Hydrostatic pressure sensors offer dependable level measurement

Hydrostatic pressure sensors offer dependable level measurement

Hydrostatic pressure sensors offer dependable level measurement

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

LEVEL MEASUREMENT<br />

SENSING A SOLUTION<br />

<strong>Hydrostatic</strong> <strong>pressure</strong> <strong>sensors</strong> <strong>offer</strong><br />

<strong>dependable</strong> <strong>level</strong> <strong>measurement</strong><br />

By Karmjit Sidhu<br />

The treatment of complex industrial wastewater systems<br />

laden with items, such as ferric chloride, ferric sulfate,<br />

hydraulic oil, animal fats and antibiotics, involves brine<br />

treatment and removal of solids and oils, as well as biodegradable<br />

organics. During waste processing, liquid <strong>level</strong> <strong>measurement</strong>s are<br />

needed at raw and finished water tanks to quantify liquid volume<br />

and overflow controls to prevent pollution. The repeatability and<br />

stability of the readings are very important in order to ensure accurate<br />

<strong>measurement</strong>s for closed-loop control systems.<br />

The Value of Level Sensors<br />

Level <strong>sensors</strong> are used extensively for the processing of<br />

wastewater in industrial wastewater treatment. Due to the size<br />

of tanks and floatation of oils and waste, hydrostatic <strong>pressure</strong><br />

<strong>sensors</strong> (also called submersible <strong>pressure</strong> <strong>sensors</strong>) with venting<br />

to atmosphere are widely used to indicate the water <strong>level</strong>.<br />

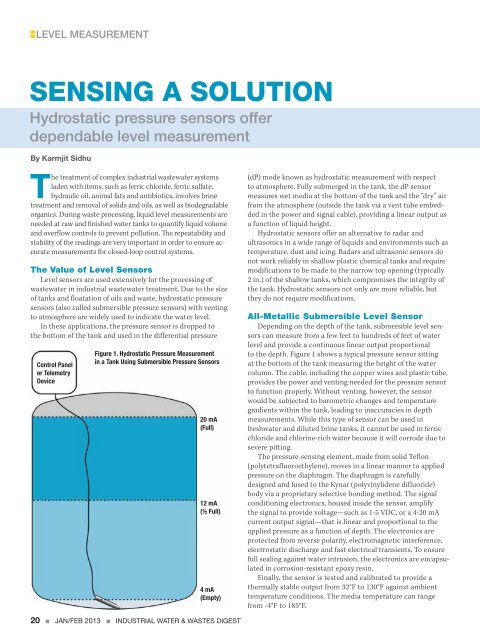

In these applications, the <strong>pressure</strong> sensor is dropped to<br />

the bottom of the tank and used in the differential <strong>pressure</strong><br />

Control Panel<br />

or Telemetry<br />

Device<br />

Figure 1. <strong>Hydrostatic</strong> Pressure Measurement<br />

in a Tank Using Submersible Pressure Sensors<br />

20 mA<br />

(Full)<br />

12 mA<br />

(½ Full)<br />

4 mA<br />

(Empty)<br />

(dP) mode known as hydrostatic <strong>measurement</strong> with respect<br />

to atmosphere. Fully submerged in the tank, the dP sensor<br />

measures wet media at the bottom of the tank and the “dry” air<br />

from the atmosphere (outside the tank via a vent tube embedded<br />

in the power and signal cable), providing a linear output as<br />

a function of liquid height.<br />

<strong>Hydrostatic</strong> <strong>sensors</strong> <strong>offer</strong> an alternative to radar and<br />

ultrasonics in a wide range of liquids and environments such as<br />

temperature, dust and icing. Radars and ultrasonic <strong>sensors</strong> do<br />

not work reliably in shallow plastic chemical tanks and require<br />

modifications to be made to the narrow top opening (typically<br />

2 in.) of the shallow tanks, which compromises the integrity of<br />

the tank. <strong>Hydrostatic</strong> <strong>sensors</strong> not only are more reliable, but<br />

they do not require modifications.<br />

All-Metallic Submersible Level Sensor<br />

Depending on the depth of the tank, submersible <strong>level</strong> <strong>sensors</strong><br />

can measure from a few feet to hundreds of feet of water<br />

<strong>level</strong> and provide a continuous linear output proportional<br />

to the depth. Figure 1 shows a typical <strong>pressure</strong> sensor sitting<br />

at the bottom of the tank measuring the height of the water<br />

column. The cable, including the copper wires and plastic tube,<br />

provides the power and venting needed for the <strong>pressure</strong> sensor<br />

to function properly. Without venting, however, the sensor<br />

would be subjected to barometric changes and temperature<br />

gradients within the tank, leading to inaccuracies in depth<br />

<strong>measurement</strong>s. While this type of sensor can be used in<br />

freshwater and diluted brine tanks, it cannot be used in ferric<br />

chloride and chlorine-rich water because it will corrode due to<br />

severe pitting.<br />

The <strong>pressure</strong>-sensing element, made from solid Teflon<br />

(polytetrafluoroethylene), moves in a linear manner to applied<br />

<strong>pressure</strong> on the diaphragm. The diaphragm is carefully<br />

designed and fused to the Kynar (polyvinylidene difluoride)<br />

body via a proprietary selective bonding method. The signal<br />

conditioning electronics, housed inside the sensor, amplify<br />

the signal to provide voltage—such as 1-5 VDC, or a 4-20 mA<br />

current output signal—that is linear and proportional to the<br />

applied <strong>pressure</strong> as a function of depth. The electronics are<br />

protected from reverse polarity, electromagnetic interference,<br />

electrostatic discharge and fast electrical transients. To ensure<br />

full sealing against water intrusion, the electronics are encapsulated<br />

in corrosion-resistant epoxy resin.<br />

Finally, the sensor is tested and calibrated to provide a<br />

thermally stable output from 32°F to 130°F against ambient<br />

temperature conditions. The media temperature can range<br />

from -4°F to 185°F.<br />

20 ■ JAN/FEB 2013 ■ INDUSTRIAL WATER & WASTES DIGEST

Wetted submersible sensor<br />

Severe corrosion in ferric chloride tank application<br />

Non-Metallic Submersible Level Sensor<br />

When injected into the water tanks, some chemicals can<br />

attack metals and cause failure due to severe corrosion. While<br />

the overall pH <strong>level</strong> can be well balanced, the initial injection<br />

of chemicals can cause the sensor to be exposed to an acidic<br />

or basic shock, depending on the location of the sensor relative<br />

to the chemical additive. To overcome this, there is a strong<br />

need to use submersible <strong>sensors</strong> constructed from chemical<br />

resistance plastics such as polyvinylidene difluoride and<br />

polytetrafluoroethylene. These two polymers are well known<br />

for their chemical resistance properties and are widely used in<br />

the chemical industry.<br />

A water treatment plant in Arizona found hydrostatic <strong>sensors</strong><br />

to be more reliable and cost-effective than the radar and<br />

ultrasonic <strong>measurement</strong> systems originally used in an application<br />

involving the injection of chemicals in the treatment<br />

plant. The chemicals, stored in a chemical tote, are corrosive<br />

in nature and attach to metals. The plant initially used a costly<br />

non-contact radar <strong>level</strong> <strong>measurement</strong> system that provided<br />

unstable readings. It was replaced by an ultrasonic <strong>level</strong> detection<br />

system that required the top tank opening to be modified<br />

to position the sensor. After modifications, the sensor only<br />

worked for a few days before chemical fumes attached to the<br />

sensor sealing to cause unit failure.<br />

Ultimately, a Kynar-Teflon <strong>level</strong> sensor utilizing a hydrostatic<br />

<strong>measurement</strong> principle was implemented and has been<br />

operating reliably after one year of use. The plant is now<br />

standardizing this technology for all wastewater and oil field<br />

injection chemical tanks.<br />

Karmjit Sidhu is vice president, business development,<br />

of American Sensor Technologies. Sidhu can be reached<br />

at kssidhu@ast<strong>sensors</strong>.com.