />

All control <strong>and</strong> power wiring shall have readily accessible test points in the control<br />

enclosures.<br />

5.6.3 Wire Termination, Labeling<br />

* For screw or screw clamp terminations, all wire ends shall be fitted with ferrules or<br />

crimp connectors. All wires shall be labeled, terminated <strong>and</strong> identified in the<br />

electrical prints. Multiple-device control panels shall be equipped with terminal<br />

blocks or attachment plugs <strong>and</strong> receptacles <strong>for</strong> all outgoing control conductors.<br />

Wiring directly to the terminal connection points on input or output modules of<br />

programmable electronic systems shall be permitted.<br />

Wire labeling method shall be specified by the customer. The machine builder is<br />

responsible <strong>for</strong> determining customer preference. Wires shall be labeled at each end<br />

either with wire numbers or termination labels. Wire numbers or termination<br />

labels shall be used exclusively.<br />

When wire numbers are used, each individual wire shall have the same<br />

number at all termination points. Terminal block labels shall match the wire<br />

numbers. Wires connecting to controller I/O shall be labeled with an I <strong>for</strong><br />

Inputs <strong>and</strong> Q <strong>for</strong> Outputs followed by the I/O address, dropping any<br />

punctuation <strong>and</strong> adding leading zeros as appropriate. For example, the wire<br />

that connects to output Q2.4 should be labeled "Q024".<br />

When wire termination labels are used, the termination label shall identify the<br />

terminal name where the wire should terminate. Example: The wires connected<br />

to terminal A1 of –K911A shall be labeled –K911A:A1<br />

Electrical Design - 5 - 5

BOSCH <strong>General</strong> <strong>Delivery</strong> <strong>Specifications</strong> <strong>for</strong> <strong>Machinery</strong> <strong>and</strong> <strong>Equipment</strong> Apr. 1, 2005<br />

5.6.4 Splicing<br />

Splicing is prohibited. Wiring shall run uninterrupted from terminal to terminal.<br />

5.6.5 Spare Wire<br />

A minimum of 15% spare wire shall exist in each wireway that is external to an<br />

enclosure.<br />

*<br />

5.6.6 Wire Type<br />

Wire shall be str<strong>and</strong>ed copper. Wire jacketing shall be type MTW <strong>for</strong> wires not<br />

leaving electrical enclosures. Elsewhere, wire jacketing shall be compatible with the<br />

associated fluids <strong>and</strong> working environment:<br />

- Type PUR: <strong>for</strong> areas with coolant, oil <strong>and</strong> diesel/gasoline calibration type fluids<br />

(e.g. VISCOR)<br />

- Type PVC: <strong>for</strong> brake fluid areas<br />

* 5.6.7 Wire Colors<br />

See plant specific requirements, Section 10 - Attachments.<br />

5.6.8 Flexible Conduit<br />

Each section of flexible conduit shall be kept to a maximum of 1 meter.<br />

5.7 Programmable Logic Controllers <strong>and</strong> Computers<br />

See plant specific requirements, Section 10 - Attachments.<br />

*<br />

5.8 Data Management <strong>and</strong> Networking<br />

The <strong>Bosch</strong> Corporate Network (BCN) is a private, global data network which interconnects<br />

all Robert <strong>Bosch</strong> GmbH sites throughout the world. The network has been designed to<br />

provide fast, secure, <strong>and</strong> reliable data transmission to all sites. To this end, it is requested<br />

that all vendors adhere to the BCN st<strong>and</strong>ards wherever possible.<br />

5.8.1 Infrastructure <strong>and</strong> Interfaces<br />

The physical connection to the BCN is generally provided via RJ-45 jacks installed<br />

as required near the equipment. These network drops will be terminated external to<br />

the equipment such that cable infrastructure troubleshooting or rewiring can be done<br />

without requiring access into the machine enclosures.<br />

Managed Cisco routers <strong>and</strong> switches comprise the backbone of the corporate<br />

network. To ensure network integrity <strong>and</strong> monitoring down to each networked<br />

device, manageable Cisco switches should be used rather than simple network hubs.<br />

Your <strong>Bosch</strong> representative should be able to obtain recommended equipment model<br />